Aging Treatment on Aluminium AA6063 against Bacterial Corrosion

Resistance in Marine Environment

Herman Pratikno

1

, Harmin Sulistiyaning Titah

2

and Nurika Primiliana

1

1

Department of Ocean Engineering, Faculty of Marine Technology, Institut Teknologi Sepuluh Nopember,

Keputih, Sukolilo, 60111 Surabaya, Indonesia

2

Department of Environmental Engineering, Faculty of Civil, Environmental and Geo Engineering,

Institut Teknologi Sepuluh Nopember, Keputih, Sukolilo, 60111 Surabaya, Indonesia

Keywords: Aging Treatment, Aluminium Aa6063, Bacterial Corrosion.

Abstract: The corrosion is a natural occurrence of metal damage caused by electrochemical interactions with the

environment. One of the causes of corrosion is the attachment of bacteria to the material. The hazard caused

by corrosion, especially on ship, corrosion can cause a failure on ship’s structure which causes the ship to not

operate properly. The purpose of the research was to determine the effects of Aluminium AA6063 aging

treatment on bacterial corrosion. The material was be treated by heat treatment (Aging Treatment) before the

bacterial corrosion test was conducted. The bacterial corrosion test was carried out in artificial seawater with

salinity of 33‰, 35‰ and 37 ‰. The addition of three species of bacteria, i.e. Thiobacillus ferrooxidans,

Pseudomonas fluorescens and Escherichia coli were applied in all salinity with 5% (v/v). The bio-corrosion

rate was determined using weight loss method and the microstructure of material was conducted at pre and

post bacterial corrosion to determine the differences in the microstructure of the material before and after the

bacterial corrosion test. The results showed the non aging treatment material has a higher corrosion rate when

compared with the material with aging treatment. The non aging treatment material has the highest corrosion

rate of 1.189 mmpy with the addition of Thiobacillus ferrooxidans at salinity of 37‰ and the lowest corrosion

rate of 0.186 mmpy at salinity of 33‰. However, the aging treatment material has the highest corrosion rate

of 0.770 mmpy and the lowest corrosion rate of 0.175 mmpy at similary condition. Based on microstructure

results, uniform and pitting corrosion occurred on all specimens with the addition of bacteria or without the

addition of bacteria. However, the bacterial corrosion rates were different. It was identified that aging

treatment on Aluminium AA6063 can reduce the bacterial corrosion rate or increase the bacterial corrosion

resistance.

1 INTRODUCTION

The usage of aluminium in maritime industry as one

of the supporting materials has considerable role.

Aluminium with 6xxx series is aluminium alloys in

which magnesium and silicon are the principal

alloying elements, commonly used for architectural

extrusions and automotive components (Davis,

2001). Aluminium with 6xxx series have a high

strength when used for building structures in the

marine environment and more corrosion resistant

when compared with other aluminium series.

However, many factors can cause the decreasing of

aluminium metal. One of the factor is corrosion.

Alloys in the 6xxx series contain silicon and

magnesium approximately in the proportions

required for formation of magnesium silicide

(Mg2Si), thus making them heat treatable. Although

not as strong as most 2xxx and 7xxx alloys, 6xxx

series alloys have good formability, weldability,

machinability, and corrosion resistance, with medium

strength (Davis, 2001).

Corrosion is considered a significant factor in the

failure and damage of metals (Nuhia, et.al, 2011).

Corrosion is a material damage that was caused by the

influence of the surrounding environment. Corrosion

can cause many losses due to the reduction of

relatively large dimensions per unit time and also

reduce the age of the building. Aluminium with

erosion corrosion can accelerate or increase the

destruction due to relative movement and corrosive

media on metal surface.

Pratikno, H., Titah, H. and Primiliana, N.

Aging Treatment on Aluminium AA6063 against Bacterial Corrosion Resistance in Marine Environment.

DOI: 10.5220/0008649701590164

In Proceedings of the 6th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management (ISOCEEN 2018), pages 159-164

ISBN: 978-989-758-455-8

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

159

In the marine environment, the rate of corrosion

increase rapidly, due to the seawater contain solution

that are able to dissolve other substances in greater

quantities than other liquids. Those substances

include inorganic salts, organic compounds derived

from living organisms (bacteria) and dissolved gases.

