Characteristics of Composite Scaffold Chitosan-Chondroitin

Sulphate / Hydroxyapatite as the Candidate of Bone Graft

Aminatun

1,2a*

; Tia Rahayu Wijayanti

1b

; Dolfi Varton

2

and Prihartini Widiyanti

1,2c

1

Department of Physics, Faculty of Science and Technology, Universitas Airlangga

Kampus C UNAIR-Jl. Mulyorejo-Surabaya-60115- Indonesia

2

Biomedical Engineering, Post Graduate School, Universitas Airlangga-

Kampus B UNAIR-Jl. Airlangga 4-6, Surabaya-60286-Indonesia

Keywords: Scaffold, Chitosan, Chondroitin Sulphate, Hydroxyapatite, Bone Graft.

Abstract: Bone defect can be addressed by using bone graft, one of them is in the form of scaffold. Tri-component

scaffold consisting of chitosan, hydroxyapatite and chondroitin sulphate is more effective for tissue

engineering since it is biocompatible, non-toxic, and biodegradable and additionally, it can be absorbed by

the body. The purpose of this study is to know the effect of adding chondroitin sulphate and to determine

the best composition of chitosan-chondroitin sulphate/hydroxyapatite as the candidate of bone graft. The

process of composite scaffold synthesis used a freeze dry method. The result of composite scaffold

chitosan-chondroitin sulphate/hydroxyapatite was obtained through characterization which covers tests on

functional group, morphology, porosity, biodegradability and cytotoxicity. The result of a functional group

test revealed that there is a stretching vibration of NH

2

on 1638.35 cm

-1

as a typical group of chitosan,

stretching vibration S=O chondroitin sulphate on 1384.41 cm

-1

, stretching vibration of P-O-C on 1089.34

cm

-1

, 1050.38 cm

-1

and 602.36 cm

-1

are the functional groups of phosphate (PO

4

3-

) hydroxyapatite. The

result of a morphology test obtained pore size range from 26-239 µm which is appropriate as the ideal

scaffold pore size. The result of a scaffold porosity test was 90.06 – 93.48% which suited the porosity of

cancellous bone. The result of a biodegradability test showed the decrease of mass on each sample which

ranged from 27.149 – 60.658% during 4 weeks. The result of a cytotoxicity test revealed that the five

samples of the composite were non-toxic toward cells. Based on these characteristics, composite scaffold

chitosan-chondroitin sulphate/hydroxyapatite has a potential to be the bone graft with the best variation on

samples with hydroxyapatite:chitosan:chondroitin sulphate composition of 50:35:15 wt%.

1 INTRODUCTION

The result of basic research by the Ministry of

Health Indonesia showed the comparison of injury

escalated in prevalence from 7.5% becoming 8.5%

from 2007 until 2013 (RISKESDAS, 2013).

Fractures happened due to traffic accidents which

reached 24 million cases per year and those caused

by osteoporosis reached 350,000 cases per year

(KEMENRISTEK, 2014). There are more than 2.2

million cases of bone-grafting in one year in all parts

of the world. In Indonesia, the growing need for

biomaterials was four times larger and the need for

bone grafts will always increase along with the

increase of bone defects caused by trauma, tumors,

congenital abnormalities, infection and so forth

(Ferdiansyah et al., 2011). Nowadays, orthopedics

mostly uses bone graft from natural bone such as

autograft, allograft dan xenograft (Darwis et al.,

2008).

Scaffold is one bone graft which is able to

provide a condition needed by cells to proliferate

and maintain each function (Humatcher and

Dietmar, 2000). Bone scaffolding is a temporal

matrix for skeletal growth and provides a specific

sphere and a construction form in regards to

developing system (Schieker et al., 2006).

Osteoblasts and chondrocyte could grow on scaffold

which will be absorbed by the body carefully and

grow as new skeletal tissue (Humatcher and

Dietmar, 2000). The ideal scaffold has three

dimensional characteristics and is porous with pore

tissue which is interconnected as a place to grow

cells and transport the flow of nutrients and

236

Aminatun, ., Wijayanti, T., Varton, D. and Widiyanti, P.

