Performance of the Ethanol Fueled Four-Stroke Engine by using the

Pressured Air Tubes and the Electric Fuel Pumps

Hedy Priyatno

1

, Hary Wibowo

1

, Anak Agung Putu S

1

, Parabelem Tinno Dolf Rompas

2

, Ellyawan

Setyo Arbintarso

1

1

Department of Mechanical Engineering, IST AKPRIND, Yogyakarta, Indonesia

2

Department of Informatic Engineering, Universitas Negeri Manado, Manado, Indonesia

ellyawan@akprind.ac.id

Keywords: Fuel Motor, Ethanol, Pressured Air Tube, Electric Fuel Pump.

Abstract:

This study presents the engine performance resulted from the use of ethanol fuel for a four-stroke

fuel motor with a fuel injection system using pressurized air tubes and an electric fuel pump.

Increase in the number of motorized vehicles has increased fuel consumption. This can increase

gas pollutants that pollute the air. So that it is necessary to convert the use of fuel oil to an

alternative fuel that is environmentally friendly and renewable, one of this is ethanol. Tests are

carried out at 4000 rpm to 7000 rpm at 1000 rpm intervals and data retrieval in the form of

torque, power and fuel consumption. The results have shown that at 4000 rpm to 5000 rpm

engine speed using a pressurized air tube there is a 40% increase in torque from the original 5

N.m to 7 N.m. Engine speed of 5000 rpm to 7000 rpm, torque and power produced using a

pressurized air tube is greater than that of an electric fuel pump. Using pressurized air tubes

increases power and specific fuel consumption (SFC) as engine speed increases

.

1 INTRODUCTION

In Indonesia, lately there are frequent fluctuations in

the supply and price of fuel oil (BBM). Data from

the 2013 oil and gas statistics center PT. Pertamina,

conveyed by the managing director, Indonesia's

crude oil production continued to experience a

fluctuating decline from 1977 to 2014, while

consumption continued to increase. This causes PT.

Pertamina as a state-owned enterprise (BUMN)

engaged in oil and gas production in Indonesia must

import crude oil to meet national fuel needs.

Indonesia's crude oil production is currently 65% of

the total national demand while the remaining 35%

is imported (Hardadi, 2015). This imbalance

between production and consumption will have an

impact on fluctuations in fuel supply and prices in

Indonesia. In the past 4 years, from 2013 to 2016,

there were 8 times changes in fuel prices on the

market. Factors that cause fuel consumption in

Indonesia are significant increase in the number of

motorized vehicles and the lack of use of renewable

energy. While fossil fuels or petroleum are fuels that

are non-renewable, we must start looking for

substitute fuels.

The use of fossil fuels also affects the negative

impacts on the environment that cause global

warming (Kartika and Kristanto, 2013). The issue of

global warming which is a world issue current

encourages several countries to implement go-green

and renewable energy-based technologies in all

industrial sectors, especially the automotive

industry. So to overcome this we have to look for

alternative fuels of many types and abundant and

environmentally friendly, one of which is ethanol.

The use of ethanol as a fuel for gasoline engines

(Otto) has been known since Henry Ford invented

the vehicle in 1896. After the exploration and

exploitation of petroleum began to be carried out by

humans, fuel oil became the main and preferred fuel

for gasoline vehicles (Otto). Although oil fuels

dominate the use of gasoline motors, ethanol has

become an alternative for the following reasons: (1)

Oxygenated Octan Booster as a substitute for

Tertiary Methyl Butyl Ether (MTBE) which is

allegedly having a bad impact on the environment,

Priyatno, H., Wibowo, H., Putu S, A., Rompas, P. and Arbintarso, E.

Performance of the Ethanol Fueled Four-Stroke Engine by using the Pressured Air Tubes and the Electric Fuel Pumps.

