Study of Shear and Pressure Flow on the Variation of Ship Hull

Shapes as One of the Biofouling Growth Factors

Muhammad Auliya Alamsyah

1

, Muhammad Luqman Hakim

1

and I Ketut Aria Pria Utama

1

1

Department of Naval Architecture, Faculty of Marine Technology, Institut Teknologi Sepuluh Nopember (ITS), Jl. Arief

Rahman Hakim, Surabaya, Indonesia

Keywords: Ship Hydrodynamics, Biofouling, Marine Growth, Pressure and Shear Force Distribution.

Abstract: In this paper, the pattern of shear force distribution and pressure on two hull models are explained using the

Computational Fluid Dynamics (CFD) numerical method. The two hull models are general cargo and barge

hulls, where they are chosen because they have a significant hull shape difference, therefore the pattern of

shear distribution and pressure force can be different. The difference in shear distribution and pressure force

is one of the growth factors of biofouling, where biofouling is a problem on ships. Biofouling causes the hull

of the ship to become rough and increase the resistance of the ship, resulting in a waste of energy and increase

the number of emissions. From the results of this study it was found that the distribution of both is almost the

same, namely the area that has the potential to be easily grown with biofouling (minimal shear force and

maximum pressure), i.e. at the end of the bow and stern end, with only slight differences in pattern and.

1 INTRODUCTION

Biofouling is the accumulation of aquatic organisms

such as microorganisms, plants, and animals that

attached to surfaces and structures that wetted into the

sea like ship hull and cause various problems (IMO,

2011). Problems arising from biofouling include:

first, ecosystem damage through the spread of

invasive species which then results in a decrease in

fishery products and the emergence of a new

epidemic of a disease; second, increasing ship

resistance which lead to increased emissions which

then have an impact on climate change and global

warming as well as economic value that is lost in

energy dissipation (Schultz, 2007; Turan, et al., 2016;

Monty, et al., 2016; Utama, et al., 2017; Hakim, et al.,

2017; Nugroho, et al., 2017; Hakim, et al., 2018).

Biofouling that attaches and grows at the hull of

the ship causes the surface of the hull to become

rough and consequently, it can increase the friction

resistance (Schultz, et al., 2011). When there is an

increase in resistance, the power requirements will

increase, from this it can be said that energy

dissipation occurs and leads to more emissions. IMO

notes that emissions generated by ships around the

world are 2.2% of total man-made emissions

worldwide in 2012 (IMO, 2015), and are predicted to

increase by 50-250 percent by 2050 (IMO, 2009).

Keeping the ship's hull clean from biofouling can

reduce emissions by up to 10% (ICCT, 2013;

Molland, et al., 2014) where this is suggested by IMO

through the Energy Efficiency Design Index (EEDI)

(IMO, 2012). For this reason, it is necessary to use an

anti-fouling system, such as the one that already

exists, with anti-fouling coating and routine cleaning

when dry docking. Unfortunately, the mechanisms of

the anti-fouling coating are to release biocide

compounds into the water, which according to

Rompay (2012), it will eventually become a new

problem for the marine environment in the future.

According to the results of an investigation and

test from Hunsucker (2014) that the growth of

biofouling on each part of the hull is not the same.

Hunsucker (2016) also conducted an experiment to

determine the effect of the hydrodynamic effect of

shear stress on biofouling growth. The effects of static

and dynamic conditions have also been observed on

water conditions (Zargiel & Swain, 2014). The effect

of ship speed on biofouling growth has also been

observed by Coutts (2010). From their explanation

that the hydrodynamic effect such as speed, shear

stress, and pressure can affect the growth of

biofouling in the hull of the ship.

Alamsyah, M., Hakim, M. and Utama, I.

Study of Shear and Pressure Flow on the Variation of Ship Hull Shapes as One of the Biofouling Growth Factors.

DOI: 10.5220/0008542900970105

In Proceedings of the 3rd International Conference on Marine Technology (SENTA 2018), pages 97-105

ISBN: 978-989-758-436-7

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reser ved

97

Based on the results of the Hunsucker (2014) and

Hunsucker (2016) research, this paper will discuss the

pattern of shear stress and pressure distribution on the

hull using numerical CFD method. As hull models,

two different types of hulls are used, namely general

cargo hull and barge hull. Both models were chosen

because they have a significantly different of hull

shape where the cargo hull has a more streamlined

form than the barge.

