Cold State Numerical Simulation of New Type

Coal-water-slurry Gasifier

H L Yu

1,*

, E H Liu

1

, G F Zhang

2

and Z W Wang

1

1

School of Petroleum Engineering, Changzhou University, Changzhou 213016,

China

2

Business School of Changzhou University, Changzhou 213164, China

Corresponding author and e-mail: H L Yu, yhl.doctor@163.com

Abstract. In order to examine the effect of different inlet angle and height of furnace side

nozzle upon the distribution of flow field, velocity distributing, turbulence intensity,

turbulence kinetic energy in a new type coal-water-slurry gasifier with 600kg/h output at cold

state was analyzed using numerical simulation method. The optimization distribution was

observed with the inlet angle is 45°and height is 0.9m far from the furnace top, which can be

seen as a guidance for designing and operating of this type gasifier.

1. Introduction

The distribution of flow field in coal-water-slurry gasifier has important influence on gasification

effect of gasifier. Uniform flow field distribution and a small amount of dead vortex area are the

basis of good gasification effect. In this paper, FLUENT numerical simulation software is used to

simulate the distribution of gasification flow field in a new coal slurry gasifier, the influence of

nozzle inlet Angle and inlet position on the flow field distribution in the gasifier is investigated.

2. Control of numerical simulation

2.1. Description of the physical model calculation

In this chapter, the physical model used for numerical simulation calculation is the three-dimensional

space within the new type of coal-water-slurry gasifier with a 600kg/h output. The inner diameter of

the gasifier is 0.5 m, with a net height of 1.5m and a height-diameter ratio of 3. The physical model

of its calculation is shown in figure 1.

346

Yu, H., Liu, E., Zhang, G. and Wang, Z.

Cold State Numerical Simulation of New Type Coal-water-slurry Gasifier.

In Proceedings of the International Workshop on Environmental Management, Science and Engineering (IWEMSE 2018), pages 346-357

ISBN: 978-989-758-344-5

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Figure1. physical model of numerical simulation calculation.

In this model, proper simplified treatment has been carried out for the actual gasifier. The small

rounded corners on the two ends of the furnace which have little impact on the flow field are

removed, and the gasifier is regarded as a cylinder, in which way the trouble and restrictions for the

model meshing are simplified, and at the same time the actual numerical simulation won’t be

impacted greatly. After confirmation of the physical model, mixed meshing will be carried out on

this model using tetrahedron and hexahedron.

2.2. The control equation of the continuous phase three-dimensional flow

In numerical simulation, the flow is described by the equation of mass, momentum and energy

conservation.

The general form of the continuity equation (mass conservation equation) [1] is:

0

z

w

y

v

x

u

t

(1)

The equation of motion of viscous fluid (momentum conservation equation) is N-S equation, and

its general form [2] is:

j

j

i

eff

ij

i

eff

i

i

i

x

u

xxx

u

x

f

Dt

Du

3

1

2

(2)

The control of turbulence kinetic energy in simulated calculation adopts viscous turbulent flow

model [3-5] of

. The general form of the governing equation which is expressed by tensor is as

follows:

G

xx

u

xt

j

effk

j

i

i

(3)

2

21

CGC

xx

u

xt

j

eff

j

i

i

(4)

In the formula:

represents the density of the mixture;

i

u

represents the velocity component of

the

i

direction;

t

means the time interval;

G

represents the turbulent kinetic energy caused by the

mean velocity gradient;

1

C

and

2

C

represents the empirical constants, and they are provided by

Cold State Numerical Simulation of New Type Coal-water-slurry Gasifier

347

literature [2], which are

1

C

= 1.42 and

2

C

=1.68, being used as the model constants; and

eff

is

the virtual viscosity here, being obtained by the following definition:

d

C

d

1

72.1

3

2

Among which

eff

;

100

C

; within high reynolds numbers,

2

C

, and in

which

0845.0

C

.

