Collaborative Design Platform for Clothing Industry from the

Perspective of Consumer Participation

Chen Pang

1

, Xiaofen Ji

2

and Haina Shen

2

1

School of Fashion Design & Engineering, Zhejiang Sci-Tech University, Hangzhou, China

2

School of International Education, Zhejiang Sci-Tech University, Hangzhou, China

Keywords: Clothing industry, Collaborative design platform, Consumer participation.

Abstract: In combination with the pain points of clothing manufacturers as well as the necessity of building up a new

design platform to realize knowledge sharing among consumers, designers and manufacturers, this paper

presented a Collaborative design platform(CDP) for clothing industry. The main functions and framework

of the platform were discussed. Three core subsystems including fashion information collection &

forecasting system, fashion custom-design system and digital fashion design system are collaborative to

provide a viable solution for customers involved design process.

1 INTRODUCTION

China has become world’s largest manufacturer after

forty years of rapid development. However most

manufacturing enterprises have still been placed in

the bottom of value chain with low - and medium-

grade products. On the “demand side”, traditional

production pattern in clothing industry with

information asymmetry between consumers’

requirement and design part, design part and

manufacturing, can not satisfy the changing

personalized needs of consumers. Accurate customer

needs can not be identified in the design process.

Information sharing failed among supply chain

partners.

In addition, longer production life cycle and

chain in clothing industry have brought high

inventories. Although clothes have become largest

category of online shopping, rate of return remains

higher than other categories. There are three main

reasons: lack of personality, poorly fitting and

longer production cycle make consumers change

their attitude towards the clothes they preferred three

weeks ago. According to TrueFit’s report for global

online clothing market, the rate of return reached up

to 50%. One-way flow of traditional supply chain in

clothing industry has made each part including

design, manufacturing or retailing as the information

island without interaction data flow. In particular, it

is truly troubling for ever-changing consumers’

demand to be sent accurately and instantly to design

and manufacturing part.

In order to deal with slow response to the market

changes and shorten production cycle in clothing

industry, we aimed to propose new design platform

and mechanism by intelligent measures, realizing

information sharing among consumers, designers

and manufacturers.

2 PAIN POINTS OF CLOTHING

MANUFACTURER

With the improvement of Chinese consumers’ living

standards, increasing enterprises should face the

coming of consumption upgrading. Consumers’

requirement for clothes appears diversification and

individuality. There is a serious mismatch between

supply and demand because merchandising planners

forecast consumers’ needs in advance in traditional

design and production mode, then manufacturers just

begin to reserve raw materials from their suppliers.

Consumers’ requirement has been regarded as an

“external” information node. Problems of inventory

and high rate of return have become outstanding.

Thus new design mode with consumers’ automatic

involvement by intelligent measures may solve the

problems above.

2.1 Problem of Inventory

Production cycle of clothing industry is longer than

other industries due to the long industrial chain and

geographic dispersed production. Traditional

production cycle from merchandising, design,

purchasing fabric and accessories, garment

manufacturing to final sale is about 6 months.

Clothing enterprises generally adopt supply mode

forecasting sales and supplying in advance.