2 PHYSICAL COMPONENTS OF

MAIN HULL RESISTANCE

When the ship sails, it will get a drag from the fluid.

The drag component can be divided into friction

resistance, pressure resistance and residual resistance

(wave). Friction resistance is strongly influenced by

the hull roughness of the ship. While the pressure

resistance and wave resistance are influenced by the

shape of the hull of the ship. In general, the equation

is written as follows:

WVPFT

R+R+R=R

(1)

WVT

R+R=R

(2)

where R

T

, R

F

, R

VP

, R

W

, and R

V

are total resistance,

frictional resistance, viscous pressure resistance,

wave resistance, and viscous resistance, respectively,

(Molland, et al., 2011).

The difference for shear force and pressure can be

seen in Figure 1, where the shear force (τ) is a force

that is parallel to the wall or surface of the hull which

is affected by fluid viscosity. meanwhile the pressure

(P) is a force perpendicular to the surface of the shape

from a ship hull.

Figure 1: Frictional and pressure forces [22].

2.1 Shear Force

Friction drag is a part of the shear stress on the object

wall and above that is affected in the area of the inner

boundary layer. If the shape of the object is

dominated by line form that is parallel to the upstream

velocity, then the component of the shear force is

dominant than the force of pressure. If the direction

of the resultant of the shear force arises in the opposite

direction of the upstream velocity axis, then it

contributes to the drag force, but if it is perpendicular

then it contributes to the lift force.

Shear stress is obtained from the boundary layer

velocity profile whether it is laminar or turbulent or

transition as shown in Figure 2. From the graph of the

velocity profile, the surface shear stress can be known

by the following formula:

μ

∂u

∂

y

(3)

where μ is the fluid dynamic viscosity and

is the

velocity gradient at the surface.

Figure 2: Boundary layer velocity profiles.

2.2 Pressure Force

Pressure force is the force generated due to the

presence of fluid which is blocked by the wall of the

object in the normal direction of the area (Molland, et

al., 2011), as shown in Figure 1. While the pressure

distribution on the vessel as shown in Figure 3.

Figure 3: Pressure variations around a body of ship

(Molland, et al., 2011).

SENTA 2018 - The 3rd International Conference on Marine Technology

98

3 THE PROCESS OF ATTACHING

BIOFOULING

Biofouling is the accumulation of aquatic organisms

such as microorganisms, plants, and animals on

immersed surfaces and structures, including

microfouling and macrofouling. Microfouling is the

bacteria and diatoms and slimy substances produced,

usually referred to as slime layers. Macrofouling is a

large multicellular organism that can be seen by the

human eye such as barnacles, tapeworms, or algae

leaves (IMO, 2011). More than 4000 species of

animals and plants are recorded as biofouling

worldwide (Nair, 2013).

The process of attaching biofouling to the

substrate immersed in the aquatic environment is

explained by Nair (2013). After the structure is

immersed, a first layer is formed consisting of

bacteria, diatoms, algal spores, and detritus. The first

layer is important because it affects macrofouling

thereafter, as shown in Figure 4 (Nybakken, 1982).

Then, the bacteria develop very quickly and form an

important constituent in the first layer. The bacteria

become firmly attached, and in just one hour the cells

grow an average of 1-2 microns and continue to

divide. This causes the population to increase twice

every four hours. The bacterial colonies secrete

polysaccharides, which make the surface of the film

slimy and sticky and afterward make the algae stick.

They also ensnare larvae, change the color of the

surface, so as a place for food for macrofouling that

comes afterward.

Figure 4: The process of attaching biofouling on metals.

In the process of attaching biofouling to a surface

is influenced by many factors, so it is very difficult to

determine the exact rules that can be used to

determine where it will stick. Based on this

uncertainty, the scientists tried to use the theory of

opportunities for the biofouling attachment phase on

the surface by considering the values of pressure,

shear, and turbulence (Mullineaux & Garland, 1993).

In the attachment phase, there are two main

requirements that must be fulfilled so that the

biofouling attachment instincts can function properly.

First, environmental disturbances (shear stress and

turbulence) are low. Second, biofouling organisms

must have good mobility. The first requirement will

guide biofouling organism's instincts to select

attachment areas with minimum disturbances, and the

second requirement serves to serve the instincts to

move attached (Mullineaux & Garland, 1993).

Based on information obtained by biofouling

organism instincts, the priority will be placed on the

relatively quiet attachment area. From the explanation

above, it can be predicted that the intensity of

attachment in areas that have low hydrodynamic

intensity will have a greater chance of attachment

compared to areas that have high hydrodynamic

intensity.

