Friction Performance of SiCp/Cu Hybrid Materials with Compound

Additive

Yunlong Zhang, Wei Zhou

*

, Haifeng Zhang and Qingxiang Yang

Anyang institute of technology, Huang he street, Anyang city, P. R. China

Keywords: Cu matrix hybrid material, Rare earth oxides, Coefficient of friction

Abstract: Copper alloy material had excellent electrical and thermal characteristics, but its poor wear resistance and low

hardness limited its wider application. So it was necessary to improve wear resistance of copper alloy. In this

paper, compound additives La

2

O

3

/Al

2

O

3

/CeO

2

were introduced into SiCp/Cu composites and hot-press

sintering method was executed to synthesize SiCp/Cu composites. The influence of rare earth oxides on the

phase constitution, micro structure and coefficient of friction of SiCp/Cu composites were investigated.

1 INTRODUCTION

Metal composites were developed into prime

candidate as functional materials. Metal-ceramics

composites exhibited superior performance such as

high specific strength, high elastic modulus and wear

resistance. Copper alloy were utilized as functional

materials with high thermal electrical properties

(Wang, 2011). However, the poor wear resistance

limited wider engineering application. Some ceramic

particles were used as reinforcement, such as metal

carbides (WC, SiC, TiC), metal nitrides (TiN, Si

3

N

4

),

metal borides (ZrB

2

, WB, TiB

2

) and metal oxides

(Al

2

O

3

, ZrO

2

). SiC particles were utilized in the Cu

matrix considering the special properties of SiC

p

on

account of high hardness, good wear, low density

(Dhokey, 2008). So SiC

p

/Cu composites were

developed as functional material due to their

excellent electrical and thermal conductivity, good

wear resistance (Zhang, 2008). At present, more

reports on SiC

p

/Cu composites were widespread (Zhu,

2007). Copper-based composites reinforced with

15-35wt.% SiC were fabricated by mechanical

alloying, so an increase in milling time and SiC

content (up to 25 wt.%) lead to a higher hardness of

Cu matrix materials due to homogenization of

microstructure and refinement of reinforcing

particles (Perumal, 2015). The effect of SiC content

and particle size on the density, hardness and

electrical conductivity were investigated (Peng,

2012). The structure and particle size of copper based

composite reinforced with a high content (15-35wt%)

of silicon carbide and prepared by mechanical

alloying in the high energy planetary mill

(Prosviryakov, 2013). However, the reports about

addition of rare earth oxides to SiC/Cu composites

were relatively scarce. In this work,

La

2

O

3

/Al

2

O

3

/CeO

2

were introduced into SiC

p

/Cu

composite. The density, phase constitution, micro

structure and coefficient of friction of SiC

p

/Cu

composites were investigated.

2 EXPERIMENTAL PROCESS

The initial materials were domestic copper powders

(D

50

=38µm), SiC powder (D

50

=38.5µm), Al

2

O

3

powders (D

50

=0.5µm) and La

2

O

3

powders

(D

50

=0.5µm). The initial powders were mixed in

accordance with the composition ratio designed in

Table 1 in which mass ratio of Al

2

O

3

and La

2

O

3

was

1:3. The content of CeO

2

was about 2wt.%. For

comparison specimen S5 without compound

additives was also studied. The initial powders were

mixed by ball-milling machine. The milling was

320rpm for 8h. Before sintering process, the mixture

was cold pressed into a cylindrical compact in a die of

40mm in diameter with pressure of 200MPa. SiC

p

/Cu

composites were sintered in a graphite die at 840℃

for 1h in hot-press sinter furnace with argon gas and

heating rate was about 30℃/min. Density measure

was carried out according to Archimedes principle.

Microstructure of composites was observed by SEM.

Phases constitution were analysized by X-ray(Bruker

Zhang, Y., Zhou, W., Zhang, H. and Yang, Q.

Friction Performance of SiCp/Cu Hybrid Materials with Compound Additive.

DOI: 10.5220/0008186100930096

In The Second International Conference on Materials Chemistry and Environmental Protection (MEEP 2018), pages 93-96

ISBN: 978-989-758-360-5

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reser ved

93

D8, Germany). The coefficient of friction of SiC

p

/Cu

composites were measured by SFT-2M type pin plate

friction and wear tester. The friction pair was GCr15

steel balls with a diameter of 6mm. Test parameters:

linear velocity is 200r/min, rotation radius was 3mm,

the load was 200g and the friction time was 600

seconds. S1, S2, S3, S4 represented SiC

p

/Cu

composites with different compound additive and S5

represented SiC

p

/Cu composites without compound

additive after friction experiment.

Table 1: Designation of SiCp/Cu materials (wt.%)

Designation

Cu

SiC

La

2

O

3

Al

2

O

3

CeO

2

S1

75.2

18.8

3

1

2

S2

73.6

18.4

4.5

1.5

2

S3

72

18

6

2

2

S4

70.4

17.6

7.5

2.5

2

S5

80

20

0

0

0

3 RESULTS AND DISCUSSION

30 40 50 60 70 80 90

×

×

×

La

2

O

3

SiC

Copper

×

S5

S4

S3

S2

S1

Intensity (a.u.)

