Analysis of Supply and Demand of Coal Terminal in Sumatera

Christino Boyke Surya Permana

1

, Hasan Iqbal Nur

1

and Syaugi Alif Fadhila

1

1

Department of Marine Transportation Engineering, Institut Teknologi Sepuluh Nopember, Surabaya, Indonesia

Keywords: Coal, Supply, Demand, Port Facilities, Capacity

Abstract: Indonesia is one of the largest coal producing countries in the world, with total production of 461 million

tons in 2017. Based on Ministry of Energy and Mineral Resources there are three regions in Indonesia that

have the largest coal reserves, namely South Kalimantan, West Kalimantan and South Sumatera. The

Sumatera region holds a national coal reserve of 45%, but only 10% of the total reserves that have been

managed. The demand of coal from Sumatera increased 17.40% in average during the past five years with

the majority of use for power plant and exports. As a result of an increase in coal demand, the flow of

cargoes at each coal terminal in Sumatera increasing, in 2017 total coal terminal troughput in Sumatera

reach 28.75 million tons. This research based on secondary and primary data analysis of 5 biggest coal

terminal in Sumatera, namely Panjang Port (Lampung), Bengkulu Port (Bengkulu), Jambi Port (Jambi),

Teluk Bayur Port (West Sumatera), Kertapati Coal terminal (South Sumatera) and Tarahan Coal terminal

(Lampung). Total coal terminal capacity in Sumatera region is 51,46 million ton / year. Based on the

forecasting of coal demand in 2037 will reach 67.75 million tons, the total capacity of coal terminal in

Sumatera will reach the maximum capacity of 80% in 2025 (41.70 million tons) . Coal terminal operator

need to consider the port development (facilities and cargo handling equipment) to increase port capacity.

1 INTRODUCTION

Indonesia is one of the largest coal producing

countries in the world, with mining points scattered

in various regions and a total production of 461

million tons in 2017. Based on Ministry of Energy

and Mineral Resources data there are three regions

in Indonesia that have the largest coal reserves,

namely South Kalimantan, West Kalimantan and

South Sumatera. The Sumatera region holds a

national coal reserve of 45%, but only 10% of the

total reserves that have been managed (Kementerian

ESDM, 2017). Based on data from the Central

Bureau of Statistics, coal production in 2016

amounted to 27.56 million tons with the majority of

use for power plant and exports (Petromindo, 2016).

The distribution of coal from Sumatera is

generally carried out through public ports and

special ports in this paper reefer as coal terminal,

some of the major public ports that serve coal

loading include Panjang Port in Lampung, Bengkulu

Port in Bengkulu, Jambi Port in Jambi and Telur

Bayur Port in West Sumatra. While the other coal

are loading in special ports managed by coal mining

companies include the Kertapati coal terminal in

South Sumatera and Tarahan coal terminal in

Lampung. The capacity of a port generally depends

on the number of berths available to ship traffic and

cargo handling capacity (Bugaric et.al., 2011).

Coal production and demand will affect the port

sector as a provider of coal handling services.

Development planning should pay attention to the

increasing trend of coal as one of the main

commodities. There are some conditions that will

affect coal production, including coal reserves,

mining business permits and mining technology.

This research aim to analyze the supply and

demand side of coal terminals, the relationship

between production in coal mining in each area of

production mines with port operating capacity based

on historical data and forecasting of future

conditions. This research is expected to provide

recommendations for coal terminals operator to

improve the efficiency of the port by developing

facilities and equipment.

2 LITERATURE REVIEW

Various research related to operations and

determination of the capacity of dry bulk terminals

have been carried out, Work of the ports with its

optimal capacity assumes a prompt accommodation

of vessels with minimal waiting time in the port and

with maximal use of berth facilities. Calculation of

230

Permana, C., Nur, H. and Fadhila, S.

Analysis of Supply and Demand of Coal Terminal in Sumatera.

