Effect of Sisal Fiber Direction Angle on Physical and Mechanical

Properties of Composites

Perdinan Sinuhaji

1*

, Awan Maghfirah

1

, Prisila Dinanti

1

and Willy Arti

1

1

Department of Physics, Universitas Sumatera Utara, Medan, Indonesia

Keywords: Composites, Fiber Direction Angle, Physical Properties, Mechanical, Epoxy Sisal-resin Fiber.

Abstract: Research on the effect of sisal fiber angle on density, water absorption, porosity, flexural strength, impact

strength, and tensile strength of sisal-epoxy resin composite fibers. Composites are made by hand lay out

method in the composition of sisal fiber material: epoxy resin = 10 wt% : 90 wt% with the fiber angle

orientation layout at: 0°, 30°, 45°, 60°, 90°. Composite properties obtained have an average density of 1.2

g/cm

3

, water absorption increases linearly, and porosity of composites rises linearly to changes in angle

increment which is greater and has flexural strength, impact strength, composite tensile strength linearly

decreases to changes in the incremental angle. Optimal mechanical properties occur at the angle of fiber 0°,

this is due to the long fiber direction, in the direction of the tensile force which is at 0°. The length of each

fiber at 30°, 45°, 60°, 90°, will have lower mechanical properties, due to the shorter load distribution.

1 INTRODUCTION

Composite is a material that is formed from a

combination of two or more materials that are macro

and insoluble to one another (GuruRaja, 2013). One

forming element is called an amplifier and one

element is called a binding (GuruRaja, 2013).

Reinforcing agents can be in the form of fibers,

particles, or flakes (GuruRaja, 2013)(Hodzic,

2013).The role of the matrix in the composite material

is to give shape to the composite part, protecting the

reinforcement and perfection of the material, together

with the reinforcement (Parandoush, 2017).

Composite materials are used for cars, ships,

airplanes, sporting goods and so on (GuruRaja, 2013).

The nature of composite materials is strongly

influenced by the nature and distribution of the

constituent elements, as well as the interactions

between the two

(Hodzic, 2013). Important parameters

that influence the nature of the composite material are

the shape, size, orientation and distribution of the

amplifier (filler) as well as the characteristics of the

matrix

(Pickerig, 2015). The mechanical properties of

composite materials depend on the nature of the

constituent materials (Pickerig, 2015)

. The main role

in fiber-reinforced composites is to move stress

between the fiber, provide resistance to the

environment, maintain the surface of the fiber,

mechanical and chemical effects (Hodzic, 2013). The

contribution of fiber is largely influential on the

mechanical strength of composite materials (Pickerig,

2015).

The choice of natural fibers and matrix materials,

fiber orientation, fiber arrangement is one of the

significant ways to increase the strength of

composites (Woo, 2006). Testing the angle of

orientation of the fiber is very important so it takes a

lot of effort to do research (GuruRaja, 2013)

(Woo,

2006)

(Marin, 2019). Therefore, researchers are

interested in knowing the physical and mechanical

properties of making sisal fiber composite boards

with epoxy resin with orientation toward sisal fiber at

0°; 30°; 45°; 60°; 90° is expected to produce

composites that are stronger, tougher, stronger and

meet quality standards so that they can be utilized by

industry (Naraganti, 2017) (Marin, 2019) (Kretsis,

1987).

Environmentally friendly composite materials

based on natural fibers can be obtained around the

environment (Pickerig, 2015)

. Natural fibers are now

widely used because of their abundance and are so

cheap that they are often used as reinforcing materials

such as kenaf, abaca, rosella, straw, sisal and many

natural fibers which are quite abundant in Indonesia

and can be renewed (Hodzic, 2013). Epoxy resins

have wide uses in the chemical, electrical,

mechanical, and civil chemical industries as

86

Sinuhaji, P., Maghfirah, A., Dinanti, P. and Arti, W.

Effect of Sisal Fiber Direction Angle on Physical and Mechanical Properties of Composites.

