Implementation of Lean Project Management in Offshore Pipeline

Installation Project

Novanti Ismi Yusri, Silvianita, Daniel M. Rosyid, Suntoyo and Wimala L. Dhanistha

Ocean Engineering Department, Institut Teknologi Sepuluh Nopember, Surabaya, Indonesia

Keywords: Lean Project Management, Waste, Critical Chain, Fuzzy FMEA, Offshore Pipelines Installation.

Abstract: Project implementation is inseparable from the risks that can affect the project will go according to plan or

not. Therefore, good project management is very important to avoid project problems such as delays. Project

delays can be caused by unproductive activities and the elements involved. The un-producibility becomes

something that does not have added value or in Lean Project Management known as Non-Value-Added

Activities (waste). In the implementation of the Offshore Pipeline Installation Project undertaken by one of

the oil and gas companies in Indonesia, there was a delay in the process, therefore a risk analysis of the causes

of the delay is required with the Lean Project Management approach to identify waste by applying the

Fishbone Analysis method and project risk analysis using the Fuzzy Failure Mode and Effect Analysis method

that will prevent or detect the failure mode earlier. And to estimate the project, it is applied by using the

Critical Chain Project Management (CCPM) method which will produce project optimization to meet the

Lean Project Management criteria, namely eliminating invaluable activities in order to make the project more

effective and efficient.

1 INTRODUCTION

The oil and gas industry have an important role in the

mineral resources needed by the state for its people.

With abundant oil and natural gas reserves in

Indonesia, facilities are needed to support these natural

resources. One of the infrastructures that are widely

used for natural resources is using subsea pipelines.

Therefore, this company carried out the offshore

pipeline installation project in order to maintain the

company's basic production and to obtain additional

production. This project is basically to install a new

pipeline and to replace the damaged pipeline.

In its implementation, the Offshore Pipeline

installation project undertaken by this company was

delayed, but in the end, the project could be

completed on time. Seeing the various things that

happened and the number of methods used in project

planning, this paper will identify an offshore pipeline

development project planning with the concept of

Lean Project Management. This paper discusses the

risks of pipeline project delay and optimize it. Many

methods can be used to analyse the delay of a project,

one of the mare using fishbone diagram which

functions as a method for analysing the causes of

project delays that are divided into several causal

indicators, namely machine, material, and method

workers (Khotimah, 2019). By using the fishbone

method to analyse project waste and using the CCPM

method to plan schedules to avoid Student Syndrome

and Parkinson's Law Effects, it allows the writer to

optimize and streamline project planning to be more

effective and efficient.

2 METHODOLOGY

The flow work in this study conducted by stages

based on the following steps. The first step is data and

reference materials collection from textbooks,

journals, previous research etc. During this stage a

comprehension study of Lean Project Management,

Critical Chain Project Management are also

conducted for optimization project.

2.1 Data Collection

The flow and procedure of the research were carried

out in the following stages. This stage includes efforts

in understanding offshore pipeline studies, the use of

the CCPM method and the collection of data needed

to complete this paper. The data required include:

100

Yusri, N., Silvianita, ., Rosyid, D., Suntoyo, . and Dhanistha, W.

Implementation of Lean Project Management in Offshore Pipeline Installation Project.

DOI: 10.5220/0010057501000105

In Proceedings of the 7th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management (ISOCEEN 2019), pages 100-105

ISBN: 978-989-758-516-6

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

• Details of project activities based on existing

schedule in accordance with project contract.

• Data analysis of the main problems of the

project.

2.2 Identify Waste using Fishbone

Diagrams

Identification of waste is done by using fishbone

diagrams made from project’s data analysis of the

major problems and then discussed with expert

judgment. Expert judgment is a major source of

information that can provide vital input to project

managers, who must ensure that projects are completed

successfully, on time, and on budget (Szwed, 2016).

2.3 Managing Variation for

Optimization of Project Scheduling

using the CCPM Method

This scheduling begins by creating a network in

accordance with project data that has been obtained.

