Magnéli-phase Ti

4

O

7

Conductive Membrane for Effective

Electrochemical Degradation of 4-chlorophenol in the

Presence of Sulfate

Y Tan and S J You

*

State Key Laboratory of Urban Water Resource and Environment, Harbin Institute of

Technology, Harbin 150090, P. R. China

Corresponding author and e-mail: S J You, sjyou@hit.edu.cn

Abstract. Electrochemical advanced oxidation has been receiving a growing attention in

wastewater treatment because of its advantages of environmental friendliness, less secondary

pollution and ease-to-handle operation. Magnéli-phase titanium oxides (Ti

n

O

2n-1

, n=4~10)

represent the most promising electrode materials, due to its high conductivity, strong

corrosion resistance and high oxygen evolution potential. In this study, we fabricated a

Magnéli-phase Ti

4

O

7

conductive membrane for electrochemical oxidation of 4-chlorophenol

pollutant. The results demonstrated that the Ti

4

O

7

electrode has lower charge transfer

resistance and solution diffusion resistance compared with carbon cloth. Based on the

optimization of key operating parameters, the optimum electrolyte concentration, current

density and membrane flux conditions are determined to be 0.03 mol/L, 5 mA/cm

2

and 0.023

m

3

/(m

2

·s), respectively. The overall removal of 4-chlorophenol could reach the level higher

than 95% under these conditions.

1. Introduction

Recently, the electrochemical advanced oxidation process (EAOP) has attracted growing attention for

treating a variety of refractory wastewater by its virtue of environmental friendliness, less secondary

pollution, high efficiency and ease-tohandle operation [1]. At present, the feasibility of EAOP has

been verified by a large number of studies that report the treatment of wastewater containing various

pollutants such as refractory carboxylic acids [2, 3], and perfluorocarboxylic acids [4]. However,

there remain several aspects of EAOP that need further efforts if the engineered applications are to be

better implemented and developed. The most important factor that affects the performance of EAOP

is the choice of electrode materials on the basis of the electrical conductivity, electrochemical activity,

chemical stability, economic reliability and environmental friendliness. For example, the SnO

2

-doped

electrode is a high-performance electrode, but its engineered application may be limited by its

instability [5]. Likewise, the PbO

2

-doped electrode has also been used with very limited success due

to the potential of leaching of toxic lead ions into solution at anodic polarization condition [6, 7].

Although boron-doping diamond (BDD) may be expected to address these problems, its extremely

high cost and complicated fabrication are also concern in practical applications for wastewater

treatment [8, 9].

Tan, Y. and You, S.

Magnéli-phase Ti4O7 Conductive Membrane for Effective Electrochemical Degradation of 4-chlorophenol in the Presence of Sulfate.

In Proceedings of the International Workshop on Environmental Management, Science and Engineering (IWEMSE 2018), pages 437-443

ISBN: 978-989-758-344-5

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

437

Recently, it has been found that TiO

2

after establishing oxygen deficiencies within the crystalline

lattice can produce a kind of unique structure leading to a combination of excellent electrical

conductivity approaching to that of metals and great corrosion resistance close to that of ceramic

materials [10]. This material has been called Magnéli-phase titanium oxides with a generic formula

of Ti

n

O

2n-1

(n=4~10). Ti

4

O

7

offers higher oxygen evolution potential (+2.6 V vs standard hydrogen

electrode) than BDD [11]. Additionally, the Magnéli-phase titanium oxides are also cost effective

because it is made of TiO

2

, one of the most available metal oxides on the earth. These outstanding

properties make the Magnéli-phase titanium oxides particularly suitable serving as anode material for

EAOP [12].

Since the electrochemical reaction occurs on the surface of electrode, the convection of electrolyte

and diffusion of reactants cause the flow of reaction region and the uneven distribution of

concentration [13]. Based on the consideration of combining electrochemical oxidation and

membrane filtration, the electrolyte can be forced to flow inside the porous structure of conductive

membrane electrode. It will be highly desirable to increase the contact probability between

electrochemical active sites and organic pollutants, such that the mass transfer can be enhanced for

electrochemical reactions [14-17].

