A Metamaterial Absorber for Microwave De-icing of Wind Turbine

Blades and Its Electromagnetic and Thermal Properties

Zehai Zhang

1*

, Jing Wang

2

, Junpu Ling

1

and Yuzhang Yuan

1

1

College of Advanced Interdisciplinary Studies, National University of Defense Technology(NUDT) ,Changsha, China

2

College of Liberal arts and Sciences, National University of Defense Technology(NUDT) ,Changsha, China

Keywords: Metamaterial Absorber; De-icing; Wind turbine blade; Microwave heating; Multi-physical simulation

Abstract: The icing of wind turbine blades in cold climates may reduce the power generation efficiency, shorten the

life of the blades and even bring safety hazard. De-icing of wind turbine blades is very necessary. The

current technical means such as heating resistance, warm air, and other means of de-icing have various

limitations, and no mass produced commercial wind turbine blade de-icing system are available currently.

Microwave heating has the characteristics of selectivity, non-contact and rapid heating, and is a potential

and flexible de-icing way of wind turbine blades. In this paper, a kind of metamaterial absorber (MA) which

can strongly absorb 2.45GHz microwave is designed. It can absorb the incident microwave and then convert

the microwave energy into heat. Multi-physical simulation is carried out to analyse the heat generation,

thermal distribution and temperature rise of the MA under microwave radiating. This preliminary simulation

results show that MA is possible to be used in microwave de-icing of wind turbine blades.

1 INTRODUCTION

Wind power as a green energy is clean and

renewable. According to the report of Technical

Research Centre of Finland (VTT, 2013), wind

power capacity is growing rapidly in the cold

climates of the world, and between 45 and 50

gigawatts of wind power would be built in cold

climates by 2017 for higher winds and proper

density of cold air. However, turbine blades are

highly susceptible to icing in these areas. Icing may

significantly reduce the aerodynamic properties of

blades and lead to mechanical failures, safety hazard

(Seifert et al., 2003), and possible stoppage of

operation (Hochart et al., 2010). Lots of wind

turbines with no de-icing equipment will only stop

to wait for ice to melt naturally. De-icing of wind

turbine blades is very necessary.

Parent and Ilinca

(Parent and Ilinca, 2011)

provided a critical review of de-icing techniques for

wind turbines include passive and active systems.

Heating resistance and warm air are most used

active techniques in de-icing. Due to direct heating,

the heating resistance systems have high efficiency

(up to 100%) (Battistil et al., 2005) and are mainly

used in current. The heating materials such as carbon

fiber sheet (Xu et al., 2018), polymer electric heating

film (Shu et al., 2017, Mu et al., 2014) are studied

intensively. However, icing of run back water at the

edges of the heating elements may occur often in the

heating resistance system, and there is no flexible

once the heating elements were buried well. Warm

air system had also been applied in wind turbines de-

icing (Zhao et al., 2016). However, the warm air

needs to heat the whole shell of the wind turbine

blade from the inner surface of the shell. As the shell

structures have small coefficient of thermal

conductivity and becoming larger and thicker, the

efficiency becomes very low. New de-icing

techniques are called for.

Microwave heating is one of the active de-icing

methods, and has the characteristic of selective,

volumetric and rapid. Microwave heating is

expected to realize wireless, scanning and rapid de-

icing, and is expected more flexible than the heating

resistance de-icing. One of the key of microwave

heating is to find materials absorbing microwave

strongly and with thin thickness as much as possible.

L. Feher et al (Feher et al., 2009) studied microwave

de-icing with carbon fiber reinforced plastic (CFRP)

aimed to be applied on aircraft, and demonstrated

selective, non-contacted and volumetric heating of

microwave experimentally. Johansson et al

(Johansson et al., 2015) demonstrate microwave

Zhang, Z., Wang, J., Ling, J. and Yuan, Y.

A Metamaterial Absorber for Microwave De-icing of Wind Turbine blades and its Electromagnetic and Thermal properties.

DOI: 10.5220/0008187802170221

In The Second International Conference on Materials Chemistry and Environmental Protection (MEEP 2018), pages 217-221

ISBN: 978-989-758-360-5

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

217

heatable CNT coatings for wind turbine blade de-

icing. The carbon fiber or CNT coatings absorb

microwave but not totally, thus reflection and

transmission of microwave power may cause

microwave leakage or reduce power efficiency.

