Drying Shrinkage Characteristics of Mortar Incorporating Different

Mineral Admixture

Fares Ali Ali Al-sairafi

1

, Jin Chen

1

,MinWei

1

, Yizhi Wang

1

and Peiqi Li

1

1

Jiangsu Key Laboratory of Coast Ocean Resources Development and Environment , Hohai University, NO. 1 Xikang Road

, Nanjing 210098, China

Keywords: Mineral Admixtures, Fly Ash, GGBS, Drying Shrinkage, Microstructure.

Abstract: This paper presents an experimental study of the effects of fly ash and ground granulated blast furnace slag

(GGBS) on drying shrinkage of mortar. Two equations that can reasonably predict the drying shrinkage

were also proposed. The test results reveal that mortar samples incorporating fly ash or GGBS exhibit

greater lower drying shrinkage compared to the plain sample. The drying shrinkage decreases significantly

with the increase in the fly ash content. While for GGBS, there is an optimal content of GGBS to restrain

drying shrinkage. The prediction equations for the shrinkage strain of fly ash and GGBS mortar were

proposed according to the dependent variable, which verified good accuracy compared to the test results.

1 INTRODUCTION

Drying shrinkage, one of the causes of cracks in

concrete structures, can be defined as the volumetric

change due to the drying of concrete (Zhang, et al.,

2015). If not appropriately considered in the design

state, the cracks can adversely affect the structural

performance when environmental conditions are

quite severe (e.g., high temperature, low humidity,

high wind velocity) (Zhang, et al., 2012). Therefore,

it is vital to study the shrinkage and shrinkage

compensation of cement mortar or concrete.

Many methods(Han, et al., 2016; Sonebi, et al.,

2015 have been proposed to restrain drying

shrinkage such as using fibers, expansion admixture,

mineral admixture, shrinkage reducing admixture

and so on. Mineral admixtures are the by-product of

some industries, which is specified as promoting

green procurement for the global environment.

Therefore, using mineral admixture such as fly ash

and GGBS to replace part of the cement is the most

economical and environmentally friendly method.

Research results showed that the concrete with

mineral admixture addition performed better in

reducing drying shrinkage and improving

workability compared to the plain concrete. Hu et al.

found that the most obvious advantage in adding fly

ash was not only a considerable reduction in

shrinkage cracking width, but also a significant

delay in first visible cracking. The shrinkage of

mortar containing 25% fly ash decreased 12.6% and

the initial cracking time was decreased by 28%

compared with the control mortar.

The experimental program in this study was

designed to assess the main drying shrinkage

behavior involving the addition of mineral

admixture. The objectives of this study are to (1)

clarify and comparison the influences of GGBS

powder and fly ash on the drying shrinkage

evolution of cement mortar, (4) propose equations

according to the dependent variable that can

reasonably predict the drying shrinkage behavior.

2 EXPERIMENTAL PROGRAMS

2.1 Materials

Jiangnan Onoda Cement Plant provided Portland

cement of Grade-52.5with a Bertrand specific

surface area of 365m2/kg and a density of

3.13g/cm3. The natural river sand was used as fine

aggregates. First grade fly ash, of fineness

modulus5.2%, with a specific surface of 457 m2/kg

and, density 2.22g/cm3produced by Huaneng

Thermal Power Plant production of primary fly ash

was used in this study. And the GGBS of

ZhongShan brand S95, of specific surface 425m2/kg

and of density 2.84g/cm3 obtained was used in the

experiment.

2.2 Mixing and Curing

The cement, river sand, fly ash or GGBS were

initially mixed dry in a mixer for about 2 minutes

until they were homogenous throughout. Then, the

entire amount of mixing water was added and the

mixing process lasted for another 3minutes, leading

to a total mixing period of 5 minutes. Finally, the

freshly mixed materials were cast in the molds and

vibrated by a mechanical vibrating table for about

1min. After that, the samples produced were cured

in air at 20 ± 3℃in molds covered by a polyethylene

film to prevent moisture loss. After 24 h, the

samples were removed from the molds and

transferred to a standard condition with T = 20 ±

3℃and RH = 50 ± 4% until the testing age.

In the current study, equivalent substitution

method was used to design mixing proportions. For

all mixtures, the mixing proportions of samples are

given in Table1.

Table 1: The mix proportions of mortars with mineral

admixtures.

