Stability Behavior of Water-in-Diesel Fuel Emulsion and Current Trends

Engine Performance and Emission

Rosid

1,3

∗

, Bambang Sudarmanta

1

and Lukman Atmaja

2

1

1Department of Mechanical Engineering, Institut Teknologi Sepuluh Nopember, Indonesia

2

Department of Chemistry, Faculty of Science, Institut Teknologi Sepuluh Nopember, Indonesia

3

Department of Mechanical Engineering, Faculty of Engineering, Singaperbangsa Karawang University, Indonesia

Keywords:

Surfactants, Emulsions, Performance.

Abstract:

Addition of water in the form of water emulsions in diesel (W/D) can reduce pollution levels and engine

performance. W/D emulsion was carried out by mixing between water, pertaminadex, and surfactant (span

80 1.3% and tween 80 0.7%). In this study the parameters used were emulsion stabilization, fuel efficiency,

neutralization of sprays, spray angles and trends using emulsions on engine performance and emissions. The

process of mixing between water, pertaminadex, and surfactant with the composition of pertaminadex + 50%

water + 2% Surfactant (span 80 + Tween 80), with stirring speed 1500 rpm for 30 minutes with stabilizer using

a sonicator for 60 minutes and stabilized for 1 hour and 24 hours. The results of this study indicated that the

emulsion of 50% W/D 1 hour emulsion stability 96% while 24 hours 92%, Density value 833 kg / m3, LHV

value 36.922 kJ / kg, Flash Point 70

◦

C, Spray Length 50 cm and spray angle 20

◦

, and analyzed trends in the

influence of emulsions on engine performance and emissions.

1 INTRODUCTION

Emulsion is a dispersion system, where one phase

is dispersed in another phase in the presence of an

emulsifying agent (Leal-Calderon et al., 2007) (Lin

and Chen, 2006). Surfactants are widely used in var-

ious fields because surfactants have the ability to in-

fluence the surface properties of a material, includ-

ing enhanced oil recovery (EOR) (Lin and Pan, 2000).

The emulsion type also determines the size of the dis-

persed phase droplet (Nadeem et al., 2006). Droplets

dispersed on multiple emulsions contain smaller sized

droplets which are different in phase, thus the size of

the double emulsion droplet will be larger than the

simple emulsion (Aserin, 2008). To make a W/D

emulsion, a lipophilic surfactant is needed to reduce

the water-oil interface tension. Span 80 is able to sta-

bilize the phase of water dispersed in the oil phase

such as liquid paraffin.

The pollutants from combustion in the atmosphere

will cause serious damage to the environment such as

the greenhouse effect, acid rain, and destruction of the

ozone layer. Some researchers have shown that the

use of water in diesel fuel to produce emulsified diesel

fuel can significantly reduce the levels of particle pol-

lution and NOx (Muzio and Quartucy, 1997) (Hagos

et al., 2011). According to Lin and Wang (2004), dur-

ing the W/D emulsion combustion process, it is at-

omized into several liquid granules through the noz-

zle. Because the boiling point of water is lower than

diesel, the layer that wraps the water will explode

through the outer layer of oil. As a result of micro-

explosion behavior, the emulsion granules which are

atomized are then atomized into finer grains (Park

et al., 2016).

At this stage the process of micro-explosion and

pufing, micro-explosion droplets break into small

grains quickly. While pufing increases granules in

fogging. According to Morozumi and Saito (2010)

micro-explosion is influenced by the volatility of the

base fuel, type of emulsion and water content, an in-

crease in the emulsifier content increases the tempera-

ture of micro-explosion. According to Fu et al. (2002)

The mechanism of micro-explosion and dependence

on various parameters will influence micro-explosion.

The research conducted by Abu-Zaid (2004) re-

lated to torque, power, brake specific fuel consump-

tion and thermal efficiency, by varying the percentage

of water volume from 0 to 20% in W/D at 5% inter-

vals. Alahmer et al. (2010) examined the performance

of the engine by varying the percentage of the vol-

ume of water from 0 to 30% water in diesel emulsion

Rosid, ., Sudarmanta, B. and Atmaja, L.