DOI: 10.5220/0009006400610066

In Proceedings of the 7th Engineering International Conference on Education, Concept and Application on Green Technology (EIC 2018), pages 61-66

ISBN: 978-989-758-411-4

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

61

(2) decreases exhaust emissions, and (3) reduce

consumption of fuel oil (Setiyawan, 2012).

Global ethanol production for transportation

fuels has tripled in 10 years, from 17 billion litres in

2000 to 86.9 billion litres in 2010, so that the total

production of ethanol can be used as an alternative

energy source to overcome fuel scarcity. The fuel

system is a system that is very important and very

influential on the performance of the motor fuel. On

gasoline fuel and air motorcycles must be able to

mix well before being burned by sparks from spark

plugs. The fuel system has the main function of

storing and distributing fuel and clouding fuel before

it is inserted into the cylinder (Rahmadi, 2012).

The application of the Electronic Fuel Injection

(EFI) system technology is expected to reduce

exhaust emissions, produce maximum power and

increase fuel efficiency (Nugraha, 2007). The engine

used in this study will be applied as a car drive

Kalisahak 28 that is energy-efficient cars fuelled by

ethanol with the concept of city car. This car is used

for energy-efficient vehicle competition where the

vehicle must travel as far as possible by using

energy to a minimum (more distance less energy) in

accordance with the slogan of the Shell Eco Marthon

Asia competition.

2 METHODS

The study process begins with preparations for the

condition of the 4 cylinder fuel motor (Pardede and

Sitorus, 2013; Sulistyo, 2011) that is not single

cylinder which will be tested using ethanol fuel and

pressurized air tube with a fuel injection system

(fuel injection). The test carried out a comparison of

the use of the pressurized air tubes with the electric

fuel pumps in the fuel injection system against the

performance of the engine produced. Engine

performance observed in this test is torque, power,

fuel consumption, and fuel efficiency.

The measurement of torque and power uses a

dynamometer and measurement of fuel consumption

using a measuring burette with a capacity of 25 ml

and a stopwatch as a timer. Retrieval of these data is

carried out at the same time.

The data collection procedures that will be

carried out are as follows:

1. Using a Pressurized Air Tube

a. Raise the motorcycle (Table 1 and Figure 1) over

the dynamometer (Figure 2) and tie it so it

doesn't move forward or backward.

b. Install the engine speed sensor on the coil cable.

c. Refuel the 100 ml transparent tank to the

maximum limit.

d. Install all components of the pressurized air tube

system according to Figure 3 and set the pressure

of the injector tube to 3.2 bar.

e. Adjust the engine speed so that it works at 4000

rpm.

f. Calculate the time for 20 seconds when the

machine is working on a specified rotation.

g. Turn off the engine.

h. Save the test results data that appears on the

Laptop.

i. Filling the fuel to the maximum limit of the tank

with a burette so that the difference in fuel

consumption used for 20 seconds in millilitres is

recognized.

j. After all test data is obtained, and then repeat the

testing procedure for engine speed from 5000 to

7000 rpm with multiples of 1000 rpm.

Figure 1: Flowchart of process study.

2. Using an Electric Fuel Pump

a. Raise the motorcycle (Table 1 and Figure 1) over

the dynamometer (Figure 2) and tie it so it

doesn't move forward or backward.

b. Install the engine speed sensor on the coil cable.

c. Filling in a measuring cup that uses the electric

fuel pump (Figures 4 and 5) with a volume of ±

800 ml until the component of the fuel pump is

submerged.

d. Turn on the engine and adjust the engine speed

to 4000 rpm.

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

62

e. Calculate the time for 20 seconds when the

machine is working on a specified rotation.

f. Turn off the engine.

g. Save test result data that appears on the monitor

screen.

h. Remove the fuel pump from the measuring cup,

then fill the measuring cup with fuel using a

burette until the initial volume so that the

difference in fuel consumption is used for 20

seconds in millilitres.

i. After all test data is obtained, and then repeat the

testing procedure for engine speed from 5000 to

7000 rpm with multiples of 1000 rpm.

