Hydrocracking of Mefa Rubber Seed Oil into Biofuels Fraction with

Co and CoMo Metals Supported on Zeolite Catalyst

Junifa Layla Sihombing

1,2

, Herlinawati

2

, Asep Wahyu Nugraha

2

, Ahmad Nasir Pulungan

2

, Moondra

Zubir

2

, Tiamina Nasution

2

, Ary Anggara Wibowo

3

and Saharman Gea

4

1

Postgraduate School, Department of Chemistry, Universitas Sumatera Utara, Jl. Bioteknologi No. 1, Medan, Indonesia

2

Department of Chemistry, Universitas Negeri Medan, Jl. Willem IskandarPasar V Medan Estate, Medan, Indonesia

3

College of Science, Energy Change Institute, College of Science Australian National University, ANU, Australia

4

Department of Chemistry, Universitas Sumatera Utara, Jl. Bioteknologi No. 1, Medan, Indonesia

aryanggarawibowo}@gmail.com,

*

s.gea@usu.ac.id

Keywords: Rubber Seed Oil, Hydrocracking, Catalyst, Impregnation, Biofuel.

Abstract: This research was aimed to produce biofuel fraction from rubber seed oil by using synthetic Zeolite Y (ZY),

Co/ZY and CoMo/ZY catalyst. The insertion of metal used a wet impregnation method. Furthermore, in or-

der to produce a good catalyst, the oxidation and reduction process at 500

o

C using oxygen and nitrogen gas-

es at approximately 2 hours were performed. Then, the effect of addition of ZY, Co/ZY and CoMo/ZY had

been investigated at catalytic hydrocracking using metyl ester fatty acid (MEFA). The reaction was con-

ducted at 450

o

C with ratio of catalyst:feed of 1:4 and 20 mL/sec with hydrogen gas flow. Moreover, the

characterization of catalyst depicted that no significant changes in wavenumber of TO4 groups and a crys-

tallinity of catalyst. Then, the crystal system of ZY and Co/ZY was indicated as monoclinic while Co-

Mo/ZY was revealed as triclinic. The surface area, pore volume and mean pore of catalysts revealed an in-

crease trend as a result of Co and Mo impregnation. These trends have also been proven with SEM analysis

which was shown an equal spreading of metals in the catalysts. Furthermore, the highest result of catalytic

performance among catalysts was shown by CoMo/ZY with 59.45% of bio-gasoline. To sum up, the im-

pregnation of Co and CoMo in Zeolit Y depicted a well-effect on its selectivity into bio-gasoline product.

1 INTRODUCTION

The world's energy needs for petroleum fuels are

increasing in accordance with technological and

industrial developments and the growth of the

world's population. Meanwhile, fossil fuel reserves

continue to decrease and have a negative impact on

the environment. This has encouraged a lot of re-

search to find alternative fuel sources that are sus-

tainable and environmentally friendly. According to

the Renewable Fuel Standard, the consumtion of

renewable fuels currently reaches is 14 billion galos

per year (BGY) and in 2022 is predicted to reach 32

BGY (Perlack et al., 2011).

Indonesia has enormous biomass potential as a

renewable and environmentally friendly alternative

energy sources (Sihombing, Gea, Kembaren, et al.,

2018). Biomass and agricultural or plantation prod-

ucts such as palm oil, soybeans and rubber seed oil

have been converted to biofuels (Vinh et al., 2011).

Rubber seed oil (RSO) is one of the biomass, that is

widely available in Indonesia and has not been wide-

ly used. The main contens of RSO is 39% of linoleic

acid and 23.52% of oleic acid (Wibowo et al., 2014),

which can be converted to liquid fuel fraction by

catalytic cracking process (Sihombing, Gea,

Pulungan, et al., 2018).

Hydrocracking method has been commonly used

to produce biofuels sourced from vegetable oils

(Bezergianni et al., 2009). The use of catalysts in

this process is more desirable because it can reduce

the activation energy (Sriningsih et al., 2014), there-

fore, it will make the process more efficient and can

reduce unnecessary byproducts, such as heteroatom-

ic substances (Khowatimy et al., 2014). In the hy-

drocracking process, breaking the C-C bond from a

long chain carbon compound to a short chain carbon

compound with simultaneous or sequential hydro-

genation. Heterogen catakyst such as Zeolit Y (De

Jong et al., 2010; Pulungan et al., 2014), porous

Layla Sihombing, J., Herlinawati, ., Wahyu Nugraha, A., Nasir Pulungan, A., Zubir, M., Nasution, T., Anggara Wibowo, A. and Gea, S.

