Effect of Cigarette Butts Extraction on the Corrosion Rate of ASTM

A36 for Jacket Platform

Caroline Agustina

1

,

Pandhu Dirga Pratama

2

, Anallenian Selviana

1

, Suntoyo

1

and Sony Junianto

1

1

Department of Ocean Engineering, Institut Teknologi Sepuluh Nopember, Indonesia

2

Department of Chemical Engineering, Institut Teknologi Sepuluh Nopember, Indonesia

Keywords: Jacket Platform, Inhibitor, Cigarette Butts, Nicotine.

Abstract: Jacket platform is one type of offshore building that used for the offshore oil exploitation process. In general,

the Jacket is designed with an operating life of 20 to 25 years and in operation must be guaranteed the safety

and strength of the Jacket structure. One of the safety factors that must be considered is corrosion growth in

all parts of the Jacket structure. To overcome corrosion problems, there is a need for alternative corrosion

improvements, namely the prevention of corrosion by using corrosion inhibitors. The organic inhibitor that

can be used as corrosion inhibitors, one of which is cigarette butts, because it is contains a lot of nicotine.

Nicotine can be used as an inhibitor by donating nitrogen atoms to nicotine to Fe

2 +

atoms so that complex

compounds [Fe (NH

3

)

6

]

2+

are formed. This compound has a higher stability than Fe so that it can be used as

protection in corrosion. The purpose of this research is to solve the cigarette butts problem by creating it a

corrosion inhibitor to minimize the cost of material replacement, maintenance costs, and over-design. This

study is an experiment by using ASTM 36 steel, material will be blast cleaned in advance with abrasive

material Steel Grid. Second steps in this study is the coating process by mixing epoxy paint and extraction of

cigarette butts, then immersed in corrosive medium namely sea water of Kenjeran. Corrosion rate testing is

carried out by using the weight loss method. The highest corrosion rate occurred at 1% mixing with a corrosion

rate of 24.61 mpy and the lowest corrosion rate at 2% mixing with a corrosion rate of 13.78 mpy Based on

this research it can be concluded that the nicotine that can be used as cathodic protection on coatings.

1 INTRODUCTION

A Jacket Platform is a very common welded tubular

space frame with three or more near vertical tubular

chord legs with a bracing system between the legs.

These platforms are virtue of their immobility,

designed for long term use. The platform exhibits a

low natural period and deflection against

environmental loads (Samanta, 2016). In the

generally Jacket is made of steel material because it

is designed with the operating life for 20 years. One

of the factors that can lower the strength of the jacket

structure is the occurrence of corrosion (Ardianto,

2017).

The major failure mode of oil and gas structures is

corrosion damage (Yasseri, 2017). The process of

corrosion in the jacket platform occurs with high

intensity because almost any aqueous environment

can promote corrosion, which occurs under numerous

complex conditions in oil and gas production,

processing, and pipeline systems (Champ-Tech,

2012). Corrosion in the jacket platform can reduce the

operating life of the jacket, this incident caused the oil

and gas companies in Indonesia suffered

disadvantages due to corrosion in the offshore

building reach to hundreds of millions of dollars are

equivalent to 2-5% of a country's Gross Domestic

Product. Therefore, it is necessary to reduce the

corrosion level of the jacket platform (Harjanto,

2014).

One of the most promising methods to improve

the protective ability of coatings is the use of

corrosion inhibitors (MCI) (Golovin, 2019).

Inhibitors had been shown to be one of the major tools

for tackling corrosion in the oil and gas industries.

(Popoola, 2013). Microencapsulation technology

greatly simplifies the process of compounding the

polymer protective coating and allows to isolate the

active components from the reactive groups of

polymer resins and hardener at the stage of curing,

correctly form the polymer base of the coating and

avoid the negative effect of the inhibitor on the

Agustina, C., Pratama, P., Selviana, A., Suntoyo, . and Junianto, S.

Effect of Cigarette Butts Extraction on the Corrosion Rate of ASTM A36 for Jacket Platform.

DOI: 10.5220/0010132102250230

In Proceedings of the 7th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management (ISOCEEN 2019), pages 225-230

ISBN: 978-989-758-516-6

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

225

adhesion of the coating to the protected substrate

(Golovin, 2019). An Inhibitor with an effective

corrosion reduction performance is generally an

organic compound consisting of atoms N, O, P, and S

(Hatch, 1984).