One of the causes of corrosion is bacteria. Bacteria

live in the marine environment extensively in their

habitats and form colonies and attach to the metal

surfaces in the form of thin layers. Factors that affect

the occurrence of bio-corrosion are temperature, pH,

and oxygen levels. Based on our previous study, 3

species of bacteria Escherichia coli, Pseudomonas

fluorescens, and Thiobacillus ferroxidans can caused

bio-corrosion on steel structures of ASTM A106 and

A53 in deep seawater (salinity of 33‰), medium

seawater (salinity of 35‰), and shallow seawater

(salinity of 37‰) (Pratikno and Titah, 2016). The bio-

corrosion rate by P. fluorescens on Aluminium Alloy

6063 at salinity of 37‰ increased by one point six-

fold compared with the condition without bacteria

addition at the same salinity (Pratikno and Titah,

2016).

Corrosion can occur rapidly if neither

environmental control or prevention. The usage of

aluminium in the maritime industry is high such as in

ship building. So that aluminium should treat with

suitable treatment to increase the resistance of

corrosion or decrease the corrosion rate. The aim of

the research was to determine the effects of

Aluminium AA6063 aging treatment on bacterial

corrosion. The material was be treated by heat

treatment (Aging Treatment) before the bacterial

corrosion test was conducted.

2 MATERIALS AND METHODS

2.1 Preparation of Specimen

Material cut with area of ± 2 cm2 with diameter ±

1mm with thickness 1-2 mm. After that, the

hardening process was conducted by heating the

specimen with temperature of 535 ºC for 6 h. This

process was called as Solution Heat Treatment. After

that, the specimen was immersed in water or

quenching phase, then re-heat it at 200 ºC for 5 h. This

process was called as Aging Treatment. After the

aging treatment, the hardness test was conducting to

all specimens using Vickers method. Vickers

Hardness Test is the standard method for measuring

the hardness of metals, particularly those with

extremely hard surfaces: the surface is subjected to a

standard pressure for a standard length of time by

means of a pyramid-shaped diamond. The diagonal of

the resulting indention is measured under a

microscope.

2.2 Preparation of Artificial Seawater

This research used a chemical solution instead of sea

water with a salinity of 35 ‰. Salinity of 35‰ is the

salinity in the ocean of medium depths, where in the

microorganism commonly found at this depth,

including bacteria. The chemical composition of

seawater replacement is in accordance with ASTM

D1141-90, 1994 (ASTM, 2004).

2.3 Preparation of Bacteria

The preparation of bacteria was conducted based on

Pratikno and Titah (Pratikno and Titah, 2017). The

pure culture of Thiobacillus ferrooxidans,

Pseudomonas fluorescens and Escherichia coli, were

be inoculated onto nutrient agar (NA) media using

streak plate technique based on Harley and Prescott

(Harley and Prescott, 2002). The age of bacteria for

the test was 24 h. After that, one colony of bacteria

was transferred to nutrient borth (NB) and keep in

shaker incubator of Innova 2000 (New Brunswick-

Eppendorf, Germany) at 150 rpm and room

temperature, 33 oC for 24 h. The cell suspension of

selected bacteria was prepared by harvesting the cells

at the middle of the logarithmic phase, based on the

typical of growth rate graph for the selected bacteria.

At this time, the OD at 600 nm was 1.0 was

determined using UV spectrophotometer Genesys 20

(Thermo, USA). The cells were harvested through

centrifugation of Jouan E82 (Thermo, USA) at 4,000

rpm for 15 min. The obtained pellet was then washed

twice using 8.5 g NaCl/1000 mL solution.The

suspension of bacteria was ready to be used in bio-

corrosion test.

2.4 Immersion Method for

Bio-corrosion Test

The specimen was tested by immersion tehnique in a

prepared seawater solution with salinity 33‰, 35‰

and 37‰ using ASTM G31-72 standard (ASTM,

2004). There were two different treatments, namely

treatment without bacterial addition as a control and

treatment with bacterial addition Testing was carried

out for 4 weeks. Immersion testing was conducted in

beaker glass with size of 300 mL and the artificial

seawater was 250 mL for each beker glass.

ISOCEEN 2018 - 6th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management

160

2.5 Calculation of Corrosion Rate

Running rate of corrosion is a rapid propagation of

material quality decline against time. There is a

formula for calculating the corrosion rate based on the

ASTM G1-03 standard (ASTM, 2002) as follows:

𝐶𝑜𝑟𝑟𝑜𝑠𝑖𝑜𝑛 𝑟𝑎𝑡𝑒

𝑚𝑝𝑦

(1)

With:

K = Constanta

T = Time of exposure (h)

A = Surface area (cm2)

W = Weight loss (gram)

D = Material density (gram/cm3)

2.6 Macrostructure and

Microstructure Testing

After corrosion testing was conducted, the

microstructure of specimens were determinated using

a microscope for detailed morphology of the

specimen structure. It was used for documentary

evidence and it can be known that the specimen

differences between before and after testing.