Table 1: Motorcycle engine test specification of Yamaha

Mio J (PT. Yamaha Indonesia Motor Mfg., 2018)

Item Standard

Engine type

4 stroke, 2 Valve SOHC,

single cylinder

Diameter x stroke

54,5 x 57,9 mm

(modification)

Cylinder volume 135 cc

Compression 13 : 1(modification)

Inlet Valve diameter 25 mm

Outlet valve

diameter

21 mm

Fuel system Fuel Injection, Single

Injector Type Indirect Injector, 4 hole

Throttle Body

Single, *Std (Yamaha Mio

Soul GT)

Fuel Injector Sensor *Std (Yamaha Mio J)

Electronic control

unit (ECU)

*Std (Yamaha Mio J)

Ignition system

Transistor Control Ignition

(digital), Busi.

Cooling system Air

Transmission

system

Automatic Sprocket

Starter system

Electric Starter & Kick

Starter

Fuel pump

Electrical Pump, (Yamaha

Mio J).

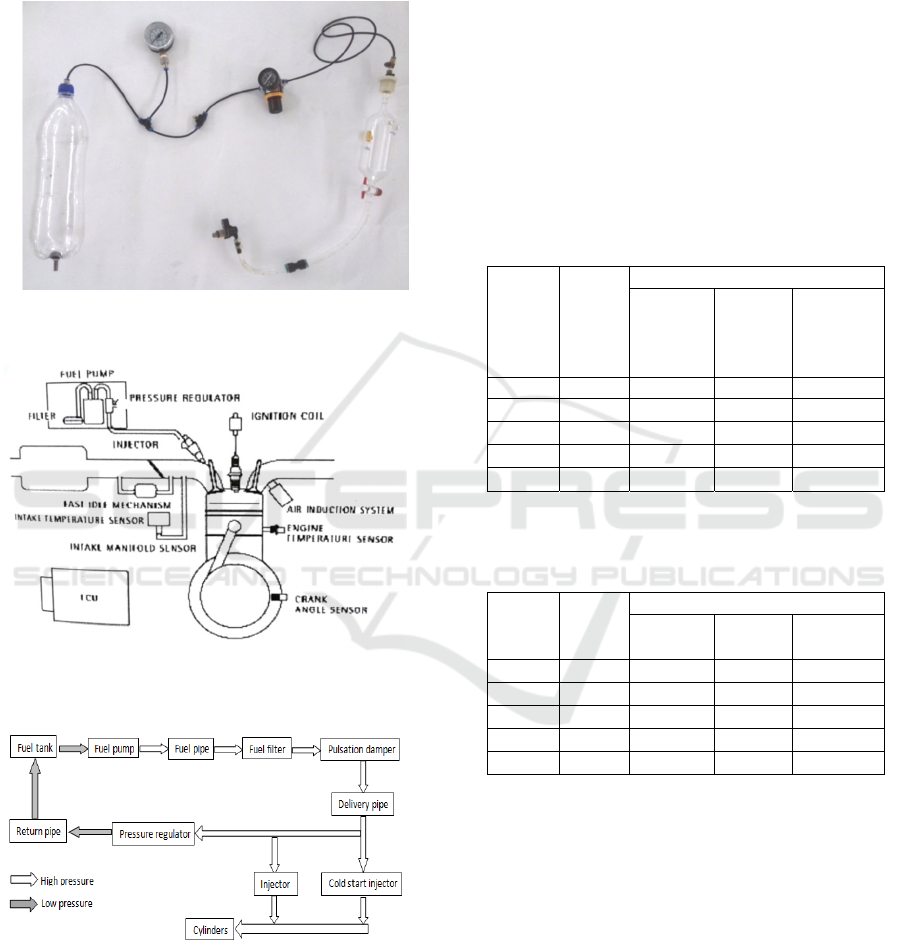

Testing of the engine performance used the

pressurized air tubes (Figure 3) as a substitute for the

function of the electric fuel pump on the fuel

injection system (Figures 4 and 5). A series of air

tubes made of modified plastic bottles and added

pressure regulator to regulate the pressure to the

injector.