This paper presents a metamaterial absorber

( MA ) different from carbon fiber and CNT

coating for wind turbine blades de-icing under

microwave radiating. The heating source may be

industrial magnetron or solid state microwave

amplifier. The reflection of -26.0dB at 2.45GHz is

reached with MA thickness of 2mm. An intuitive

impression of electromagnet-thermal conversion of

MA under microwave radiating is also presented.

This paper is organized as follows: The first part

is introduction. The second part presents the design

of electromagnetic absorbing property. The third

part studies the electromagnet-thermal conversion

under microwave radiating with multi-physical

simulation software. Temperature distribution is also

given. The forth part concludes the paper. These

efforts have laid a solid foundation for further study

of the MA.

2 ELECTROMAGNETIC DESIGN

2.1 MA for De-icing of Wind Turbine

Blades under Microwave Radiating

The original form of MA is Landy’s Perfect

Metamaterial Absorber, which is consisting of two

distinct metallic elements and a dielectric layer

between them (Landy et al., 2008). Through fine

adjusting of the metallic elements, the MA can

absorb the incident microwave at a single frequency

point almost totally. Gradually, whole back metallic

layer replaces the split cut wires and various front

metallic patterns emerge. The simple form made the

design of perfect absorption easily achieved. In this

situation, the double-facet Copper Clad Laminate

(CCL) was usually used to fabricate MA.

The MA absorbs the incident microwave within

a small thickness which usually less than one tenth

of the operating wavelength. The small thickness

and thereby a small volume made MA little self-

heated energy consumed when used for microwave

heating. Thus the MA is suitable for microwave de-

icing.

From a concept view, the microwave source can

be arranged inside the blade and fixed on the web.

The microwave radiated from source by antenna and

penetrates the balsa wood (heat insulator and

transparent to microwave) or other supporting

materials and reached onto the MA, as schematically

shown in Figure 1. Due to the MA has entire back

metal film and covers the entire outer surface of the

blade, no microwave can leak outside and thus the

microwave seldom has impacts on environment

around the turbine.

Figure 1: Schematic diagram of part of wind turbine blade

under microwave heating.

2.2 The Electromagnetic Property

Design of the MA

As higher energy conversion efficiency is expected,

the absorption rate of microwave is expected as high

as possible. The design of the MA is aimed to absorb

the incident microwave totally at given frequency

2.45GHz. HFSS (Ansoft Inc, 2009)

simulation study

is carried out to achieve the goal. Hollow square ring

is adopted as the front metallic pattern of the MA

due to its simple and central symmetric property. A

single unit of the periodic model is built. The model

and the above air box in HFSS are shown in Figure 2.

Top layer (yellow): hollow square copper film ring;

Middle dielectric layer (green): FR-4, 2mm;

Back film (unseen): copper film

Figure 2: Model of the hollow square MA unit built within

HFSS.

MEEP 2018 - The Second International Conference on Materials Chemistry and Environmental Protection

218

Master-slave boundaries are imposed on each

pair of the opposite side faces of the domain to

match the periodical model. Floquet port is imposed

on top face of the computational domain. The

material of the metallic ring and the back film are

both 18μm copper films with conductivity of

5.998e7 S/m. The middle dielectric layer is FR-4

with 2mm thickness. The relative permittivity ε

r

and

permeability μ

r

are 4.3 and 1.0, respectively. The

dielectric loss factor of FR-4 is 0.02.

Table 1:Components parameters of the optimized MA.

Components

layers

Parameters(mm)

material

Thickness

L_Outer

L_Inner

Hollow square

ring

copper

0.018

25.2

10.0

Mid-dielectric

FR-4

2.0

50.0

-

Back film

copper

0.018

50.0

-

Figure 3: Parameter swept S11 curves of the MA.

Geometric parameters of the MA affect the

absorb frequency point and absorbing intensity. The

resonant frequency was mainly governed by the

length of central line of the metallic ring, while the

absorbing intensity is mainly affected by the

thickness and the dielectric loss of the dielectric

layer (Pang, 2013). The following optimization

keeps in line with these principles.

In order to obtain a MA as thin as possible, the

thickness of the MA is expected no greater than

2mm. Besides, the period of the unit is expected to

be kept integer for convenience. The aim of

optimization is to obtain a higher absorption rate

while thickness and period of the MA kept fixed.