2.3 Testing Methods

The drying shrinkage is calculated from

following equations respectively:

(1)

(2)

where Si, ɛi and L are the mass loss rate, drying

shrinkage and loss on ignition of the mortar sample

respectively, W0 and L0 are the initial weight and

initial length and of sample respectively, Wi and Li

are the weight and length of sample after water loss

at different days respectively, G1 is the weight of

sample before combustion and G2 is the weight of

sample after combustion.

3 RESULTS AND DISCUSSION

3.1 The Influence of GGBS on Drying

Shrinkage of Mortars

The drying shrinkage of cement mortars that

increase with the age is presented in Fig.2. It can

been observed that when the replacement amount of

fly ash is 90kg/m3, 135kg/m3 and 180kg/m3, the

drying shrinkage of mortar is 0.0639%, 0.0588%

and 0.0539%,respectively, compared with the plain

sample 0.0708% at 28 days. The obtained results

show that the drying shrinkage of mortar decreases

evidently with the increasing content of fly ash. This

is mainly due to the content of cement reduces and

content of fly ash increases in mortar incorporating

fly ash. The hydration rate of fly ash is slower, so

the hydration rate of mortar incorporating fly ash

decreases. Moreover, the unreacted fly ash particles

play a role to keep a stable skeleton and restrain

deformation, which decreases the drying shrinkage

of mortar significantly.

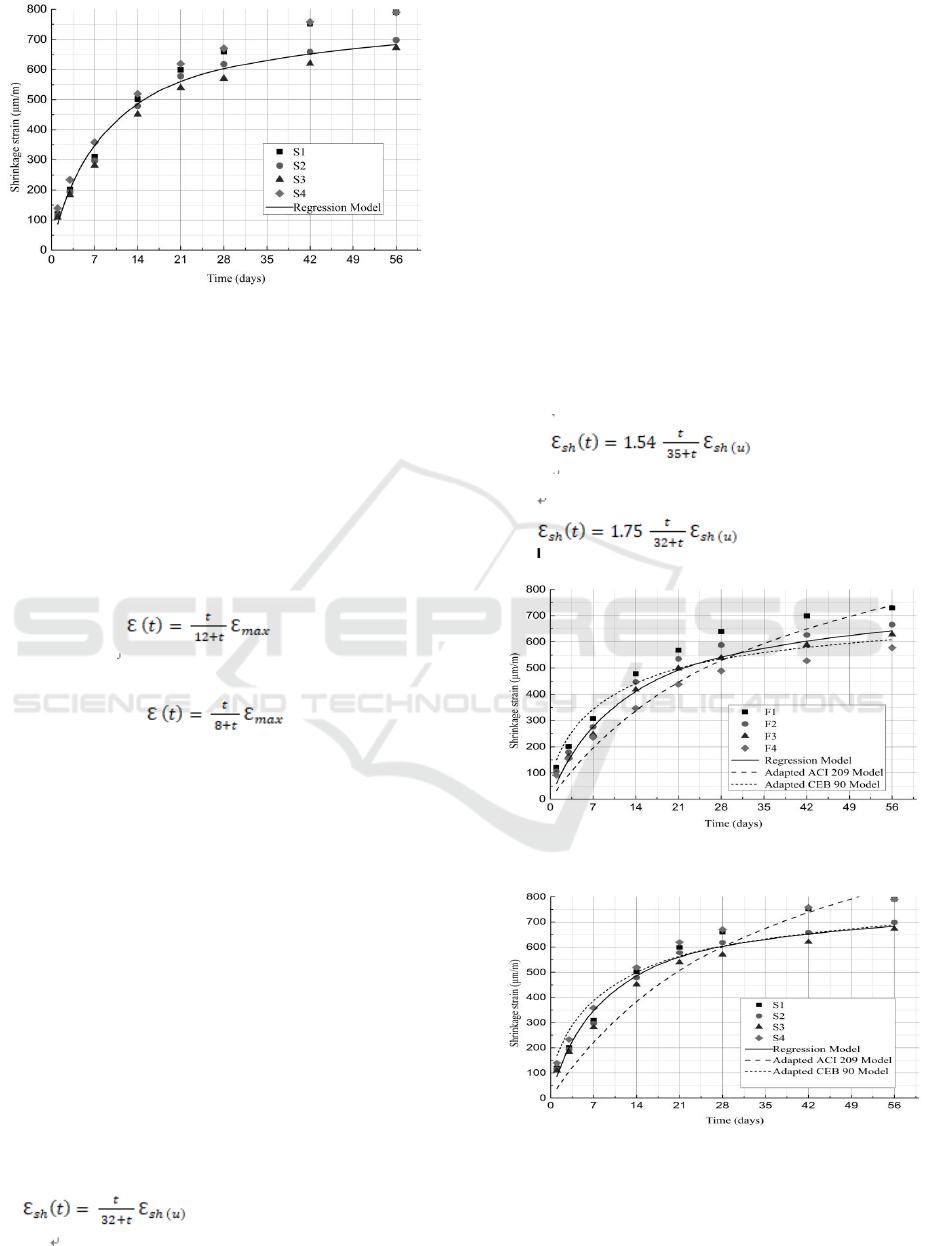

Fig. (a)