Adding definite condition to the above equations, the instantaneous solution of the fluid

movement in the flow field can be reached with the finite element method, including the velocity

distribution, pressure distribution, turbulence intensity distribution and other information of the fluid

motion[6-10].

3. Result of numerical simulation

3.1. The influence of the position of the nozzle inlet on the side of the furnace

In order to determine a appropriate location for the nozzle inlet on the furnace side, the author has

conducted numerical simulation of cold state for the flow field distribution, particle residence time,

particle concentration distribution and other aspects within the gasifier, with the condition when the

nozzle inlet respectively locates in the positions where the distances between the nozzle and the

furnace top take up 40%, 50% and 60% of the furnace height, which means the distance (h) between

the nozzle and the furnace top are 0.6m, 0.75m and 0.9m. Based on the result of the numerical

simulation calculation, the laws of the influence of the position of the nozzle inlet on the furnace side

on these factors have been analyzed and the optimal location for the nozzle inlet on the furnace side

have been obtained.

In the process of numerical simulation calculation, except for the change of the nozzle inlet

position, other working conditions are exactly the same, for which the details are: the angle of the

nozzle inlet on the side of the furnace is 45°; the spray angle of the various nozzles is 30°; the

velocity of the air flow near the nozzle outlet on the top of the furnace is 30 m/s; the velocity of the

air flow near the nozzle outlet on the side of the furnace is 25 m/s; the pulverized coal particles

entering the furnace are of the size of 100um~160um; the flow rate of the pulverized coal from the

nozzles on the top of the furnace is 10.8kg/h; the flow rate of the pulverized coal from each of the

nozzles on the side of the furnace is 2.7kg/h; and that the pulverized coal particles are injected into

the furnace from the various nozzles at the same time. The pulverized coal particles here only mean

the tracer particles, which are used to describe the concentration distribution of the particles in the

furnace and the retention time of the particles in the test furnace. During the numerical simulation

calculation, there will not be any chemical reaction occurred with the gas phase since they are inert

particles. The pressure in the gasifier is normal pressure in order to compare with the later tests. For

cold-state gasifier, the effect of the pressure in the furnace on the flow field distribution is very small.

Instead, the flow field distribution in the furnace is mainly affected by the furnace type of the gasifier,

the position and angle of the nozzle inlet, the velocity and kinetic energy of the nozzle inlet and the

nozzle flow. The pressure change in the gasifier is very small, being similar to a container with

constant pressure, that’s why when the numerical simulation is performed, normal pressure still can

well reflect the flow field distribution inside the gasifier under high pressure, and it will have no

impact on the model selection of gasifier.

IWEMSE 2018 - International Workshop on Environmental Management, Science and Engineering

