Experimental Study on Rheological Properties of

Basalt Fiber Polymer Concrete

Yinghua Yu

1

, Jiaxing Shen

1

, Ping Xu

1

and Guoyue Ruan

1

1

Department of Mechanical Engineering, Liaoning Technical University, Fuxin, China

Keywords: Basalt fiber polymer concrete; rheology; resin proportioning; aggregate; fly ash; basalt fiber.

Abstract: In order to explore the basalt fiber polymer concrete (BFPC) rheology change law on the main component

content, the four-factor and five-level proportion orthogonal scheme is designed. The change laws of yield

stress τ

0

and viscosity coefficient η with the E44 and E51 mass ratio, the amounts of aggregate, fly ash and

basalt fiber were studied. It is shown that significant influence on τ

0

and η from large to small are the

amount of aggregate, the E44 and E51 mass ratio, the amount of basalt fiber and the amount of fly ash. τ

0

and η reduce monotonously with the reduction of the amount of aggregate and basalt fiber as well as

increasing of the amount of fly ash but reduce with the reduction of E44 and E51 mass ratio firstly then

increases when it is sufficiently small.

1 INTRODUCTION

Basalt fiber polymer concrete (BFPC) is also called

polymer mineral concrete. It is a new type of fiber-

reinforced composite material that has been surface

treated basalt fiber incorporated into the resin

concrete in accordance with the appropriate mass

ratio and length-to-diameter ratio, after being stirred,

formed and maintained. Compared with other fiber

polymer concrete, it can not only further improve the

damping and thermal stability of the concrete, but

also make the concrete commutable,

environmentally friendly and economical. Therefore,

BFPC is considered to have good application

prospects in machine tool manufacturing and

construction (mine construction, civil construction,

highway bridge construction, tunnel construction,

etc.) [1-3].

The rheological properties of the studied

materials are the basis of materials, structural design,

manufacturing processes, and tooling design [4-9].

At present, the research on BFPC mainly focuses on

the optimization of the material grouping ratio and

the study of its mechanical properties, but the

research on the rheological properties of BFPC is

rarely reported [1-3]. Therefore, it is of great

theoretical and practical significance to study the

rheological properties of BFPC. In this paper, the

influence of aggregate ratio, fly ash, E44 and E51

mass ratio and basalt fiber content on rheological

properties of BFPC is studied by means of

experimental method in BFPC. This study lays the

foundation for the optimization design, mechanical

structure design and manufacturing process design

of BFPC, and even promoting its application in

engineering.

2 BFPC RHEOLOGICAL MODEL

The fresh wet BFPC concrete can be regarded as a

viscoplastic Bingham (Bingham) fluid whose

rheological equation is

γ

η

τ

τ

′

+=

0

(1)

Where τis the shear stress, Pa;τ0is the yield

stress, Pa; η is the plastic viscosity

coefficient,Pa·s;γ’ shear rate,s-1. Among them, the

yield stressτ0and plastic viscosity coefficientη are

the basic rheological parameters that determine the

rheological properties of BFPC [4-8].