DOI: 10.5220/0010136700002775

In Proceedings of the 1st International MIPAnet Conference on Science and Mathematics (IMC-SciMath 2019), pages 86-89

ISBN: 978-989-758-556-2

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

adhesives, coating paints, and printed objects

(Baheshtizadeh, 2018)

(Kretsis, 1987). Besides having

high strength, epoxy resin also has good chemical

resistance (Baheshtizadeh, 2018) (Kretsis, 1987).

Sisal is the most widely used natural fiber, most of

this economical and renewable material has not been

fully utilized Naraganti,(Hodzic, 2013). At present

the main use of sisal is limited to the fields of marine

and agriculture (Naraganti, 2017). Sisal fiber

applications include the manufacture of yarn, ropes,

mats, fish nets (Naraganti, 2017).

2 MATERIALS

The material used is sisal fiber obtained from

Surabaya sisal rope suppliers, epoxy resin and epoxy

hardener obtained from the chemical store PT. Justus

Kimiaraya. The tools used are digital balance sheet,

hot press, 2 pieces of iron plate, sample molds,

GOTECH Universal Testing Machine (UTM),

GOTECH Impactor.

3 METHODS

The selection of sisal fiber, described to obtain the

smallest strands used as reinforcement, is then

prepared by epoxy resin and hardener in a ratio of 2:

1. Made fiber mass: epoxy resin mass = 10 wt%: 90

wt%, then calculate the fiber mass and epoxy resin

mass. prepare the mold, then arrange the direction of

the fibers at 0°, 30°, 45°, 60° and 90° on each

composite board, glue together, mix the resin and

hardener into the measuring cup, stir evenly, pour the

resin and hardener mixture into the mold that has been

glued to the fiber, evenly, closed the mold using a

second iron plate coated with aluminum foil and

waxed. Furthermore, the mold is placed on a hot

press, pressurized 5 tons at a temperature of 90°C

within 20 minutes. Then the sample is removed,

conditioned 1 x 24 hours. Composite boards are cut

to standard test sizes, and samples are made in the

same way at an angle of 30°; 45°; 60°; 90°, then each

sample is ready to be tested.