DOI: 10.5220/0008543002300234

In Proceedings of the 3rd International Conference on Marine Technology (SENTA 2018), pages 230-234

ISBN: 978-989-758-436-7

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

port capacity related to capacity of facilities and

equipments. Bert capacity use the equation below

(Velsink, 2012):

Cb = P x N x n x m (1)

Where :

Cb = Berth Capacity (tons / year)

P = Productivity of loading / unloading tools

(tons / hour)

N = Number of Gang

n = Annual Operating Time (hours)

m = BOR (%)

Equipment capacity shows the total amount of

cargo that can be served by equipment:

KT = n x V x t (2)

Where :

KT = Capacity of equipment (tons / year)

n = Number of Tools (units)

V = Tool Productivity (ton / hour)

t = Annual Operating Time (hours / years)

Stockpile capacity shows the total amount of

cargo that can be stock by the area:

TY = (Vb x 0.745) x D/Dt (3)

Where :

TY = Stacking Field Capacity (tons / year)

Vb = The volume of coal that is accommodated

(m³)

0.745 = Coal Type Mass (m³ / ton)

D = Working Days in 1 Year (days)

Dt = Dwelling Time (days)

In other studies about the layout of dry bulk

ports, it is explained that the location will affect the

service of cargo loading and unloading time at the

port, the distance between the berth and stockpile for

example is very influential on the speed of cargo

transfer (Nur et.al., 2013).

3 METHODOLOGY

In this section, the methodological framework

applied in this research is presented. This research

based on secondary and primary data. Secondary

data is obtained from the Ministry of Energy and

Mineral Resources, the Central Statistics Bureau,

coal terminal operators, and other references. As for

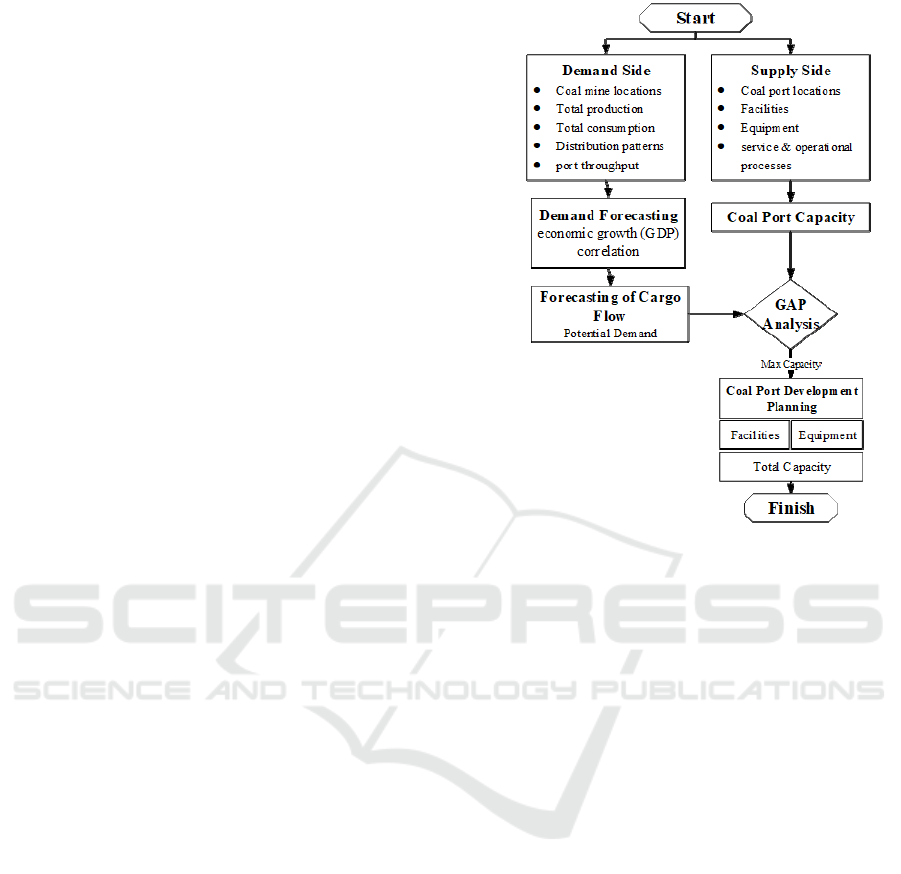

Figure 1: Research flow diagram.

the primary data obtained by surveying the operation

of coal terminal activities and the handling process.