Stability Behavior of Water-in-Diesel Fuel Emulsion and Current Trends Engine Performance and Emission.

DOI: 10.5220/0008549302150220

In Proceedings of the 3rd International Conference on Marine Technology (SENTA 2018), pages 215-220

ISBN: 978-989-758-436-7

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

215

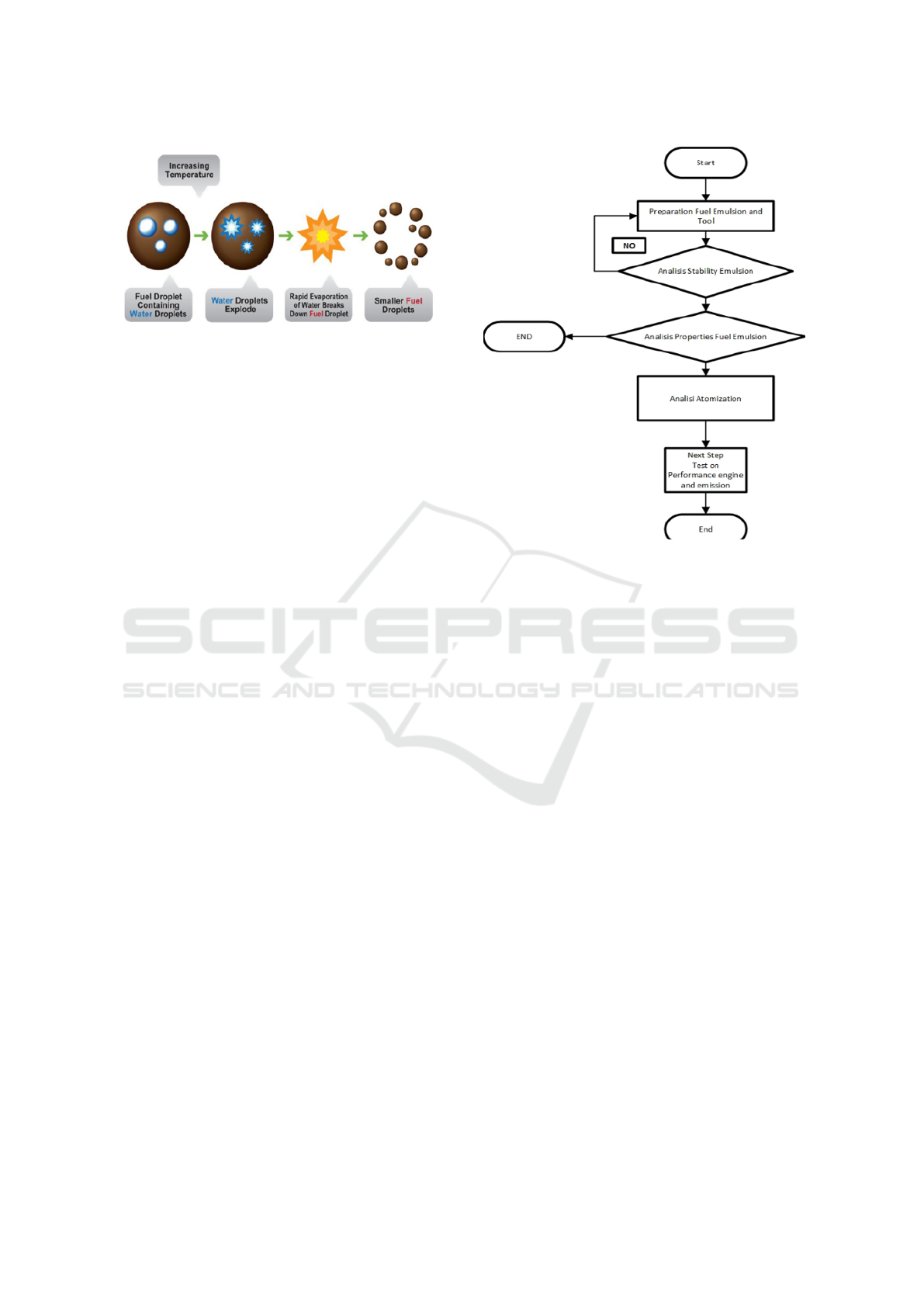

Figure 1: Mechanism of Micro-explosion Phenomenon.

