The Durability of Asphalt Concrete with Dammar Resin Binder

Thien Giang Hao and Ary Setyawan

Department of Civil Engineering, Faculty of Civil Engineering, Sebelas Maret Surakarta Universitas (UNS), Jalan Sutami

36 A Surakarta 57126, Central Jawa, Indonesia

Keywords: Marshall Quotient, Long Term Oven Aging, Short Term Oven Aging, Indirect Tensile Stiffness Modulus

Abstract: The aging process of daspal on paved concrete pavement layers occurs during mixing in the Asphalt Mixing

plant and the time of service life. The process of aging of the daspal when mixing is called short-term aging

and aging of the daspal during the lifetime of the road service is called long-term aging. The study was

conducted in a laboratory with an oven method for simulating aging. The short-term aging method (Short

Term Oven Aging, STOA) is the testing of the specimens at 135

0

C before compacting for 4 hours representing

aging of the daspal mixture at the time of production of the asphalt mixture from on-site carriage to sealing.

The long-term aging testing methods (Long Term Oven Aging, LTOA) was performed 85

0

C after the

condensation for 48 hours representing a service period of 5 years. The aim of this research is to know the

effect of the process of daspal aging with respect to concrete asphalt. The research covers the value of

Stability, Flow, Marshall Quotient, VIM, VFB, Density, and Indirect Tensile Stiffness Modulus. This research

uses the optimum modification of the basic composition of resin (100 gr of pure resin or chunks + 350 gr of

dammar powder), fly ash powder (150 gr) and cooking oil (205 gr) and 4 % latex mixed by way of cooking

at temperatures below 150

o

C. The composition scored a ductility of 115.5 cm, flash point 260

o

C, penetration

43 dmm and specific gravity 0.99 gr/cm3. Results indicated stability (1906.48 kg), Flow (4.6 mm), VIM

(3.79%), VFB (74.2 %), Marshall Quotient (421,45 kg/mm), Density (2,36g /cm

3

). Therefore, it can be said

that the daspal test object satisfies the requirements as a mixture of AC - WC of coarse gradation. Result of

ITSM test at temperature 20

0

C is equal to 11156 MPa, at 30

0

C equal to 6930 MPa and at 40

0

C equal to 5127

MPa. For flexible pavement layer thickness analysis with SPDM Software Bisar 3.0 at all temperature

variation, results showed that Thickness value that is 24 cm at temperature of 20

0

C, 30,6 cm at 30

0

C and

35,3 cm at 40

0

C.

1 INTRODUCTION

The development of highway construction is very

rapidly developed, where all human activities are

using land transportation, so the construction and

maintenance of the highway is the main concern of

the government, to get a sense of security,

comfortable for the users of the highway. One of the

causes of a decrease in the strength of the mixture on

the flexible pavement is the aging process. According

to Huber and Decker (1995) in his research entitled

Engineering Properties of Asphalt Mixtures and the

Relationtiship to Their Performance which refers to

the ASTM method says that the short term ovulation

process (Short Term Oven Anging, STOA), oven

done at 135

°

C for 4 hours before compacting. The

STOA simulation was carried out to determine the

aging of the asphalt mixture during the process of

preparing the dosage mixture of the dioxide mixing

base (AMP), during the transporting and spreading of

the field, while the Long Term Oven Anging (LTOA)

testing procedure was carried out at 85

0

C for 48 hours

after compaction. LTOA simulation is done to find

out aging of asphalt mixer during service period. In

the study stated that the test at 85

°

C for 48 hours

represents mixed ages for 5 years in the field.

Therefore, this research is done by making specimens

of STOA and LTOA by testing using Marshall Test

method so that the aging daspal mixture can be known

the level of air (porosity), stability and flow.

In this research will be aging process on

aggregate mixture with Asphalt Concrete Wearing

Course (AC-WC) coating, by making specimens

STOA and LTOA using Marshall Test. The AC-WC

mixture is used because it is a wear-resistant coated

top surface that has direct contact with the vehicle

load on it, which is affected by temperature so that it

undergoes aging.