Generally, demand side analysis related to

mining production as well as trends and forecastings

of coal consumption. The supply side analysis is

related to port coal facilities and equipment as well

as coal terminal operations and services. The stages

of this research consist of:

o Demand side analysis: identification of coal

mine locations, total production, total

consumption, distribution patterns and port

throughput;

o Supply side analysis: identification of coal

terminal locations, facilities, equipment and

service operational processes;

o Analysis of demand and supply correlation:

coal demand forecastings based on demand

trends and economic growth. Calculation of

coal terminal capacity, to determine the

maximum limit of coal services and

development plans;

o Analysis of port development plans:

calculation of port development needs,

including facility planning (berth and

stockpile) and coal handling equipment.

Development plan based on capacity

requirements and coal service demand

forecastings.

Analysis of Supply and Demand of Coal Terminal in Sumatera

231

4 ANALYSIS AND DISCUSSION

Analysis in this research includes 6 (six) main coal

terminals of Sumatra: (1) Panjang Port in Lampung,

(2) Bengkulu Port in Bengkulu, (3) Jambi Port in

Jambi, (4) Telur Bayur Port in West Sumatera, (5)

Kertapati Port in South Sumatera and (6) Tarahan

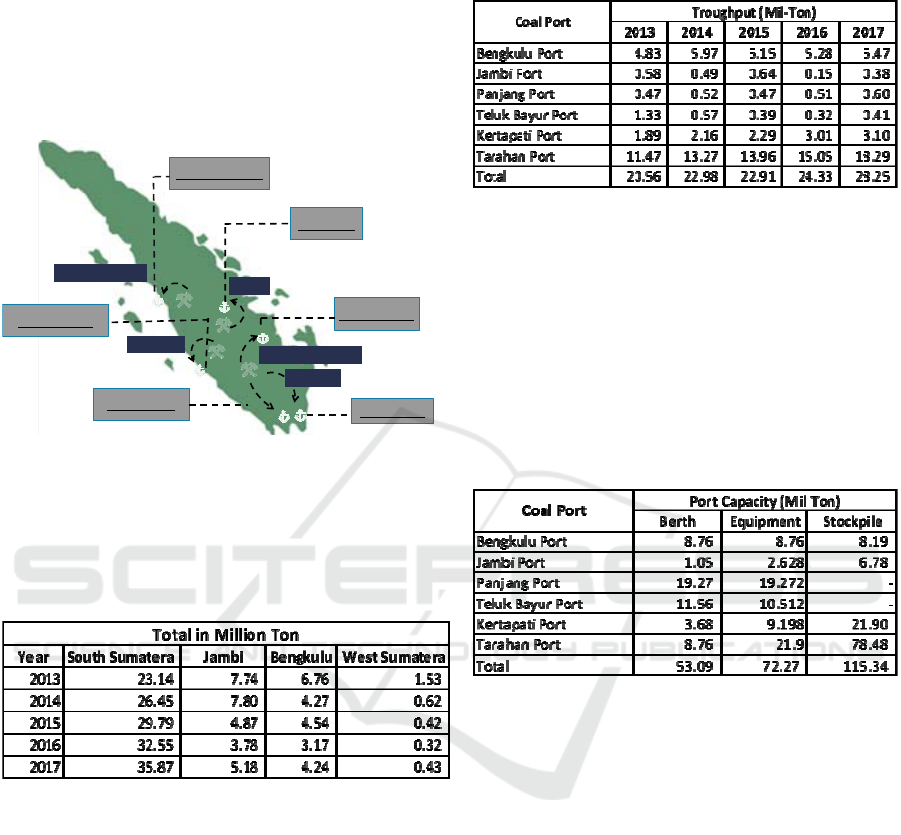

Port in Lampung (Figure 2).

Figure 2: Six main coal terminal of Sumatera.

4.1 Analysis of Demand Side

Data on coal production in the Sumatera during the

last 5 years (2013 - 2017) show on Table 1 below:

Table 1: Coal production of Sumatera.

The total coal production of Sumatera in 2013

was 39.17 million tons, for 2015 is 39.65 million

tons and in 2017 is 45.73 million tons. The average

growth of coal production is 17.40%. Distribution

process coal from the mine to coal terminal using

multimodal mode, such as truck and train,

consumers of coal from Sumatra are majority from

java.

Total coal throughput of Sumatra in 2013 is

20.56 million tons, in the year 2015 is 22.91 million

tons and in 2017 is 28.25 million tons. The average

growth of coal cargo flow is 3.97% (Table 2).