Hydrocracking of Mefa Rubber Seed Oil into Biofuels Fraction with Co and CoMo Metals Suppor ted on Zeolite Catalyst.

DOI: 10.5220/0010152200002775

In Proceedings of the 1st International MIPAnet Conference on Science and Mathematics (IMC-SciMath 2019), pages 279-286

ISBN: 978-989-758-556-2

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

279

material MCM-41 (Zubin et al., 2010) and multi

porous Composite MC-ZSM-5/ MCM-41 [14] have

been used in this process. The fuel products pro-

duced have low density and good physical and

chemical properties as petroleum fuels.

Based on several heterogeneous catalyst types

used, zeolite is the catalyst most widely used in the

petroleum process, because it has a large surface

area, high thermal stability and high acidity

(Degnan, 2000). One type of zeolite which is very

important is Y zeolite. It is widely used as a catalyst

for the process of fluid catalytic cracking, hy-

drocracking, and alkylation in the process of oil

refining and petrochemical synthesis (Choi et al.,

2009). This is because Zeolite-Y has a high concen-

tration of active acid sites, high thermal stability and

high size selectivity (Sato et al., 2001).

One method to increase the activity and selectivi-

ty of the catalyst is by impregnation of transition

metals into zeolites. Co and Mo metals loaded into

pore of alunina have been tested in the heavy oil

hydrocracking and hydrotreating process, which

shows high conversion results and low coke for-

mation (Da Silva, 2014; Parkhomchuk et al., 2013;

Pashigreva et al., 2010). Sihombing, Gea,

Kembaren, et al. (2018) has also been reported that

loaded Co and Mo on natural zeolites as catalysts for

mefa rice bran oil hydrocracking processes have

increased the selectivity of biogasilen products.

Therefore, in this study a modification of the ZY

catalyst character by impregnation of Co and CoMo

metals and an activity test on MEFA hydrocracking

from rubber seed oil to biofuel was carried out. This

modification is expected to provide high conversion

products and good selectivity for the biogasoline

fraction.

2 MATERIALS AND METHODS

2.1 Materials

MEFA Rubber Seeds, Synthetic Zeolite Y (ZY) was

obtained from Tosoh-Japan, Precursor Metal

Co(NO3)2.6H2O, (NH4)6Mo7O24.4H2O were

purchased from Merck. Distilled water was

purchased from CV.Bratachem. Hydrogen Gases,

Oxygen Gases and Nitrogen Gases were purchased

from PT. Aneka Gas.

2.2 Experimental

2.2.1 Preparation of Catalysts

The impregnation of Co and CoMo on ZY according

to Sihombing, Gea, Kembaren, et al. (2018). As

much as 1% (w/w) of Co (NO3)2.6H2O was poured

into 100 grams of zeolite Y through the wet impreg-

nation method. Then, the mixture was refluxed for 5

hours at a temperature of 80

o

C to produce Co-ZY.

After that, the Co-ZY mixture was oxidized with

oxygen gas (± 20 mL/sec) for 2 hours at 500

o

C.

Then, the reduction process was conducted by using

hydrogen gas (±20 mL/sec) for 2 hours at a tempera-

ture of 500

o

C to produce Co/ZY catalyst.

An amount of 1% (w/w) of

(NH4)6Mo7O24.4H2O was poured into 100 grams

of zeolite Y and treated with wet impregnation

method. Then, the mixture was refluxed for 5 hours

at 80

o

C to produce Mo-ZY. After that, a total of 1%

(w/w) of Co(NO3)2.6H2O was added to Mo-ZY. It

was then refluxed for 5 hours at 80

o

C and Co-Mo-

ZY was resulted. The oxygen gas (± 20 mL/sec) was

flowed to Co-Mo-ZY mixture in order to perform

the oxidation process. This was conducted for 2

hours at 500

o

C. Finally, the reduction process was

carried out by using hydrogen gas (± 20 mL/sec) for

2 hours at a temperature of 500

o

C to produce the

CoMo/ZY catalyst.