Then determine where the critical path is located.

Critical Chain Project Management (CCPM) is a

TOC tool used for planning and project management.

It can be used both in one-project and multi-project

structures where resources are being used in several

projects simultaneously (Izmailov, 2016).

2.4 Risk Control

In this risk control precautions are taken to reduce the

impact of the occurrence of risk variables that are in

the red zone, while in the green zone risk control is

not carried out because the impact can still be

tolerated. Efforts to minimize this risk are carried out

by implementing steps directed at the results of the

assessment of data obtained from the risk analysis

process. This is done by developing options and

determining actions to increase opportunities and

reduce threats to project objectives. Risk analysis

have been used in many areas namely risk analysis for

gas platform (Silvianita et al 2016).

3 RESULTS

3.1 Project Overview

Projects are one-time activities, with limited time and

resources to achieve predetermined outcomes, for

example products or production facilities (Soeharto,

1999). This project requires to maintain the

company's production base and obtain additional

production. This project is basically to install new

pipes and to replace pipes that are already damaged.

The project is located in the working area of one of

the oil and gas industries which is located about 80 -

200 km northeast of Jakarta. The replacement pipe

that will be replaced is 8 "NPS Gas Line from

Platform X to Platform Y.

Table 1: Pipe Description.

Year 2018

No

Pipeline

Name

Size

(inch)

Length

(Km)

Repair

Strategy

1. B – A 12” 1 Full

2. E – C 10” 7.2 Full

3. D – E 8” 7.2 Full

3.2 Data Collection

In this stage, data collection was obtained from the

results of Major Problem reports that occurred in the

project. Then the data is validated with interviews with

an expert that related to the causes of waste in this

study which is Offshore Pipeline Installation project.

3.3 Work Breakdown Structure

Work Breakdown Structure shows overall project

activities that used as a basis for determining volume

of work, duration of activity and also used as a

scheduling guide. Below is the table of activities on

Offshore Pipeline Installation project as follows:

Table 2: Work Breakdown Structure of Offshore Pipelines

Installation Project.

Activity Duration (Days)

Basic Engineering 210

Project Management Team (PMT) 129

Detail Engineering 113

Coated Pipe 10” 251

Pipe Bend 250

Crossing Material 274

Riser Clamp dan Riser Fabrication 49

Survey 8

Preparation 79

Pipeline Laying 8

Mobilization 26

Riser Installation 14

Instalasi Crossing 14

Precommissioning 8

Certification 33

Final Acceptance 22

Implementation of Lean Project Management in Offshore Pipeline Installation Project

101

3.4 Project System

A project that is experiencing delays is certainly due

to factors that influence waste (Hapsari, 2014). A

project that is experiencing delays is certainly due to

factors that influence waste. Waste in the project is

actually something that must be considered in the

sustainability of the project. Project system have been

carried out by understanding the project and

discussions with the implementer to identify the

waste that is likely to arise in project implementation.