(W/D) at 5% intervals.

Evaporation of water due to absorption of heat

around it will reduce the temperature in the combus-

tion chamber thereby reducing NOx (Maiboom and

Tauzia, 2011). The addition of a small amount of wa-

ter to NO and NOx emulation fuels increases, while

for the addition of water content a lot of NO and NOx

decreases. In the study of Ghojel and Honnery (2005),

the reduction in HC emissions was 60-90% at W/D

13% by volume. Research conducted by Samec et al.

(2000) decreased Hydrocarbon emissions by 52% and

33%, while for soot emission it was reduced by 68%

and 75% compared to pure diesel fuel in the water in

diesel content of 10% and 15% respectively.

2 MATERIALS AND METHODS

This research was conducted using experimental

method. The mixer equipment used was magnetic

stirrel, a stabilizer using a sonicator. The materials

used were; PertaminaDex + 50% Water + 2% Sur-

gaktan ( span 1.3%, tween 0.7%). The analysis was

carried out starting from the mixer process, stabiliza-

tion, stability emulsion, fuel properties test, neutral-

izing spray test and spray angle to the developer of

emulsion fuel usage trends on engine performance

and emissions.

The mixer process was carried out for 30 minutes

of water and pertaminadex mixed first after several

minutes of span and tween were added gradually, af-

ter the mixer process the fuel emulsion + water + sur-

factant was stabilized using a 60-minute sonicator and

left for 1 hour and observed and measured changes in

emulsion volume, after 24 hours observed and mea-

sured again the changes that occurred in the emul-

sion process, Testing the emulsion making process

and properties test carried out in the Chemical Instru-

mental Laboratory of FIA ITS.

The fuel properties test was carried out only on

Density, Viscosity, LHV, and Flash Point, after testing

Figure 2: Schematic Diagram of The Emulsion Process.

properties and declared feasible to be used as fuel, a

spray test was carried out at the Burning and Energy

Laboratory of the ITS Mechanical Engineering De-

partment

The spray test was carried out at a pressure of

200 bar comparing PertaminaDex and PertaminaDex

+ 50% water + Emulsion (Span 80 1,3 + Tween 80

0.7), from the results of the spray analysis then mea-

sured the length of the spray and the spray angle.

3 RESULTS AND DISCUSSIONS

In the process of making W/D emulsions it is gener-

ally a different liquid mixture, therefore it is necessary

to know the dispersed duration phase which is spread

evenly throughout the continuous phase. Emulsion

formation criteria were carried out by two methods,

namely Emulsion Stability (ES) and Emulsion Activ-

ity (EA) [11].

3.1 Emulsion Stability (ES)

ES shows the ability of the emulsion to stabilize the

emulsifying layer after being stored immobile for a

certain time. The ES value is determined by calculat-

ing the volume ratio of the emulsifying layer to the to-

tal volume of the emulsion. Experimental studies con-

ducted by pertamina dex and water emulsion showed

SENTA 2018 - The 3rd International Conference on Marine Technology

216

Figure 3: Result of Emulsion Volume.

that the emulsion layer remained stable at 1 hour up

to 96 hours indicated by Dex + 50% emulsion. Per-

centage of sediment 1 hour 96%, 24 hours 92%, 48

hours 91%, 72 hours 91%, 96 hours 90.5% shown

in (Figure 3). For emulsion volume in Dex emulsion

observation + 40%, the most stable emulsion volume

was observed at 72 hours 17.5% for Dex emulsion +

50% volume most stable at 48 hours 32% observa-

tion, while Dex + 60% for the most stable emulsion

volume observed 48 hours 40% (Figure 4).