2.2.2 Characterization of Catalysts

At last, the ZY, Co/ZY and CoMo/ZY catalysts were

analyzed using the FTIR (Shimadzu-Prestige-21),

XRD (shimadzu), SEM (ZEISS Mode EVO MA 10)

and specific surface area measurements with Gas

sorption analyzer through BET method.

2.2.3 Catalyst Activity Test

The activity test of Co/ZY and CoMo/ZY catalysts

towards Catalytic Hydro Cracking process was

performed. MEFA rubber seed oils in a fix-bed

system reactor. The reaction temperature was set at

450 oC and with the ratio of feed:catalyst was 1: 4

with a reaction time of 2 hours [2]. The conversion

yield of each product was calculated using the

equation used by Sriningsih et al. (2014) and the

resulting liquid product was analyzed by GC and

GC-MS method (GC-FID Agilent Technologies

6890N Network).

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

280

3 RESULTS AND DISCUSSIONS

3.1 The Characterization of Catalyst

The catalyst used in this study was synthetic zeolite

Y (ZY). It is a synthetic zeolite which is included in

the classification of faujasite. The cell unit is cube-

shaped with large cell dimensions approaching 25Å

and consists of 192 tetrahedral of (Si, Al)O4. Zeolite

Y is very good for carrying various types of metals

in catalytic hydrocracking reactions since it has a

uniform pore structure and a high concentration of

active sites, so it has excellent thermal stability and

selectivity (Htay & Oo, 2008). In this research, the

ZY catalyst was used by inducing the Co metal and

CoMo metal combination using the wet

impregnation. Then, it was followed by the process

of calcination, oxidation and reduction in the

presence of hydrogen. The calcination process,

oxidation and reduction were carried out to produce

strong interactions between metal and carrier

(Schwarz et al., 1995). From the series of processes,

a uniform distribution of catalyst metal will be

obtained on the surface of the carrier. In addition,

the calcination, oxidation and reduction processes

affect the metal dispersion in the carrier. Metal

preparation of the carrier and the basic properties of

the carrier can affect the physical structure and

chemical properties of metal deposits. The

significant changes to the catalytic properties of a

metal can occur with variations in the composition

of the carrier from different metal development

preparations. To analyze the success of the treatment

given, several analysis of catalyst material were

performed with FTIR, XRD, BET and SEM

methods.