Giang Hao, T. and setyawan, A.

The Durability of Asphalt Concrete with Dammar Resin Binder.

DOI: 10.5220/0009007001030107

In Proceedings of the 7th Engineering International Conference on Education, Concept and Application on Green Technology (EIC 2018), pages 103-107

ISBN: 978-989-758-411-4

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

103

Figure 1: Process of the specimens production.

One of the mixed performance parameters in the

flexible pavement is the durability of the pavement

due to weather and water effects. Road conditions that

are always submerged by water will decrease the

durability of the pavement layer of the pavement.

This becomes even worse when at the time of the

process of preparing a mixture of batches, during

transport, on-site deployment, and during the service

period aging on the dacal mixture, thereby reducing

the performance of asphalt pavement such as low

stability values, intercellular cavities or less dense

mixtures and bad durability. The parameters used to

see the durability level of the asphalt mixture are the

parameters used in comparing the stability test value

with the standard stability.

2 EXPERIMENTAL

2.1 Specimens Preparation

This research uses the composition of resin (100 gr of

pure resin or chunks blend to 350 gr of damar

powder), fly ash powder (150 gr) and cooking oil

(205 gr) and 4% latex mixed by way of cooking at

temperatures below 150

o

C (Haryanto, 2012). The

details of specimens production process is shown in

Figure 1.

After completion daspal modification, will make

the specimen samples.

Mix the aggregate and the asphalt according to the

result of the mix design of the optimum dosage

content.

Mix the mixture evenly in the presence of heating

to 150 ° C, then mix it in the mold.

The mixture is compacted with the compactor 75

times on both sides.

Provide code on each specimen.

The test object is silenced at room temperature,

then remove from the mold with the help of the

jack.

2.2 Test Procedure

The design of the baseball mixture begins by testing

the quality of the base material consisting of

aggregates and some materials, among the resin gum,

goring oil, latex, used oil, fly ash, which is presented

as a binder layer of dspal. The test standard used is

for job design mix testing based on SNI 03-1737-

1989 (BSN, 1989). Preparation of test specimens with

optimum dosage content of resin (100 gr of pure resin

or chunks + 350 gr resin pack or powder), fly ash (150

g), cooking oil (205 g) and 4% latex mixed by

cooking at below temperature 150

o

C. With this

optimum level, the test object will be tested for

resistance to short-term aging (STOA) and long-term

(LTOA).

The short-term aging method (Short Term Oven

Aging, STOA) is the testing of the specimens at

135

0

C before compacting for 4 hours representing

aging of the daspal mixture at the time of production

of the asphalt mixture from on-site carriage to sealing.

The long-term aging testing methods (Long Term

Oven Aging, LTOA) was performed 85

0

C after the

condensation for 48 hours representing a service

period of 5 years. Furthermore, to measure the effect

of weathering is done by measuring the stability and

melting with the Marshall testing apparatus

complying with AASHTO T245-74 (Braceras, 2015).

The research covers the value of Stability, Flow,

Marshall Quotient, VIM, VFB, Density, and Indirect

Tensile Stiffness Modulus with standard test

temperatures of 20

o

C, 30

o

C and 40

o

C.

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

104

Table 1: Determining Characteristics of AC-WC mixture.

Mixture Characteristics Spec. AC-WC Corse Gradation

Effective daspal content (%) Min. 4.3

Void in aggregate (VMA) (%) Min. 14

Void in mixture (VIM)(%)

Min. 3

Maks. 5

Void in asphalt (VFB) (%) Min. 65

Marshall stability (kg) Min. 800

Flow (mm) Min. 3

Marshall Quotient (kg/mm) Min. 250

In this study, the analysis used the comparison

method with characteristic properties of the daspal

mixture with the characteristics of the mixed layer

AC-WC on the Bina Marga (2010) specification.