Characteristics of Composite Scaffold Chitosan-Chondroitin Sulphate / Hydroxyapatite as the Candidate of Bone Graft.

DOI: 10.5220/0007540602360243

In Proceedings of the 2nd International Conference Postgraduate School (ICPS 2018), pages 236-243

ISBN: 978-989-758-348-3

Copyright

c

2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

metabolical waste. A scaffold must be biocompatible

and bioresorbable with controllable degradation

levels and absorption levels which are suitable for

the growth of cells or tissue. Additionally, scaffold

must have mechanical characteristics which are

appropriate for tissue located in implantation areas

(Humatcher and Dietmar, 2000). Thus, the

biomaterial of bone scaffold is a potential alternative

as the improvement technique of bone defects

caused by trauma, tumor resection, and abnormal

development (Mitsak et al., 2011).

The process of making a bone graft which is

based on a composite scaffold has been conducted

by several researchers, i.e. Venkatesan et al. (2008),

by synthesizing the composite scaffold chitosan,

chondroitin sulphate, and hydroxyapatite. Chitosan

was chosen since it has some characteristics of

biocompatibility, biodegradability, and also it was

expected to be able in shaping pores and be an

appropriate media for the cells’ growth. Since the

ideal scaffold provides a suitable atmosphere for cell

proliferation, it is necessary to add materials which

could support the process of cell proliferation, such

as hydroxyapatite (HA). The biggest potential of

bone substitution indicated by HA is the ability to

build strong connection with skeletal groups, which

is osteoconductive and stable toward biological

absorption and preventing bad impacts for humans

(Orlovskii et al., 2002). The study showed that the

additional chondroitin sulphate with

collagen/hydroxyapatite caused the increase of

skeletal remodeling, new bone construction, and

osteoblast differentiation (Venkatesan et al., 2012).

Therefore, by adding chondroitin sulphate, it was

expected that the composite scaffold chitosan-

chondroitin sulphate/hydroxyapatite could be a bone

graft which could stimulate the cell growth and

accelerate the process of the skeletal remodeling

process. The research will be conducted by using

composition variations of hydroxyapatite, chitosan,

and sulphate chondroitin with comparison (A)

50%:50%:0%, (B) 50%:40%:10%, (C)

50%:35%:15%, (D) 50%:30%:20% and (E)

50%:25%:25% from the total mass. The objective of

this research is to know the effect of adding

chondroitin sulphate and determine the best

composition of composition variation of chitosan-

chondroitin sulphate/hydroxyapatite as the candidate

of bone graft.

2 RESEARCH METHOD

2.1 Materials

The materials used are commercial hydroxyapatite

produced by Tissue Bank of Dr. Soetomo Hospital

Surabaya, chitosan with 70% DA, the synthetic

result of Bogor Agricultural Institute, chondroitin

sulphate by Interlab CV, 2% acetic acid, 10% NaOH

solution, distilled water, ethanol and dehydrated

alcohol and the making of Simulation Body Fluid

(SBF) solution by using K

2

HPO

4

.3H

2

O, CaCl

2

.2

H

2

O, NaCl, NaHCO

3

, Na

2

SO

4

, KCl, HCl, MgCl

2

.6

H

2

O and (HOCH

2

)

3

CNH

2

.

2.2 The Synthesis of Scaffold

Composite of Chitosan-Chondroitin

Sulphate/ Hydroxyapatite

The solution of chitosan-chondroitin sulphate/

hydroxyapatite which has been prepared was moved

into a pot bottle. To create a scaffold, the solution

was frozen at -80

o

C temperature for 5 hours. After

that a process named freeze-drying was done to the

frozen solution for 30 hours.