348

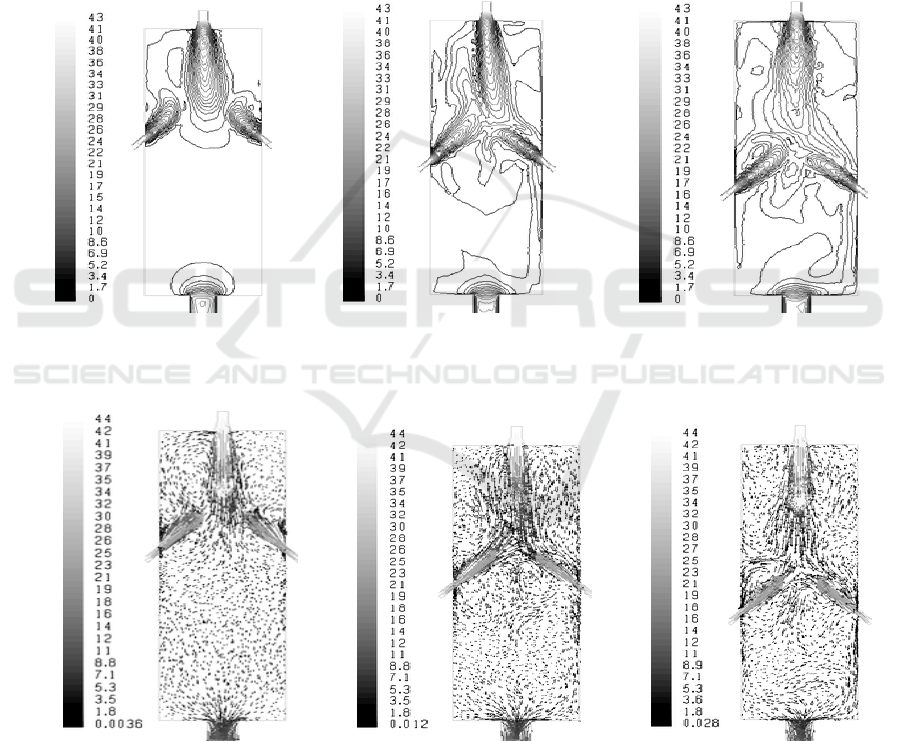

The following figure 2 and figure 3 are respectively the velocity distribution contour map and the

velocity distribution vector diagram of the internal furnace when the distances of the position of the

nozzle inlet to the top of the gasifier are 0.6m, 0.75m and 0.9m. As you can see from (1) in Figure 1

that when the distance of the nozzle inlet on the side of the furnace to the top of the gasifier is 0.6m,

the impact and the interception of the nozzle jet flow on the side of the furnace on the nozzle jet flow

on the top of the furnace is very little, in which way the function and advantage of the nozzle jet on

the side of the furnace cannot be achieved. In this case, the nozzle jet flow on the top of the furnace

passes through the middle of the nozzle jet flow on the side of the furnace before the strike of the

nozzle jet flow on the side of the furnace happens, and the nozzle jet flow on the side of the furnace

will be pushed to the side of the furnace wall by the main flow of the nozzle jet on the top of the

furnace; thus a scour of the furnace wall will exist. So, this kind of flow field distribution is very

unreasonable and the nozzle inlet on the side of the furnace cannot be located in this position.

(a)h=0.60m (b)h=0.75m c)h=0.90m

Figure 2.contours map of velocity distributing in coal-water-slurry gasifier.

(a)h=0.60m (b)h=0.75m c)h=0.90m

Figure 3.vectorgraph of velocity distributing in coal-water-slurry gasifier.

Cold State Numerical Simulation of New Type Coal-water-slurry Gasifier

349

(a)h=0.60m (b)h=0.75m c)h=0.90m

Figure 4.turbulence intensity distributing in coal-water-slurry gasifier.

(a)h=0.60m (b)h=0.75m c)h=0.90m

Figure 5.turbulence kinetic energy distributing in coal-water-slurry gasifier.

IWEMSE 2018 - International Workshop on Environmental Management, Science and Engineering

350

As you can see from (b) in Figure 2 and Figure 3 that when the distance of the nozzle inlet on the

side of the furnace to the top of the gasifier is 0.75m, the above undesirable phenomena weaken

evidently, the impact and interception of the nozzle jet flow on the side of the furnace on the main

flow of the nozzle jet on the top of the furnace become strong greatly, and the nozzle jet flow on the

side of the furnace dose not scour the wall of the furnace. However, the authors find out that the main

flow of the nozzle jet on the top of the furnace collides with the nozzle jet flow on the side of the

furnace without reaching the state of full development. In this way the jet flow from the various

nozzles will collide with each other after a very short time when they enter into the gasifier, which

will be disadvantageous for the nozzles to realize their sound atomization performance fully.