Later, the Inderect Tensile Stiffness Modulus test to

find the modulus of rigidity in purpose of designing

the thickness of daspal in the field.The AC-WC

mixture characteristics are shown in Table 1.

Indirect Tensile Stiffness Modulus is the most

conventional laboratory testing method to calculate

the asphalt stiffness modulus mixture. This method

became the UK Standard Draft for the Development

of BS DD 213 (BSI1998) and is similar to the resilient

modulus test described by ASTM D-4132 (ASTM

1996). According to standard, Indirect Tensile

Stiffness Modulus this test is a non-destructive test

and has been identified as a method for calculating

the average stiffness of the modulus of the material.

The ITSM Test Specimens are shown in Table 2.

Table 2: ITSM Test Specimen

Sample

Code

Target Temperature

Number of

Specimens

20

°

C 30

°

C 40

°

C

DP 3 3 3 9

STOA 3 3 3 9

LTOA 3 3 3 9

(Note: DP: sample daspal murni, STOA: sample daspal

after short term oven aging process, LTOA: sample daspal

after long term oven aging process).

With uniaxial sinusoidal loading, the modulus

stiffness is generally defined as the ratio of maximum

stress to maximum strain. Indirect Tensile Stiffness

Modulus in MPa is calculated sing equation (1).

ITSM

27

(1)

Where, L is the highest value of vertical load

applied (N), D is the average amplitude from

horizontal deformation obtained from 2 or more

applied loads (mm), T is an average thickness of

specimen (mm) and V is Poisson’s ratio (0.35).

3. RESULTS AND DISCUSSION

3.1. Characteristics of Daspal

Volumetric testing was performed prior to Marshall

testing. After the specimen is compacted using a

manual compactor, the test object is silenced for

approximately 2 hours or the specimen is in a state of

room temperature.

Volumetric testing was performed prior to

Marshall testing. After the specimen is compacted

using a manual compactor, the test object is silenced

for approximately 2 hours or the specimen is in a state

of room temperature. Results of daspal volumetric

and Marshall test are shown in Table 3 and 4

respectively.

Table 3: Results of Daspal Volumetric Test

Sample

Code

VIM

(%)

VMA

(%)

VFB

(%)

Density

(t/m3)

DP 3.79 14.6 74.2 2.36

STOA 4.42 15.16 70.83 2.34

LTOA 3.19 14.06 77.29 2.37

Spec. 3.5-5 Min 14 Min 65 --

Table 4: Results of Daspal Marshall Test

Sample

code

Daspal

Contain

(%)

Flow

(mm)

Stability

(kg)

MQ

(kg/m)

DP 5.5 4.6 1906.48 421.45

STOA 5.5 4.8 2290.61 479.45

LTOA 5.5 3.8 2812.88 741.42

Spec - min 3 min 800 min 250

The result shows that in DP condition, STOA

condition, LTOA condition the VIM, VMA and VFB

is good value, with the minimum specification

requirement, it can be said that the condition of the

The Durability of Asphalt Concrete with Dammar Resin Binder

105

Figure 2: Resilient modulus of daspal against varying daspal temperature.

specimen above meets the requirements as a mixture

of coarse gradation AC-WC.

The value of stability has increased, this can be

seen with the result of 1906.48 kg in normal

conditions, 2290,61 kg at 5 years condition STOA,

and 2812,88 kg at 15 years condition LTOA. This

suggests that with added time of heating causes

locking between the aggregate particles and the

binding capacity of the aggregate becoming stronger,

as well as better cohesion and adhesion of the

carbons. However, the higher the stability the more

likely it can cause the pavement to crack and if too

low causing deformation. With a minimum

specification requirement of 800 kg, it can be

concluded that the condition of the specimen above

meets the requirements as a coarse-gradation AC-WC

mixture.