After the freeze-drying process, the sample of

composite scaffold chitosan-chondroitin

sulphate/hydroxyapatite was marinated in 10%

NaOH solution for 24 hours to neutralize the acetic

acid residual present in the sample. After that, it was

cleansed by using equades until it reached the

neutral pH. Next, freeze-dying was done once again

to relieve the water wastes in the composite sample

of chitosan-chondroitin sulphate/hydroxyapatite

scaffold.

The next process is the characterization covering

functional group testing with a Fourier Transform

Infra-Red (FTIR) spectrophotometer American

Perkin Elmer Co, morphological surface testing by

using a Scanning Electron Microscope (SEM)

inspect S50, FEI Corp., porosity test,

biodegradability and cytotoxicity test by using MTT

assay.

Porosity test was done by using a fluid

displacement method. During the test, the sample of

composite scaffold which would be used was

initially weighed to find the initial weight of the

sample. After that, the sample was marinated in 98%

ethanol for 48 hours. After marinating, the scaffold

sample was re-scaled along with the ethanol to find

the weight of marinated scaffold in ethanol. The last

step was measuring the ethanol whose sample has

been taken over. The final result of porosity testing

was acquired from the initial weight of the scaffold

(w

1

), the weight of scaffold and ethanol which

are being marinated (w

2

), and the final weight of

ethanol after the scaffold was taken over (w

3

). Then,

the percentage of porosity of each composite

Characteristics of Composite Scaffold Chitosan-Chondroitin Sulphate / Hydroxyapatite as the Candidate of Bone Graft

237

scaffold sample was then calculated by using

Equation 1.

(1)

Biodegradability in-vitro test was done by

marinating the composite scaffold sample in a

Simulated Body Fluid (SBF) solution. In this test,

the composite scaffold sample was immediately

measured to see the basic weight of the scaffold.

Further, the sample of composite scaffold was

marinated in a Simulated Body Fluid (SBF) solution

for 4 weeks. The data of the biodegradability in-vitro

testing result was collected on 1

st

, 2

nd

, 3

rd

, and 4

th

week. In each data collection, the scaffold sample

was dried initially, a while later it was weighed to

reveal its final weight after being marinated. The

data acquired from the test was in the form of the

initial weight (w

0

) of each composite scaffold and

the final weight (w

1

) after marinating process. The

percentage of degradation or lost mass acquired

from the data was calculated by using Equation 2.

(2)

The cytotoxicity testing was conducted by using

MTT Assay consisting of tetrazolium salt [3-(4,5-

dimetiltiazol-2-yl)-2,5-difeniltetrazolium bromide].

The systematic principal of the MTT Assay method

is following the ability to live of the living cell based

on mothocondrial activities of cell culture. The

changes happened on tetrazolium salt [3-(4,5-

dimetiltiazol-2-yl)-2,5-difeniltetrazolium bromide]

which became formazan in an active mothocondria

as the base of the MTT Assay method. The living

cell will change MTT which was then cracked

through the reduction of reductase enzym in a chain

of mothocondrial respiratory system to formazan

which was dissolved in purple. The bigger the

absorbance, the more the living cells calculated by

using Equation 3.

(3)

where ODT = OD treated cells, ODM = OD media

control and ODC = OD cells control.