The outer and inner side lengths of the hollow ring

are selected as variables for optimization. The

genetic algorithm built-in HFSS about the outer and

inner side lengths with their physical limits range for

better absorption at 2.45GHz are carried out, while

other parameters are kept unchanged. The optimized

L_outer and L_inner and other parameters are shown

in Table 1.

Under the optimized parameters, the S

11

reaches

-26.0dB at 2.45GHz when L_outer=25.2mm, while

the best absorb point is located at 2.4487GHz and

the S

11

reaches -27.3dB, the curves of S

11

with swept

L_outer as shown in Figure 3.

3 MULTI-PHYSICAL

SIMULATION

The MA absorbs and converts microwave energy

into heat. With the optimized parameters of the MA

obtained above, we investigate the electromagnet-

thermal conversion and energy efficiency with

COMSOL (COMSOL Inc, 2012), a commercial

simulation software suitable for multi-physical

problems.

3.1 The Simulation Model of MA in

COMSOL

A single unit model of MA similar to that in HFSS is

built with COMSOL. The back of the model was set

as an ideal conductor boundary rather than copper

film while other components kept unchanged. As the

thickness of the hollow copper ring is too small to

resolute, a transition boundary is adopted to replace

for. No meshes are built within the transition

boundary, but physical properties including

conductivity, thickness, etc are kept.

Periodic boundaries were assigned onto the side

face pairs and periodical port was assigned onto the

top face with TEM mode. The boundaries, port and

incident mode made this unit model equivalent to an

infinite plane MA radiated by plane microwave.

Balsa wood or other supporting materials are not

considered currently.

3.2 Electromagnet-thermal Conversion

The heat generated within the MA mainly come

from microwave dielectric loss in FR-4 and ohmic

loss in copper, and the loss occurs when

electromagnetic field established within the MA.

The temperature distribution of the MA will be

governed by thermal conduction and convection and

the conduction plays a major role.

To describe the time variant temperature

T(x,y,z,t) distribution of the MA unit heated by

microwave, one can accordingly solve the heat

equation for temperature T given by ( Pitchai, 2011a)

A Metamaterial Absorber for Microwave De-icing of Wind Turbine blades and its Electromagnetic and Thermal properties

219

2 2 2

2 2 2

()

T

c k T P

t x y z

(1)

Where P is the heat power density which came

from the dielectric loss and ohmic loss of the

incident microwave,

is the density of the

corresponding material, c is the specific heat

capacity and k is the thermal conductivity. The heat

power density can be expressed as a function of the

electric field component in a non-magnetic loss

medium by (Pitchai, 2011b)

'' 2

0

PE

(2)

Here E is the electric component of the

electromagnetic field built within the MA,

''

is the

imaginary part of the dielectric FR-4,

is the

angular frequency of the incident microwave and

0

is the permittivity of free space.

Equations (1) and (2) describe that temperature

distribution within the MA are governed by the

electric field strength and the distribution of the

electromagnetic field. The electric component

strength is proportional to the microwave absorption

rate of the MA, thus the energy conversion

efficiency between the microwave and heat is

strongly related to the absorption rate and the

dielectric imaginary part of the FR-4.

As the microwave is radiated by antenna and

transmitted through free space, and no extra wires

and other accessories are needed, the microwave

heating will be more flexible than electric heating.

Besides, as equation (2) implies, the heat generated

once the microwave field built up in MA, thus

microwave heating is rapid.

3.3 Multi-physical Simulation Results

The frequency of the input microwave is 2.45GHz.

In COMSOL, the default input power into the

periodical port is 1W, and the power density is

calculated of 400W/m

2

according to the cross

section area of 50mm×50mm. The tangential loss

angle of FR-4 is 0.02, while the magnetic one is 0.

The simulation duration is set as 300s and total input

energy calculated 300J. The ambient temperature

surround the model is set as 20℃.

In COMSOL, the S

11

drops to -3.25dB while the

S

11

is -26dB in HFSS, the parameters of the model

are the same. This dramatic drop results in increase

of reflection and decrease of absorbing which is

effective in heating. Furthermore, simulations show

that the relative permittivity ε

r

of FR-4 has strong

influence on microwave absorbing. Simulations are

carried out on the variation of ε

r

and the

corresponding S

11

are shown in Table 2. The power

absorbed can be calculated from S

11

, and then the

temperature rise due to the absorbed power △T

ab

can

be calculated from the following equation

0

()Q c V T T

(3)

Where Q is heat energy, V is volume. Take FR-4

into account, c=1369J/kg·K,

=1900kg/m

3

,

V=0.05×0.05×0.002m

3

and T-T

0

=△T

ab

.