Herein, we have fabricated Magnéli-phase Ti

4

O

7

conductive membrane as anode for

electrochemical oxidation of 4-chlorophenol, a kind of recalcitrant contaminant that often occurs in

many industries. Following the characterization of morphology, crystal, and surface area, the

electrochemical properties of Ti

4

O

7

electrode were investigated. Thereafter, the electrochemical

oxidation performances of Magnéli-phase Ti

4

O

7

conductive membrane was examined and assessed

for removing 4-chlorophenol in synthetic wastewater. Last, the operating conditions were also

optimized and discussed.

2. Materials and methods

2.1. Characterization of the Magnéli-phase Ti

4

O

7

conductive membrane

The surface structures of the Magnéli-phase Ti

4

O

7

electrode was observed by using field-emission

scanning electron microscopy (SEM, Helios Nano-lab600i, FEI, U.S.). The powder X-ray diffraction

(XRD) analysis was conducted on an X-ray diffractometer (Bruke D8 Adv., Germany). The electrode

surface area was calculated based on the adsorption and desorption branches measured by BET

surface area measurement (3H-2000BET-A, China).

The electrochemistry impedance spectroscopy (EIS) analysis of the magnéli-phase Ti

4

O

7

electrode were tested by making a comparison with carbon cloth upon PARSTAT electrochemical

workstation (CHI 750D, Chenhua Co. Ltd., China). The EIS data obtained from the test were fitted

by using Zsimpwin software to determine the ohmic resistance, charge transfer resistance and

diffusion resistance of the tested electrode materials.

2.2. Experimental setups

The EAOP containing Magnéli-phase Ti

4

O

7

conductive membrane anode is schematically illustrated

in Figure 1. Unless stated otherwise, the experiments were conducted with 4-chlorophenol and

Na

2

SO

4

electrolyte solution. The initial concentration of 4-chlorophenol was 20 mg/L and the volume

was 580 mL. The effects of Na

2

SO

4

concentration, current density, and membrane flux on the

degradation of 4-chlorophenol were studied and optimized at the reaction time of 2 h.

2.3. Analyses methods

The samples were taken of 1.00 mL at regular time intervals. The 4-chlorophenol was determined by

using High Performance Liquid Chromatography (HPLC, Waters 2695, U.S.A) with a C18 column

(250×4.6, 5 μm) and a photodiode array detector (wavelength=254 nm). The flow phase was V

IWEMSE 2018 - International Workshop on Environmental Management, Science and Engineering

438

(methanol): V (hyperpure water) = 80:20, and the flow rate was 1.0 mL·Min

-1

. The sampling amount

was 20 μL and the column temperature was 25 °C .

Figure 1. The scheme of lab-scale EAOP reactor containing Magnéli-phase Ti

4

O

7

conductive

membrane for electrochemical oxidation of 4-chlorophenol.

3. Results and discussion

3.1. Electrode characterization

The XRD profiles (Figure 2A) were indexed to the characteristic peaks of Ti

4

O

7

according to

reference spectrum (JCPDS No. 18-1402) and prior literatures [18]. At the same time, a small amount

of diffraction peaks of Ti

5

O

9

was also shown in the profiles, which indicated that it is difficult to

generate a single Ti

4

O

7

phase during the preparation of the titanium oxide material. Figure 2B

provided the surface morphology structures of the magnéli-phase Ti

4

O

7

electrode, and results

indicated surficial pores on the order of 1-2 μm. The phenomenon of sintering and melting caused

particles to adhere to each other, thus forming a rich porous structure, which expected beneficial for

facilitating interfacial mass transfer during electrochemical reaction with the electrode BET surface

area of 0.1884 m

2

·g

-1

.

3.2. Electrochemical properties

The ohmic resistance of monolithic Ti

4

O

7

electrode was measured to be 58.07 Ω, which was an

indication of high conductivity similarly like the carbon cloth (Figure 2C). However, further analysis

of the EIS data revealed that the charge transfer internal resistance and diffusion internal resistance of

the two electrodes are quite different. The charge transfer internal resistances of the Ti

4

O

7

electrode

and the carbon cloth anode were 10 Ω and 588.3 Ω respectively, the former was far lower than the

latter. The diffusion internal resistance of the Ti

4

O

7

electrode was 11.89 Ω, while that of the carbon

cloth was 3411 Ω, which was two orders of magnitude higher than that of the Ti

4

O

7

electrode. It

means that under the same reaction conditions, the Ti

4

O

7

electrode is more conducive to the diffusion

and reaction of the solute in the solution during the reaction process, which provides a good

condition for the electrochemical reaction to take place quickly and efficiently.