Meanwhile, when comparing (c) in Figure 2 and Figure 3, the recirculation zone formed around the

nozzle on the top of the furnace is relatively small because the distance of the nozzle inlet on the side

of the furnace to the top of the gasifier is very near. For gasifier of thermal operation, if the

recirculation zone around the nozzle on the top of the furnace is small, the volume of the air

entrainment of the surrounding high temperature gas by the nozzle jet flow on the top of the furnace

will be less, which is not good for the nozzle jet flow on the top of the furnace and the ignition and

burning in the collision area, and at the same time will reduce the stability of the ignition and

operation within the gasifier. So, the increase of the air entrainment of the surrounding high

temperature gas by the nozzle jet flow on the top of the furnace should be considered properly, for

which the most direct way is to increase the recirculation zone. When the distance of the nozzle inlet

on the side of the furnace to the top of the gasifier is 0.9m, the nozzle jet flow on the top of the

furnace collides with the nozzle jet flow on the side of the furnace when it’s fully developed. In this

way, the sound atomization performance of the nozzles on the top and both sides of the furnace can

be fully realized, and the time from the entering of the jet flow of the nozzle into the gasifier to the

collision is prolonged, which have provided precondition for the full development of jet flow,

increase the recirculation zone around the nozzle jet flow on the top of the furnace, strengthen the

nozzle jet flow on the top of the furnace, and increase the stability of the ignition and operation

within the gasifier. So, from the perspective of the distribution effect of the flow field, it’s

comparatively ideal when the distance of the nozzle inlet on the side of the furnace to the top of the

gasifier is 0.9m.

(a), (b), (c) in Figure 4 and Figure 5 are respectively the contour map of the turbulence intensity

distribution and turbulent kinetic energy distribution of the gasifier when the distances of the position

of the nozzle inlet to the top of the gasifier are 0.6m, 0.75m and 0.9m. As you can see from the

figures that when the distance is 0.6m, the turbulence intensity distribution and turbulent kinetic

energy distribution are apparently different from that of 0.75m and 0.9m. When the distance is 0.6m,

the nozzle jet flow on the side of the furnace dose not impact the internal flow field of the nozzle jet

flow on the top of the furnace; because the nozzle inlet on the side of the furnace is very near to the

top of the furnace, the position of the collision of the nozzle jet flow on the side of the furnace and on

the top of the furnace is just the position where the rigidity of the nozzle jet flow on the top of the

furnace are comparatively strong. In this case, the impact and interception effect of the nozzle jet

flow from the side on the jet flow from the top are not evident, and the kinetic energy of the flow

from the side of the furnace has been exhausted before it comes to intervene the internal flow field of

the nozzle jet flow on the top of the furnace, and thus the function of the nozzle jet flow on the side

of the furnace does not realize fully. However, the situation for the distances of 0.75m and 0.9m is

much better compared to 0.6. Especially when the distance of the nozzle inlet to the top of the

gasifier is 0.9, the kinetic energy of the flow from the side of the furnace are fully realized, the

impact and the interception of the nozzle jet flow on the top of the furnace are very evident, and the

area with comparatively intensified turbulent mixing strength becomes larger, all of which can be

seen from (c) in figure 4.9. So, from the perspective of the distribution of the turbulence intensity

distribution and turbulent kinetic energy distribution, it’s comparatively ideal when the distance of

Cold State Numerical Simulation of New Type Coal-water-slurry Gasifier

351

the nozzle inlet on the side of the furnace to the top of the gasifier is 0.9m, which is consistent to the

result author’ve got from the perspective of the flow field distribution.

3.2. Influence of nozzle inlet angle on the side of the furnace

After the position of the nozzle inlet on the side of the furnace is confirmed, the inlet angle becomes

another important parameter which will affect the distribution of flow field in the gasifier and the

particle concentration distribution. In order to find the proper angle, the numerical simulation

calculation for the internal flow field distribution, particle concentration distribution and average

residence time of the particles is carried out, with various inlet angles of 30°, 45°, 60°, and 90°.