3 RESULTS AND DISCUSSION

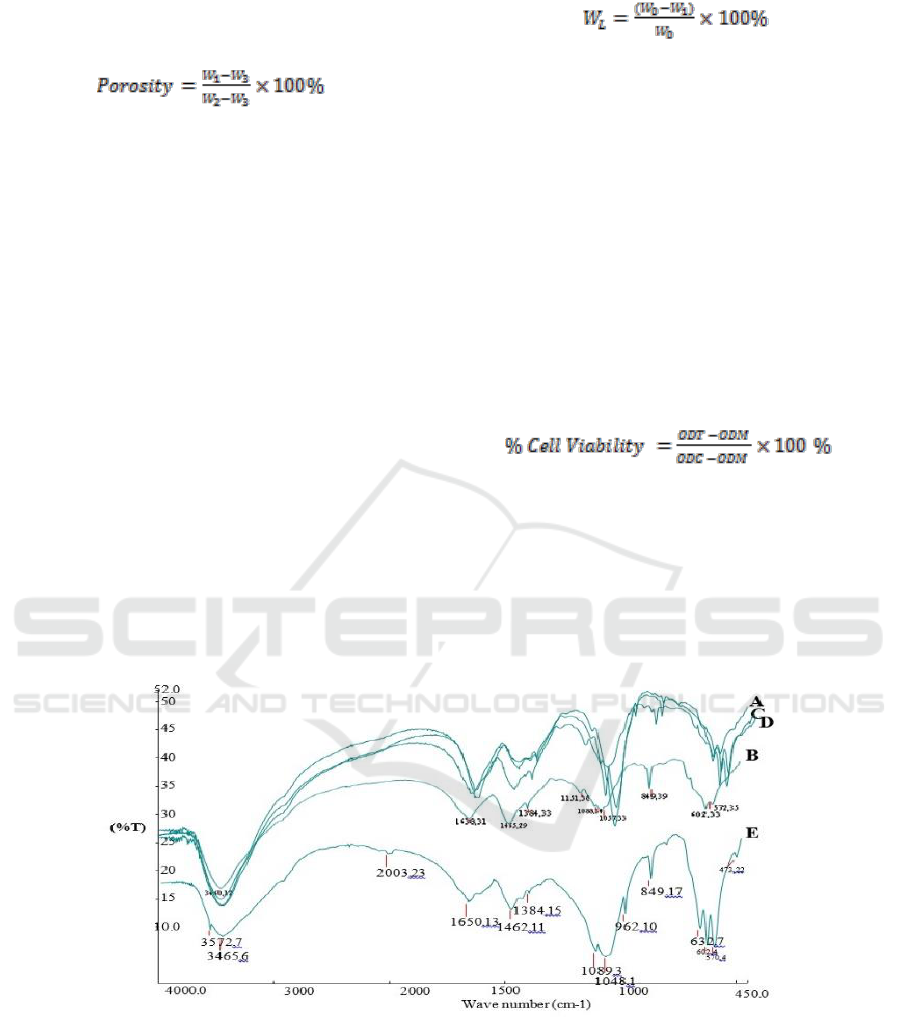

3.1 The Analysis of Functional Group by Using Fourier Transform Infra-Red (FTIR)

Figure 1: FTIR Spectrum of Composite Scaffold Chitosan-Chondroitin Sulphate / Hydroxyapatite.

Based on Figure 1, the result of FTIR test, it was

acquired wavenumber as the stretching vibration of

O-H, the O-H of all materials consisting of OH

functional group. The absorption area on the

wavenumber 1638.35 cm

-1

was the stretching

vibration of Amina (NH

2

) and carbonyl (C=O)

functional group. The wavenumber of 1459.39 cm

-1

is the bending vibration of C-H from CH

2

group. On

each absorption, the wavenumber 1384.41 cm

-1

is

the stretching vibration of S-O, the characteristic of

SO

3

-

functional group as the group of chondroitin

sulphate. The stretching vibration of P-O-C was

shown by the absorption area on the wavenumber

1089.34 cm

-1

, 1050.38 cm

-1

and 602.36 cm

-1

ICPS 2018 - 2nd International Conference Postgraduate School

238

included in the phosphate functional group (PO

4

3-

),

the specification of hydroxyapatite. The carbonate

functional group (CO

3

2-

) found on the absorption

band on wavenumber 849.49 cm

-1

. Besides, it was

the distinctive characteristic of the chondroitin

sulphate absorption band. The absorption band on

the waveband 571.35 cm

-1

belongs to

hydroxyapatite. The carbonate functional group

(CO

3

2-

) appearing in the result of FTIR test was

originally from the absorption of carbon dioxide

from the atmosphere.