3 EXPERIMENTAL

3.1 Experimental Instruments

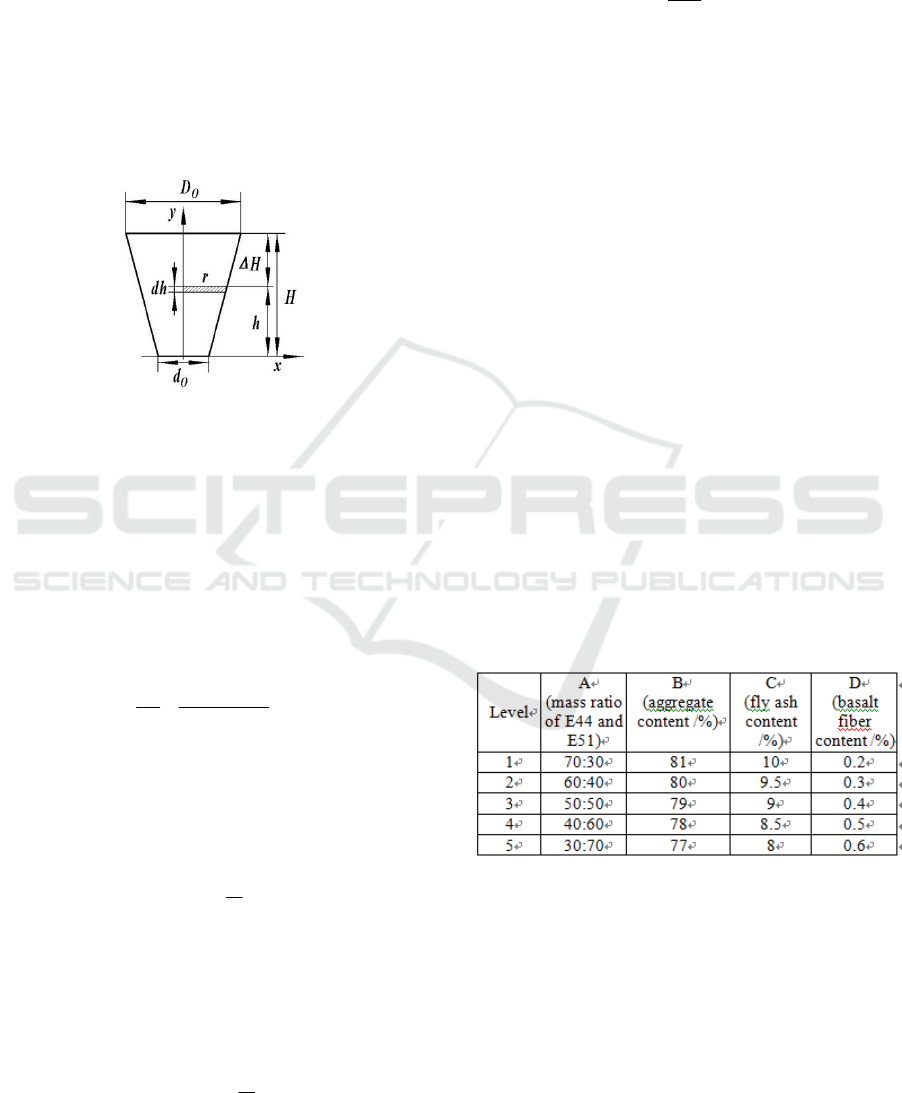

The test device is shown in Figure 1. It is an inverted

truncated inverted fall barrel, which is welded from

a stainless steel plate, where D

0

=300 mm, d

0

=100

mm, and H=100 mm. The bottom portion of the

device can control the outflow of the BFPC material.

The top of the device is equipped with a scale for

recording the descending height of the BFPC

material.

Figure 1: Collapsed down tube and test principle diagram.

3.2 Test Methods and Principles

This article adopts the two-points method to

determine the rheological properties of BFPC

materials[9]. The measurement principle is as

follows.

Establish a coordinate system as shown in Figure

1, the height h and radius r have the following

relationship:

H

hdDd

r

2

)(

2

000

−

+=

(2)

When pour the concrete into the collapsed down

tube, and the height is reduced by dh, the reduced

volume of the concrete in the collapsed down tube is

equal to the volume of flowing out of the collapsed

down tube.

2

0

2

4

ddtvdhr

π

π

⋅⋅=

(3)

Wherev is the speed which the concrete flows

out from the bottom of the collapsed down tube, m.

When the falling height of concrete in the

collapsed down tube is ΔH, and the time is Δt, the

formula 3 is integrated, as showed in formula (4).

∫

⋅Δ=

h

H

dtvdhr

2

0

2

4

π

π

(4

)

Whereh and Δ H can be measured by

experiments, and only v is an unknown quantity.

Therefore, the shear rate can be obtained.