In the STOA condition, the MQ value has

increased from normal condition. In STOA condition

MQ value of 479.45 kg/mm while in normal

condition has a value of 421.45 kg/mm. This is due to

the aging process which causes evaporation/oxidation

to the daspal mixture so that the interlocking bond

between the aggregates and daspal increases,

resulting in the mixture having proven increased

flexibility. With the minimum specification

requirement of 250 kg/mm, it can be judged that the

condition of the specimen above meets the

requirements as a coarse-grained AC-WC mixture.

3.2 Indirect Tensile Stiffness Modulus

Indirect Tensile Stiffness Modulus is performed to

calculate the dispersion resistance capability of a

mixture on the pavement and back to its original

shape. After the manufacture of specimens with

optimum asphalt content (KAO), the ITSM tests of

each of the 9 test specimens were tested at 20

o

C, 30

o

C

and 40

o

C temperature using Material Testing

Apparatus (MATTA). Test Results Indirect Tensile

Stiffness Modulus is presented in Table 5.

Table 5: Results of Daspal Marshall Test

Sample Code

Resilient Modulus (MPa)

20

0

C 30

0

C 40

0

C

DP 11156 6930 5127

STOA 19378 9540 6029

LTOA 18648 7868 5234

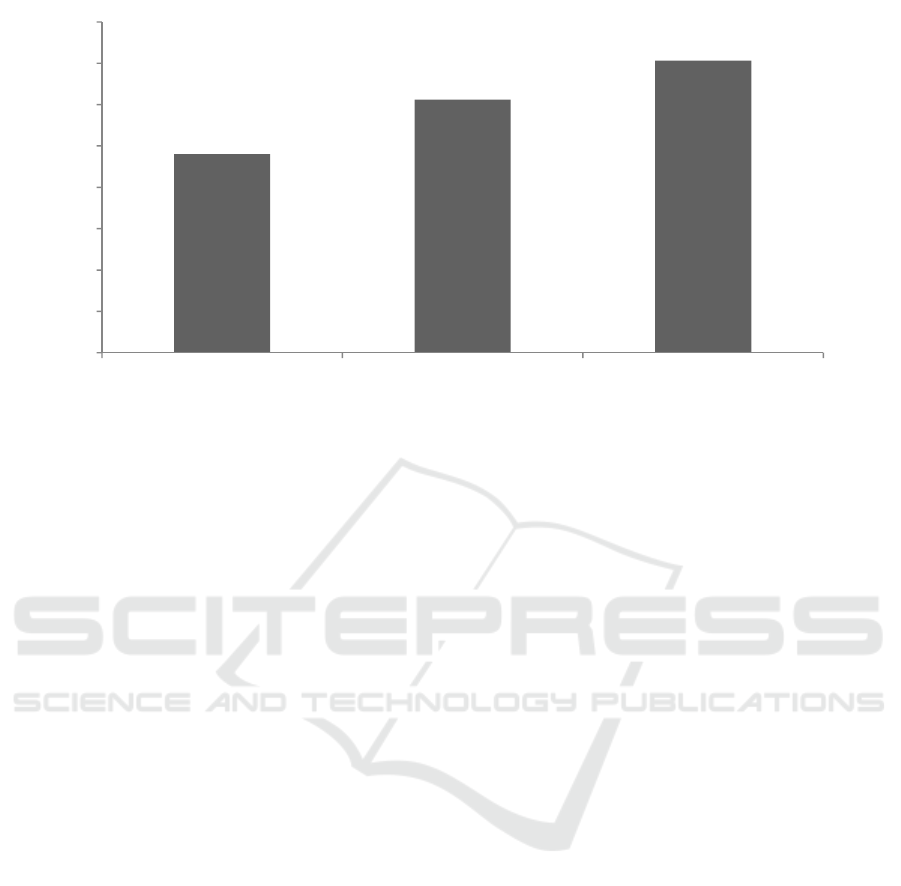

From Table 5 it can be converted into a total graph

of the relationship between the Resilient Modulus of

the daspal and the varying temperature of the daspal

can be presented in Figure 2.

The value of ITSM is greater at lower

temperatures. This corresponds to the nature of the

asphalt becoming more rigid at lower temperatures.