Table 2: Coal terminal troughput.

4.2 Analysis of Supply Side

The supply side analysis is related to port coal

facilities and equipment as well as coal terminal

operations and services. Port capacity calculation

use to determine the total amount of cargo that can

be served and when a development plan is needed.

The calculation of port capacity includes the

calculation of the berth capacity and stockpile.

Table 3: Coal terminal capacity (berth, equipment &

stockpile).

Table 3 above, show coal terminal capacity in

Sumatera, for berth capacity 53.09 Mil Ton/year,

equipment handling capacity 72.27 Mil Ton/year

and for stockpile capacity 115.34 Mil Ton/year.

4.3 Analysis of Demand and Supply

Correlation

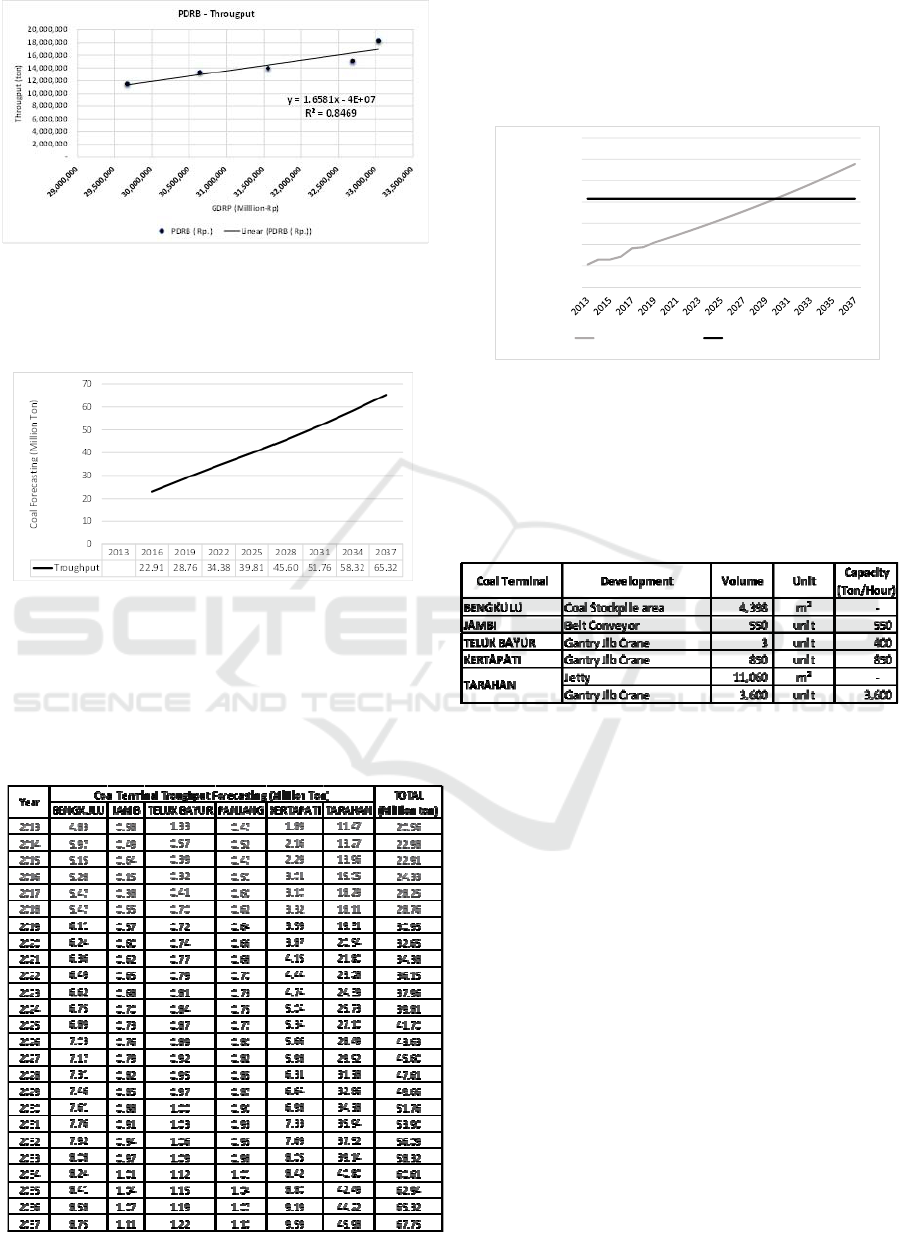

Analysis of coal demand is carried out by

forecasting coal troughput of terminal, trend analysis

combine with regression analysis between coal

troughput and the value of Gross Domestic Regional

Products (GDRP) use for the forecasting method.