H

v

Δ

Δ

=

'

γ

(5

)

When the height of concrete in the slump is h,

the shear stress is

hf ⋅⋅=

ρ

τ

(6)

Where f is friction coefficient of concrete; ρ is

specific gravity of concrete, 2530kg/m

3 [1]

.

Combining equations (2) to (6) and bringing in

the relevant parameters, the τ, τ

0

, and γ’ of the BFPC

material can be obtained, andηcan be obtained by

inverse calculation

[4]

.

3.3 Preparation of Experimental Raw

Materials

Aggregate size, filler, diluent, curing agent,

toughening agent and adhesive are the same as those

in document [1]~[3]. The length and diameter of

fiber and the way of processing fiber are also the

same as those in document [1]~[3]. In order to

investigate the rheological behavior of BFPC with

its content of main components, there are 4 factors,

namely the aggregate content, mass ratio of E44 and

E51, fly ash content, and basalt fiber content, each

of which Take 5 levels. BFPC's yield stress and

plastic viscosity coefficient were used as evaluation

indicators.

Table 1: Factor level.

4 RESULTS AND ANALYSIS

4.1 Orthogonal Test Results

The results of the orthogonal experiment are shown

in table 2.

Table 2: Orthogonal experimental designs and results.

4.2 Range Analysis

The yield stress and viscosity coefficient of BFPC

are analyzed by range analysis. The results are

shown in Table 3. It can be seen that the order of the

factors affecting the yield stress and the viscosity

coefficient is B>A>D>C, that is, the amount of

aggregates is the main factor affecting the

rheological properties, and the influence of the mass

ratio of E44 and E51 and the amount of fiber used is

the second, and the amount of fly ash is the least.

Table3: Results of range analysis.

Yield stress Viscosity coefficient

A B C D A B C D

K1 462.0 475.6 409.0 406.3 2317.8 2242.8 1678.6 1733.0

K2 431.9 464.5 418.6 408.5 2044.2 2170.9 2022.7 1988.8

K3 430.4 415.0 419.1 420.6 1912.5 2066.9 2088.6 2012.4

K4 389.6 384.7 423.4 425.4 1814.9 1950.9 2090.5 2079.2

K5 391.0 365.1 434.7 444.1 1930.3 1588.2 2139.3 2206.3

R 72.4 110.5 25.7 37.8 502.9 654.6 460.7 473.3

4.3 Effect Curve Analyses

Based on the results of table3, the effect curves of

four factors on yield stress τ

0

and viscosity

coefficient η are plotted, respectively, as showed in

Figure 2 and 3.

As shown in Figure 2 and 3, the influence of four

factors on τ

0

and η is as follows:

(a) The effect of E44:E51 mass ratio(Factor A):

with the decrease of factor A, both τ

0

and η decrease,

but when factor A decreases to a certain value, τ

0

and

η increase with the decrease of factor A.The reason

is that E44 and E51 have the same structure of two

phenolpropane (DPP) and epichlorohydrin (ECH)

polymerized bisphenol A epoxy resin. However,

because of the different ratio of DPP to ECH and

different reaction conditions, their molecular weight

is different. E44 has a larger molecular weight, a

longer molecular chain, and more polar parts

throughout the chain. When the long molecular

chains are tangled together, the internal friction is

large and the corresponding viscosity is large, but

the adhesive layer has a poor wettability with the

surface of the adherend and the adhesive force is

small. The situation in E51 is the opposite

[2]

.

Therefore, when the factor A is large, the stickiness

of the E44 accounts for the major factor. As the

factor A decreases, both the yield stress and the

viscosity coefficient decrease. When factor A

decreases to a certain value, the relative content of

E51 increases. As a result, the wettability of the

entire surface of the binder and the adherend is

increased. For this reason, even if the amount of E44

is reduced, theτ

0

and η of the entire fresh BFPC

increase.

Figure 2: Yield stress curve.

Yield stress curve/Pa

Figure 3: Viscosity coefficient curve.