Magnéli-phase Ti4O7 Conductive Membrane for Effective Electrochemical Degradation of 4-chlorophenol in the Presence of Sulfate

439

Figure 2. (A) XRD profiles,

(B) SEM observation of Magnéli-phase

Ti

4

O

7

conductive membrane

(C) Nyquist plot obtained from EIS

measurements.

3.3. Electrochemical oxidation of 4-chlorophenol

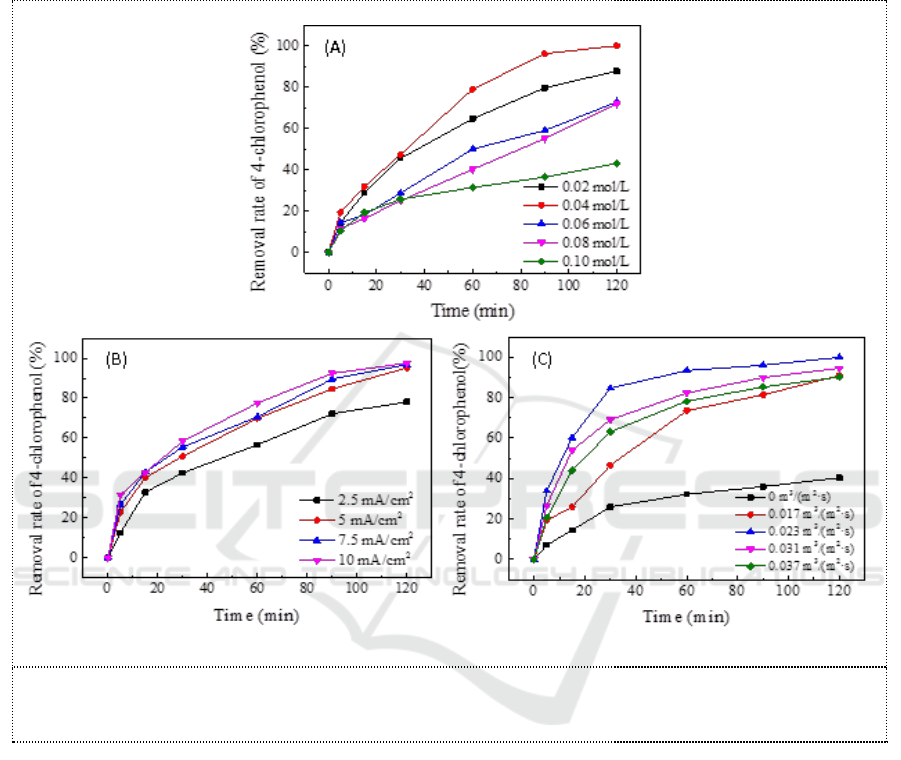

3.3.1. Effect of Na

2

SO

4

concentration on removal of 4-chlorophenol. At a current density of 5

mA/cm

2

, the synthetic 4-chlorophenol wastewater was electrolyzed with the Na

2

SO

4

concentration in

the electrolyte solution increased from 0.02 mol/L to 0.10 mol/L, the removal rate is shown in Figure

3A. It can be seen that the removal rate of 4-chlorophenol increases from 87.78% to 100% as the

concentration of electrolyte increases from 0.02 mol/L to 0.04 mol/L. When the electrolyte

concentration was continued to increase further, the removal rate of 4-chlorophenol started to reduce,

and at a electrolyte concentration of 0.10 mol/L, the 4-chlorophenol removal rate dropped to 43.21%.

Considering multiple factors comprehensively, 0.03 mol/L was used as the optimal sodium

electrolyte concentration condition in this paper.