3.2 Emulsion Activity (EA)

Emulsion Activity is the ability of the emulsion to

maintain the emulsifying layer under the centrifugal

force, with the same amount of water and pertam-

ina dex in W/D, when the centrifugal edge increases,

the height of the sediment layer from W/D increases.

This is because the specific gravity of the oil is lighter

than the water and the emulsion is W/D.

3.3 Properties of Fuel

Specific Gravity to be able to calculate the mass of oil

if the volume is known or to know whether there is

contamination thus it can change the size of specific

gravity. SG shows the weight per unit volume. Diesel

specific gravity is measured using the ASTM D4052

or ASTM D1298 method.

Whereas Viscosity is the resistance held by the

fluid if it is flowed in a capillary tube to the gravi-

tational force, viscosity indicates the ease of whether

liquid fuel is pumped and atomized. If the viscosity

is higher, the resistance to flow is higher, this charac-

teristic is very important because it affects the perfor-

mance of the injector in the diesel engine. Viscosity

is measured using the ASTM D445 or D1298 method.

Fuel properties value as in Table 1.

Figure 4: Result of Volume Emulsion.

Table 1: Properties of Pertamina Dex + 50% Water

Density kg/m

3

833

LHV, kJ/kg 36,922

Viskosity, cSt 3.62

Flash Pont,

◦

C 70

Flash point is the lowest temperature point where

fuel can turn on spontaneously (Joshi and Pegg,

2007). This characteristic is determined by the ASTM

D93 method. Heating Volue is measured using a tool

called the bomb calorimeter.

3.4 Atomization of Pertamina dex fuel

and W/D 50%

The atomization process is the process of converting

liquid fuels injected by a machine injector into a sheet

(thin sheet which later forms a ligament (bond) and

breaks into a dropet with a certain pattern and direc-

tion. A more perfect atomization will produce bet-

ter engine performance, this is because the injected

fuel droplets are getting smoother as the fuel injection

pressure increases which results in more perfect com-

bustion in the combustion chamber (Watanabe et al.,

2010). The parameters that can affect the atomization

of fuel include Density, Viscosity, Flash Point, and

Cetane numbers.

In Figure 5, the spray results for pertamina dex

fuel injection pressure by Diamond Di 800 engine in-

jector at injection pressure of 200 kg/cm

2

, it is shown

that the atomization results obtained spray length (L)

with a length of 50 cm and spray angle (φ) of 19

◦

,

While in Figure 6 the results of the spray / droplet

are shown for fuel injection pressure Pertamina dex

Emulsion + 50% water by the Diamond engine injec-

tor Di 800 at an injection pressure of 200 kg/cm

2

, it

is shown that the spray (L) is 50 cm long and spray

angle (φ) of 20

◦

. From the results of the two atomiza-

Stability Behavior of Water-in-Diesel Fuel Emulsion and Current Trends Engine Performance and Emission

217

Figure 5: The Result of Pertamina Dex Atomization.

Figure 6: The Result of Pertamina Dex Atomization + 50%

Water.

tion above it is stated that the 50% W/D emulsion can

be used as a substitute fuel for pertamina dex, because

the atomization value is almost the same.