The weighted mean temperature △T

ave

represents

a supposed spatial uniform temperature rise within

FR-4. It can be read directly from COMSOL, and

the power conversion efficiency

/

ave ab

TT

from microwave to heat can be calculated out. The

corresponding calculation results are summarized

and shown in Table 2. The efficiency is about 82%

when ε

r

changes. If the reflection is taken into

account, the overall efficiency η

a

drops to 21.2% to

58.1%.

Table 2: The EM-thermal conversion efficiency v.s. ε

r.

ε

r

4.1

4.2

4.3

4.4

S

11

/dB

-2.28

-5.27

-3.25

-1.30

P

ab

/W

0.41

0.70

0.52

0.26

△T

ab

/℃

9.5

16.1

12.0

6.0

△T

ave

/℃

7.8

13.4

10.0

4.9

η/%

82.1

83.0

83.3

81.6

η

a

/%

33.7

58.1

43.3

21.2

Figure 4 gives the electric field strength

distribution from a bottom view at the end of the

simulation when ε

r

=4.2. One can find that the

electric component mainly concentrates below the

copper ring, and the field distribution splits into two

parts obviously. Animation of the field versus time

reveals that the electromagnetic field acts like

standing wave, which implies the incident

microwave resonate within the MA. During this

progress, the dielectric loss and ohmic loss occurred

and the electromagnetic energy converted into heat.

Figure 4: Electric field strength(V/m) distribution.

MEEP 2018 - The Second International Conference on Materials Chemistry and Environmental Protection

220

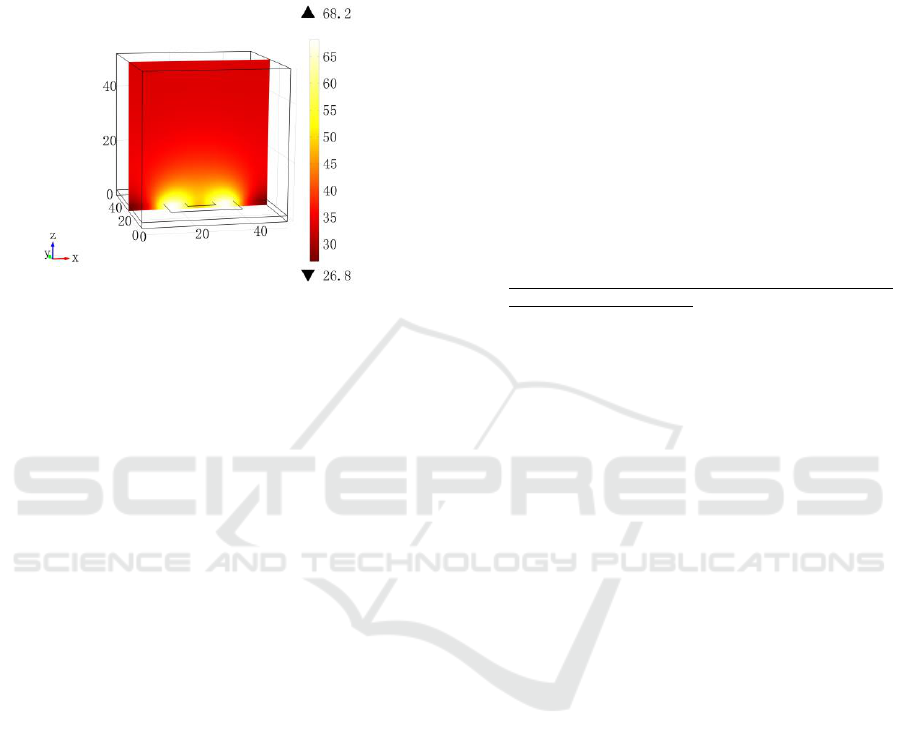

The temperature distribution on the middle cut

plane of the simulation when ε

r

=4.2 is shown in

Figure 5. The maximum temperature is 68.2℃,

48.2℃ higher than the ambient temperature due to a

microwave power density of 400W/m

2

and heating

duration of 300s.

Figure 5: Temperature(deg) distribution on x-z cutting

section of the MA unit model (simulation duration: 300s).

This simulation is preliminary for only FR-4 is

taken into consideration in the calculation. But the

power conversion and heating figure are presented.