3 RESULTS AND DISCUSSION

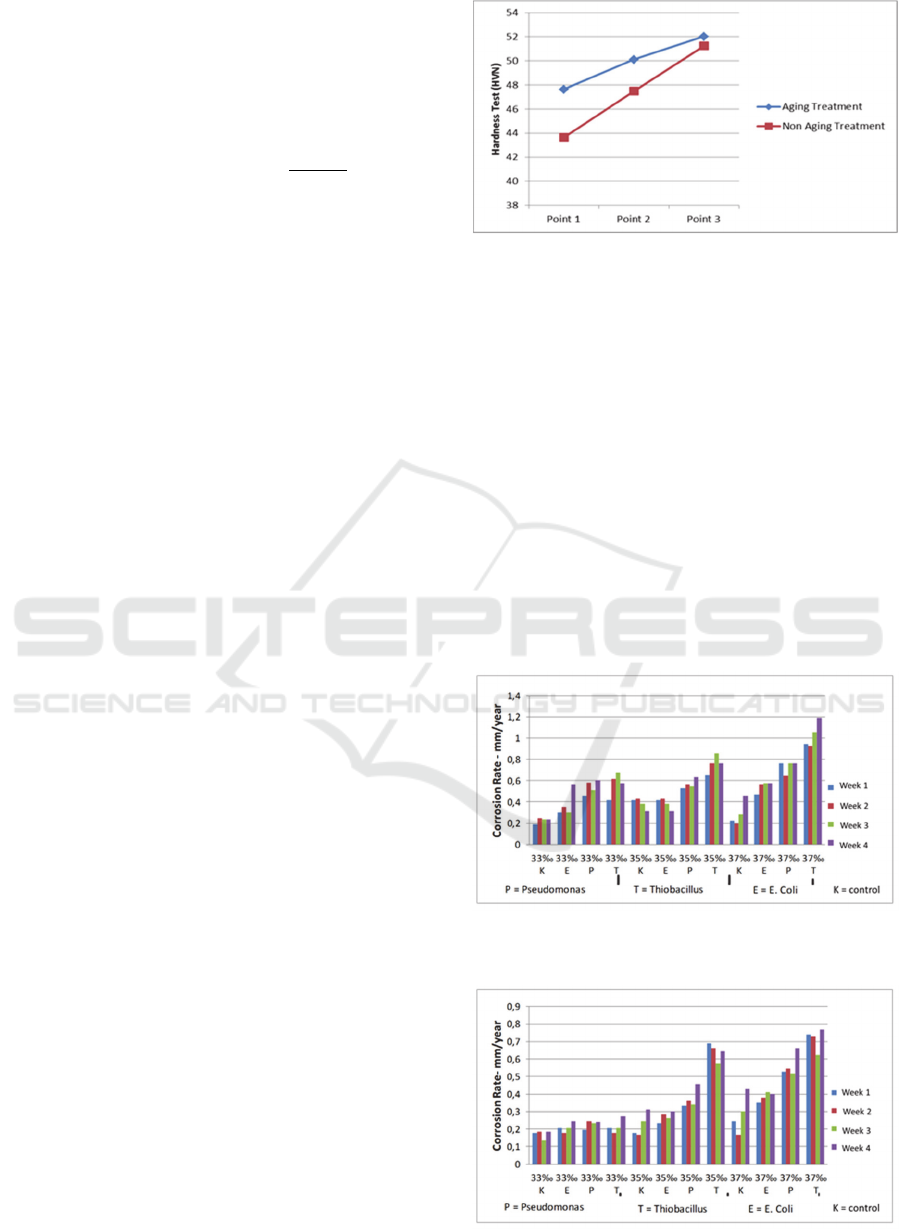

Figure 1 showed the results of hardness test on

AA6063 before and after aging treatment. Based on

the Figure 1, the value of hardness test on AA6063

increased after aging treatment. The high value of

Vickers hardness was 52.02 HVN after aging

treatment. It indicated that aging treatment can

accelerate the hardness value. According to Abel-

Rahman et al. (2010), the Vickers hardness of 6066

alloy has a maximum value of 80 HVN after 10 days

of quenching at 530oC which is the solution

temperature of this alloy. The hardness of 6063 alloy

has a maximum value of 40 HVN after 14 days of

quenching at 520 oC. A tremendous increase in

hardening of the Al-Mg-Si alloys is caused by

precipitates formed from solution with merely 1 wt%

of Mg and Si added to aluminum. During natural or

artificial aging, Al-Mg-Si alloys first produce clusters

of a few nm sizes. These clusters are an enrichment

of the Mg and Si precipitates (Abdel-Rahman, et.al,

2010). Extrudability of the alloy is strongly

influenced by the amount of Mg and Si and the size

and distribution of Al-Mg2Si precipitate particles

(Andersen, et.al, 1998).