In the biofouling growth phase, there are three

main factors that influence the growth process. The

three processes include the supply of food

ingredients, food filtration mechanisms and food

digestion. If the hydrodynamic conditions support the

above three processes, then the growth will take place

optimally. Distribution of food ingredients along with

other living substances will be difficult to take place

due to turbulent flow. The next factor that affects the

growth process is filtering food ingredients. If the

screening process takes place effectively, more food

will be obtained. Most biofouling organisms that live

(statically) use a filtering method to get their food.

This filter is in the form of antennas which are

equipped with fine hairs to filter the food ingredients

dissolved in the water and enter into the mouth

(Pascual, 1992).

The explanation above explains that the

hydrodynamic characteristics affect the biofouling

growth process. The hydrodynamic factors include:

patterns of the tendency to speed, pressure and

surface shear stress and turbulence.

4 MODELS

The hull models of the cargo ship and barge used for

this study were made to have the same size as

described in Table 1. From the table, it can be seen

that the value of WL Length, Breadth (B) and

Draught (T) have the same value, whereas the

different are Displacement, WSA, and Cb, where the

barge has a higher value.

Study of Shear and Pressure Flow on the Variation of Ship Hull Shapes as One of the Biofouling Growth Factors

99

Table 1: This caption has one line so it is centered.

Item Barge Cargo Units

Displacement 2569 2364 ton

WL Length 60 60 m

B 15 15 m

T 3.2 3.2 m

WSA 1187 1092 m

2

Cb 0.87 0.8 -

LCB % 48.97 51.05 %

Figure 7: Body plan of General Cargo.

Figure 8: Body plan of General Cargo.

To find out how different the hull shape of the

general cargo and barge model used in this study can

be seen in Figure 7 for the general cargo body plan

and in Figure 8 for the barge. Then the shape of the

sheer plan and half breadth plan can be seen in Figure

5 and Figure 6 respectively.

In this analysis, the roughness model of biofouling

is not carried out. The surface of the two models is

made smooth. Because the purpose of this analysis is

to compare the effects of different hull forms on shear

stress distribution and pressure force as one of the

biofouling growth factors on a ship.

5 NUMERICAL METHODS

In this analysis, the results needed are only viscous

and pressure value, so the domain and boundary

condition set applied are one fluid computation, or

without taking into account the effects of wave

resistance.

The size of the domain and boundary condition in

the numerical model of this study can be seen in

Figure 9. In the Figure 9, it can also be seen the

quality of the mesh generation used. the number of

elements in this calculation is around 6 million

elements and has met the convergence criteria. Then

the turbulence model used is k-ω-SST, with the

second order computation method and residual

targets up to 10-4.

Figure 5: Sheer plan of (A) General Cargo and (B) Barge.

Figure 6: Half breadth plan (A) General Cargo and (B) Barge.

SENTA 2018 - The 3rd International Conference on Marine Technology

100

In this numerical modeling, velocity variations

have been carried out just for 5 knots and 10 knots.

Because the author believes that the pattern of shear

stress distribution and surface pressure due to

differences in speed does not change, but what

changes is only the value. Therefore, in this

simulation, the velocity of 5 knots and 10 knots are

chosen.

6 RESULT AND DISCUSSION

6.1 Grid Sensitivity Test

To get the optimal mesh size so that the calculation

results from the model are close to the true value and

are still within computer capabilities, a grid

sensitivity test is performed. The result of the test can

be seen in Figure 10, where from the result the

number of elements that can be used in computing is

around 6 million elements because the calculation

results for the number of elements 6 million and 13

million only have a difference under 2%.

Figure 10: Result of grid sensitivity test.

6.2 Validation Study

Validation of this analysis is comparing the result

from numerical method with empirical method. The

CFD results of the two models is compared with

Holtrop [27] as empirical calculation method. Based

on the calculation of the resistance in formula 1 and

formula 2, if it is changed in the form of a coefficient

it will become:

WVT

C+C=C

(4)

Where C

T

, C

V

, and C

W

are total drag coefficients,

viscous resistance coefficients, and wave resistance

coefficients, respectively.

Table 2: Comparison of computed RV values between

numeric and empiric.