Diffraction angle (2-theta)

Figure 1: XRD pattern of SiC

p

/Cu composites with

different compound additive.

XRD pattern of SiC

p

/Cu composites with different

compound additive was showed in Figure 1, Cu and

SiC peaks were detected as main phase, and La

2

O

3

was formed as trace phase. Other phase such as Al

2

O

3

and CeO

2

was not found in the SiC

p

/Cu composites.

The intensity of diffraction peaks of SiC and Cu

phase was not obvious even if compound additive

content was different. Copper was main crystal phase

and its diffraction peak corresponds to the standard

card of copper synthesis (JCPDS 04-0836). The

diffraction peak of 6H-SiC standard card (JCPDS

29-1131). The intensity of diffraction peaks of La

2

O

3

phase increased as the content of compound additive

content was higher.

Figure 2 revealed density of SiCp/Cu composites

with different content of compound additive. From

the data of the density, the density varied from

5.73~6.05g/cm

3

. As the total content of the

compound additive was beyond 8%, ( La

2

O

3

> 4.5%),

the density reduced due to more porosity and defects.

The density variation was not distinct. For improving

the density, too high or low additive was unsuitable.

Especially when La

2

O

3

content was about 4.5%, the

density was higher.

2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5 7.0 7.5 8.0

5.5

5.6

5.7

5.8

5.9

6.0

6.1

6.2

6.3

6.4

Density (g/cm

3

)

La

2

O

3

content (%)

Figure 2: Density of SiC

p

/Cu composites with different

content of compound additive.

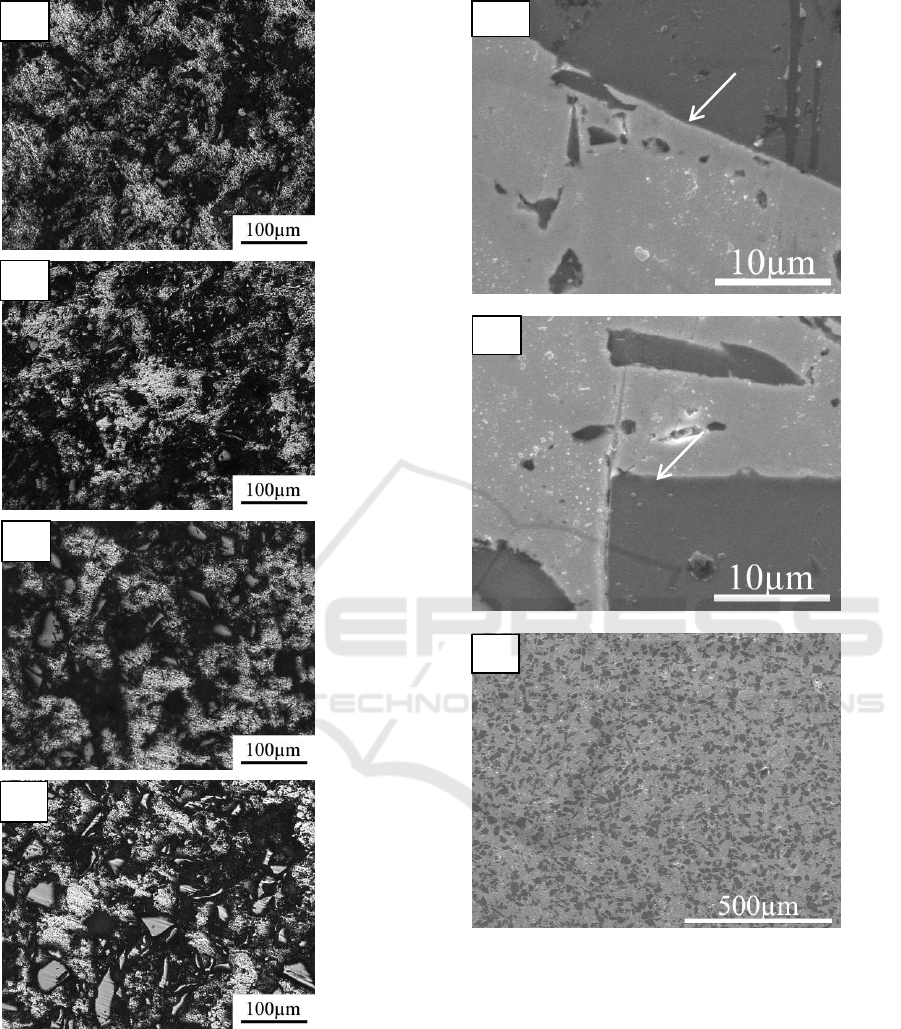

The microstructure of SiC

p

/Cu composites with

different content of compound additive was listed in

Figure 3 a), b), c) and d) represented S1, S2, S3, S4

for SiC

p

/Cu composites with different compound

additive. White particles were SiC

p

and grey part was

Cu matrix. Moreover, Cu matrix was continuous and

no obvious hole appeared. It was difficult to

distinguish distribution variation of SiC

p

in the Cu

matrix, considering that proportion of SiC introduced

in the composition does not change significantly.

