Effect of Applied Voltage on Properties of Micro-arc Oxidation

Coating on TC4 Alloy

Wei Zhou, Yunlong Zhang

*

, Chaojun Cui, Zhigang Wang, Haifeng Zhang and Qingxiang Yang

Anyang institute of technology, Huang he street, Anyang city, P. R. China

Keywords: Micro-arc oxidation, Yttrium nitrate, Micro-hardness

Abstract: In order to resolve biological toxicity of TC4 titanium alloy, the micro-arc oxidation (MAO) technology was

introduced to fabricate ceramic coating on the surface of TC4 titanium alloy. Yttrium nitrate was introduced

into the silicate electrolyte system as additive. The micro-structure, phase composition, surface morphology

and micro-hardness of MAO coatings were characterized. When applied voltage increased, the content of

rutile-TiO

2

in the coating increased. The maximum value of surface roughness was about 11μm as applied

voltage was 300V. The maximum micro-hardness was about 5210MPa.

1 INTRODUCTION

Ti-based alloys are widely used in aerospace, weapon

and other fields owing to their low density, high

specific strength and excellent corrosion resistance

(Boyer, 1996; Wang, 2015; Wang, 2017). TC4 alloy

has biological toxicity, so it is seriously limited in the

clinical medicine applications. Therefore, various

modifying techniques such as salt cyaniding (Lai and

Wu, 1993), plasma immersion ion implantation

treatment (Yilbas and Shuja, 2000), laser treatment

(Yerokhin, 2000), micro-arc oxidation (Mandl, 2007)

and PVD process, were introduced to

improve performances for practical applications. The

main purpose of surface treatment is to keep

vanadium elements in titanium alloy matrix and

avoid its releasing.

Micro-arc oxidation technology (MAO) has

distinguished advantage to prepare ceramic coating

on the Mg, Ti and Al alloys. The ceramic coating can

improve both wear and corrosion resistance of alloys.

Rare earth materials have important scientific

research value, so they are widely used in the field of

metal matrix modification. In this work, yttrium

nitrate was introduced into the silicate electrolyte

system as additive. The TC4 alloy was oxidized

under different applied voltages by MAO method.

The micro-structure, phase composition, surface

morphology and micro-hardness of MAO coatings

were characterized.

2 EXPERIMENTAL

Before micro-arc oxidation treatment, TC4 alloy

were cut into the size of 20mm×20mm×2mm. The

specimens were polished by SiC sandpapers with grit

sizes of 600#, 1000# and 2000#, respectively. And

they were rinsed by distilled water, acetone several

times and dried. The electrolyte is composed of 30g/L

Na

2

SiO

3

·5H

2

O, 10g/L EDTA-2Na, 2g/L KF and

1.5g/L Y(NO

3

)

3

in aqueous solution. In MAO

process, applied voltage was designed as 240V, 270V,

300V, 330V and 360V, respectively. And the

samples were correspondingly nominated as S1, S2,

S3, S4 and S5. The MAO equipment with power of

100kW was composed of an AC power supply and

ultrasonic systems. The stainless steel container and

TC4 alloy were used as cathode and anode separately.

For comparison, MAO was carried out at 330V

without Y(NO

3

)

3

in the electrolyte, and the sample

was nominated as S6. After MAO treatment, the

samples were rinsed with distilled water and dried.

X-ray diffraction device (Bruker D8 Advance) was

used to analyse the phase structures with a scan rate

of 4°/min. Surface morphology and roughness was

analysed by Olympus self-focusing microscope and

field emission scanning electron microscope. At least

five areas within 480μm×640μm were measured to

calculate surface roughness. The hardness was tested

by digital micro-hardness tester (HVS-1000A,

Huayin L.L.C., China). The average hardness was

surveyed at least five spots. The Olympus

164

Zhou, W., Zhang, Y., Cui, C., Wang, Z., Zhang, H. and Yang, Q.

Effect of Applied Voltage on Properties of Micro-arc Oxidation Coating on TC4 Alloy.

DOI: 10.5220/0008187101640167

In The Second International Conference on Materials Chemistry and Environmental Protection (MEEP 2018), pages 164-167

ISBN: 978-989-758-360-5

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

metallographic microscope was utilized to take

images of indentations.

3 RESULTS AND DISCUSSION

The XRD patterns of MAO coatings on the TC4 alloy

with different applied voltages is illustrated in

Figure 1 The coatings are composed of rutile-TiO

2

and anatase-TiO

2

. As the applied voltage increased,

the intensity of diffraction peaks of rutile-TiO

2

increased gradually, while those from TC4 alloy

became weaker. It was possible that TiO

2

coating

became thicken as applied voltage increased,

therefore the intensity of diffraction peaks from TC4

matrix became weak. Meanwhile, the enhanced

diffraction peaks of rutile-TiO

2

meant the increased

content of rutile-TiO

2

. As applied voltage increased,

the heat released per unit time also increased, which

facilitated the transformation from anatase to rutile.