Speed 5 knots

ΔR

V

(%)

Metho

d

CFD Holtrop

R

V

R

T

C

V

C

W

R

V

Barge

13,46

6

16,65

7

3,20

0

0,51

3

14,35

6

-6%

Cargo

10,10

9

13,00

5

2,86

3

0,10

8

12,53

2

-

19%

Speed 10 knots

ΔR

V

(%)

Metho

d

CFD Holtrop

R

V

R

T

C

V

C

W

R

V

Barge

50,05

1

68,10

0

2,93

7

0,73

8

54,42

4

-8%

Cargo

37,21

6

54,47

4

2,60

1

0,54

0

45,10

9

-

17%

Figure 9: Domain computation and mesh generation.

Study of Shear and Pressure Flow on the Variation of Ship Hull Shapes as One of the Biofouling Growth Factors

101

By using numerical CFD modeling with the

method in this case, the viscous resistance (R

V

) values

for each model will be obtained for speeds of 5 knots

and 10 knots. Then the value is compared with the

results of the Holtrop empirical calculation for both

models and at the same speed. The results of the

comparison can be seen in Table 2, where the results

can be said to be quite valid.

6.3 Shear Stress Distribution

In all the results plots illustrated in this paper are the

simulation results with a speed of 5 knots. The speed

of 10 knots is not displayed because the result of the

distribution pattern is the same as the result of the

speed of 5 knots, which is different only the value.

The results of the shear force distribution pattern

are shown in Figure 11 and Figure 12. The results

show that the distribution pattern on the two hull

models is different.

For the results of the general cargo, hull model

plotted on the rear and front view in Figure 11A and

B (body plan), the smallest shear force is at the front

and rear with a value of less than 2 Pa. For the front

(see Figure 11 B) it is around the bulbous bow area

slightly up with a small area. While on the afterward

(see Figure 11 A), it occurs in the stern bow area

upwards with extended area until the end. In this area,

it can be said that disruption due to shear force to

biofouling growth is minimal.

Still, with the general cargo model, the highest

shear force value occurs in the hull curve which will

lead to the propeller area and the curve after the

bulbous bow. In that area, the shear force is 5 times

higher, 10 Pa. Therefore, in this area biofouling gets

the biggest disturbance from the influence of the

shear force. For more details about the distribution of

the shear force pattern can be seen in Figure 12 A and

B as the appearance of the side and bottom view to

get a longitudinal view.

In Figures 11 C D and 12 C D, they are the shear

force distribution pattern for barge model. The

highest shear force value is at the back, which is the

meeting area between the parallel middle body and

the stern. Then at the front, there is shear force value

that is not as high as general cargo model, only with

a value of around 8 - 9 Pa but with a wider area. In

this area, biofouling growth has a higher disturbance.

Then the lowest shear force value on the barge

occurs at the end of the bow and the stern end is

almost similar to general cargo but with a slightly

wider area. In this area, biofouling receives the least

interference from the shear force effect.

6.4 Pressure Distribution

The computational results for the distribution of

pressure forces on both models can be seen in Figures

13 and 14. From the results of calculations on both

models also obtained a different pressure distribution

pattern. If shear force interferes with the biofouling

growth process, it is different from the pressure force.

The force of pressure can help biofouling stick to the

hull more easily.

The two models have almost the same distribution

pattern, which is at the fore and after ends as

described in Figure 3 above. At general cargo, the

Figure 11: Shear stress distribution: (A) back view of General Cargo, (B) front view of General Cargo, (C) back view

of Barge, and (D) front view of Barge

SENTA 2018 - The 3rd International Conference on Marine Technology

102

highest pressure is at the end of the bulbous bow and

stern after the propeller, while the barge also occurs

at the end of the bow and the stern area. These areas

are areas where the shear force value is weak, so

biofouling can be found more often in this area.