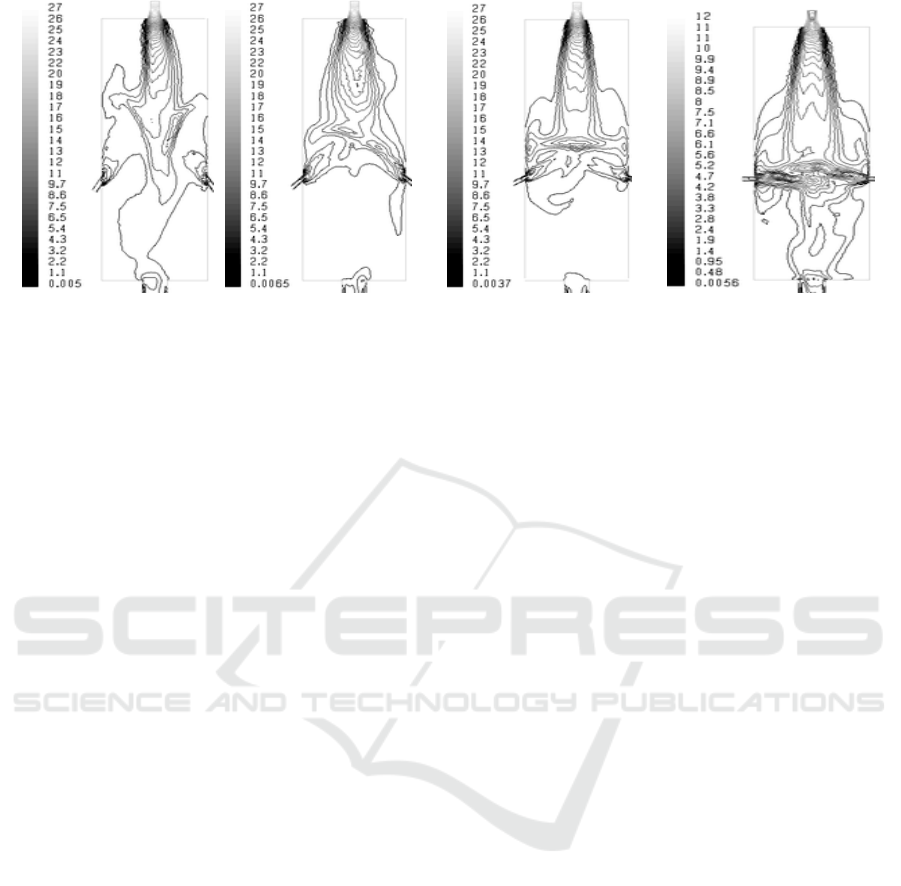

(a)

=30° (b)

=45° (c)

=60° (d)

=90°

Figure 6.contours map of velocity distributing in coal-water-slurry gasifier.

During the calculation of numerical simulation, except for the changing of the nozzle angle on the

side of the furnace, other working conditions are completely consistent, the detailed conditions are:

the distance between the nozzle on the side of the furnace and the top of the furnace is 0.9m; the

atomizing angle of the various nozzles is 30˚; the air velocity of the nozzle outlet on the top of the

furnace is 30m/s; the air velocity of the nozzle outlet on the side of the furnace is 25m/s; the

pulverized coal particles coming into the furnace are with the size of 100um~160um; the flow rate of

the nozzle on the top of the furnace is 10.8kg/h; the flow rate of each of the nozzles on sides of the

furnace is 2.7kg/h, and the pulverized coal particles will be jetted into the furnace from the various

nozzles at the same time. The same as above, the pulverized coal particles are just tracer particles too,

which are used to describe the concentration distribution of particles in the furnace and their retention

time in the test furnace. In the process of the numerical simulation, no chemical reaction will occur

with the gas phase, since they belong to inert particles, and in order to compare with the later tests,

the pressure in the gasifier is under normal pressure.

IWEMSE 2018 - International Workshop on Environmental Management, Science and Engineering

352

(a)

=30° (b)

=45° (c)

=60° (d)

=90°

Figure 7.vectorgraph of velocity distributing in coal-water-slurry gasifier.

(a)

=30° (b)

=45° (c)

=60° (d)

=90°

Figure 8.turbulence intensity distributing in coal-water-slurry gasifier.