One of the groups of organic compounds

containing such components is nicotine, on the other

hand hazardous substances have been identified in

cigarette butts – including arsenic, lead, nicotine and

ethyl phenol (Eriksen, 2013). Nicotine is widely

contained in tea, coffee, tobacco and cigarette butts,

but the component of nicotine on cigarette butss more

than coffee and tea is equel to 3,43% (Rodgman,

2006). Nicotine can be used as an inhibitor by

donating the nitrogen atom in the nicotine to the atom

Fe

2

+

so that the compound is formed [Fe (NH

3

)

6

]

2 +

.

This compound has a higher stability than the Fe so

that it can be used as a protection in corrosion

(Haryono, 2010).

In general, tobacco is the main ingredient of

cigarette composition, but when cigarettes turn into

cigarette butts, the cigarette butts Filter absorbs

chemical content in cigarettes as much as 80%

(Novotny, 2009). This is caused by paper and

cellulose acetate, that collects chemicals that are

produced by smoking. (Novotny, 2014). This plastic

component of filtered cigarettes may not degrade in

the environment for many years (Bonanomi, 2015).

There are numerous advantages of using tobacco

extract as a metallic corrosion inhibitor is a natural,

renewable, environmentally benign, and relatively

inexpensive source. The active constituents in

tobacco can be commercially extracted in a simple

operation using only water as an extraction medium

(Fouda, 2014).

Almost six-trillion cigarettes are produced

globally each year, with approximately one-third to

two-thirds of those cigarette butts being possibly

deposited in the environment and ending up in parks,

beaches, streets, and communities (Granados, 2019).

According to the World Health Agency (WHO)

survey about 36.3% of the population of Indonesia is

an active smoker and Indonesia produces at least 52

million sticks of cigarette butts waste every year.

Therefore, cigarette butts are potential to be used as

an alternative to corrosion inhibitor material and can

tackle cigarettes butt garbage in Indonesia. Previous

research stated that the use of tobacco as a corrosion

inhibitor on spikes still have a 23% lower corrosion

rate reduction compared to using cigarette butts waste

with an average value of corrosion rate of 0.16 mpy

(Andeka, 2015). The greater the addition of cigarette

butts extract then the higher the rate of the

corrections. Therefore, this research needs to be done

to assess the utilization of waste cigarette butts as a

corrosion inhibitor material on the platform jacket.

The purpose of this research is to determine the

parameters that affect the use of cigarette butts as

coating material and to know the reliability of coating

coatings from the cigarette butts. There are also

benefits achieved from this research the first is to

utilize waste cigarette butts so as to reduce the amount

of waste in Indonesia and for the protection of oil rig

building so as to reduce the accommodation and

maintenance cost. As for the potential results that can

be created from this work is the scientific article. The

second is a reference for

scientists/societies/institutions.

2 METHOD

2.1 Time and Place of Execution

The research began on April 1, 2019 until July 13,

2019. The first stage author do is to find cigarette

butts in the surrounding area Faculty of Marine

Technology, ITS. Then proceed with the purchase of

specimen and perform various stages of testing in the

laboratory environment of ITS Metallurgical Material

Department and in CV Cipta Agung.

2.2 Tools and Materials

The equipment used in this research was

spychrometer (wet and dry thermometer), evaporator,

dry abrasive blast cleaning, WFT measuring

instrument (Wet Film Comb), DFT measuring device

(Dry Film Thickness), (pull of test) power test

equipment, FTIR (Fourier Transform (Infrared),

stereo microscope, and optical microscope.

The materials used were methanol, cigarette butts,

tobacco, original powdered tea, paint jotun penguard

Primer grey compenent A and B, thinner Jotun No.