Therefore, it is probably occurred that most

companies may encounter the problems of supply

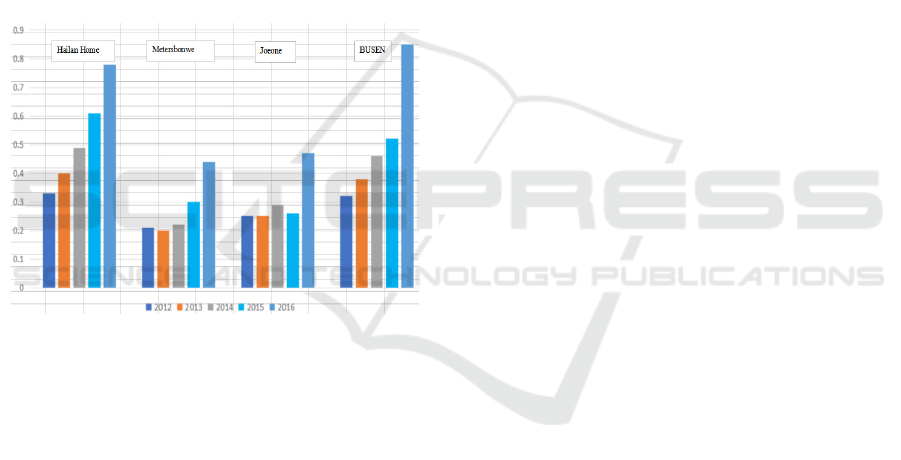

exceeding demand and high inventories. Figure 1

presents four famous Chinese clothing companies

(Hailan Home, Metersbonwe, Joeone and Busen)

and their stock-to-sales ratio from 2012-2016. It is

obvious that stock has been troublesome issue

considered by clothing industry even for outstanding

companies.

Figure 1: Four clothing enterprises’ stock-to-sales ratio

from 2012-2016.

2.2 High Rate of Return

Clothing products are considered as non-standard

goods need to be physically inspected by touching

and tried on to evaluate the quality(Ji and Pang,

2007). It is commonly recognized that perceived risk

is high when consumers purchase apparel products

online because of the inaccuracy and uncertainty of

garment color, fabric and details. However, it is

easily overlooked by researchers that consumers are

fickle - they may dislike clothes received three

weeks after they ordered them online even though

these clothes are quite same with what they saw on

the website before. They could return the clothes

without any reasons.

From the perspective of retailers, shortening

delivery cycle can promote the customers'

satisfaction as well as to some extent reduce rate of

return without reason or impulsive consumption.

2.3 Solution: Consumer Participation

and Intelligent Measures

To realize consumers’ individual demands, we need

design a platform as a bridge connecting consumers,

designers and manufacturers. Intelligent measures

are adopted to ensure accuracy and efficiency of

automotive embedded consumers’ requirements as

well as self-correction of process.

2.3.1 Consumer Participation

The traits of design with consumer participation

include value co-creation, enthusiastic to

communicating and uniqueness of products(Smets et

al, 2013; Fang, 2008; Guixin, 2014). Regulated

processes are important for success of new design

mode. Structure of platform and information

communication between supply and demand were

also regarded as crucial(Sunley et al, 2008) .

2.3.2 Functions of Collaborative Design

Platform(CDP)

Different parts can acquire and provide different

information to shorten and promote their efficiency.

Designer: directly meet the customer, saving

a lot of costs and time;

Manufacturer: acquire fabric fashion trend,

prepare yarn and fabric in advance, shortening fabric

preparation cycle;

For manufacturers, they need open some ports,

upload data about capacity of production, equipment,

progress of orders etc.

Retailer: obtain information about

manufacturers’ capacity, current production

arrangement, choose proper supplier according to

purchase order.

For retailers, they need upload data about

consumers’ needs, feedback and body size from

measuring in stores.

3 LAYER CONSTRUCTION OF

CDP

Building up a cloud platform for intelligent clothing

design can improve traditional clothing design

process. Structurally, this collaborative design

platform is composed of three core systems

interrelated:

Fashion information collection and

forecasting system;

Fashion custom-design system;

Digital fashion design system.

3.1 Fashion Information Collection and

Forecasting System

By means of cloud platform for collecting data of

fashion trends, development and forecasting system

can be adopted into manufacturing enterprises. This

system will undertake two main tasks: collecting

fashion trends and analyzing fashion elements of

fabric, silhouette, color, pattern, style and accessory,

see Figure 2. The sources of fashion trends can be

runway show, web fashion information from web

crawler software or sale data and customers’

evaluation. Fashion design is an activity with both

objective market feedback and sensual creation.

Therefore designer team need to be integrated into

this analyzing system to obtain final fashion

elements which are crucial for connecting to the next

system: fashion custom-design system.