3.2 Morphology Test

a

b

c

d

Characteristics of Composite Scaffold Chitosan-Chondroitin Sulphate / Hydroxyapatite as the Candidate of Bone Graft

239

Figure 2: Results of Morphology Test of Composite Scaffold Chitosan-Chondroitin Sulphate/Hydroxyapatite with the

variation composition of (a)50:50:0 wt% transversal, (b) 50:50:0 wt% vertical, (c) 50:40:10 wt% transversal, (d) 50:40:10

wt% vertical, (e) 50:35:15 wt% transversal (f) 50:35:15 wt% vertical, (g) 50:30:20 wt% transversal (h) 50:30:20 wt%

vertical, (i) 50:25:25 wt% transversal dan (j) 50:25:25 wt% vertical

e

f

g

h

i

j

ICPS 2018 - 2nd International Conference Postgraduate School

240

The observation on morphology test was done on

the sample by seeing the transversal and vertical

longitudinal plane with 200x and 500x enlargement.

The measurement of pore on the scaffold sample

was done by using a software available in SEM. A

ruler was used to meter the diameter of pore seen

from the smallest and biggest diameter on the

picture as the result of SEM.

A very porous scaffold facilitated the seeding

and immigration of cells while the smaller pores

enable the growth of tissue. Based on data in Table

1, it was acquired the A, B, C, D, and E samples

have fulfilled the criteria of diameter ideal size of a

scaffold’s pore to help the process of

osteoconduction on range 200-350 µm. Meanwhile,

the most suitable criteria was on sample C since it

has the closest range of diameter size to the pore size

of the scaffold which could assist the growth of

fibroblast and osteoconduction.

Table 1: Pore Size of Composite Scaffold Chitosan-

Chondroitin Sulphate/Hydroxyapatite.

Samples:

Hydroxyapatite:

Chitosan:Chondroitin

Sulphate (wt%)

Pore Size (µm)

A (50:50:0)

26 - 150

B (50:40:10)

57 - 223

C (50:35:15)

27 - 208

D (50:30:20)

30 - 205

E (50:25:25)

57 - 239

3.3 Porosity Test

The porosity of a scaffold has an essential role in

regenerating tissue. It provides the temporal

mechanical function and facilitates the migration of

cells. High porosity (90%) was chosen for various

scaffold designs since it is possible to diffuse

adequate nutrition during the tissue growing and

provide sufficient area for cells and biomaterial to

interact with each other. The biggest percentage of

porosity (Figure 3) was on sample A, the composite

scaffold of chotisan/hydroxyapatite with 50:50%

composition compared to samples B, C, D, and E by

adding variation of chondroitin sulphate composition

40%wt, 35%wt, 30%wt, and 25%wt each. The

declined percentage of porosity of sample B, C, D,

and E, if compared to sample A, happened due to the

additional chondroitin sulphate on the composite

scaffold sample causing an intermolecular knot of

hydrogen between chitosan and hydroxyapatite.

From the results of the porosity test using a fluid

displacement method, it can be concluded that

sample C was the best result with porosity

percentage of 90.06%.