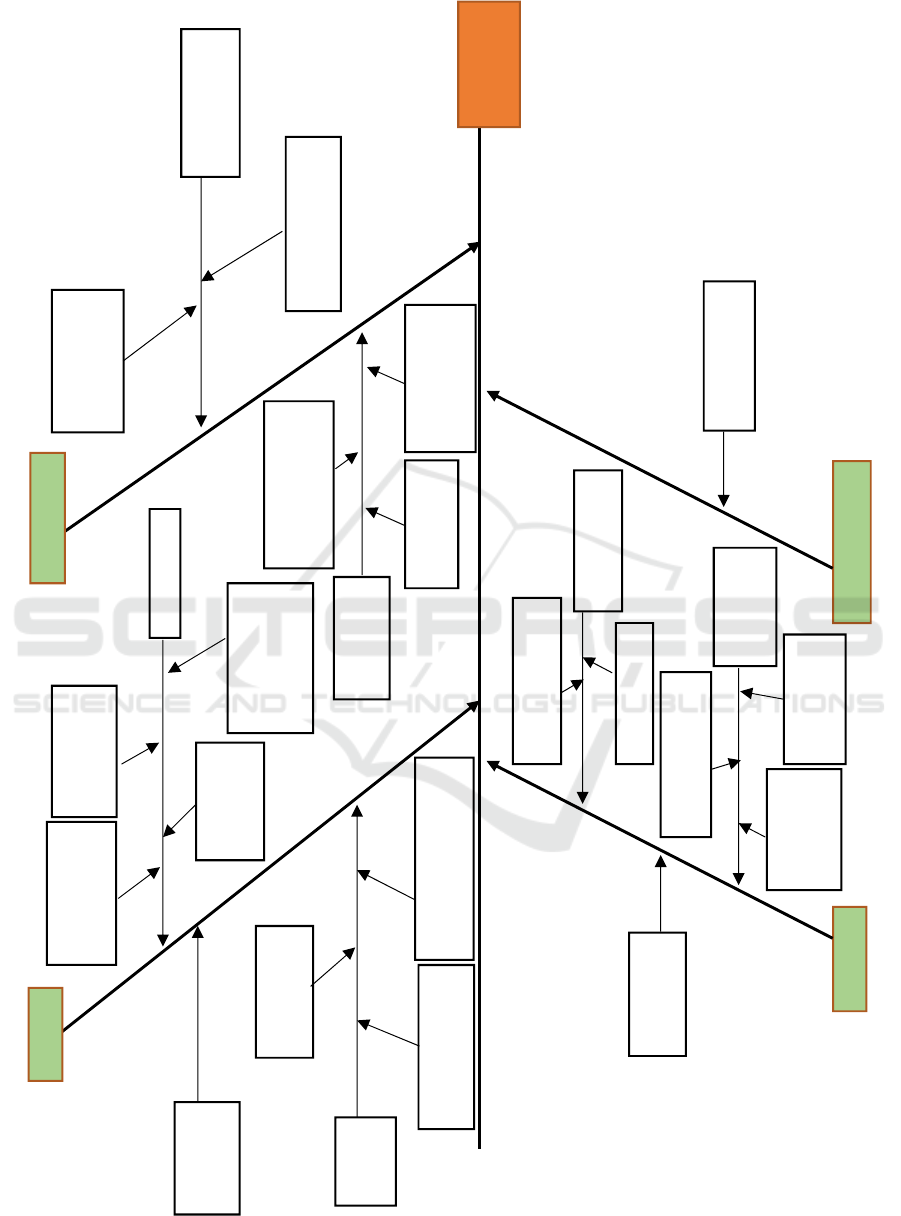

3.5 Waste Identification using Fishbone

Diagrams

Lean is an often-used adjective in business these days,

but there’s some confusion over its exact definition.

In essence, the goal of Lean is to maximize value

while minimizing waste (Eby, 2017). Identification of

waste or known as Non-Value-Added activity aims to

determine the waste that occurs in the project. The

identification process is done by using fishbone

diagrams and If-Then formulations so that the project

implementer can take appropriate corrective and

preventive actions for future projects where there is

the potential for waste to occur so that excessive

waste can be avoided. Based on fishbone diagrams

below, it can be seen the types of waste that most

often appear in Offshore Pipeline installation projects

from 8 waste that have been defined by Womack and

Jones (1996) are Waiting and Unnecessary Motion.

Waiting, which is a condition where project

activities have been delayed so that the delayed

activity can result in delays in project

implementation.

Unnecessary Motion, which is the movement that

is not necessary, where the movement of

unproductive workers that should not need to be done

in the implementation of the project.

From Figure 1, the Fishbone Diagram above can

be seen as the causes of waste generation in the

project. It contains 9 failure modes and 20 causes that

have been classified based on factors causing waste.

Those are Man, Material, Method, also Tools and

Machine. The causes of waste then processed into If-

Then formulation to further know possible actions

that implementer can take to minimize waste with

preventive or corrective steps.