Figure 4 showed high magnification SEM photos

of S2 and S5 specimen. As the compound additives

were introduced into the SiC

p

/Cu composites, the

interface was more clear and more tightly integrated

between SiC and Cu matrix (shown in Figure 4a) As a

contrast, more defects and holes were found on the

interface between SiC and copper of SiC

p

/Cu

composites without compound additive. So the

introduction of composite additives with appropriate

content can improve interfacial adhesion between

SiC and copper matrix. The SiC particle were

distributed uniformly in the Cu matrix (shown in

Figure 4c) For all experimental specimens, SiC

particles was distributed uniformly in the Cu matrix.

MEEP 2018 - The Second International Conference on Materials Chemistry and Environmental Protection

94

Figure 3: Microstructure of SiC

p

/Cu composites with

different content of compound additive. a), b), c) and d)

represented S1, S2, S3, S4.

Figure 4: High magnification SEM photos of S2, S5 and S4

specimen. a), b) and c) represented S2,S5 and S4.

Figure 5 showed friction coefficient of SiC/Cu

materials with different content of compound

additive. As a comparison, friction coefficient of S5

was about 0.6~0.7. In comparison, friction coefficient

of SiC/Cu materials decreased significantly when

compound additive was introduced into SiC/Cu

materials. For four different SiC/Cu hybrid materials,

friction coefficient varied between 0.08~0.18.

Especially, when content of additive La

2

O

3

was

4.5%, its friction coefficient was about 0.07~0.09.

a)

d)

c)

b)

b)

interface

interface

c)

a)

Friction Performance of SiCp/Cu Hybrid Materials with Compound Additive

95

The friction coefficient of SiC/Cu composites

without compound additive was high. The addition of

compound additive played an important role, so it

effectively relieved plastic deformation of Cu matrix

during the friction process and improved wear

resistance, thus the abrasion resistance improved.

0 30 60 90 120 150 180 210 240 270 300 330 360

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

S5

S4

S3

S2

S1

Coefficient of friction

Time ( s)

Figure 5: Friction coefficient of SiC/Cu materials with

different content of compound additive.

4 CONCLUSIONS

SiC

p

/Cu composites were fabricated by hot-press

sinter method. The introduction of compound

additive played an important role on the friction

coefficient. Micron SiC

p

were distributed uniformly

in the Cu matrix. Compared with SiC

p

/Cu without

compound additive, friction coefficient of SiC

p

/Cu

materials with compound additive was low, so it

meant that SiC

p

/Cu materials with moderate

compound additive had better wear resistance.

ACKNOWLEDGEMENTS

Authors thank for fund support by science and

technology research projects from Anyang city (

project " thermal conductivity behavior research of

copper matrix hybrid materials with

wear-resisting/low expansion for aviation electric

contact field”),scientific research projects in

education department of Henan province

(No.18A430006), Higher education teaching reform

research and practice project for Henan Province (No.

2017SJGLX117), the scientific research project from

Anyang institute of technology (No. BSJ2017007,

BSJ2018018). Meanwhile, Part of the data in this

paper was provided by Key laboratory of Aerocraft

Simulation Design and Airborne Equipment of

Anyang City.

REFERENCES

Dhokey, N.B., 2008. Study of wear mechanisms in

copper-based SiCp reinforced composite [J].Wear,

(265): 117-133.

Peng, J., 2012. The effect of SiC particle size on the

properties of Cu–SiC composites, Mater. Des. 36:

633–639.

Perumal, A., 2015. SiC content effect on the properties of

Cu–SiC composites produced by mechanical alloying

[J], Journal of Alloys & Compounds. 632 :707-710.

Prosviryakov, A.S., 2013. Mechanical alloying of Cu–SiC

materials prepared with utilisation of copper waste

chips[J], Powder Metall. 54: 382–384.

Wang, C. C., 2011. Thermal Conducting Property of

SiCp-reinforced Cu Matrix Composites by Hot

Pressing [J]. J. Compos. Mater.,45(18):1849–1852

Zhang, L., 2008. Thermo-physical and Mechanical

Properties of High Volume Fraction SiCp/Cu

Composites Prepared by Pressureless Infiltration [J].

Materials Science and Engineering A, 489: 285–293

Zhu, L., 2007. Microstructure and performance of

electroformed Cu/nano-SiC composite [J]. Mater.

Design, (28): 1958-1962.

MEEP 2018 - The Second International Conference on Materials Chemistry and Environmental Protection

96