Fig. (b)

Fig.1: The effect of mineral admixture on the drying

shrinkage of mortars: (a) fly ash and (b) GGBS.

Similarly, Fig.1 (b) shows that the drying

shrinkage of mortar decreases with the increase of

the replacement amount of GGBS within a certain

range. When the replacement amount of GGBS is

90kg/m3. 135kg/m3 and 180 kg/m3, the drying

shrinkage of mortar is 0.0660%, 0.0618% and

0.0570%, respectively, compared with the plain

sample with a drying shrinkage of 0.0710% at 28

days. However, the drying shrinkage of mortar is

0.0670% at 28 days when the replacement amount of

GGBS is 270kg/m3, which is slightly higher than

that of the replacement amount of 135 kg/m3 and

180 kg/m3. The results reveal that there is an

optimal content of GGBS to restrain drying

shrinkage. It can be explained that the GGBS has

potential activity and using the GGBS to replace

cement will decrease the content of cement thus the

total hydration rate of products of cementations

materials will change. Furthermore, the part of the

unreacted GGBS particles plays a role of micro-

aggregate which restrains the drying shrinkage.

However, when the content of GGBS exceeds a

certain amount, the ability of autogenous shrinkage

of mortar exceed the ability to restrain drying

shrinkage of GGBS causing the drying shrinkage of

mortar to increase, but is still lower than that of

mortar without mineral admixture. This

phenomenon has been analyzed by some previous

research, which indicated that autogenous shrinkage

of mortar incorporating GGBS increased with the

increase content of GGBS. Tazawa et al. reported

that the autogenous shrink age of mortar relatively

rapid increased with the amount increasing of GGBS

when the replacement content of GGBS between of

50 ~ 70%.

3.2 Shrinkage Model

Quantification of concrete shrinkage allows the

designer to design concrete that meet the

construction requirements based on the shrinkage

model. So it is necessary to find the most suitable

shrinkage model. There have been some American

and European empirical models that predict the

shrinkage strain of Portland cement concrete. These

models were developed and calibrated based on

some experimental measurements involving

different types of concrete mixes. The objective of

these models was to predict the long-term shrinkage

strain based on few short-term measurements. There

are two well-known models, ACI 209 and CEB-FIB

1990 that were considered in this study to validate

and/or adapt their use for compared cement mortar.

Fernandez-Gomez and Lands berger confirmed that

these methods were applicable.

3.2.1 56 Days Shrinkage Measurements

Shrinkage of the four mortar samples shown in

Table 3 were monitored over a 56 days period and

the results are shown in Fig.1. In those figure, the x-

axis represents the age of the samples at which the

shrinkage measurement are taken, while the y-axis

shows the measured shrinkage strain for the different

samples. Fig.1 (a) shows that the shrinkage strains of

fly ash mortar for the four samples were in the same

order of magnitude and varied between 570 and

730μm/m for an age of 56 days. The figure shows

also that shrinkage strain increases rapidly during 56

days. Fig.1 (b) indicates that the GGBS mortar has

similar tendency.

Fig. (a)

Fig. (b)

Fig.2: Average measured shrinkage strain over a 56 days

period: (a) fly ash and (b) GGBS.

Since the four mixes presented roughly the same

trend for their shrinkage strain evolution with

respect to time, two regression models were

developed to fit all measured date. For mortar

incorporating fly ash and GGBS, the models are

shown by solid curve in Fig.2 (a) and (b) and are

represented by Equation(3) and Equation(4).

(3)

(4)

Where t is the mortar concrete age in days, and

ɛmax represents the long-term shrinkage strain,

which is found to be equal to 780μm/m. For fly ash

mortar, the model had a coefficient of determination

R2 of 0.997 and a standard error of 20μm/m. For

GGBS mortar, with a coefficient of determination

R2 of 0.990 and a standard error of 34μm/m was

obtained. These mean that Equation(3) and Equation

(4) describe well the shrinkage behaviour of mortar

incorporating fly ash or GGBS.