The fuel mass flow rate (Cengel and Boles,

1989) used equation (1) for calculation of the

specific fuel consumption where fuel volume (

) in

millilitre, ρ

(fuel specific weight) in kg/m

3

, and t

(time) in sec.

=

ρ

(1)

s =

(2)

Figure 1: Sample of test (motorcycle of Yamaha

MIO J).

Figure 2: Dynamometer.

Performance of the Ethanol Fueled Four-Stroke Engine by using the Pressured Air Tubes and the Electric Fuel Pumps

63

The specific fuel consumption (Cengel and

Boles, 1989; Moran and Saphiro, 200)) in equation

(2) is calculated for using the pressurized air tubes

and the electric fuel pump respectively where the

power (Ne) in kW.

Figure 3: Components of pressurized air tubes.

Figure 4: Electronic fuel pump system.

Figure 5: Fuel delivery scheme in electronic fuel

pump system.

3 RESULTS AND DISCUSSION

Table 2 shows the effect of engine speed on torque,

power, and fuel consumption by using pressurized

air tubes for 20 seconds. Engine speed up to 5000

rpm, torque increases but after that the torque starts

to decrease and fuel consumption continues to

increase. Whereas power is increasing steadily with

increasing engine speed and fuel consumption.

When after 5000 rpm engine speed, torque begins to

decrease due to the influence of pressurized air tubes

that can reduce fuel when unused (Susilo and

Nugroho, 2012).

Table 2: Effect of engine speed on torque, power and fuel

consumption using pressurized air tubes.

Engine

Speed

(rpm)

Time

(sec)

Electric Fuel Pump

Torque

(Nm)

Power

(kW)

Fuel

Consump

tion

(ml)

Idle 20 0.00 0.00 3.00

4000

20

6.00 2.50 5.50

5000

20

5.95 3.10 9.10

6000

20

6.10 3.85 10.20

7000

20

5.25 4.10 23.50

Table 3: Effect of engine speed on torque, power and fuel

consumption using electric fuel pump.

Engine

Speed

(rpm)

Time

(sec)

Pressurized Air Tube

Torque

(Nm)

Idle

20 0.00 0.00

1.40

4000

20 5.00

2.10 4.30

5000

20 7.00

3.70 8.30

6000

20

6.15

4.00

14.80

7000

20

5.90 4.25 17.90

Table 3 shows the effect of engine speed on

torque, power, and fuel consumption using an

electric fuel pump. At an engine speed of 4000-7000

rpm, torque fluctuates while power and fuel

consumption increase respectively. The torque

fluctuates due to the use of an electric fuel pump that

functions to make fuel more economical, cleaner

exhaust gas, and more perfect combustion of fuel

and air (Hidayat, 2012).

Figure 3 shows a comparison of the specific fuel

consumption between the use of pressurized air

tubes and an electric fuel pump. Specific fuel

consumption increases in the use of pressurized air

tubes, while in the use of electric fuel pumps, it

fluctuates. At engine speeds of up to 5000 rpm and

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

64

7000 rpm, the use of compressed air tubes is more

economical fuel consumption compared to the use of

electric fuel pumps. That's because the air pressure

given by the use of pressurized air tubes is lower

than the use of electric fuel pumps. In contrast, at

6000 rpm engine speed, the use of electric fuel

pumps is more economical than the use of

pressurized air tubes. That is because the air pressure

provided by the electric fuel pump is lower than the

use of pressurized air tubes. In principle, both uses

function to regulate the fuel entering the combustion

chamber according to the working conditions of the

engine (KMHE, 2016).

Figure 3: Comparison of specific fuel consumption

using pressured air tube and fuel pumps.