3.5 Trends of using Emulsion Fuels on

Diesel Engines

3.5.1 Effects of Water Emulsion in Diesel (W/D)

on the Process of Combustion

Emulsion fuel when sprayed into the combustion

chamber, heat will be transferred to the surface of

the emulsion granules through the process of con-

version and radiation, because diesel fuel and water

have different temperatures, the evaporation rate will

also be different. As a result the water molecules

will reach the super-heat stage faster than diesel fuel

and there will be a breakdown of the steam expansion

(Elazzazy et al., 2015). At this stage the process of

micro-explosion and pufing, micro-explosion droplets

break into small grains quickly. While pufing in-

creases granules in fogging. According to Morozumi

and Saito (2010), micro-explosion is influenced by

the volatility of the base fuel, type of emulsion and

water content, an increase in the emulsifier content

increases the temperature of micro-explosion. Ac-

cording to Fu et al. (2002) the mechanism of micro-

explosion and dependence on various parameters will

affect micro-explosion .

Ochoterena et al. (2010) in their study that the

W/D spray characteristics, micro water emulsion in

diesel at conventional diesel at high pressure and con-

stant volume at high temperatures, observed neutral-

ization and measurement of the cone angle of atom-

ization, neutralization of longer droplets and wider

crank angle with emulsion fuel compared to pure

diesel fuel. The ignition delay is a little long. The

longer duration of combustion occurred in emulsion

fuels, an effect of lower flame temperatures, igni-

tion delays up to 29%. According to Subramanian

(2011),in his research, the ignition delay is much

higher W/D than water injection into the manifold

during the suction step.

3.5.2 Effect of Water Emulsion in Diesel (W/D)

on the Performance Engine

The research conducted by Abu-Zaid (2004) related

to torque, power, brake specific fuel consumption and

thermal efficiency, by varying the percentage of wa-

ter volume from 0 to 20% in W/D at 5% intervals.

Alahmer et al. (2010) examined the performance of

the engine by varying the percentage of the volume of

water from 0 to 30% water in a diesel emulsion (W/D)

at 5% intervals. Park et al. (2004) analyzed the effect

of the percentage of water volume in diesel emulsion

(W/D) 0, 16.67%, 28.6% about combustion charac-

teristics with emulsion fuel. In other study of Park

et al. (2000), he analyzed the combustion characteris-

tics with pure diesel and W/D variations of 13%, 15%,

17% based on the volume of water in the emulsion.

In the study of Abu-Zaid (2004), torque increases

with increasing percentage of water in the emulsion.

According to research conducted by Alahmer et al.

(2010), maximum torque was obtained at 5% mois-

ture content based on emulsion volume. A decrease

in torque occurs in emulsion fuel because the calorific

value is reduced in the emulsion fuel system.

The research conducted by Abu-Zaid (2004) about

the effect of water content in the emulsion system af-

fected the power produced, the higher the percentage

of water content in the emulsion, the higher the power.

Alahmer et al. (2010) explained that the maximum

SENTA 2018 - The 3rd International Conference on Marine Technology

218

engine power is achieved by adding 5% water to the

emulsion based on volume. However, in Barnes et al.

(2000)’s study on the use of water-in-diesel emul-

sion fuel (W/D) it decreased or lost power by 7-8%

at diesel W/D with a moisture content of 10% based

on volume.

The research conducted by Abu-Zaid (2004) by

increasing the percentage of water in the emulsion

had an effect on the decrease in BSFC, the great-

est decrease occurred in the use of a percentage of

20% water in emulsion, this was due to secondary at-

omization due to micro-explosion. In the study con-

ducted by Kaliaperumal and Udayakumar (2009) the

percentage effect on emulsion, a decrease in BSFC

along with an increase in the percentage of water vol-

ume in the emulsion, the minimum BSFC value oc-

curred at a percentage of 20% W/D. Whereas the re-

search conducted by Ghojel et al. (2006) experienced

a 22-26% increase in BSFC with 13% emulsion fuel

water in volume based emulsions compared to diesel

fuel.

3.5.3 Effect of Water Emulsion in Diesel (W/D)

on Emissions

Evaporation of water due to absorption of heat around

it will reduce the temperature in the combustion

chamber thereby reducing NOx. The addition of a

small amount of water to NO and NOx emulation fu-

els increases, while for the addition of water content

a lot of NO and NOx decreases. The decrease in NO

at W/D variations of 10% and 20% were 18% and

21.5%, while NOx decreased were 10% and 25% re-

spectively. In the study of Ghojel et al. (2006) the de-

crease in NOx was 29-37% at W/D 13% by volume.