(b) The effect of aggregate content (factor

B):within the scope of changes in the aggregate

content of this study, both τ

0

and η decreased as the

aggregate content decreased. Because with the

decrease of aggregate content, the accumulation of

particles is sparse, and the spacing of the aggregates

becomes large, so that the interparticle interaction

force is reduced. As a result, the flow resistance is

reduced, so τ

0

and η are reduced.

(c) The effect of fly ash content (factor C):within

the scope of this study, both τ0 and ηdecreased with

increasing fly ash content. This is because fly ash is

a mineral admixture. The main components of fly

ash areSiO2 、 A12O3 、 Fe2O3and CaO. It is a

glassy particle, which has low hydration activity,

low density, and requires less water or glue.

Appropriate increase of fly ash content can increase

the volume ratio of concrete slurry, which is

beneficial to the flow of concrete. In addition, fly

ash can play a "ball effect" and it can lubricate all

parts. For this reason, properly increasing the

amount of fly ash can lead to a decrease in the τ0and

η of fresh concrete.

(d) The effect of fly ash content (factor D):within

the scope of this study, bothτ0 and η increased with

increasing fiber content. When the fiber content

increases to a certain value, the network structure

formed between the fibers will limit the rheology of

the matrix. With the gradual increase of fiber

content, the fiber network will become more secret.

The fiber network will have greater restrictions on

the rheological properties of concrete.

5 CONCLUSIONS

The effect of various factors on the yield stress and

viscosity coefficient of BFPC from large to small is

the following: aggregate content, mass ratio of E44

and E51, content of basalt fiber and fly ash content.

The yield stress and viscosity coefficient of

BFPC decreased monotonically with the decrease of

aggregate content and fiber content, and the yield

stress and viscosity coefficient of BFPC decreased

with the increase of fly ash content.The yield stress

and viscosity coefficient of BFPC decrease with the

decrease of E44:E51 mass ratio. However, when the

mass ratio of E44:E51 decreases to a certain value,

the yield stress and viscosity coefficient of BFPC

increase with the decrease of E44:E51.

ACKNOWLEDGEMENTS

The work of this paper is supported by the National

Natural Science Foundation of China (Grant No.

51375219).

REFERENCES

1. Xu P, Shen J. X, Yu Y. H,et al, 2017. Study on

damping properties of basalt fiber reinforced polymer

concrete.Non-Metallic Mines, 40(1):39-32.

2. Xu P, Shen J. X, Yu Y. H,et al, 2016. Influence of

coupling time on strength of basalt fiber reinforced

polymer concrete. Non-Metallic Mines, 9(5):39-48.

3. Yu Y. H, Shi R. R, Xu P,et al, 2015. Experiment

research on optimization of component in polymer

mineral concrete reinforced by basalt fiber. Non-

Metallic Mines, 38(3):16-18,39.

4. Song W. M, Yi J, 2012. Summary of the rheology

performance of the fresh-mixed fiber-reinforced

concrete.Coal Ash,(2):41-44.

5. Huang F. L, Li H. J, Xie Y. J, et al, 2015. Research

progress on the correlation between workability and

rheological parameters of fresh concrete.Concrete,

(10):41-44.

6. Tomasz P, 2013. Rheological properties of self-

compacting concrete with chosen steel fibers.Pragu:

Czech Republic:1-12.

7. Tomasz P, 2011. The rheological of fresh steel fibres

reinforced self-compacting mixtures. Rchitecture Civil

Engineering Environment,(2):65-72.

8. Gao X. J, Sun B. C, Ye H, et al, 2016. Influence of

mineral admixtures on the rheological behavior of

self-compacting concrete.Journal of Jilin University

,Engineering and Technology Edition ,46(2):439-444.

9. Cao M. L, Zhang C, Han L.D, 2012. Experimental

study on the rheological properties of fresh mineral

powder concrete based on two-point method.

Concrete, 267(1):138-141.

Viscosity coefficient /Pa·s