3.6 Managing Variations

The variations contained in the project is considered

as uncertainty, therefore the project executor needs to

adjust the existing variations by estimating. In this

project, the variation made estimation is time. The

aim is that the project executor can estimate the time

needed during implementation.

Identification of waste in the project system

project analysis found that the most influential waste

in the project is waiting and unnecessary motion. By

knowing the waste, then the scheduling improvement

recommendations will be made with the Critical

Chain Project Management (CCPM) as follows.

3.7 Critical Chain Project

Management

All projects are carried out in a dynamic environment.

This is an inherent characteristic of project activities

which duration cannot be estimated precisely.

Estimate Activity Durations is the process of

estimating the number of work periods needed to

complete individual activities (PMBOK, 2013).

Among other factors, the accuracy of the estimation

depends on the level of uncertainty. Variation

problems must be addressed early in the development

schedule. Safety time must be included in the project

and must ensure its robustness. Time analysis have

been used in many areas such as in graving dock

project (Silvianita et al, 2018).

Table 3: Work Breakdown Structure with CCPM.

Pipeline Installation

Summary Task CCPM Duration (Days)

Basic Engineering 91

Project Management

Team (PMT)

105

Coated Pipe 10” 126

Pipe Bend 125

Crossing Material 137

Riser Clamp dan

Riser Fabrication

25

Survey 4

Preparation 40

Pipeline Laying 7

Mobilization 4

Riser Installation 13

Crossing Installation 7

Precommissioning 4

Certification 16

Final Acceptance 11

ISOCEEN 2019 - The 7th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management

102

Figure 1: Fishbone Diagram of Waste.

Waste

Man

Material

Tool & Machine

Method

Less

Competent

of Workers

Lack of dedicated

personnel on QC

personnel

Absence of

Supervisor and weak

su

p

ervision

Delay in the development of the

Offshore Installation Procedure

There is no material control

in the warehouse and

offshore

Material certification

has exceeded the

deadline and forgotten

e

q

ui

p

ment

Availability of

purchase material

re

q

uires a lon

g

time

Lack of

cooperation

between workers

Incompatibility of

Material

There are many

additional jobs per

da

y

Crew competency lacks

during project execution

Lack of dedicated

personnel on

Commissionin

g

Lack of Manpower to

prepare for procedure

execution

Shorthanded

Some QCs in the field

lack experience in

pipeline work and lack

of familiarity of Scope

Projects

Design Concrete

Mattress is too long

Riser Clamp installed

requires a long time

because it is not in

accordance with fabrication

Material supply is not

appropriate

Not using a measuring

instrument

p

ro

p

erl

y

Incompatibility of

Work Procedures

Worker accident

Job changes are not

accordin

g

to

p

rocedure

Work Planning

Not Running

Smoothly

Does not take into account

the installation system

Determination of

instructions lasts a

long time

There is no

coordination in the

installation

Implementation of Lean Project Management in Offshore Pipeline Installation Project

103

However, the addition of time will increase the

overall project duration, so that the lowest possible

amount of safety time must be added to the schedule.

CCPM controls several problems by including

buffers in the project schedule (Leach, 2000). In this

case, the CCPM adds a safety factor to the activity by

solving several factors that impact human actions in

the project environment. By applying the CCPM

method to project scheduling, it is expected that

problems that occur in the project, such as student

syndrome and Parkinson's law effects can be avoided.

3.8 Network Planning

In the initial stage, the Work Breakdown Structure

(WBS) is defined as a predecessor and successor

between activities.

Table 4: Network Activities.