4 RESULTS AND DISCUSSION

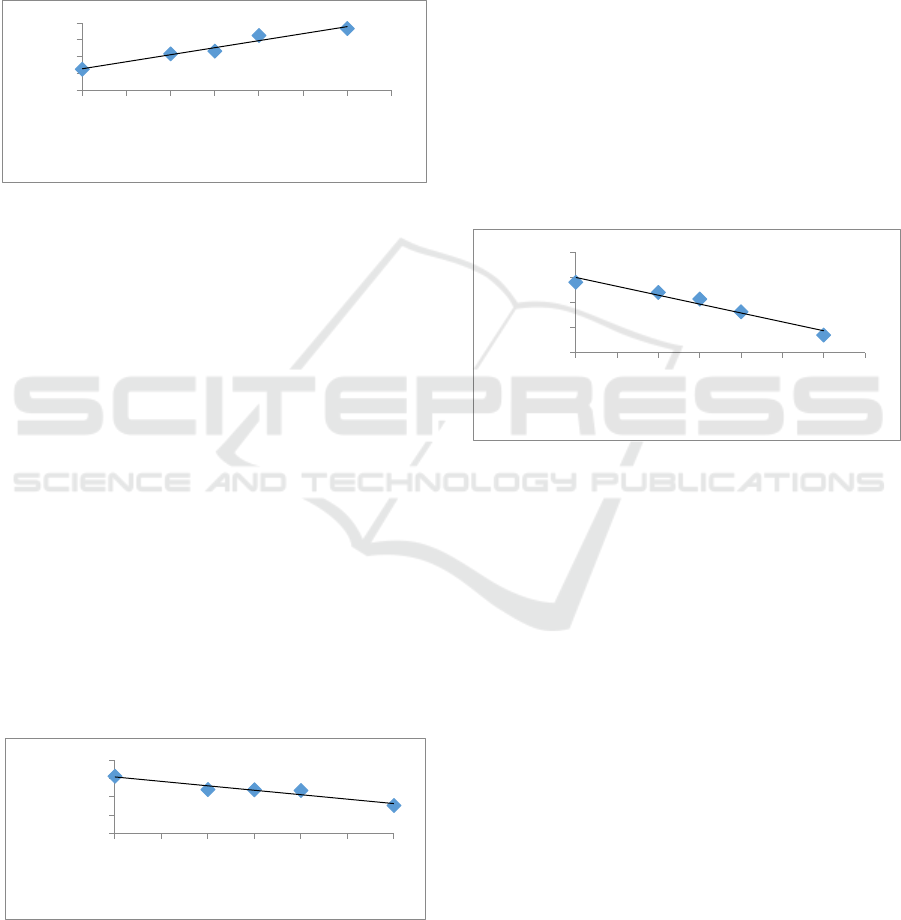

4.1 Density Test

Testing the density of sisal-epoxy fiber composites is

first weighed on the composite mass, then the sample

volume is measured to be able to calculate the

composite density. The results of the measurement of

composite density with the orientation angle of the

fiber 0°; 30°; 45°; 60°; 90° shown in the following

figure 1.

Figure 1: Density vs fiber direction angle.

From Figure 1 above it can be analyzed that the

relationship between density and fiber direction angle

is 0°; 30°; 45°; 60°; 90° tends to be linearly flat, this

is due to the fact that the mass of the fiber remains for

each change in direction angle of the fiber at 0°; 30°;

45°; 60°; 90°, so that it will produce a fixed composite

density. The average density of sisal-epoxy fiber

composites is 1.2 g/cm

3

.

4.2 Absorption Water Test

Composite water uptake was carried out to determine

the percentage of water absorbed by the composite

soaked in water for 24 hours. Water absorption tests

have been carried out on composites with each fiber

angle orientation 0°; 30°; 45°; 60°; 90°. The results of

the composite water absorption test are shown in

Figure 2 below.

Figure 2: Absorption water vs fiber direction angle.

From Figure 2 above it can be analyzed that the

relationship between composite water uptake and

fiber direction angle at 0°; 30°; 45°; 60°; 90° tends to

rise linearly, this is due to the arrangement of the

laying direction of the fiber at 0°; 30°; 45°; 60°; 90°

has a fixed mass, but when cutting a composite board

sample results in the cut section of the incision having

fibers not covered by epoxy resin getting bigger.

y=‐7E‐05x+1,207

R²=0,0385

1

1,2

1,4

0 153045607590

Density (g/cm

3

)

Fiber direction angle (°)

y=0,0451x+2,115

R²=0,9831

0

2

4

6

8

0 153045607590105

Absorbtion water

(%)

Fiber direction angle (°)

Effect of Sisal Fiber Direction Angle on Physical and Mechanical Properties of Composites