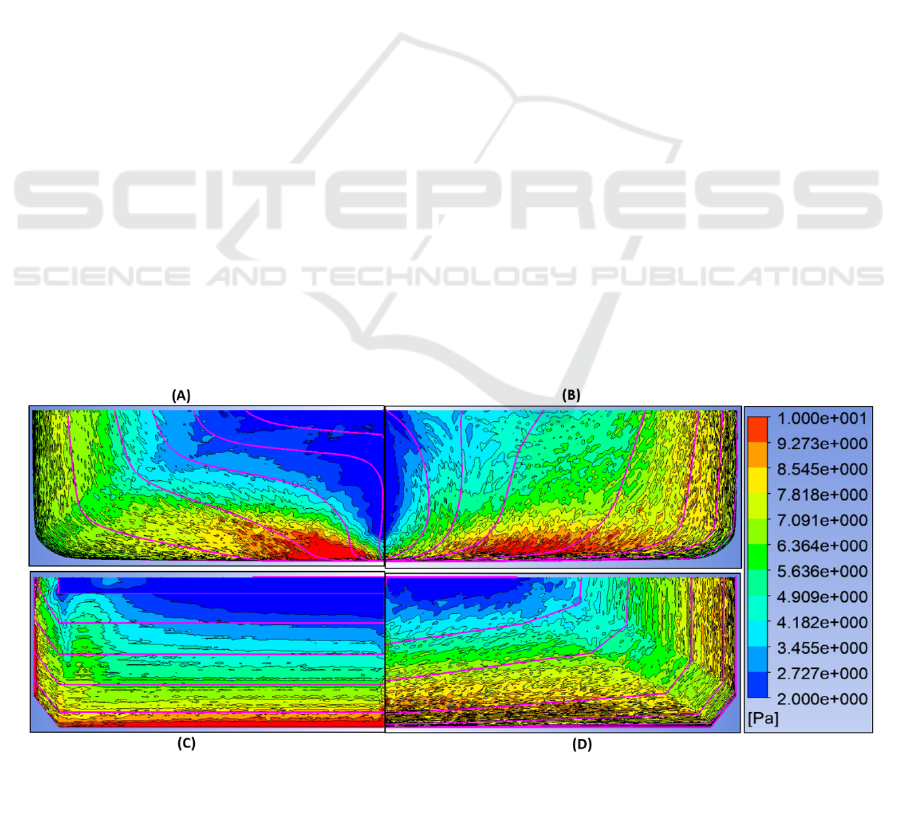

Figure 12: Shear stress distribution: (A) side view of General Cargo, (B) bottom view of General Cargo, (C)

side view of Barge, and (D) bottom view of Barge.

Figure 13: Pressure force distribution: (A) back view of General Cargo, (B) front view of General Cargo, (C) bac

k

view of Barge, and (D) front view of Barge

Figure 14: Pressure force distribution: (A) side view of General Cargo, (B) bottom view of General Cargo, (C)

side view of Barge, and (D) bottom view of Barge.

Study of Shear and Pressure Flow on the Variation of Ship Hull Shapes as One of the Biofouling Growth Factors

103

Then for at the middle hull, both have pressure

with very small to negative values as shown in Figure

14 in color of blue. In this area, biofouling is more

difficult to stick to than the front and rear areas of the

stomach.

7 CONCLUSIONS

One way to reduce emissions on ships is to maintain

the hull clean of biofouling by using an anti-fouling

system or cleaning when docking. Biofouling can

grow in the hull of the ship with various factors, one

of which is the hydrodynamic characteristics of water

flow such as shear and pressure force. On ships, the

distribution of shear and pressure forces are

influenced by the hull shape of the ship itself.

From the results of this study, the distribution of

shear and pressure forces was obtained for general

cargo and barge hulls. The distribution of both is

almost the same, namely an area that has the potential

to be easily grown with biofouling (minimal shear

force and maximum pressure), ie at the end of the arc

and the tip of the stern, with only slight differences in

patterns, values, and extent. Subsequent suggestions

need to be taken into account other influential factors

such as speed, type, and quality of anti-fouling,

operating patterns, and other hull forms.

REFERENCES

Coutts, A. D. et al., 2010. Effect of Vessel Voyage Speed

on Survival of Biofouling Organisms: Implications for

Translocation of Non-indigenous Marine Species.

Biofouling, Volume 26 No. 1, pp. 1-13.

Hakim, M. L. et al., 2018. Assessment of Drag Penalty

Resulting from the Roughness of Freshly Cleaned and

Painted Ship-Hull Using Computational Fluid

Dynamics. 11th International Conference on Marine

Technology (UTM). Kuala Lumpur.

Hakim, M. L. et al., 2018. Investigation of Fuel

Consumption on an Operating Ship Due to Biofouling

Growth and Quality of Anti-Fouling Coating. The First

Maluku International Conference on Marine Science

and Technology (Unpatti). Ambon.

Hakim, M. L. et al., 2017.. Review of Correlation between

Marine Fouling and Fuel Consumption on A Ship.

SENTA: 17th Conference on Marine Technology

(ITS). Surabaya.