The research conducted by Samec et al. (2002) de-

creased NOx emissions by 20% and 18% compared

to pure diesel fuel in the water in diesel content of

10% and 15% respectively. Barnes et al. (2000) in

their study of the effect of 10% of water based on the

volume mixed with diesel fuel in emulsions reduced

NOx emissions by 9%.

In the study of Ghojel et al. (2006), the reduc-

tion in HC emissions was 60-90% at W/D 13% by

volume. Research conducted by Samec et al. (2002)

decreased Hydrocarbon emissions by 52% and 33%,

while those for soot emission were reduced by 68%

and 75% compared to pure diesel fuel at 10% and

15% respectively in water in diesel. Barnes et al.

(2000) in their research PM emissions decreased 20%

at 10% W/D based on volume.

4 CONCLUSION

This research conclude that addition of water in the

form of water emulsions in diesel (W/D) can reduce

pollution levels and engine performance. W/D emul-

sion was carried out by mixing between water, per-

taminadex, and surfactant (span 80 1.3% and tween

80 0.7%) where the parameters used were emulsion

stabilization, fuel efficiency, neutralization of sprays,

spray angles and trends using emulsions on engine

performance and emissions. The water was mixed

with pertaminadex and surfactant with the composi-

tion of pertaminadex + 50% water + 2% Surfactant

(span 80 + Tween 80), under stirring speed 1500 rpm

for 30 minutes with stabilizer using a sonicator for

60 minutes and stabilized for 1 hour and 24 hours.

The results of this study indicated that the emulsion

of 50% W/D 1 hour emulsion stability 96% while

24 hours 92%, Density value 833 kg/m

3

, LHV value

36.922 kJ / kg, Flash Point 70

◦

C, Spray Length 50 cm

and spray angle 20

◦

. Trends in the influence of emul-

sions on engine performance and emissions were also

analyzed.

REFERENCES

Abu-Zaid, M. (2004). Performance of single cylinder, direct

injection diesel engine using water fuel emulsions.

Energy Conversion and Management, 45:697–705.

Alahmer, A., Yamin, J., Sakhrieh, A., and Hamdan, M.

(2010). Engine performance using emulsified diesel

fuel. Energy Conversion and Management, 51:1708–

1713.

Aserin, A. (2008). micro-explosione Emulsions: Technol-

ogy and Applications. John Wiley & Sons, Ltd, Hobo-

ken, New Jersey.

Barnes, A., Duncan, D., Marshall, J., Psaila, A., Chadder-

ton, J., and Eastlake, A. (2000). Evaluation of water-

blend fuels in a city bus and an assessment of perfor-

mance with emission control devices.

Elazzazy, A. M., Abdelmoneim, T. S., and Almaghrabi,

O. A. (2015). Isolation and characterization of bio-

surfactant production under extreme environmental

conditions by alkali-halo-thermophilic bacteria from

Saudi Arabia. Saudi Journal of Biological Sciences,

22:466–475.

Fu, W., Hou, L., Wang, L., and Ma, F. (2002). A unified

model for the micro-explosion of emulsified droplets

of oil and water. Fuel Processing Technology - FUEL

PROCESS TECHNOL, 79:107–119.

Ghojel, J. and Honnery, D. (2005). Heat release model for

the combustion of diesel oil emulsions in di diesel en-

gines. Applied Thermal Engineering, 25:2072–2085.

Ghojel, J., Honnery, D., and Al-Khaleefi, K. (2006). Per-

formance, emissions and heat release characteristics

of direct injection diesel engine operating on diesel

Stability Behavior of Water-in-Diesel Fuel Emulsion and Current Trends Engine Performance and Emission

219

oil emulsion. Applied Thermal Engineering, 26:2132–

2141.