Figure 1: Hardness test.

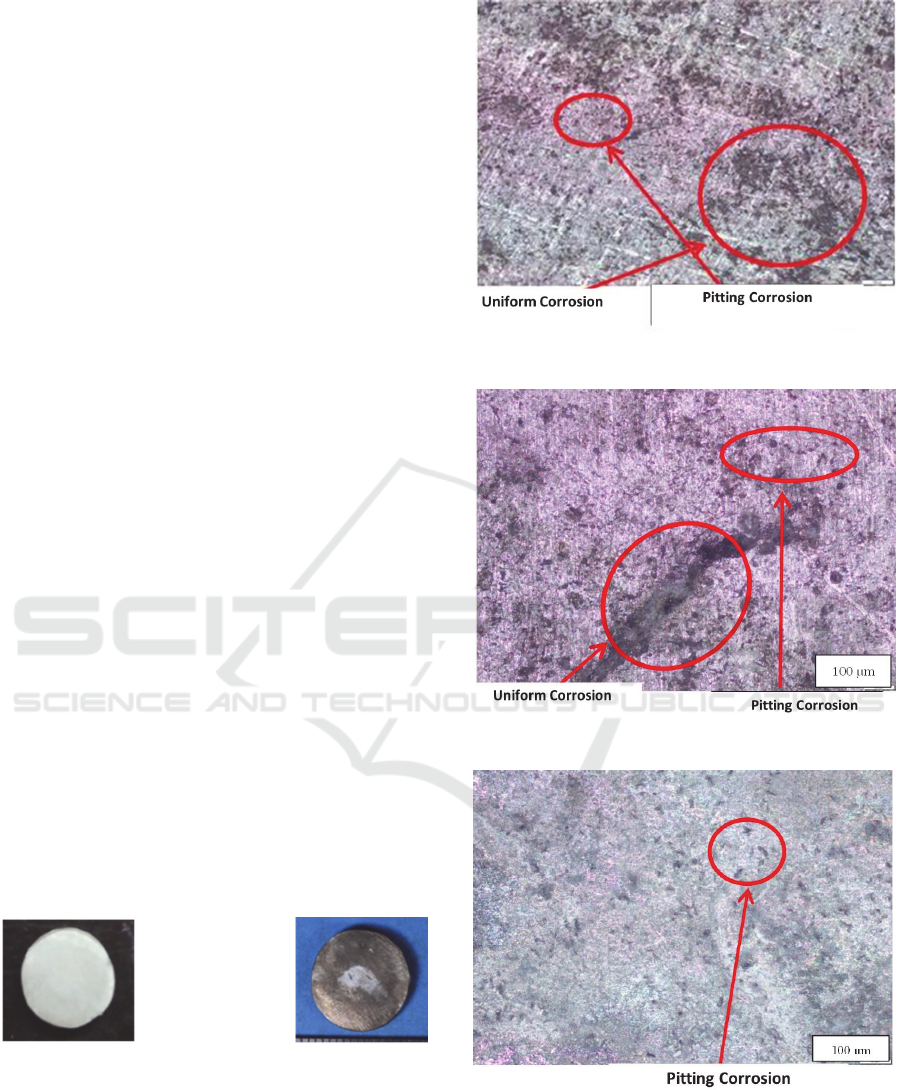

Based on Figure 2 and 3, the higher of salinity can

accelerate the rate of corrosion. The higher of salinity

contain chloride ions due to cause pitting corrosion and

other damage to the material. The corrosion rate on

alumnium alloys with the highest heat treatment at

salinity 33 ‰ with addition of Thiobacillus ferroxidans

was 0.565 mmpy, meanwhile the lowest corrosion rate

in the control specimens was 0.175 mmpy. At salinity

35 ‰, the highest corrosion rate occurred in specimens

with the addition of Thiobacillus ferroxidans (0.692

mmpy), and the lowest corrosion rate in control

specimens was 0.178 mmpy. Similarly, the highest

corrosion rate in specimens with the addition of

Thiobacillus ferroxidans was 0.770 mmpy at salinity

37 ‰ and the lowest corrosion rate on the specimen

with the addition of Escherichia coli (0.175 mmpy).