3.1.1 FT-IR Analysis

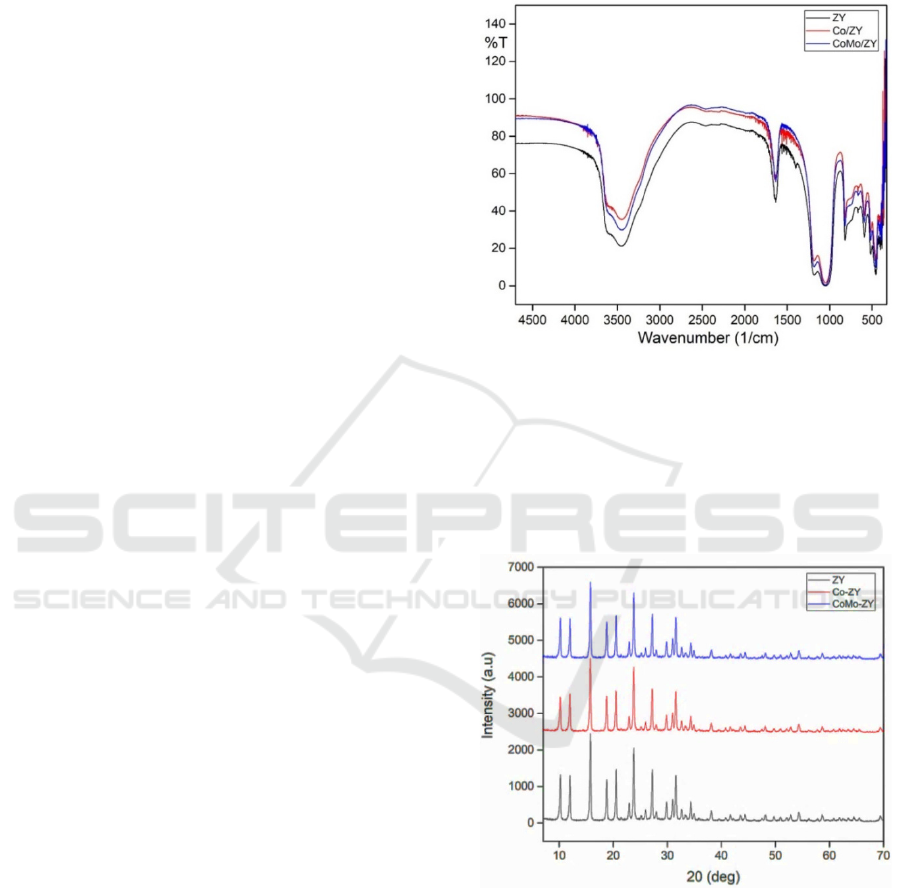

Based on Figure 1, it can be seen that the wave

numbers that show the adsorption of FTIR spectra

on protonated zeolite is at 4000 to 400 cm-1. All

spectra display great intensity at 3451-3442 cm-1

which indicates the vibration of O-H stretching from

Si-OH and Al-OH groups. The spectra recorded at

1642-1635 cm-1 correspond to a buckling vibration

of Si-OH. Then, the peak at 1049-1180 cm-1

indicates the presence of internal and external

asymmetric vibrations of the TiO4 group, while the

peak at 816-817 cm-1 shows the TiO

4

symmetrical

stretching vibration. The intensity of the band

around 591-590 cm-1 indicates the internal buckling

of the tetrahedron while the band around 456-454

cm-1 shows the D4R ring. It can be seen that all

peaks reveal no significant change in the catalyst

after the metal addition. So it can be concluded that

metal development does not contribute damage to

the framework of zeolite.

Figure 1: The comparison of FTIR spectra of ZY, Co/ZY

and CoMo/ZY catalysts.

3.1.2 XRD Analysis

The XRD characterization results are spectra with

abscissa which shows the diffraction and ordinate

angles indicating the intensity.

Figure 2: The XRD diffractogram of ZY, Co/ZY and

CoMo/ZY catalysts.

Based on the comparison of the intensity shown

in Figure 2, it can be inferred that the process of Co

and CoMo metals addition in zeolite Y (ZY) carrier

results in a decrease of some ZY diffraction main

peaks intensity in the range 10-30 θ degrees, yet it

still has the same diffractogram shape. This indicates

that the addition of metal does not damage the crys-

tal structure and the spread of the metal occurs even-

Hydrocracking of Mefa Rubber Seed Oil into Biofuels Fraction with Co and CoMo Metals Supported on Zeolite Catalyst

281

ly on the surface of the ZY pore. The results of this

analysis correlate with the results of the surface area

analysis as shown in Table 2. Further analysis was

carried out using the Expo 2014 method to deter-

mine the catalyst crystal structure. The results of the

analysis are described in Table 1.

Table 1 reveals that the addition of Co metal

does not change the ZY carrier crystal system. How-

ever, the crystal system change was occurred in

CoMo / ZY. This is probably the result of strong

interaction of Co and Mo metals on the pore surface.

The Interactions between metals can cause the for-

mation of alloys. Moreover, alloy formation in the

ZY carrier pore will cause a geometric change due to

the limitation of the size of each component.

Table 1: The result of XRD data analysis on ZY, Co/ZY and CoMo/ZY catalysts via EXPO method.

Catalysts A (Å) B (Å) C (Å) a (

0

) b (

0

) g (

0

) Vol (Å

3

)

Crystal

System

ZY 8.14904 8.98075 12.48393 117.9507 122.3303 91.5312 633.1 Triclinic

Co/ZY 10.26336 11.39037 10.24643 60.73391 67.99091 48.9241 785.11 Triclinic

CoMo/ZY 14.33625 8.65771 7.50814 89.99995 100.0584 89.99995 917.58 Monoclinic

3.1.3 BET Method Analysis

Table 2 shows the results of determining the catalyst

surface area using the Bruener-Emmer-Teller (BET)