Hagos, F., Aziz, A., and Tan, I. (2011). Water-in-

diesel emulsion and its micro-explosion phenomenon-

review.

Joshi, R. M. and Pegg, M. J. (2007). Flow properties of

biodiesel fuel blends at low temperatures. Fuel Fuel,

86(1-2):143–151.

Kaliaperumal, K. and Udayakumar, M. (2009). Nox and

hc emission control using water emulsified diesel in

single cylinder diesel engine. 4:59–62.

Leal-Calderon, F., Schmitt, V., and Bibette, J. (2007). Emul-

sion Science Basic Principles.

Lin, C.-Y. and Chen, L.-W. (2006). Emulsification charac-

teristics of three- and two-phase emulsions prepared

by the ultrasonic emulsification method. Fuel Pro-

cessing Technology, 87:309–317.

Lin, C.-Y. and Pan, J.-Y. (2000). Corrosion characteristics

of furnaces burning with emulsified diesel oil contain-

ing sodium sulphate. Corrosion Prevention and Con-

trol, 47:83–92.

Lin, C.-Y. and Wang, K.-H. (2004). Diesel engine perfor-

mance and emission characteristics using three-phase

emulsions as fuel. Fuel, 83:537–545.

Maiboom, A. and Tauzia, X. (2011). Nox and pm emis-

sions reduction on an automotive hsdi diesel engine

with water-in-diesel emulsion and egr: An experimen-

tal study. Fuel, 90:3179–3192.

Morozumi, Y. and Saito, Y. (2010). Effect of physical prop-

erties on microexplosion occurrence in water-in-oil

emulsion droplets. Energy & Fuels - ENERG FUEL,

24.

Muzio, L. and Quartucy, G. (1997). Implementing nox con-

trol: Research to application. Progress in Energy and

Combustion Science, 23:233–266.

Nadeem, M., Rangkuti, C., Anuar, K., Haq, M., Tan, Y. Y.,

and Shah, S. (2006). Diesel engine performance

and emission evaluation using emulsified fuels stabi-

lized by conventional and gemini surfactants. Fuel,

85:2111–2119.

Ochoterena, R., Lif, A., Nyden, M., Andersson, S., and

Denbratt, I. (2010). Optical studies of spray develop-

ment and combustion of water-in-diesel emulsion and

microemulsion fuels. Fuel, 89:122–132.

Park, J. W., Huh, K. Y., and Park, K. H. (2000). Experimen-

tal study on the combustion characteristics of emulsi-

fied diesel in a rcem. Technical report, SAE Technical

Paper.

Park, K., Kwak, I., and Oh, S. (2004). The effect of wa-

ter emulsified fuel on a motorway-bus diesel engine.

KSME International Journal, 18:2049–2057.

Park, S., Woo, S., Kim, H., and Lee, K. (2016). The charac-

teristic of spray using diesel water emulsified fuel in a

diesel engine. Applied Energy, 176:209–220.

Samec, N., Dobovi

ˇ

sek, ., and Hribernik, A. (2000). The ef-

fect of water emulsified in diesel fuel on diesel exhaust

emission. 39(6):386–392.

Samec, N., Kegl, B., and Dibble, R. (2002). Numerical and

experimental study of water/oil emulsified fuel com-

bustion in a diesel engine. Fuel, 81:2035–2044.

Subramanian, K. (2011). A comparison of water–diesel

emulsion and timed injection of water into the intake

manifold of a diesel engine for simultaneous control

of no and smoke emissions. Energy Conversion and

Management - ENERG CONV MANAGE, 52:849–

857.

Watanabe, H., Suzuki, Y., Harada, T., Matsushita, Y., Aoki,

H., and Miura, T. (2010). An experimental investi-

gation of the breakup characteristics of secondary at-

omization of emulsified fuel droplet. Energy, 35:806–

813.

SENTA 2018 - The 3rd International Conference on Marine Technology

220