Figure 2 shows that the results of ITSM on daspal

under STOA conditions decreased from 19378 MPa

values at 20

0

C to 9540 MPa at 30

0

C and 6029 MPa at

40

0

C. As for pure daspal (DP) conditions and daspal

of LTOA conditions also decreased in ITSM with

temperature rise. Thus, the daspal of STOA condition

has better values of ITSM than the pure daspal of

LTOA conditions. This suggests that the aging

process makes the daspal better than the daspal before

aging.

3.3 Daspal Thickness Design According

to ITSM Values

The outcome of flexible pavement thickness design

with SPDM Bisar 3.0 Software Program is presented

in Figure 14 as follows:

The thickness design of daspal pavement layer

using Bisar 3.0 software as shown in Figure 3

confirms that the smallest thickness design value (24

0

2500

5000

7500

10000

12500

15000

17500

20000

20°C 30 °C 40 °C

Resilient Modulus

Daspal Temperature

Poly. (DP) Poly. (STOA) Poly. (LTOA)

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

106

Figure 3: Daspal thickness design with different temperature variations

cm) at 20

0

C temperature compared to other

temperature conditions. This shows that for effective

daspal pavement thickness should be designed at

20

0

C as optimal.

4 CONCLUSION

Based on this research with the effect of aging on the

characteristics of daspal using Bina Marga 2010

Specification, it can be concluded that the stability

value of the concrete mixture of the daspal has

increased significantly due to the aging of daspal in

the mixture. When value of daspal stability is too high

it leads to easy cracking. The flow value of mixture

slightly increased in STOA condition and decreased

in LTOA condition due to longer oven periods. The

void in the mixture (VIM) increased in STOA

condition and slightly decreased in LTOA condition

due to aging process. The value of void in daspal

(VFB) decreased in STOA conditions and increased

in LTOA conditions due to the aging process.

Indirect Tensile Stiffness Modulus (ITSM) value

under conditions DP, STOA and LTOA test

specimens can be concluded that the STOA is the

most effective condition because it has the greatest

rigidity modulus value.

The result of daspal pavement layer thickness

analysis with SPDM Software Bisar 3.0 method

concluded that in all temperature variation, it is better

to design the thickness of daspal layer based at the

temperature 20

0

C because the smallest thickness

design value (24 cm).

REFERENCES

Huber, G. A., Decker, D. S., 1995. Engineering Properties

of Asphalt Mixtures and the Relationtiship to Their

Performance, ASTM. Philadelphia, 1

st

Edition.

Haryanto, H., 2012. The Development of Research-based

Learning and Education for Sustainable Development

for Pavement Highway Course by Utilizing the Results

of Applied Research Eco-material, Gajah Mada

University. Yogyakarta.

BSN, 1989. SNI 03-1737-1989 TATA CARA Pelaksanaan

Lapis Aspal Beton (Laston) Untuk Jalan Raya, Badan

Standarisasi Nasional. Indonesia.

Braceras, C. M., 2015. AASHTO T245-2015 - American

Association of State Highway and Transportation

Officials, Standard Method of Test for Resistance to

Plastic Flow of Asphalt Mixtures Using Marshall

Apparatus. American Association of State Highway

and Transportation. Wasington.

Marga, B., 2010. Specification Document of General

Specification of Road and Bridge Construction Works,

Departemen Pekerjaan Umum – Direktorat Jendral

Bina Marga. Jakarta.

Institution, B. S., 1998. Indirect Tensile Stiffness Modulus

Test (BSI DD 213 1998), British Standard Institution,

United Kingdom.

ASTM D-4132. American Society for Testing and

Materials. Standart Test Method for Indirect Tension

Test for Resilient Modulus of Bituminous

Mixtures.Wasington.

0

5

10

15

20

25

30

35

40

20 °C 30 °C 40 °C

Thickness Daspal (cm)

Temperature

The Durability of Asphalt Concrete with Dammar Resin Binder

107