20 30 40 50 60 70 80 90

S6

S5

S4

S3

S2

S1

×

×

×

×

Ti

Anatase-TiO

2

Rutile-TiO

2

×

Intensity (a.u.)

Diffraction angle (2-theta)

Figure 1: XRD patterns of TiO

2

coating on the TC4 alloy

with different applied voltages.

The surface morphology of TiO

2

coatings was

showed in Figure 2. It was obvious that many micro

pores evenly distributed in the TiO

2

coating. The

similar distribution characteristics appeared in all

samples. For comparison, larger pore structure was

found in S6. The introduction of Y(NO

3

)

3

in the

electrolyte would helpful in reducing the pore size.

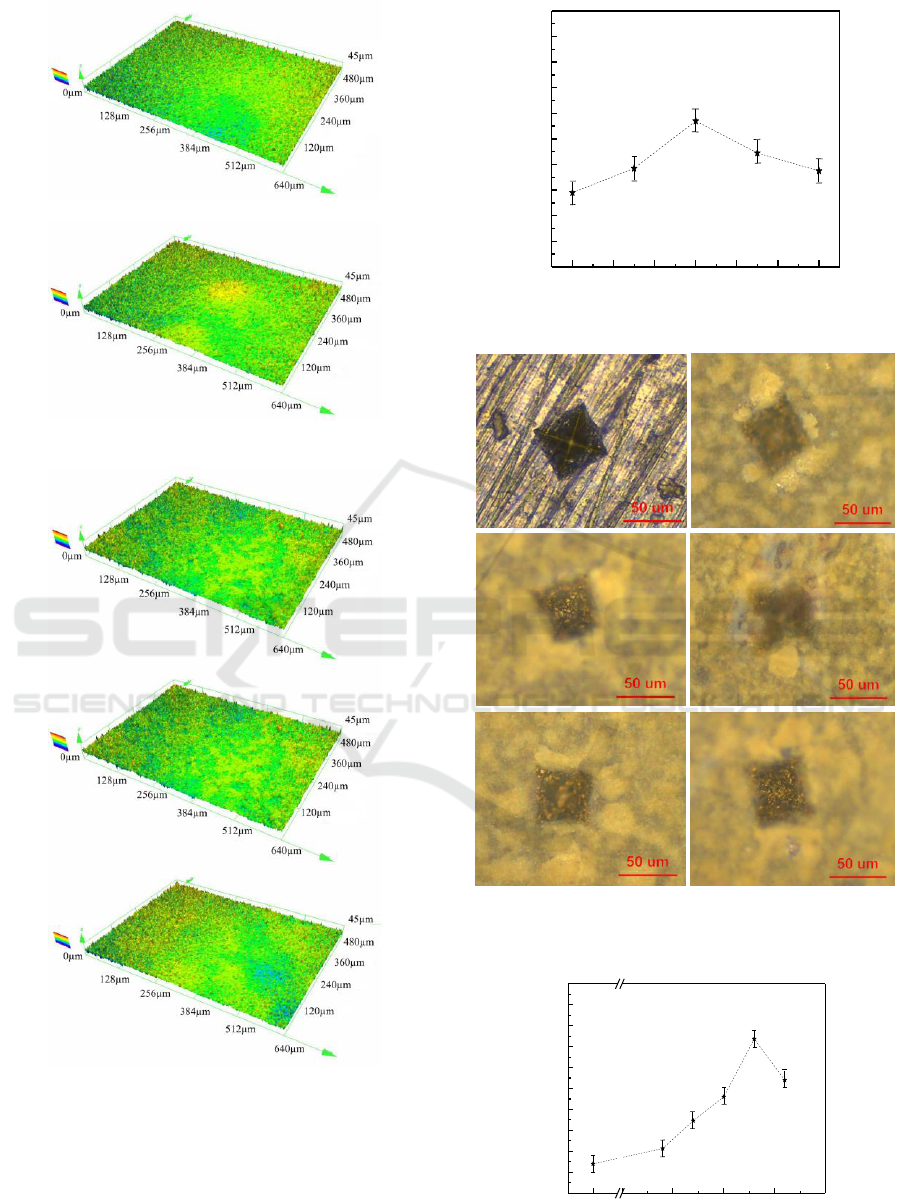

Three dimensional topographic contour map of

TiO

2

coatings were rendered in Figure 3. The

surfaces of the five samples S1-S5 were relatively flat

on macro level.