87

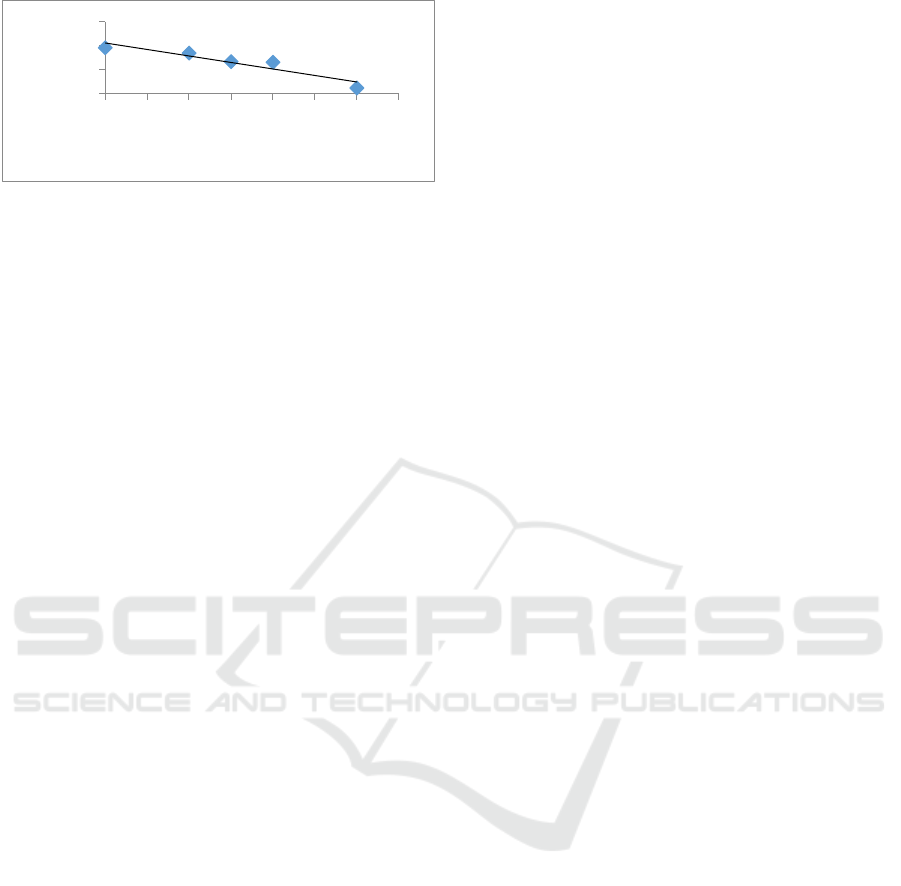

4.3 Porosity Test

Composite porosity test is performed to determine the

ratio between pore volume to total volume of the

composite. Porosity test has been carried out with the

orientation of sisal fiber angle at 0°; 30°; 45°; 60°;

90°, the results of the composite porosity test with the

orientation angle of the sisal-epoxy fiber are shown in

Figure 3 below.

Figure 3: Porosity vs fiber direction angle.

From Figure 3 above it can be analyzed that the

relationship of porosity of the composite with the

fiber direction angle at 0°; 30°; 45°; 60°; 90°, tends to

increase linearly, this is due to the increase in the

direction angle of the composite fiber at the same

mass and when cutting the test sample will cause the

porosity of the composite to rise. At the incision of

the sample trapped air between sisal fibers, can not be

pressed out and form air bubbles or voids so

susceptible to porous.

4.4 Flexural Strength Test

The flexural strength test uses the GOTECH

Universal Testing Machine type Al-7000M, to

determine the resistance of the composite to loading

at three bending points and also to determine the

elasticity of the composite. The results of the

composite flexural strength test with the fiber

direction angle at 0°; 30°; 45°; 60°; 90°, shown in

figure 4 below.

Figure 4: Flexural strength vs fiber direction angle.

From Figure 4 above it can be analyzed that the

relationship between the flexural strength of the

composite with the fiber direction angle 0°; 30°; 45°;

60°; 90° tends to decrease linearly. This is because

the load from the matrix to the fiber is smaller and the

interfacial bond is even stronger, because the length

of the fiber at 0° gives higher strength than the shorter

fiber length. Composite flexural strength at the angle

of fiber 0o has the greatest flexural strength of 62.72

MPa, compared to other flexural strengths due to the

long pieces of fiber arranged on the 0° composite

being longer than the fibers arranged at an angle of

30°, 45°, 60°, and 90°.

4.5 Impact Strength Test

The test samples used were rectangular in accordance

with ASTM D256. Impact testing is done with the

GOTECH Impactor tool. Strong composite impact

test results with fiber angles at 0°; 30°; 45°; 60°; 90°,

shown in figure 5 below.

Figure 5: Impact strength vs fiber direction angle.

From Figure 5 above we can analyze the impact

of the strong impact on the fiber direction angle at 0°;

30°; 45°; 60°; 90°, tends to be linearly decreased, this

is because the shorter fiber length will have a bond

between and the matrix is much lower than the fiber

length at 0°. The maximum impact strength is 27.97

J/mm

2

and there is a decrease in impact strength at

each decrease in fiber direction angle.