3.3.2. Effect of current density on the removal of 4-chlorophenol. At a concentration of sodium

sulfate in the electrolyte solution of 0.03 mol/L, the synthetic 4-chlorophenol wastewater was

electrolyzed with the current density increased from 2.5 mA/cm

2

to 10 mA/cm

2

, the removal rate is

shown in Figure 3B. Within the experiment time range of 120 min, the removal rates of 4-

chlorophenol were 78.14%, 95.17%, 96.78% and 97.54%, respectively. From the data, it can be seen

that the removal rate of 4-chlorophenol increases with the current density, but the increasing rate

gradually decreases. When the current density increases from 2.5 mA/cm

2

to 10 mA/cm

2

in turn, the

removal rate increased by 21.79%, 1.69%, 0.79%. It means the percentage increase of 4-

chlorophenol removal rate is far less than that of current density and electrolysis under large current

IWEMSE 2018 - International Workshop on Environmental Management, Science and Engineering

440

density obviously causes great waste of electric energy. Therefore, in the electrolysis reaction, the

current density should be appropriately increased within a certain range, which cannot be too large to

cause the waste of energy. This study selected 5 mA/cm

2

as the optimal current density of the

experiment.

Figure 3. Effects of (A) Na

2

SO

4

electrolyte concentration, current density (B) and membrane

flux (C) on removal of 4-chlorophenol.

3.3.3. Effect of membrane flux on the removal of 4-chlorophenol. When the concentration of the

electrolyte solution was 0.03 mol/L and the current density was 5 mA/cm

2

, the membrane flux was

adjusted by changing the rotation speed of the peristaltic pump. 0, 0.017 m

3

/(m

2

·s), 0.023 m

3

/(m

2

·s),

0.031 m

3

/(m

2

·s), 0.037 m

3

/(m

2

·s) were selected as flux gradients to apply to the Magnéli-phase Ti

4

O

7

electrochemical membrane, the removal rate is shown in Figure 3C. At 0 m

3

/(m

2

·s), there was no

suction of the peristaltic pump and only the Magnéli-phase Ti

4

O

7

electrode played the role of

electrolysis. After 60 min, the removal rate of 4-chlorophenol reached 32.32%, and then the removal

process was almost performed stagnated. Compared with zero flux, i.e. 0 m

3

/(m

2

·s), the removal rate

of 4-chlorophenol increased significantly after increasing the suction of peristaltic pump, and could

reach more than 90% under all membrane fluxes. However, it was worth noting that the removal rate

of 4-chlorophenol did not increase with the increase of membrane flux, but first increased and then

decreased. At the end of the experiment, the removal rate was 90.98%, 100%, 94.59% and 90.21%,

respectively. Taken together, 0.023 m

3

/(m

2

·s) was selected as the optimal membrane flux condition

in this study.

Magnéli-phase Ti4O7 Conductive Membrane for Effective Electrochemical Degradation of 4-chlorophenol in the Presence of Sulfate

441

4. Conclusions

In this study, the Magnéli-phase Ti

4

O

7

conductive membrane was fabricated for electrochemical

oxidation of 4-chlorophenol in the presence of sulfate electrolyte. The Ti

4

O

7

electrode achieved

efficient abatement of recalcitrant organic pollutants without any extra addition of chemicals.

The XRD profiles were indexed to the characteristic peaks of Ti

4

O

7

and a small amount of

diffraction peaks of Ti

5

O

9

for the membrane electrode. The Ti

4

O

7

electrode had surficial pores on the

order of 1-2 μm and BET surface area of 0.1884 m

2

·g

-1

, which would be beneficial for facilitating

interfacial mass transfer.

The Ti

4

O

7

electrode has lower charge transfer resistance and solution diffusion resistance

compared with the carbon cloth, suggesting high activity for oxygen evolution to produce hydroxyl

radicals and organic degradation at anodic polarization conditions.

Based on the optimization of key operating parameters, the optimum Na

2

SO

4

electrolyte

concentration, current density and membrane flux conditions were determined to be 0.03 mol/L, 5

mA/cm

2

and 0.023 m

3

/(m

2

·s), respectively. More than 95% 4-chlorophenol could be removed under

these conditions.

Acknowledgement

This work was supported by the National Natural Science Foundation of China (No. 51678184) and

the State Key Laboratory of Urban Water Resource and Environment (Grant No. 2015TS01).