Figure 4 showed the surface roughness of the

samples. The surface roughness started to increase as

the applied voltage increased, then reduced when the

applied voltage reached 300V. The maximum value

of surface roughness was about 11μm. It was noted

that the additive Y(NO

3

)

3

in the electrolyte would

decrease striking voltage remarkably and make the

coating smooth. The striking voltage averagely

reduced in the range of 15~25V. In addition, cooling

treatment with frozen ice was used to control the

temperature of electrolyte. The above conditions

would be benefit for obtaining smooth and compact

micro-arc oxidation coatings.

Figure 2: Surface morphology of TiO

2

coatings with

different applied voltages, a) S1, b) S2, c) S3, d) S4, e) S5

and f) S6.

Indentation morphologies of the samples were

showed in Figure 5 The original TC4 alloy had much

deeper indentation than others. With the increase of

applied voltage, the depth of indentation decreased.

And the minimum indentation occurred as applied

voltage reached 330V.

The micro-hardness of TiO

2

coatings was

illustrated in Figure 6 The micro-hardness of the

coatings showed a trend of gradual increase as the

applied voltage increased to 330V. And the

maximum value was about 5210MPa. The TiO

2

coating was directly grown on the TC4 matrix, so it

was beneficial for improving the micro-hardness.

b)

a)

E

e)

d)

c)

f)

a)

b)

Effect of Applied Voltage on Properties of Micro-arc Oxidation Coating on TC4 Alloy

165

Figure 3: Three dimensional topographic contour maps of

the samples: a) S1, b) S2, c) S3, d) S4 and e) S5.

240 260 280 300 320 340 360

0

2

4

6

8

10

12

14

16

18

20

Surface roughness (Micron)

Applied voltage (V)

Figure 4: Surface roughness of the samples.

Figure 5: Indentation morphologies of the samples, a)

original TC4 alloy, b) S1, c) S2, d) S3, e) S4 and f) S5.

0 200 250 300 350 400

3000

3300

3600

3900

4200

4500

4800

5100

5400

5700

6000

Microhardness (MPa)

Applied voltage (V)

Figure 6: Micro-hardness of TiO

2

coatings.

a)

c)

e)

d)

b)

a)

b)

c)

d)

e)

f)

MEEP 2018 - The Second International Conference on Materials Chemistry and Environmental Protection

166

4 CONCLUSIONS

Micro-arc oxidation technology was utilized to

grow TiO

2

coating on the TC4 alloy with different

applied voltages in the silicate electrolyte system

containing yttrium nitrate as additive. The

micro-structure and phase composition of the

MAO coatings were characterized. As the applied

voltage increased, the intensity of diffraction peaks

of rutile-TiO

2

increased gradually. The maximum

values of surface roughness and micro-hardness

were about 11μm and 5210MPa.

ACKNOWLEDGEMENTS

The authors were grateful for fund support by the

science and technology research projects from

Anyang city (project “thermal conductivity

behaviour research of copper matrix hybrid materials

with wear-resisting/low expansion for aviation

electric contact field”), the scientific research

projects in education department of Henan province

(No.18A430006), the higher education teaching

reform research and practice project of Henan

Province (No. 2017SJGLX117), the scientific

research project from Anyang Institute of

Technology (No. BSJ2017007, No. BSJ2018018, No.

BSJ2017004). Meanwhile, part of the data in this

paper was provided by Key Laboratory of Aerocraft

Simulation Design and Airborne Equipment of

Anyang City.

REFERENCES

Boyer, R., 1996. An overview on the use of titanium in the

aerospace industry [J]. Mater. Sci.Eng. A., 213:

103-114.

Lai, F. D., Wu, T. I., 1993. Surface modification of

Ti-6Al-4V alloy by salt cyaniding and nitriding [J].

Surface and Coating Technology, 58: 79-81.

Mandl, S., 2007. PIII treatment of Ti alloys and NiTi for

medical applications [J]. Surface and Coating

Technology, 201: 6833-6838.

Wang, L. Q., 2017, Microstructure evolution and

superelastic behavior in Ti-35Nb-2Ta-3Zr alloy

processed by friction stir processing [J]. Acta

Materialia, 131: 499-510.

Wang, L. Q., 2015. Investigation of deformation

mechanisms in-type Ti-35Nb-2Ta-3Zr Alloy via FSP

leading to surface strengthening [J]. Metallurgical and

Materials Transactions A., 46: 4813-4818.

Yerokhin, A. L., 2000. Characterisation of oxide films

produced by plasma electrolytic oxidation of a

Ti-6Al-4V alloy [J]. Surface and Coating Technology,

130: 195-206.

Yilbas, B. S, Shuja, S. Z., 2000. Laser treatment and PVD

TiN coating of Ti-6Al-4V alloy [J]. Surface and

Coating Technology, 130: 152-157.

Effect of Applied Voltage on Properties of Micro-arc Oxidation Coating on TC4 Alloy

167