The equation result from the regression is y =

0.7592x + 388775 and R² = 0.9462 (Figure 3).

JAMBI

BENGKULU

SUMATERABARAT

SUMATERASELATAN

LAMPUNG

TelukBayur Port

JambiPort

BengkuluPort

Kertapati Port

PanjangPort

Tarahan Port

SENTA 2018 - The 3rd International Conference on Marine Technology

232

Figure 3: Regression of coal troughput & GDRP.

Based on the forecasting, coal demand from

Sumatera in 2025 will reach 39.81 million tons, in

2037 will reach 65.32 million tons (Figure 4).

Figure 4: Coal demand forecasting (2019 – 2037).

Tarahan coal terminal with the largest coal

handling proportion of 62%, forecasting coal

demand through the terminal in 2037 reaches 45.95

million tons. Detail of coal forecasting of each

terminal can bee seen on Table 4 below:

Table 4: Coal terminal troughput forecasting.

The total capacity of coal terminal in Sumatera

will reach the maximum capacity of 80% in 2025

with the total coal demand of 41.70 million tons.

Figure 5 show the relation of coal terminal capacity

and coal forecasting:

Figure 5: Coal demand forecasting and terminal capacity.

Coal terminal operator need to consider the port

development, including terminal facilities and cargo

handling equipment to increase port capacity. Table

5 below, show coal terminals development need to

meet demand of coal handling.

Table 5: Coal terminal development.

5 CONCLUSIONS

There are 4 (four) regions in Sumatera which have

largest coal production in 2017, there are South

Sumatera (35.87 million tons), Bengkulu (3.02

million tons), Jambi (5.18 million tons) and West

Sumatra (0.43 million tons). Total production in

2017 reach 45.73 million tons. The average growth

of coal production is 17.40% during the past five

years with the majority of use for power plant and

exports. The total existing capacity of coal terminal

in Sumatera is 51.46 million tons, which include

Bengkulu Coal Terminal (8.18 million tons), Jambi

Coal Terminal (1.05 million tons), Panjang Coal

Terminal (19.27 million tons), Teluk Bayur Coal

Terminal (10.51 million tons), Kertapati Coal

Terminal (3.68 million tons) and Tarahan Coal

Terminal (8.76 million tons). Based on the

forecasting of coal demand in 2037 will reach 67.75

million tons, the total capacity of coal terminal in

Sumatera will reach the maximum capacity of 80%

10.00

20.00

30.00

40.00

50.00

60.00

70.00

80.00

CoalTerminalTroughputForecasting

(MillionTon)

TOTAL(Millionton) CoalTerminalCapacity

Analysis of Supply and Demand of Coal Terminal in Sumatera

233

in 2025 (41.70 million tons). Coal terminal operator

need to consider the port development (facilities and

cargo handling equipment) to increase port capacity.

REFERENCES

Kementerian ESDM, 2017. Statistik Mineral dan

Batubara, Kementerian Energi dan Sumber Daya

Mineral. Jakarta

Petromindo, 2016. Indonesia Coal Book, Petromindo.

Jakarta.

Bugaric, U., Dusan, P., Zoran, P., Miroslav, P., and

Gordana, M. P., 2011. Determining the Capacity of

Unloading Bulk Cargo Terminal Using Queuing

Theory, Journal of Mechanical Engineering, pp. 405-

416.

Velsink, H., 2012. Ports and Terminals, VSSD

Netherlands.

Nur, Iqbal, H. H., and Firmanto, 2013. Model Optimisasi

Tata Letak Pelabuhan Curah Kering dengan

Pendekatan Simulasi Diskrit: Studi Kasus Pelabuhan

Khusus PT Petrokimia Gresik, Jurnal Teknik ITS, pp.

E11-E16. Surabaya.

SENTA 2018 - The 3rd International Conference on Marine Technology

234