Various analysis modules will also contribute to

the success of sharing data flow throughout fashion

enterprise’s life cycle. For example, the fabric

analysis module will help implementing fabric

network manufacturing, global purchasing and

flexible supply chain with collaborative

manufacturing.

Figure 2: Fashion information collection and forecasting

system.

3.2 Fashion Custom-Design System

Fashion elements extracted from fashion information

collection and forecasting system can be regarded as

the key part in fashion custom-design system, see

Figure 3. Based on fashion elements, design service

and popular styles can be provided to clothing

manufacturing inclined to be out of market under

traditional design mode. Meanwhile, according to

online customization (body shape’s characteristic

collecting by mobile application) and offline

experience(3D body data collecting by multi-

functional physical stores ) , customers’ shape

classification is gradually enriched and consumers

can receive accurate style recommendation

automatically from large data sets. After consumers

decide the style, they can choose fabric, color and

other details in a modular way within individual

virtual fitting room. Finally, customers place the

order while new preference has been generated.

Figure 3: Fashion custom-design system.

3.3 Digital Fashion Design System

According to customers’ orders, digital fashion

design system (Figure 4) is responsible for

transferring consumers’ demand to technical

document suitable for manufacturing.

Figure 4: Digital fashion design system.

Clothing pattern database will be searched base

on specific module. Then 3D virtual design module

will provide unique design according to the

customer’s body shape database established in

fashion custom-design system. The final step is 2D

pattern making module which creating technical

documents including pattern, process sheet, material

purchase orders, even additional service with the

arranging of garment procedure and cost calculation.

In short, this system aims to provide necessary

information to manufacturer timely which guarantee

keeping pace with design process.

3.4 Database for CDP

These three systems above are mutually connected

based on various databases. Considering cost

saving, current individual clothing design still have

to refer to the existing style to a large extent.

Therefore, clothing databases (Figure 5) need to be

knowledgeable and feasible to be queried, including:

Knowledge expressing database: building up

clothing conceptual model including style, color,

material, pattern, technology and so on;

Fashion style database: mapping data of apparel

elements to corresponding conceptual model,

constructing clothing logical model.A great mass of

fashion styles collected from consumers are stored

and shared in the cloud;

Material and pattern database: combining

function superposition method to time-space

transform measure to deal with model based on

chaotic mathematics theory and fractal theory.

Figure 5: Main databases for CDP.

4 CONCLUSIONS

This paper has presented an collaborative design

platform(CDP) for clothing industry to solve

problems of inventory and high rate of return. Three

core subsystems including fashion information

collection and forecasting system, fashion custom-

design system and digital fashion design system are

collaborative by consumer involved and various

databases to promote design process more accurate

and instant. Some intelligent measures will be

adopted to ensure accuracy and efficiency of

automotive embedded consumers’ requirements, it is

still a beneficial attempt to change traditional

developing, designing and manufacturing process.

ACKNOWLEDGEMENTS

This work was financially supported by general

project of Zhejiang province ministry of education

(Y201636739).

REFERENCES

1. Xiaofen, J., Chen, P., 2007. Online Visual

Merchandising of Apparel E-retailers. International

Engineering Management Conference, IEEE.

2. Smets, L.P.M., Langerak, F., Rijsdijk, S.A., 2013.

Shouldn't Customers Control Customized Product

Development? Journal of Product Innovation

Management, 30 (6) :1242-1253.

3. Fang, E., 2008. Customer Participation and the Trade-

Off between New Product Innovativeness and Speed

to Market. Journal of Marketing, 72 (4) :90-104.

4. Guixin, G., 2014. An investigation of motivations of

Consumer participation in co-creation activities

through communities: A case study of the fashion

industry. Personality & Individual Differences, 60

(5) :588-591.

5. Sunley, P., Pinch, S., Reimer, S., Macmillen, J., 2008.

Innovation in a creative production system: the case of

design. Journal of Economic Geography, 2008 , 8 (5)

:675-698.

Knowledge

expressing

Fashion

style

Material

and pattern