17, Kenjeran sea water, sandpaper No. 150, glue

stardard setting epoxy adhesive, and ASTM A36 steel

with specimen sizes is 20 mm x 20mm x 6 mm and

50 mm x 50 mm x 6 mm, where the properties of

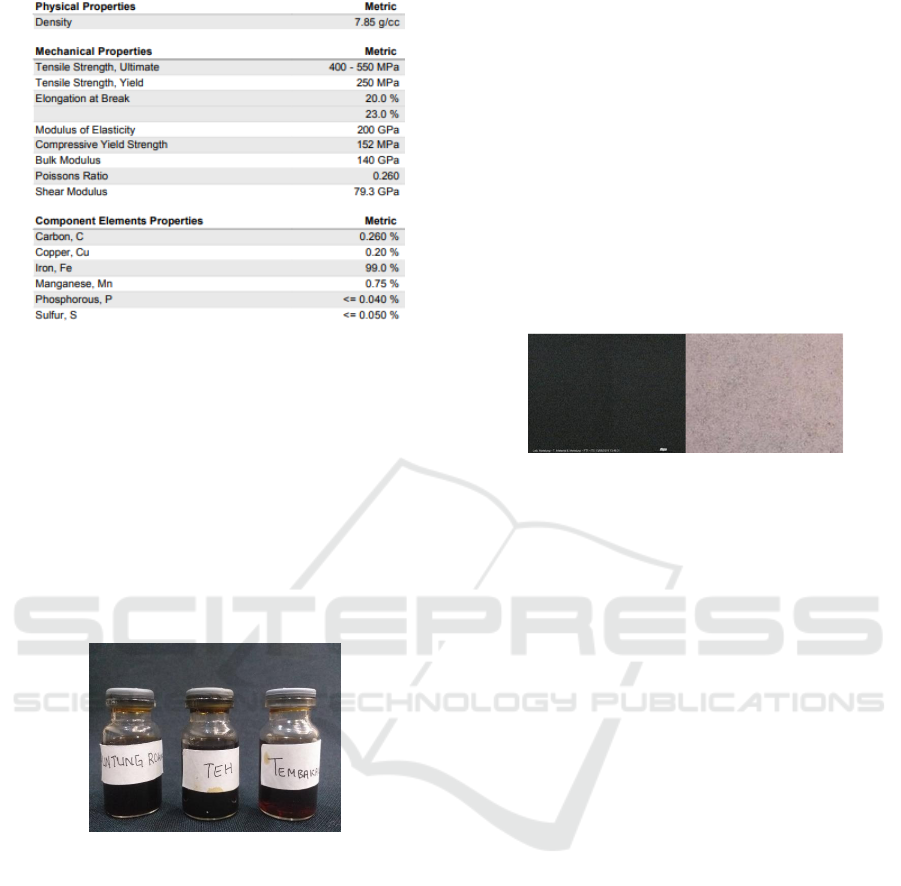

ASTM A36 shown in figure 1.

ISOCEEN 2019 - The 7th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management

226

Source: http://www.matweb.com/

Figure 1: The Properties of ASTM A36 Steel.

ASTM A36 steel based on figure 1 including steel

that has a low carbon composition, which is equel to

0, 26 % (low carbon steel).

3 RESULTS AND DISCUSSION

3.1 Extraction Inhibitor Solution

Result

Figure 2: Extraction results of inhibitors from (a) cigarette

butt waste (b) tea (c) tobacco.

After extraction process is done, then obtained result

of cigarette butts extract, tea extract, and tobacco

extract. Solution of extract corrosion inhibitor has

thick brown characteristic with the volume of each

cigarette butts extract as much as 15 mL with pH 6.2,

tobacco extract 13 mL with pH 7.8, and as much as

18 mL with pH 7, 3 On every 1 scale of the reaction

size (batch).

3.2 Surface Preparation and Blast

Cleaning Testing Results

The result of the surface preparation test was

determined by using a value parameter of RH

(humidity ratio) and dew point. This parameter

derived from dry bulb and wet data respectively at 30

°C and 25 ° C. According to the test parameters, it can

be noted that cigarette butts have a RH and Dew Point

value of 67% and 23% respectively.

This indicates that the cigarette butts extract has a

normal moisture level in accordance with with the

standard namely less than 85% (ASTM D-3451-06,

2017). The results of visual observation Blast

cleaning SA2 1/2 shown in Figure 3, namely Steel SS

400/JIS G3101/ASTM A36 is a type of Steel with low

carbon content so that the Blasting process is needed

to clean the surface of the Steel due to oxidation

process.

Figure 3: (a) Steel A36 before the blast cleaning process SA

2

1

/

2

(b) Steel A36 after blast cleaning process SA 2

1

/

2

.

3.3 Surface Roughness and Coating

Measurement Results

After the blasting process is done on the steel, the next

process is the measurement of roughness done using

ASTM D4417-2014 standard. According to the

ASTM D4417-2014 standard range of steel

roughness is 37 μm to 137 μm. In this roughness

measurement the average roughness value obtained

was 94.6 μm for specimens measuring 50 mm x 50

mm x 6 mm and 96.3 μm for specimens measuring 20

mm x 20 mm x 6 mm. This indicates that the surface

roughness value has been accordance with standards.

At this stage the WFT (Wet film Thickness) and DFT

(thick dry film) values were obtained at the same

time, 120 μm and 55 μm in compliance with ISO

2808-2007(R2010) standard.