method. From these data, it can be seen that the

addition of Co and CoMo metals on ZY increases

the total pore volume of ZY catalyst. This indicates

that the metals were spread evenly on the pore sur-

face of the ZY carrier. In contrast to the results of

the measurement of the pore spacing, the addition of

metal into the pore of the ZY carrier results in a

greater average pore radius. This is possible since

the more metals are impregnated into the pores of

the carrier, and then the pores of the carrier with

smaller fingers will be more clogged so that the

average pore radius increases. Meanwhile, the cata-

lyst surface area after metal Co has increased from

342.651 m2g-1 (ZY) to 491.246 m2g-1 (Co / ZY),

but it has decreased with CoMo/ZY metal addition

with the value of 435.239 m2g-1. However, when it

is compared to basic ZY catalysts, the addition of Co

and CoMo increases the catalyst specific surface

area. Similar results were reported by Semeykina et

al. (2016), showing that Co, Mo and Ni metals in

mesoporous alumina (Al2O3) carriers increased the

catalyst specific surface area. Surface area, pore

volume and mean pore size are important character-

istics of the catalyst which greatly affect the activity

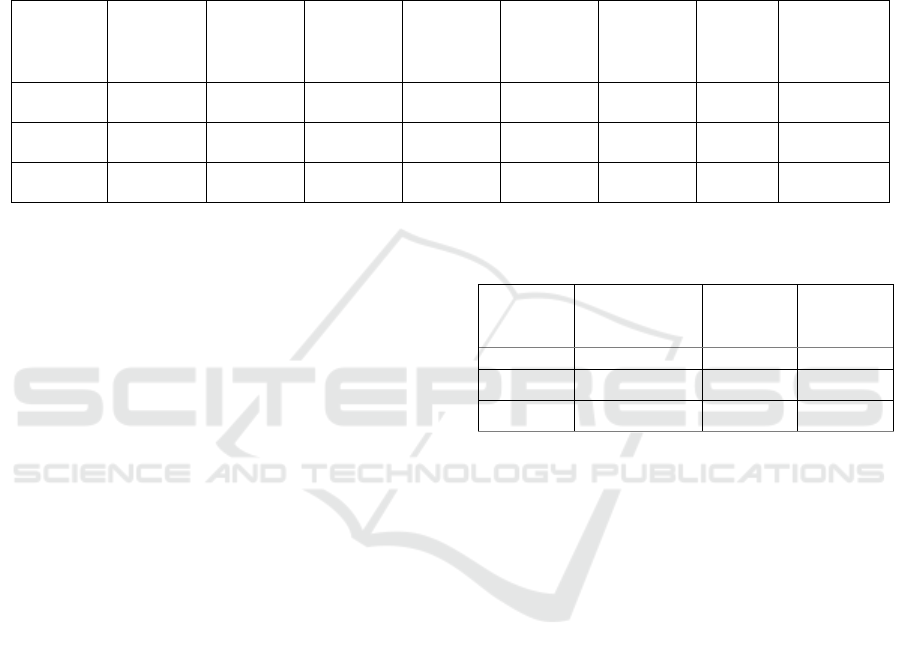

and selectivity of the catalyst. The scheme of metal

loaded to the ZY catalyst presented in figure 3.

Table 2: The result of BET analysis on ZY, Co/ZY a

CoMo/ZY catalysts.

Catalyts Area

(m

2

g

-1

)

Pores

Volume

(

cc/

g

r

)

Average

Pore Size

(

Å

)