The overall efficiency is low in current simulation

and further investigation on improving absorbing

rate will be carried out to improve the overall EM-

thermal conversion efficiency.

4 CONCLUSIONS

In this paper, we present the idea of the wind turbine

blades de-icing with MA under microwave heating.

The design of electromagnetic absorbing property of

MA is presented. Multi-physical simulation is

carried out to analyse the heat generation, thermal

distribution and temperature rise of the MA under

microwave heating. The energy conversion

efficiency is given based on the multi physical

simulation. This preliminary simulation show that

MA is possible to be used in microwave de-icing of

wind turbine blades as a wire-less, rapid and flexible

means.

ACKNOWLEDGEMENTS

The author wants to express his gratitude to Dr. Prof.

Jelonnek for his valuable suggestions.

This work is supported partially by the National

Natural Science Foundation of China [Grant number

51706242]; and partially by Natural Science

Foundation of National University of Defense

Technology [Grant number ZK16-03-05].

REFERENCES

Ansoft Inc, 2009. HFSS online Help,Version 12.

Battistil, BrighentiA., DalSavio, S. DellAnna. 2005. Evaluation of

anti-icing energy and power require- ment for wind turbine

rotors in cold climates. BOREAS, VII, FMI, Saariselka,

Findland, p13.

Comsol Multiphysics uers’s guide. 2012. Version.4.3.

Feher, L., Seitz, T. and Nuss, V., 2009. Microwave De-/Anti-

Icing Using the Midas-Technology. Journal of Microwave

Power & Electromagnetic Energy ONLINE. Vol. 43, No. 1.

Hochart, C., Fortin, G., Perron, J. et al., 2010. Wind turbine

performance under icing conditions[J]. Wind Energy,

11(4):319-333.

http://windren.se/WW2015/WW2015_12_311_Karthauser_

ReTurn._Deicing_Micro.pdf

Johansson, K. et al., 2015. Deicing of Wind Turbines using

Microwave Technology.

Landy, N. I., Sajuyigbe, S., Mock, J. J., Smith, D. R. and Padilla,

W. J., 2008. Perfect Metamaterial Absorber. Physics

Review Letter, 100(207402).

Mu, S., Wu, R., Chen, C., Yan, S. Y., 2014. RESEARCH ON

THE THERMAL HEATING DE-ICING PROPERTIES OF

WIND TURBINE BLADE COMPOSITE PLATES BASED

ON POLYMER ELECTRIC HEATING FILM. Fiber

Reinforced Plastics/Composites (FRP/CM).(in Chinese)

Pang, Y., 2013. The Theory and Design of Metamaterial

Absorbers. Changsha: National University of Defense

Technology.

Parent, O., Ilinca, A., 2011. Anti-icing and de-icing techniques for

wind turbines: Critical review. Cold Regions Science and

Technology 65 88–96.

Pitchai, K., 2011a. Electromagnetic and Heat Transfer Modeling

of Microwave Heating in Domestic Ovens. University of

Nebraska at Lincoln. P30.

Pitchai, K., 2011b. Electromagnetic and Heat Transfer Modeling

of Microwave Heating in Domestic Ovens. University of

Nebraska at Lincoln. P13.

Seifert, H., Westerhellweg, A., Kröning, J., 2003. Risk Analysis

of Ice Throw from Wind Turbines[J]. Boreas.

Shu, L., Qi, J., Hu, Q. et al., 2017. Anti-icing Model and

Sectionalized Anti-icing Method by Electrical Heating for

Wind Turbine Blades[J]. Proceedings of the Csee,

37(5):1448-1454.( in Chinese)

Technical Research Centre of Finland (VTT), 2013. Cold climate

wind energy showing huge potential. ScienceDaily.

ScienceDaily.

Xu, B., Lu F., Song, G., 2018. Experimental Study on Anti-Icing

and Deicing for Model Wind Turbine Blades with

Continuous Carbon Fiber Sheets[J]. Journal of Cold

Regions Engineering, 32(1).

Zhao, J., Yang, W., Peng, C. et al., 2016. ANTI-ICING AND

DEICING METHOD AND DEVICE FOR HIGH-POWER

WIND TURBINE BLADES, WO/2016/037476[P].

A Metamaterial Absorber for Microwave De-icing of Wind Turbine blades and its Electromagnetic and Thermal properties

221