Cold State Numerical Simulation of New Type Coal-water-slurry Gasifier

353

(a)

=30° (b)

=45° (c)

=60° (d)

=90°

Figure 9. turbulence kinetic energy distributing in coal-water-slurry gasifier.

Diagrams of (a), (b), (c), and (d) in figure 6 and figure 7 are the velocity distribution contour map

and the velocity distribution vector diagram with the angles of the nozzle inlets on the side of the

furnace respectively being 30°, 45°, 60°, and 90°. As you can see from figure 6 (a) and figure 7 (a)

that when the angle is 30°, the impact and interception effect of the nozzle jet flow from the side of

the furnace on the main flow from the nozzles on the top is very little. The main flow from the

nozzles on the top of the furnace goes through the middle of the nozzle jet flow from the side of the

furnace, in which case the nozzle jet flow from the side of the furnace will be pushed to one side of

the furnace wall and the main jet flow from the nozzles on the top of the furnace will become long

and narrow. In the diagram, it shows clearly that the jet flow from the nozzles on the side of the

furnace is obviously bent to one side of the furnace wall in the later stage, and it has a serious scour

effect on the wall of the furnace; besides, the main jet flow on the top of the furnace rushes directly

to the bottom outlet of the furnace after going through the inter-space, which should be avoided all

the time in actual operation. So, from the perspective of the flow field analysis, it’s totally unsuitable

with the angle of the nozzle inlet on the side of the furnace being 30°. Compare the diagrams of (b),

(c), and (d) in figure 6 and figure 7, and you will find when the angle is 45°, the timing for collision

between the nozzle jet flow from the side of the furnace and the main nozzle jet flow from the top of

the furnace is the most appropriate, in which time the main jet flow is just fully developed when

colliding and both the nozzle jet flows from the side of the furnace and the main nozzle jet flow from

the top of the furnace are with a relatively higher speed and larger kinetic energy. In this case, the

turbulence mixing degree during the collision is higher, and the period before the collision is longer

compared to the angles of 60° and 90°. So the various flows from the sides of the furnace can be fully

developed, and the sound atomization performance of the various nozzles is fully realized. When the

angle of the nozzle inlet on the side of the furnace is 60° or 90°, since the time before the collision of

the nozzle jet flow from the side of the furnace and the main nozzle jet flow from the top of the

furnace is prolonged, the latter is reaching its decay phase, thus the collision will occur with a

relatively lower speed and the weaker kinetic energy. In this case, the turbulent mixing degree is not

very good when colliding; besides, the increase of the angle of the nozzle inlet on the side of the

furnace, the time between the entering of the jet flow from the various nozzles on the side of the

furnace and the collision will be less, which will result in the underdevelopment of the jet flow from

the nozzles on the side of the furnace when the collision happens and the sound atomization

performance of the nozzles on the side of the furnace will not be easy to be realized. At the same

time you can see that there is still scour on the inner wall of the furnace existing when the angle is

60° or 90°, which may cause severe scour and corrosion for the internal wall of the gasifier, and even

worse for the service life of the firebrick. Moreover, when the angle is 90°, the downward impact

IWEMSE 2018 - International Workshop on Environmental Management, Science and Engineering

354

flow caused by the mutual offset of the nozzles on both sides of the furnace will rush directly at the

bottom outlet of the gasifier, which greatly increases the possibility of "short circuit" phenomenon.

Comparing the various graphics,as you can see that the probability of the "short circuit" phenomenon

from big to small is happening in the following sequence: 90°> 30° > 60° > 45°. Based on all the

above analysis, the collision of the jet flow from the various nozzles on the side of the furnace is

having the best timing when the angle of the nozzle inlet is 45°, and the possibility of "short circuit"

phenomenon is comparatively smaller. So, from the result of the numerical simulation calculation,

the most ideal angle of the nozzle inlet is 45° under the various conditions.