Holtrop, J. & Mennen, G., 1978. A Statistical Power

Prediction Method. International Shipbuilding

Progress, Volume 25.

Hunsucker, J. T., Hunsucker, K. Z., Gardner, H. & Swain,

G., 2016. Influence of Hydrodynamic Stress on the

Frictional Drag of Biofouling. Biofouling, Volume 32

No. 10, pp. 1209-1221.

Hunsucker, K. Z., Kokaa, A., Lundb, G. & Swain, G., 2014.

Diatom Community Structure on In-service Sruise Ship

Hulls. Biofouling, Volume 30 No. 9, p. 1133–1140.

ICCT, 2013. Long-Term Potential for Increased Shipping

Efficiency Through the Adoption of Industry-Leading

Practices. International Council on Clean

Transportation. Washington.

IMO, 2009. Second IMO GHG Study 2009. International

Maritime Organization. London.

IMO, 2011. Guidelines for The Control and Management

of Ships Biofouling, Resolution MEPC.207 (62).

s.l.:Marine Environment Protection Committee.

London.

IMO, 2012. Guidelines on Survey and Certification of the

Energy Efficiency Design Index (EEDI) MEPC 214

(63),. s.l.:Marine Environment Protection Committee.

London.

IMO, 2012. Guidelines on the Method of Calculation of the

Attained Energy Efficiency Design Index (EEDI) for

new ships MEPC.212 (63). s.l.:Marine Environment

Protection Committee. London.

IMO, 2015. Third IMO GHG Study 2014. International

Maritime Organization. London.

Molland, A., Turnock, S. & Hudson, D., 2011. Ship

Resistance and Propulsion. Cambridge University

Press. Cambridge.

Molland, A., Turnock, S., Hudson, D. & Utama, I., 2014.

Reducing Ship Emissions: A Review of Potential

Practical Improvements in The Propulsive Efficiency of

Future. International Journal of Maritime Engineering,

Volume 156 A2, pp. 175-188.

Monty, J. P. et al., 2016. An Assessment of the Ship Drag

Penalty Arising from Light Calcareous Tubeworm

Fouling. Biofouling, Volume 32 (4), pp. 451-464.

Mullineaux, S. Y. & Garland, E. D., 1993. Larva

Recruitment in Response to Manipulated Filed Flows.

Marine Biology, Volume 116.

Nair, N. U., 2013. Marine Fouling and Control Measures

Cochin: Former Scientist Emeritus (ICAR). s.l.:Central

Institute of Fisheries Technology. Kochi, India.

Nugroho, B. et al., 2017. In-situ Turbulent Boundary Layer

Measurements over Freshly Cleaned Ship-Hull under

Steady Cruising. International Conference on Ship and

Offshore Technology (RINA). Jakarta.

Nybakken, J., 1982. Biologi Laut : Suatu Pendekatan

Ekologis. Gramedia. Jakarta.

Pascual, C., 1992. Small Scale Turbulance on Zooplankton

Metabolism Affect Torbulence on Heartbeat Rates

Planktonic Crustaccean. Marine Biology, Volume 124.

Rompay, B. V., 2012. Surface Treated Composites White

Book. Tahoka Press. Clearwater, FL.

Schultz, M. P., 2007. Effects of Coating Roughness and

Biofouling on Ship Resistance and Powering.

Biofouling, Volume 23 (5), pp. 331-341.

Schultz, M. P., Bendick, J. A., Holm, E. R. & Hertel, W.

M., 2011. Economic Impact of Biofouling on A Naval

Surface Ship. Biofouling, Volume 27, pp. 87-89.

SENTA 2018 - The 3rd International Conference on Marine Technology

104

Turan, O., Demirel, Y. K., Day, S. & Tezdogan, T., 2016.

Experimental Determination of Added Hydrodynamic

Resistance Caused by Marine Biofouling on Ships.

Transportation Research Procedia, Volume 14, pp.

1649-1658.

Utama, I. K. A. P. et al., 2017. A Study of Skin Friction-

Drag from Realistic Roughness of a Freshly Cleaned

and Painted Ship Hull. International Symposium on

Marine Engineering (ISME). Tokyo.

Zargiel, K. A. & Swain, G. W., 2014. Static vs Dynamic

Settlement and Adhesion of Diatoms to Ship Hull

Coatings. Biofouling, Volume 30 No. 1, pp. 115-129.

Study of Shear and Pressure Flow on the Variation of Ship Hull Shapes as One of the Biofouling Growth Factors

105