Figure 3: Porosity Percentage Samples of Composite

Scaffold Chitosan-Chondroitin Sulphate/Hydroxyapatite

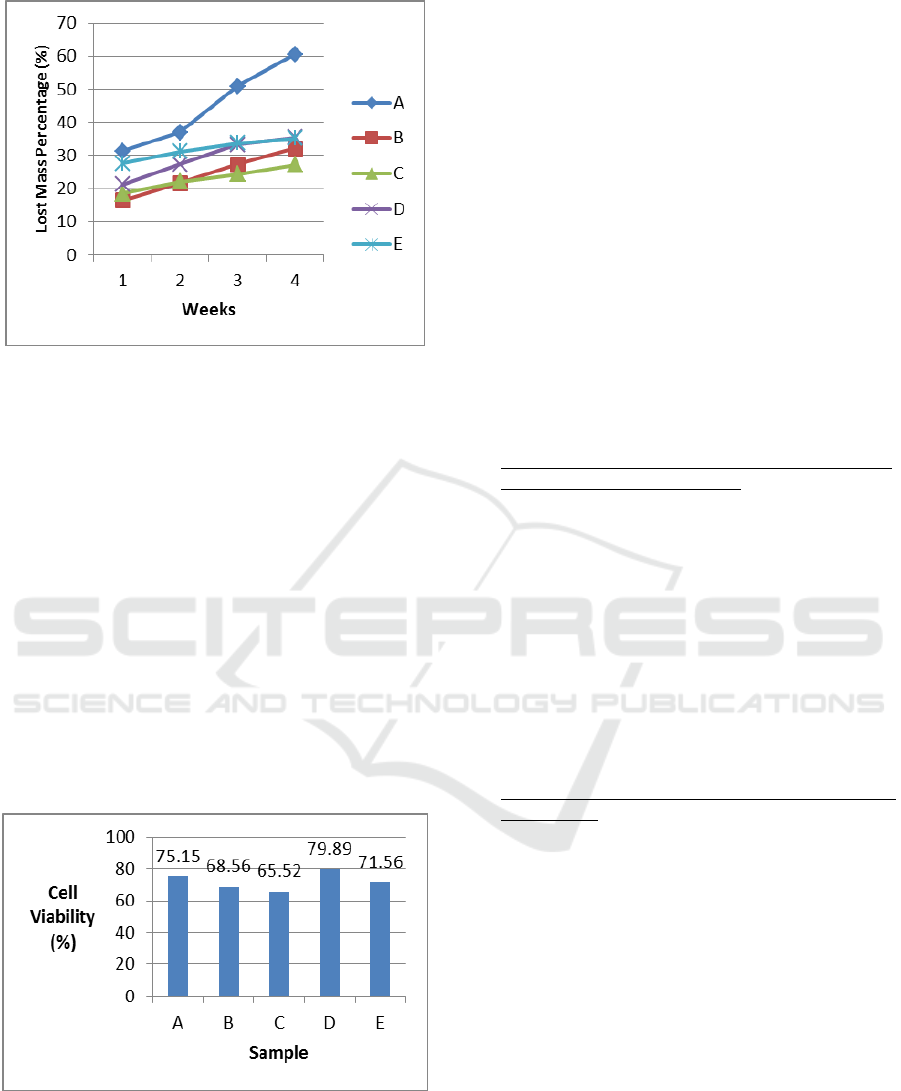

3.4 Biodegradability In Vitro Test

The ideal scaffold has a controllable degradation

level which suits the skeletal reparation process. The

purpose of a biodegradability in vitro test on a

composite scaffold sample is to know the level of

composite scaffold biodegradation in the

environment of body fluid. The result of a

biodegradability in vitro test using SBF fluid

increased the degradation level from the first until

the fourth week. In the fourth week, it can be seen

that composite scaffold still has not been degraded

thoroughly, so that it was not good enough for the

development of skeletal tissue. While vascular

development was in progress, the collagen matrix

was secreted by osteoid then mineralized, which

directed the formation of soft callus around the

reparation area. The callus is broken in 4-6 weeks

from the recovery process and needed adequate

protection in the form of bracing or internal fixation.

Thus, it can be concluded that after 4 weeks, the

composite scaffold chitosan - chondroitin sulphate

/hydroxyapatite could still provide space for the

growth of skeletal tissue so that it could increase in

vitro bioactivity on the scaffold, with sample C as

the best result with lost mass of 27.1485% during 4

weeks (Figure 4).

Characteristics of Composite Scaffold Chitosan-Chondroitin Sulphate / Hydroxyapatite as the Candidate of Bone Graft

241

Figure 4: Graphic of Lost Mass Percentage of Samples

Composite Scaffold Chitosan-Chondroitin

Sulphate/Hydroxyapatite

3.5 Cytotoxicity Test

Cytotoxicity test aims at knowing the nature of

cytotoxicity in a sample of composite scaffold

chitosan-chondroitin sulphate/hydroxyapatite toward

the living cell perceived from the viability cell or

living cell percentage. A material is called non-toxic

if the percentage of cell viability is more than 50%

(Spielmann et al., 2007). On the cytotoxicity test

using MTT Assay on the composite scaffold sample

A, B, C, D, and E, it obtained the percentage of the

living cell as high as 75.15%, 68.56%, 65.52%,

79.89 and 71.56% (Figure 5). This shows that by

adding chondroitin sulphate on the composite

scaffold sample, the sample became intoxicating for

the living cell.