4.6 Tensile Strength Test

The test sample used is rectangular in shape, the size

is adjusted to ASTM D 638-01 standard. Flexural

strength test is performed using the GOTECH

Universal Testing Machine type Al-7000M. The

results of the composite tensile strength test with a

fiber angle of 0°; 30°; 45°; 60°; 90°, presented in

Figure 6 below.

y=0,0555x+2,565

R²=0,9589

0

2

4

6

8

0 153045607590105

Porosity (%)

Fiber direction angle (°)

y=‐0,3249x+61,897

R²=0,9168

0

20

40

60

80

0 153045607590

Flexuralstrength

(MPa)

Fiber direction angle (°)

y=‐0,235x+29,88

R²=0,9537

0

10

20

30

40

0 153045607590105

Impact strength

(J/mm

2

)

Fiber direction angle (°)

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

88

Figure 6: Tensile strength vs fiber direction angle.

From Figure 6 above it can be analyzed that the

relationship of flexural strength to the angle of

orientation of the fiber decreases linearly, this is due

to the change in the angle of direction of the fiber at

0°; 30°; 45°; 60°; 90° gives a lower tensile strength,

due to the load received by the fiber at each lower

angle, because the distribution of load to the fiber will

decrease lower at a greater fiber angle. The greatest

tensile strength of composites occurs at a direction

angle of 0o by 19.28 MPa, and a decrease occurs due

to the length of the fibers arranged at 0° longer than

the length of fibers arranged at an angle of 30°; 45°;

60°; 90°, so the distribution of the load on the

composite decreases.

5 CONCLUSIONS

From the results of the study the influence of the

direction angle of sisal fiber with composite epoxy

resin can be concluded that:

Sisal fiber composites - epoxy resin with fiber mass

ratio: epoxy resin mass is 10 wt%: 90 wt% has an

average density of 1.2 g/cm

3

, water uptake rises

linearly and porosity also rises linearly for each

change in direction angle fiber at 0°; 30°; 45°; 60°;

90°. The flexural strength of the composite has

decreased linearly, the impact strength of the

composite also has decreased linearly and the tensile

strength has also decreased linearly at each change in

the angle of direction of the fiber at 0°; 30°; 45°; 60°;

90°. Composite properties at sisal fiber direction

angle with epoxy at 0° shrinkage, 30° angle, 45° angle

and 60° angle, can be used as a car bumper material,

composite flexural strength greater 32 MPa.

REFERENCES

Baheshtizadeh, N., 2018. Three point bending test of

glass/epoxy composite healt monitoring by acoustic

emission.

GuruRaja, M.N. dkk, 2013. Influence of Angle Ply

Orientation on Tensile Properties of Carbon/Glass

Hybrid Composite. J. Miner. Mater. Charact. Eng. 1,

231–235.

Hodzic, A., 2013. Natural Fibre Composites. B. Sci.

Kretsis, G., 1987. A Review of the Tensile, Compressive,

Flex- ural and Shear Properties of Hybrid Fibre

Reinforced Plastics. Composites 18, 13–23.

Marin, J.C., 2019. On the optimal choice of fibre orientation

angle in off-axis tensile test using oblique end-tabs:

Theoretical and experimental studies. Compos. Sci.

Technol. 1–51.

Naraganti, S., 2017. Impact resistance of hybrid fibre

reinforced concrete containing sisal fibres 1–9.

Parandoush, P., 2017. A review on additive manufacturing

of polymer-fiber composite. Compos. Struct. 36–51.

Pickerig, K.L., 2015. A review of recent developments in

natural fibre composites and their mechanical

performance. Composites 98 – 109.

Woo, 2006. Effect of Fiber Aspect Ratio And Area Ratio

Getting To Accuracy Of Intensity Method In Fiber

Orientation Angle Distribution Measurement. KEM

326–328.

y=‐0,1802x+21,237

R²=0,8828

0

10

20

30

0 153045607590105

Tensile strength

(MPa)

Fiber direction angle (°)

Effect of Sisal Fiber Direction Angle on Physical and Mechanical Properties of Composites

89