3.4 Adhesion Test Result

The nature of adhesion between cigarette butts extract

with steel is an important parameter in its application

when coated on the jacket platform and in this

research the adhesion properties are measured

through the “Pull Off” method in accordance with

D4541 2017 standard, which the results can be shown

in Figure 4. Overall, the variation of cigarette butts

extract 2% has a high adhesion power compared with

other varieties. The result from the tobacco extract

has the adhesion of lower. This becomes the

advantage of cigarette butts as a corrosion inhibitor

(a)

(b)

Effect of Cigarette Butts Extraction on the Corrosion Rate of ASTM A36 for Jacket Platform

227

on the jacket platform in physical terms because it has

a high adhesive power due to great adhesion power.

Figure 4: Adhesion Testing Results.

3.5 Measurement of Salinity of

Seawater Results

The sea water of Kenjeran as much as 500 mL is

heated at temperature 200 °C using the electric heater

until it shrinks and becomes granules salt. At this

stage, the salinity of seawater obtained is 3.32‰,

which means that in seawater there are 0.032 grams

of salt/mL of seawater so that the salinity obtained is

0.032 ppt with pH 8.2.

3.6 Corrosion Rate Testing Results

Testing of steel corrosion rate with specification of

dimensions 20 mm x 20 mm x 6 mm is done through

weight loss test with data obtained Inserted into the

equation (1).

CR (M) =

(1)

Description:

CR = Rate of corrosion (miles per year (mpy))

W = Weight change from specimen (gram)

K = Constant factor (3, 45x106)

D = Density of specimen in units (g/cm³)

As = Area of specimen (cm ²)

T = Time (hours)

The constant

parameters in equation (1) are the

factor constant (K) is 3.45 x106, the material density

is 7.85 g / cm³ and the surface area of all materials is

12.8 cm2, while the observation time is 144 hours (6

days). Based on the calculation obtained in equation

(1), the corrosion rate values are obtained for all

variations, both variations in mass percent of cigarette

butt extract and other inhibitor type extracts which

can be shown in Figure 5.

The lowest corrosion rate obtained in cigarette

butts extracts of 2 % which is 28.6 mpy, even that

value is still lower than tea and tobacco extracts at the

same mass percent which shows that cigarette butts

extract is a type of corrosion inhibitor that has the

highest corrosion inhibition rate compared to other

inhibitor materials.

Figure 5: Corrosion Rate Results (mpy).

The calculation of corrosion rate can be evidenced

by the efficiency of inhibitors calculated through the

equation (2).

EI =

100%

(2)

Description:

XA = rate of corrosion without inhibitors

XB = corrosion rate with inhibitors

By using the equation (2), the result of the

efficacy of B inhibitors was obtained 83%. It is also

reinforced by the use of FTIR test results to identify

the bonds contained in the compound, which can be

shown in Figure 6. The red waves show FTIR spectra

results from cigarette butts extract inhibitors. Based

on these results, the sharp peaks are shown in the

number of waves 3323.12 cm

-1

and 1019.79 cm

-1

.

The sharp and strong ribbon spectrum is shown at

1019.79 cm

-1

. It shows the C-N group stretching and

on the 3323.12 cm-1 ribbon showing the NH

stretching cluster.

The blue color waves show FTIR spectra results

of mixing of cigarette butts extract inhibitors with

epoxy paint with sharp peaks at 2918.79 cm

-1

,

1455.32 cm

-1

, and at 1011.27 cm

-1

. On the Spectrum

2918.79 cm

-1

tape shows the N-H cluster stretching.

As for 1011.27 cm

-1

indicates the C-N group

stretching. Wave of black color showed FTIR results

from paint 100% without added inhibitors.

Based on figure 6, it can be concluded that the

nicotine substance found in inhibitors does not lose

its ability as an inhibitor of resistor corrosion,

because when added to the

paint, the nicotine is still

present and not lost, which means the ability of the

inhibitor is not interrupted, according to the desired

results.

ISOCEEN 2019 - The 7th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management

228

Figure 6: FTIR Spectra of Cigarette Butts Extract, 100%

Paint, 2% wt Cigarette Extract, and Mixing of 2% wt

Cigarette Extract with 98% Paint.

3.7 Material Characterization Results

Physical characterization of morphology of the steel

surface is performed to compare the corrosion

behaviour on the surface of the steel before and after

coated by a corrosion inhibitor. Characterization is

performed with the stereo microscope that the result

can be shown in Figure 7. Based on the

characterization, the addition of a 2% cigarette butts

Extract can be seen that the corrosion is inflicted at

the lowest in comparison to other variations.

Corrosion spots can be seen clearly in the variation

of the addition of cigarette butts extract by 1% which

indicates that the inhibitory efficiency of the highest

corrosion rate is obtained in the addition of a 2%

cigarette butts extract. It is in accordance with the

results Obtained at the corrosion rate measurement

that the lowest corrosion rate is also obtained when

the addition of 2% cigarette butts extract.