Figure 2: Corrosion Rate on AA6063 without aging

treatment.

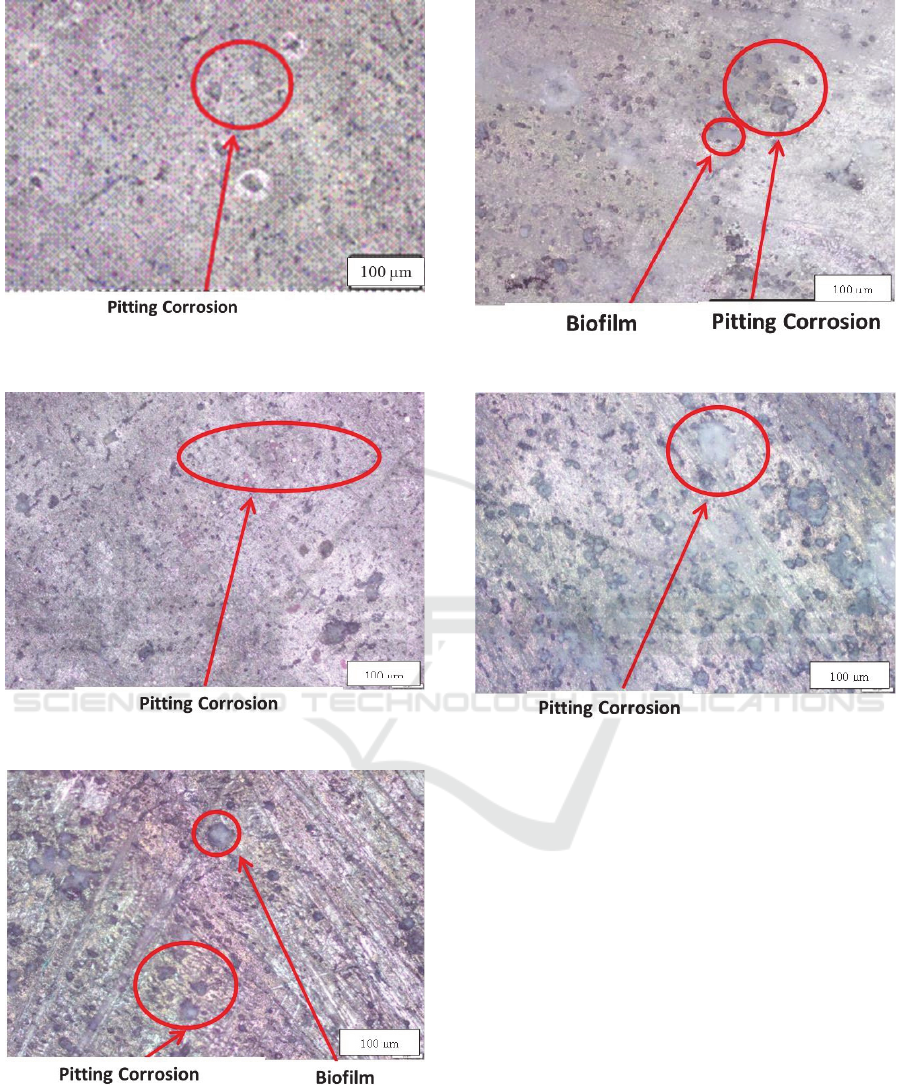

Figure 3: Corrosion Rate on AA6063 with aging treatment.

Aging Treatment on Aluminium AA6063 against Bacterial Corrosion Resistance in Marine Environment

161

Based on graph, the most corrosive bacteria to test

specimens on corrosion rate of aging material and non

aging treatment was Thiobacillus ferroxidans.

Thiobacillus ferroxidans has the highest corrosion

rate due to this bacteria can produce more organic

acids, pigments, H2S ligands that can remove heavy

metal ions from the material. The non aging treatment

material has a higher corrosion rate when compared

with the material with aging treatment. The non aging

treatment material has the highest corrosion rate of

1.189 mmpy and the lowest corrosion rate of 0.186

mmpy, meanwhile the aging treatment material has

the highest corrosion rate of 0.770 mmpy and the

lowest corrosion rate of 0.175 mmpy.