References

[1] Martínezhuitle C A, Rodrigo M A, Sirés I and Scialdone O 2015 Single and coupled

electrochemical processes and reactors for the abatement of organic water pollutants: a

critical review Chemical Reviews 115(24) pp 13362-13407

[2] Garciasegura S and Brillas E 2011 Mineralization of the recalcitrant oxalic and oxamic acids

by electrochemical advanced oxidation processes using a boron-doped diamond anode

Water Research 45(9) pp 2975-2984

[3] Queiroz J L A D, Silva A R L D, Moura D C D, Silva D R D and Martínez-Huitle C A 2017

Electrochemical study of carboxylic acids with nb-supported boron doped diamond anode.

part 1: potentiodynamic measurements and bulk oxidations Journal of Electroanalytical

Chemistry 794 pp 204-211

[4] Gomez-Ruiz B, Gómez-Lavín S, Diban N, Boiteux V, Colin A, Dauchy X and Urtiaga A 2017

Boron doped diamond electrooxidation of 6:2 fluorotelomers and perfluorocarboxylic acids.

Application to industrial wastewaters treatment Journal of Electroanalytical Chemistry 798

pp 51-57

[5] Liu H, Vajpayee A and Vecitis C D 2013 Bismuth-doped tin oxide-coated carbon nanotube

network: improved anode stability and efficiency for flow-through organic electrooxidation

Acs Applied Materials & Interfaces 5(20) pp 10054-10066

[6] Li X, Pletcher D and F Walsh C 2011 Electrodeposited lead dioxide coatings Chemical Society

Reviews 40(7) p 3879

[7] Vargas R, Borrás C, Méndez D, Mostany J and Scharifker B R 2016 Electrochemical oxygen

transfer reactions: electrode materials, surface processes, kinetic models, linear free energy

correlations, and perspectives Journal of Solid State Electrochemistry 20(4) pp 875-893

[8] Shestakova M and Sillanpää M 2017 Electrode materials used for electrochemical oxidation of

organic compounds in wastewater Reviews in Environmental Science & Bio/technology

16(2) pp 223-238

[9] Yu X, Zhou M, Hu Y, Serrano K G and Yu F 2014 Recent updates on electrochemical

degradation of bio-refractory organic pollutants using BDD anode: a mini review

Environmental Science & Pollution Research 21(14) pp 8417-8431

IWEMSE 2018 - International Workshop on Environmental Management, Science and Engineering

442

[10] Padilha A C M, Osorio-Guillén J M, Rocha A R and Dalpian G M 2014 Ti

n

O

2n-1

, Magnéli

phases studied using density functional theory Phys.rev.b 90(3)

[11] You S, Liu B, Gao Y, Wang Y, Tang C Y, Huang Y and Ren N 2016 Monolithic Porous

Magnéli-phase Ti

4

O

7

, for Electro-oxidation Treatment of Industrial Wastewater

Electrochimica Acta, 214 pp 326-335

[12] Liang S, Lin H, Yan X and Huang Q 2018 Electro-oxidation of tetracycline by a Magnéli

phase Ti

4

O

7

, porous anode: kinetics, products, and toxicity Chemical Engineering Journal

[13] Su J 2011 Characterization of fluid dynamics and mass transfer in an Electrochemical

Oxidation Reactor for organic pollutants (China: Jilin University)

[14] Zaky A M and Chaplin B P 2014 Mechanism of p-Substituted Phenol Oxidation at a Ti

4

O

7

Reactive Electrochemical Membrane Environmental Science & Technology 48(10) pp

5857-5867

[15] Zaky A M and Chaplin B P 2013 Porous Substoichiometric TiO

2

Anodes as Reactive

Electrochemical Membranes for Water Treatment Environmental Science & Technology

47(12) p 6554

[16] Guo L, Jing Y and Chaplin B P 2016 Development and Characterization of Ultrafiltration TiO

2

Magnéli Phase Reactive Electrochemical Membranes Environmental Science & Technology

50(3) pp 1428

[17] Guo L, Ding K, Rockne K, Duran M and Chaplin B P 2016 Bacteria inactivation at a sub-

stoichiometric titanium dioxide reactive electrochemical membrane Journal of Hazardous

Materials 319 pp 137-146

[18] Regonini D, Dent A C E, Bowen C R, Pennock S R and Taylor J 2011 Impedance

spectroscopy analysis of Ti

n

O

2n-1

Magnéli phases Materials Letters 65(23) pp 3590-3592

Magnéli-phase Ti4O7 Conductive Membrane for Effective Electrochemical Degradation of 4-chlorophenol in the Presence of Sulfate

443