Diagrams of (a), (b), (c), and (d) in figure 8 and figure 9 represent the turbulent intensity and

turbulent kinetic energy distribution of the gasifier with the angles of the nozzle inlet being 30°, 45°,

60°, and 90°. Seeing from the turbulent intensity distribution in figure 8, the nozzle jet flow on the

side of the furnace and the main nozzle jet flow from the top of the furnace will form a local

stagnation zone in the edge of the collision area no matter under what working condition. In the

stagnation zone, the turbulent mixing is in the least level, which is most evident when the angle of the

nozzle inlet on the side of the furnace is 30°; because when the angle is 30°, both the jet flow from

the top and the side of the furnace do not reach the state for fusion, thus the nozzle jet flow on the

side of the furnace will bent to the inner wall of the gasifier after its collision with the jet flow from

the nozzle on the top of the furnace, without reaching the internal of the main jet flow from the

nozzle on the top of the furnace. That’s why the mixing effect will be surely very poor. Hover when

the angle of the nozzle inlet on the side of the furnace is 90°, the collision mixing zone of the jet flow

from the nozzle on the top of the furnace and on the side of the furnace is not evident, and a turbulent

flow with a downward high turbulent strength is formed after the collision of the jet flow from the

nozzles on the side of the furnace, which will rush directly at the bottom outlet of the gasifier. In this

case, the possibility of "short circuit" phenomenon will surely increase. The turbulent intensity

distribution is comparatively much better when the angles are 45° and 60°, compared with angles of

30° and 90°, with a more intensified turbulent strength in the collision zone. When the angle is 45°,

the turbulent mixing degree in the flow field from the nozzle on the top of the furnace and in the

surrounding backflow zone is higher, and there isn’t any downward impinging stream with high

turbulent strength at the bottom of the flow field from the nozzles on the side of the furnace. Seeing

from the turbulent kinetic energy distribution in figure 9, when the angle is 45°, all the kinetic

energy of the nozzle jet flow from the side of the furnace is consumed on the collision with main jet

flow from the nozzles on the top of the furnace, in which case the impact and interception effect of

the nozzle jet flow on the side of the furnace is fully realized and the turbulence mixing effect of the

nozzle jet flow on the top of the furnace increases maximally. When the angle is 30°, the nozzle jet

flow on the top of the furnace cannot collide with the nozzle jet flow on the side of the furnace in a

sound way, thus a strong turbulent mixing effect does not come into being. Most of the kinetic

energy of the nozzle jet flow from the top of the furnace is consumed on pushing the jet flow of itself,

thus the main jet flow from the nozzles on the top of the furnace directly rush at the bottom outlet of

the furnace. Similar to this, when the angle is 90°, even the jet flow from the nozzles on the top of the

furnace is ll intercepted into the upper- and middle-part within the furnace, part of the collision flow

with larger kinetic energy rushes into the bottom of the furnace after the collision. The formation of

the downward impact flow can be clearly seen from the distribution of turbulent kinetic energy in the

furnace. The turbulent kinetic energy distribution in the furnace is much better when the angle is 60°

compared to the situation when the angles are 30° and 90°, but kind of worse when compared to the

situation when the angle is 45°. So, from the perspective of the effects of turbulent kinetic energy and

turbulence intensity distribution, it’s most ideal when the angle is 45°, in which point the distribution

of flow field in the gasifier is the best, and this is consistent to the result have got earlier.

Cold State Numerical Simulation of New Type Coal-water-slurry Gasifier

355

4. Conclusions

In this thesis, numerical simulation calculation research is carried out for

the cold aerodynamical field, turbulence intensity and turbulent kinetic energy distribution in the

new-type coal-water-slurry gasifier under conditions of different positions and angles of the nozzle

inlet on the side of the furnace, from which the optimum position of the nozzle inlet on the side of the

furnace and the optimum angle of the nozzle inlet on the side of the furnace are reached under the

simulated working condition. The result can provide empirical data and theoretical reference for the

model selection and the confirmation of the specific parameters. After the simulation, the author

carries out verification for the result of the numerical simulation calculation with experiments (the

details will not be discussed here because of the limited length of the paper), from which the

experiment data and the numerical simulation calculation results coincide ll. This shows that this

numerical simulation calculation research is feasible. The major conclusions are:

1) Establish the physical and mathematical model of the cold-state numerical simulation for the

flow field distribution in the gasifier, and after verification, it shows that these models are

right and feasible.