Figure 5: Cell Viability of Composite Scaffold Chitosan-

Chondroitin Sulphate /Hydroxyapatite

4 CONCLUSIONS

Composition variation of chondroitin sulphate

affects the pore size, porosity, and the percentage

of lost mass on a composite scaffold. Composite

scaffold chitosan - chondroitin

sulphate/hydroxyapatite can be used as the

candidate of bone graft. The best result was

acquired from sample C (35:15:50 wt%) with pore

size range 27-208µm, porosity 90.06%, lost mass

percentage was 27.187% for 4 weeks, and cell

viability was 65.52%.

REFERENCES

Badan Penelitian dan Pengembangan Kesehatan

Kementrian Kesehatan RI. 2013. Riset Kesehatan

Dasar (RISKESDAS 2013). Downloaded from:

http://www.litbang.depkes.go.id/sites/download/rkd20

13/Laporan_Riskesdas2013.PDF on 10 December

2014 at 06.09 WIB.

Darwis, Darmawan, dan Yessy Warastuti. 2008. Sintesis

dan Karakterisasi Komposit Hidroksiapatit (HA)

Sebagai Graft Tulang Sintetik. Jurnal Ilmiah Aplikasi

dan Radiasi Vol 4 No.2 Desember 2008.

Ferdiansyah, Djoko Rushadi, Fedik Abdul Rantam,

Aulani’am. 2011. Regenerasi pada Massive Bone

Defect dengan Bovine Hydroxyapatite sebagai Scaffold

Mesenchymal Stem Cell. JBP Vol 13, No.3.

Hutmacher, Dietmar W. 2000. Scaffolds in tissue

engineering bone and cartilage. Elsevier B.V:

Biomaterials 21 (2000) pp. 2529-2543.

Kementrian Riset dan Teknologi Republik Indonesia.

2014. Accessed on November 2014 at 17.58 WIB in:

http://www.ristek.go.id/index.php/module/News+News

/id/12533/pdf

Mitsak, Anna G, Jesscia M. Kemppainen, Matthew T,

Harris, Scott J Hollister. 2011. Effect of

Polycaprolactone Scaffold Permeability on Bone

Regeneration in Vivo. Michingan: Tissue Engineering:

Part A, Vol 17, Numbers 13 and 14.

Orlovskii, V.P., V. S. Komlev, dan S. M. Barinov. 2002.

Hydroxyapatite and Hydroxyapatite-Based Ceramics.

Russia: Inorganic Materials, Vol. 38, No. 10, 2002,

pp.973-984.

Schieker, Matthias, Herman Seitz, Inga Drosse, Sebastian

Seitz, Wolf Mutschier. 2006. Biomaterials as Scaffold

dor Bone Tissue Engineering. German: European

Journal of Trauma 2006 No.2.

Spielmann, H. Hoffman, S. Botham, P. Roguet, R. Jones,

P. 2007. The ECVA International Validation Study on

In Vitro Test for Acute Skin Irritation Report on the

Validity of the EPISKIN and EpiDerm Assays on the

Skin Integrity Function Test. Germany: ATLA.

Venkatesan, Jayachandran, Ramjee Pallela 2012.

Chitosan-amylopectin/hydroxyapatite and chitosan-

chondroitin sulphate/hydroxyapatite composite

ICPS 2018 - 2nd International Conference Postgraduate School

242

scaffolds for bone tissue engineering. International

Journal of Biological Macromolecules 51 (2012)

halaman 1033-1042.

Characteristics of Composite Scaffold Chitosan-Chondroitin Sulphate / Hydroxyapatite as the Candidate of Bone Graft

243