Figure 7: Observation Results of Stereo Microscope on

Extract Sample (A) Cigarette butts 0.3% (B) Cigarette butts

0.2% (C) Cigarette butts 0.1% (D) Tobacco (E) Tea (F) Cat

100%.

4 CONCLUSIONS

Based on research the extract of cigarette butts

potentially as alternative corrosion inhibitors on the

jacket platform. The higher the percentage of mass

extract cigarette butts, the smaller the rate of

corrosion with the optimum cigarette butts extract of

2% with a corrosion rate of 28.6 mpy. In addition,

cigarette butts extract has a higher corrosion rate

reduction efficiency than in other types of corrosion

inhibitors.

REFERENCES

Andeka, B., Suharto, B., and Sutanhaji, a.T. 2015.

Efektifitas Limbah Puntung Rokok Sebagai Bahan

Inhibitor Korosi Pada Paku Besi Dalam Media Air

Tawar. Jurnal Sumber Daya Alam Dan Lingkungan,

Journal of Universitas Brawijaya, II (2), P. 1-6.

Ardianto, P. 2017. Pengaruh Cacat Coating Dan

Perbedaan Salinitas Terhadap Laju Korosi Pada

Daerah Splash Zone Menggunakan Material Baja A36.

Bonanomi, Et Al. 2015. Cigarette Butt Decomposition and

Associated Chemical Changes Assessed by

13

C

CPMAS NMR. Plos One, Journal Pone, 10.

Champion Technologies. 2012. Corrosion Mitigation for

Complex Environments. Houston: Champion

Technologies.

Eriksen M, Mason S, Wilson S, Box C, Zellers a, Edwards

W, Et Al. 2013. Microplastic Pollution in the Surface

Waters of the Laurentian Great Lakes. Marine

Pollution Bulletin. LXXVII (1-2), Pp. 177–182.

Fouda, SA, Et Al. 2014. Tobacco Plant Extracts as save

Corrosion Inhibitor for Carbon Steel in Hydrochloric

Acid Solutions. International Journal of Advanced

Research. II (3), Pp. 817.

Golovin, VA and Tyurina, SA. 2019. Microencapsulation

of Corrosion Inhibitors and Active Additives for

Anticorrosive Protective Polymer Coatings.

International International Journal of Corrosion and

Scale Inhibition. VIII (2), Pp. 180.

Granados, P. Stigler, Et Al. 2019. Global Health

Perspectives on Cigarette Butts and the Environment.

International Journal of Environmental Research and

Public Health. XVI, Pp. 1-2.

Harjanto. 2014. Korosi Ancam Industri Minyak Dan Gas RI

[Interview] (02 September 2014).

Haryono, G., Sugiarto, B., Farid, H., Dan Tanoto, Y. 2010.

Ekstrak Bahan Alam Sebagai Inhibitor Korosi.

Yogyakarta, UPN Veteran Yogyakarta Onine, P.1

Hatch, G. and Nathan, C.C. 1984. Corrosion Inhibitor.

California: Corrosion Inhibitor. National Association

for Corrosion Engineers.

Novotny, T., Lum, K., Smith, E., Wang, V., Dan Barnes, R.

2009. Cigarettes Butts and the Case for an

Environmental Policy on Hazardous Cigarette Waste.

BEFORE

AFTER

Effect of Cigarette Butts Extraction on the Corrosion Rate of ASTM A36 for Jacket Platform

229

International Journal of Environmental Research and

Public Health, VI (5), Pp. 1691-1705.

Novotny TE and Slaughter E. 2014. Tobacco Product

Waste: an Environmental Approach to Reduce Tobacco

Consumption. Curr Environ Health Rpt. I (3), Pp. 208–

16.

Popoola, Lekan T, Et Al. 2013. Corrosion Problems during

Oil and Gas Production and Its Mitigation.

International Journal of Industrial Chemistry. IV (35),

Pp. 13.

Rodgman, a. 2006. The Composition of Cigarette Smoke; a

Catalogue Ot the Polycyclic Hydrocarbon, Beiträge

Zur Tabakforchung. XXII (1), Pp.69.

Samanta, Sneha M and Kumbhar, Popat D. 2007. A Review

on Advancements in Jacket Platform. International

Journal of Innovative Research in Science, Engineering

and Technology. V (6), Pp. 9350.

Yasseri, Sirous F. and Bahai, Hamid. 2017. Prognosis of

Time to Failure of Corroding Pipelines. International

Journal of Coastal and Offshore Engineering. I (2), Pp.

11.

ISOCEEN 2019 - The 7th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management

230