2) Numerical simulation calculation is carried out for the flow field distribution, turbulence

intensity and turbulent kinetic energy distribution in the new-type coal-water-slurry gasifier

under conditions of different positions of the nozzle inlet on the side of the furnace, and

according to the result of the simulation, it shows that the flow field distribution, turbulence

intensity and turbulent kinetic energy distribution within the gasifier is most reasonable when

the distance of the nozzle inlet on the side of the furnace to the top of the gasifier is 0.9m,

with the particle concentration distribution being the evenest and the time of the mean

detention time of the particles in the gasifier being the longest. So the position of the nozzle

inlet on the side of the furnace is the most ideal with the distance of 0.9m from the nozzle to

the top of the gasifier.

3) Numerical simulation calculation is carried out for the flow field distribution, turbulence

intensity and turbulent kinetic energy distribution under conditions of different angles of the

nozzle inlet on the side of the furnace, and according to the result of the simulation, it shows

that the flow field distribution, turbulence intensity and turbulent kinetic energy distribution

within the gasifier is most reasonable when the angle of the nozzle inlet on the side of the

furnace is 45°.

Acknowledgment

This work was supported by Henan Province natural science foundation project (Grant No.

182300410133)

References

[1] Fei X L 1995 Advanced hydromechanics Xi an: Xi an Jiaotong University publishing company

530-540

[2] Choudhury D 1993 Introduction to the Renormalization Group Method and Turbulence

Modeling Fluent Inc. Technical Memorandum TM-107

[3] Morsi S A and Alexander A J 1972 An Investigation of Particle Trajectories in Two-Phase

Flow Systems J. Fluid Mech. 55(2):193-208

[4] Haider A and Levenspiel O 1989 Drag Coefficient and Terminal Velocity of Spherical and

Nonspherical Particles. Powder Technology, ,(58):63-70

[5] Ounis H, Ahmadi G and McLaughlin J B 1991 Brownian Diffusion of Submicrometer Particles in

the Viscous Sublayer Journal of Colloid and Interface Science 143(1):266-277

[6] Yu H L, Zhao X, Zhou Z J and et al 2004 Numerical Simulation Analysis on The Effects of

O/C Ratio and Coal Concentration in Coal Water Slurry on Gasification Process Journal of

IWEMSE 2018 - International Workshop on Environmental Management, Science and Engineering

356

Fuel Chemistry and Technology 32(4):370-374

[7] Yu H L, Zhao X, Zhou Z J and et al 2004 Numerical Simulation of Effect of Oxygen Coal

Mole Ratio on Coal Water Slurry Gasification Process Journal of China Coal Society

29(5):606-610

[8] Yu H L, Liu J Z, Fan X and et al 2005 Experimental Study of Atomizing performance of a

New Type Nozzle for Coal Water Slurry Journal of Shanghai Institute of Electric Por.

25(22): 99-103

[9] Yu H L, Liu J Z, Fan X and et al Experimental Study of Atomizing performance of a New

Type Nozzle for Coal Water Slurry-Ⅱ Journal of Shanghai Institute of Electric

Po.r(already be employed)

[10] Yu H L, Zhao X, Zhou Z J and et al 2005 Numerical Simulation of coal-water-slurry

Concentration Effect on coal-water-slurry gasification Process Chinese Journal of Por

Engineering 25(2):217-220,238

Cold State Numerical Simulation of New Type Coal-water-slurry Gasifier

357