3.2.2 ACI 209 Shrinkage Model

The American Concrete Institute proposed the

ACI 209 shrinkage model in 1992. The shrinkage

strain as a function of time, ɛsh (t), is calculated as

follows:

(5)

Where ɛsh(u) is the ultimate shrinkage strain,

which is equal to 780μm/m for ordinary Portland

cement concrete. The Portland cement concrete ACI

209 model did not fit well with mortar incorporating

fly ash or GGBS experimental shrinkage date.

However, when two correction factor of 1.54 for fly

ash mortar and 1.75 for GGBS mortar were applied

to the model, the corrected ACI 209 model fit well

the measured experimental data as shown in Fig.3

(a) and (b). Therefore, for mortar incorporating fly

ash or GGBS, the adapted ACI 209 model could be

represented by Equation (6) and Equation (7). The

calculated coefficient of determination, R2 ,for this

model of fly ash mortar was 0.986 while the

calculated standard error was 67μm/m , for GGBS

mortar, the model had a coefficient of determination

R2 of 0.986 and a standard error of 79μm/m.

(6)

(7)

Fig. (a)

Fig. (b)

Fig.3: Experimental shrinkage data with developed

prediction models: (a) fly ash and (b) GGBS.

3.2.3 CEB 90 Shrinkage Model

For CEB-FIP model, the shrinkage strain as a

function of time is given by

(8)

Where t is the concrete age in days, ɛcs0 is the

ultimate shrinkage strain, and βs (t) is given by

Equation (9).

(9)

Where h0 is the effective thickness of the

specimen in mm. Two correction factor of 0.92 for

fly ash mortar and 1.04 for GGBS mortar were

applied to the model, the adapted CEB-FIP model

could be represented by Equation(10) and

Equation(11). The calculated coefficient of

determination, R2 , for this model of fly ash mortar

was 0.992 and the calculated standard error was

49μm/m, for GGBS mortar, the model had a

coefficient of determination R2 of 0.993 and a

standard error of 51μm/m.

(10)

(11)

3.2.4 Interpretation of Results

The figures from Fig.3 (a) and (b) show that the

measured experimental date and the three models

developed to fit the date. It is noted that the two

regression models predict better the average

measured shrinkage strain over time than the

ordinary Portland cement concrete adapted models.

This observation is proved by the calculated

standard errors of three models. For fly ash or

GGBS mortar, the regression models had the lowest

standard error of 20μm/m and 34μm/m, respectively.

4 CONCLUSIONS

The mortar samples incorporating fly ash or GGBS

exhibits greater lower drying shrinkage compared to

that of the mortar samples without mineral

admixture.

The result shows that the drying shrinkage of

mortar decreases obviously with the increasing

content of fly ash. While there is an optimal content

of GGBS to restrain drying shrinkage, a replacement

content of 180kg/m3for GGBS, the sample presents

the lowest drying shrinkage. The drying shrinkage

became greater with the increase in water

evaporation. A greater mass loss resulted in a greater

drying shrinkage.

Shrinkage strain of mortar incorporating fly ash

or GGBS could be predicted using the well-known

ACI 209 and CEB 90 shrinkage models after

applying minor correction factors. Two rational

equations (Equation (3) and Equation (4)) can

predict the shrinkage strain of mortar incorporating

fly ash or GGBS. And two regression models predict

better than the ACI 209 and CEB 90 shrinkage

models.

REFERENCES

1. Han J G, Jia D, Yan P Y. 2016. Understanding the

shrinkage compensating ability of type K expansive

agent in concrete. Journal of

construction and building materials, 116, pp 36-44.

2. Sonebi M, Garcia-Taengua E, Hossain K M A, Khatib

J, Lachemi M. 2015. Effect of nanosilica addition on

the fresh properties and shrinkage of mortars with fly

ash and superplasticizer Journal of construction and

building materials. ,85, pp 269-276.

3. Zhang W Y, Hama Y, Na S H. 2015. Drying shrinkage

and microstructure characteristics of mortar

incorporating ground granulated blast furnace slag and

shrinkage reducing admixture. Journal of construction

and building materials, 93, pp267 – 277.

4. Zhang W, Zakaria M, Kishimoto Y, Hama Y. 2012.

Drying shrinkage and microstructure characteristics of

ground granulated blast furnace slag-cement mortar.

Journal of construction and building materials, 34 pp

388-393.