Activity Predecessor Successor

Basic Engineering START A3,B2,B3,C1

Project Management

Team (PMT)

C1 D2

Detail Engineering A1,C1 C3

Coated Pipe 10” START B4

Pipe Bend A1 B4

Crossing Material A1 C4

Riser Clamp dan

Riser Fabrication

B1,B2 C5

Survey A1 A2,A3,C2

Preparation C1 C4

Pipeline Laying A3 D1

Mobilization B3,C2 C6,C7,D1

Riser Installation B4 C6,C7

Instalasi Crossing C4,C5 D1

Precommissioning C4,C5 D1

Certification C5,C6,C7 D2

Final Acceptance A1,D1 END

3.9 Buffer Management Analysis

This analysis is used to monitor the schedule that

already exists in Network Planning when the project

is executed. The application of the CCPM method

only requires supervision on the Project Buffer, in

contrast to some other scheduling methods that must

be monitored throughout the entire project activity.

This Buffer Management is useful for maintaining the

reliability of the project schedule but does not change

the critical trajectories that exist.

Figure 2: Buffer Distribution Area (Valikoniene, 2014).

Buffer Size =

2 x

⋯

(Eby, 2017)

Based on calculations and analysis, it has been

found that the amount of project buffer is 82.4 days.

From these results, will be divided equally based on

buffer distribution area.

Table 5: Buffer Use.

Buffer

Region

Range

Project

Buffer

(Days)

Used

Duration

(Days)

Green 0 % - 33 % 82 < 27,06

Yellow 34 % - 67 % 82

27,06 -

54,94

Red 68 % - 100 % 82 > 54,94

4 CONCLUSIONS

Based on the result of the analysis, it can be

concluded that the delay of the offshore pipeline

installation project was caused by 9 failure modes and

20 causes. And non-value-added activities or waste

that arises in offshore pipeline installation projects

based on 8 types of waste are waiting and

inappropriate processing. Activities that do not added

a value or waste that appears in offshore pipeline

installation projects based on 7 types of waste are

waiting and unnecessary motion. The application of

the CCPM method, the acceleration of work time in

ISOCEEN 2019 - The 7th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management

104

scheduling is 183 days and when the project buffer

has been used for more than 59 days or has entered

the red zone, the project implementer must take

action.

REFERENCES

Eby, K., 2017. The Definitive Guide to Lean Project

Management. Smartsheet.

Hapsari, R. I., 2014. Penerapan Metode Lean Project

Management dalam Perencanaan Proyek Konstruksi

pada Pembangunan Gedung SDN Bektihad 2 di

Semanding Tuban, Surabaya, Institut Teknologi

Sepuluh Nopember

Izmailov, Azar, et al. 2016. Effective Project Management

with Theory of Constraints. Science Direct. Russia.

Khotimah, H., 2019. Analisis Risiko Keterlambatan Proyek

Perbaikan Kapal Keruk Jenis Cutter SuctionDredger,

Surabaya, Institut Teknologi Sepuluh Nopember

Leach, L. P. 2000. Critical Chain Management. Boston:

Artech House.

PMBOK Project Management Body of Knowledge. 2013.

A Guide to the Project Management Body of

Knowledge 5th Edition. Pennsylvania Project.

Management Institute Standards Committee.

Soeharto, Iman. 1999. Manajemen Proyek dari Konseptual

sampai Operasional. Jakarta: Erlangga.

Szwed, P. S. 2016. Expert Judgment in Project

Management: Narrowing the Theory-Practice Gap.

United State of America: Project Management Institute,

Inc.

Valikoniene, L. 2014. Resource Buffer in Critical Chain

Project Management. Thesis. Faculty of Engineering

and Phisycal Science University of Manchester,

Manchester.

Silvianita Mohamad Lukman Nur Khakim, Daniel M.

Rosyid, Belinda Ulfa Aulia. 2016. “Risk Analysis Of

Return Support Material On Gas Compressor Platform

Project.” In International Conference, Coastal

Planning for Sustainable Marine Development, CITIES

2016. Surabaya, Indonesia.

Silvianita, Nur Aprillia, Yeyes Mulyadi, Wahyudi

Citrosiswoyo, and Suntoyo. 2018. “Cost and Time

Analysis of Graving Dock Project.” MATEC Web of

Conferences 177: 1–7. https://doi.org/10.1051/

matecconf/201817701028.

Implementation of Lean Project Management in Offshore Pipeline Installation Project

105