3.1 Macro Structure and

Microstructure

Macrostructure showed that appearance of specimen

before and after corrosion test. Based on Figure 4 (a),

the specimen was clear, however the apprearance of

specimen was different after corrosion test Figure 4

(b). Microstructure were determined on two sides of

the specimen's surface to detect the characteristics of

corrosion forming on each surface. Based on the

microstructure results, the corrosion on the specimens

test were pitting and uniform corrosion. There was a

difference of pitting corrosion in specimens

immersed at difference of bacteria species. The

observation of the visible side of the specimen soaked

in E. coli bacteria, the pitting corrosion was a small

holes clumped. The pitting corrosion in

Pseudomonas was slightly larger and not clustered.

The last of pitting corrosion in Thiobacillus

ferroxidans addition was hole tends to be large and

not clustered. However, all the shape of corrosion was

a pitting corrosion. The observations on the bottom

side showed no difference, however it have a

relatively similar form of pitting corrosion.

Figure 4: Image of macrostructure aging treatment material

(left) before corrosion test (rigth) after corrosion test.

(a)

(b)

(c)

Figure 5: Microstructure of top of material aging treatment

with (a) kontrol, (c) Escherichia coli (e) Pseudomonas

fluorescens (g) Thiobacillus ferrooxidans, and on bottom of

specimen with (b) kontrol, (d) Escherichia coli (f)

Pseudomonas fluorescens (h) Thiobacillus ferrooxidans.

ISOCEEN 2018 - 6th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management

162

(d)

(e)

(f)

(g)

(h)

Figure 5: Microstructure of top of material aging treatment

with (a) kontrol, (c) Escherichia coli (e) Pseudomonas

fluorescens (g) Thiobacillus ferrooxidans, and on bottom of

specimen with (b) kontrol, (d) Escherichia coli (f)

Pseudomonas fluorescens (h) Thiobacillus ferrooxidans

(cont.).

4 CONCLUSION

The non aging treatment material has the highest

corrosion rate of 1.189 mmpy with the addition of

Thiobacillus ferrooxidans at salinity of 37‰ and the

lowest corrosion rate of 0.186 mmpy at salinity of

33‰. However, the aging treatment material has the

highest corrosion rate of 0.770 mmpy and the lowest

corrosion rate of 0.175 mmpy at similary condition.

Based on microstructure results, uniform and pitting

corrosion occurred on all specimens with the addition

of bacteria or without the addition of bacteria.

However, the bacterial corrosion rates were different.

Aging Treatment on Aluminium AA6063 against Bacterial Corrosion Resistance in Marine Environment

163

It was identified that aging treatment on Aluminium

AA6063 can reduce the bacterial corrosion rate or

increased the corrosion resistance.

REFERENCES

American Society for Testing and Materials. 2004. ASTM

D1141-98 Standard Practice for Artificial Sea Water

ASTM Society.

American Society for Testing and Materials. 2002. ASTM

G1-03 Standard Practice for Preparing, Cleaning, and

Evaluating Corrosion Test. ASTM Society.

American Society for Testing and Materials. 2004. ASTM

G31-72 Standard Practice for Laboratory Immersion

Corrosion Testing of Metals. ASTM Society.

H. Pratikno, H.S. Titah. IPTEK, 2017. The J for Technol

and Sci 28(2) 55-58.

H. Pratikno, H.S. Titah. 2016. Asian J of Appl Sci 9 120-

125.

H. Pratikno, H.S. Titah. 2016. Int J of ChemTech Res 9(12)

600-609.

J. S. J. Andersen, H. W. Zandbergen, J. Jansen, C. Tráholt,

U. Tundal, and O. Reiso, 1998. Acta Mater., 46[9].

J.P. Harley, L.M. Prescott. 2002. Laboratory exercises in

microbiology. Fifth Edition McGraw−Hill Companies

Texas.

J.R. Davis Alloying: Understanding the Basics J.R. Davis,

2001. p351-416 DOI:10.1361/autb2001p351 ASM

International.

M. A. Abdel-Rahman, Alaa Aldeen Ahmeda and Emad A.

Badawi. 2010. Defect and Diffusion Forum 303-304:

107-112.

T. Nuhia, Abu Seerb , A. M. Al Tamimia , M. Modarres, A.

Seibib, 2011. Reliability Analysis for Degradation

Effects of Pitting Corrosion in Carbon Steel Pipes M.

Procedia Engineering 10:1930–1935.

ISOCEEN 2018 - 6th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management

164