Based on the results obtained in Table 2, Table

3, and Figure 3, it can be explained that the

performance of the four stroke motor which uses

pressurized air tubes is more efficient in consuming

ethanol fuel than the use of electric fuel pumps,

especially at 4000 rpm engine speed, 5000 rpm and

7000 rpm.

4 CONCLUSIONS

The performance of the engine produced by using

the pressurized air tubes at engine speed of 4000

rpm to 5000 rpm increase torque of 40% and

decrease at engine speed of 5000 rpm to 7000 rpm.

Increased power and specific fuel consumption

followed by increase engine speed. The use of

electric fuel pumps for engine speed of 4000 rpm is

more powerful than the use of pressurized air tubes.

At engine speed of 5000 rpm to 7000 rpm where

torque and power generated by using the pressure air

tube is greater than that of an electric fuel pump. At

6000 rpm engine speed, the use of electric fuel

pumps is more fuel efficient than pressurized air

tubes. The performance of the 4 stroke fuelled

ethanol engine is better by using the pressurized air

tubes as a whole than by using the electric fuel

pumps.

ACKNOWLEDGEMENTS

The authors wish to thankful to head of engine

laboratory, IstAkprind Yogyakarta who helped in the

studi.

REFERENCES

Cengel, Y. A., Boles, M. A., 1989. Thermodynamics: an

engineering approach, McGraw-Hill Book Co,

Singapore.

Hardadi, R., 2015. Kondisi Pasokan dan Permintaan BBM

di Indonesia dan Upaya Pertamina dalam Pemenuhan

Kebutuhan BBM Nasional”, Direktur Pengolahan, PT.

Pertamina.

Hidayat, W., 2012. Motor bensin modern, Rineka Cipta,

Jakarta.

Kartika, I. S., Kristanto, P., 2013. Konversi penggunaan

bahan bakar bensin ke

bahan

bakar ethanol pada

motor bakar 4 langkah untuk sepeda motor, Tugas

Akhir

Teknik

Mesin, Universitas Kristen Petra,

Surabaya.

KMHE, 2016, Regulasi teknis kontes mobil hemat energi

(KMHE), UGM, Yogyakarta.

Moran, M. J., Saphiro, H. N., 2000, Termodinamika

teknik jilid 2, Terjemahan

oleh

Yulianto Sulistyo

Nugroho & Adi Surjosatyo, 2004, Erlangga,

Jakarta.

Nugraha, B. S., 2007. Aplikasi Teknologi injeksi bahan

bakaar elektronik (EFI) untuk mengurangi emisi gas

buang sepeda motor, UNNES, Semarang. Vol. 5, pp.

692-706.

Pardede, S. T., Sitorus, T. B., 2013. Kinerja mesin sepeda

motor satu silinder dengan

bahan

bakar premium

dan etanol dengan modifikasi rasio kompresi,

Jurnal e-Dinamis.,

Vol.

4, No.4 March 2013, pp.

229-238.

PT. Yamaha Indonesia Motor Mfg., 2018, Yamaha

genuine parts, Available in http://www.yamaha-

motor.co.id/nc/spare-parts/ygp/ygp-detail/item/fi-

parts.html. Accessed on 30 June 2018.

Performance of the Ethanol Fueled Four-Stroke Engine by using the Pressured Air Tubes and the Electric Fuel Pumps

65

Setiyawan, A., 2012. Kajian ekperimental pengaruh etanol

pada premium terhadap karakteristik pembakaran

kondisi atmosferik dan bertekanan di motor otto

silinder tunggal sistem injeksi, Disertasi Teknik

Mesin, Universitas Indonesia, Depok.

Sulistyo, B., 2011. Karakteristik electronic ethanol

injection pada mesin bersilinder tunggal, Tesis ,

UGM, Yogyakarta.

Susilo, T., Nugroho, A. A., 2015. Sistem bahan bakar pada

mobil proto type diesel, Tugas Akhir Teknik Mesin,

IST AKPRIND, Yogyakarta.

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

66