ZY 342.651 0.24 13.78

Co/ZY 491.246 0.40 16.38

CoMo/ZY 435.239 0.66 30.43

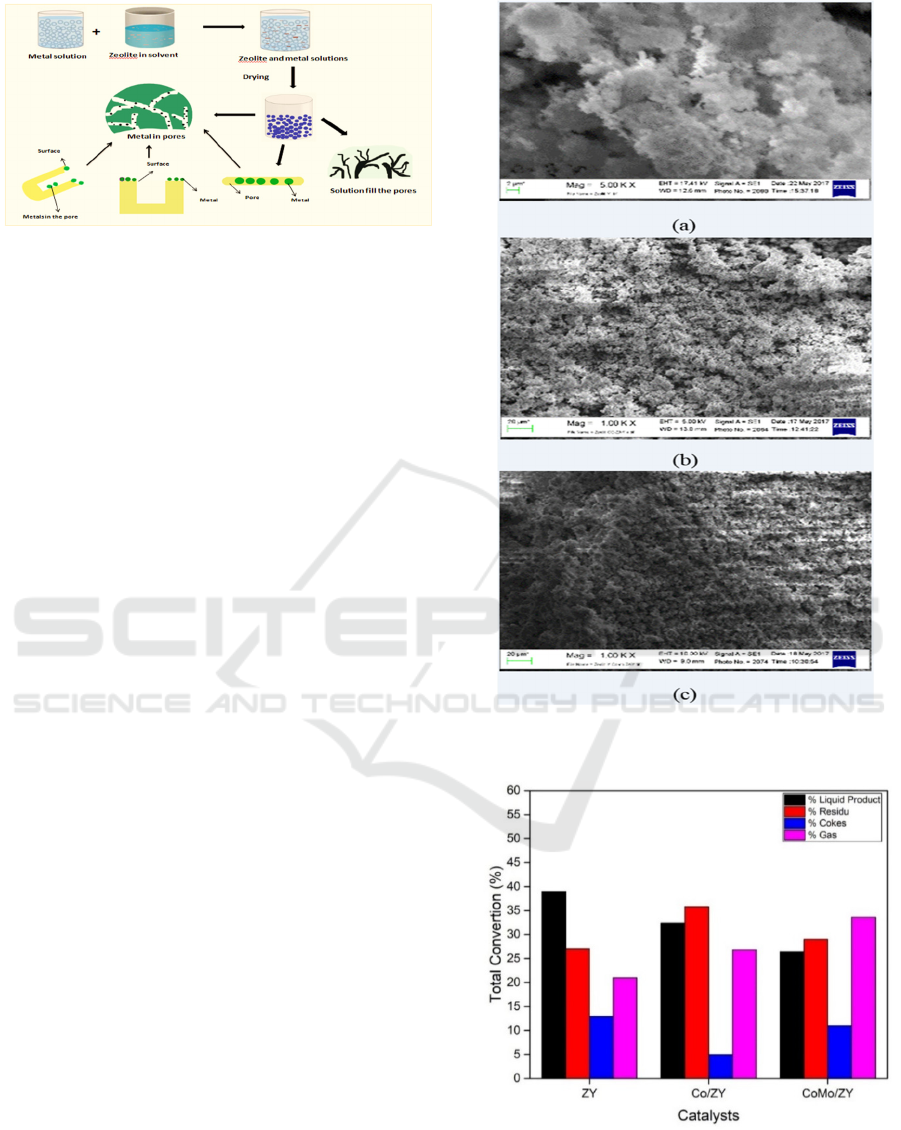

3.1.4 SEM Analysis

SEM (Scanning Electron Microscopic) analysis is

used to determine the catalyst surface topology.

Moreover, it aims to determine the dispersion level

of the metal which is applied to ZY. The visualiza-

tion of the Co and CoMo addition on the ZY carrier

pliers was evenly distributed on the surface of the

ZY carrier pore illustrated in Figure 4. The result of

SEM analysis is shown in Figure 4, which shows

that the distribution of metals in ZY is evenly dis-

tributed and does not show sintering metals on the

pore surface of the ZY carrier. This is indicated by

the shape of the surface morphology of each catalyst

which is relatively homogeneous. This SEM data

correlates with previous XRD and BET data.

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

282

Figure 3: The scheme of metal loaded to the ZY catalyst.

3.2 Catalytic Performance of Catalyst

The catalyst activity test was carried out on the hy-

drocracking reaction of rubber seed oil. The feed

solution used was MEFA from rubber seed oil with

the ratio of catalyst and feed used was 1:4 (w/w).

Rubber seed oil MEFA hydrocracking reaction was

carried out at a temperature of 450

o

C with hydrogen

gas flow of 20 mL/minute for 2 hours. The products

which were produced are gas, liquid and coke. The

resulting liquid product was analyzed by GC and

GC-MS. The coke formation can be seen from

changes in the color of the catalyst which tends to be

darker after the reaction process takes place. The

results of the activity and selectivity test of each

catalyst are presented in Figure 5 and figure 6. Fig-

ure 5 show that the metal addition of the Co/ZY

catalyst gives a larger gas product than the ZY cata-

lyst which was 26.60%. This is caused by the entry

of Co metal in the carrier pore gives more active

sites which play a role in the reaction process. Zhang

et al., 2003 reported that homogeneously distributed

metals on zeolite surfaces and pores had increased

catalytic active sites. In addition, the Co/ZY catalyst

has a larger surface area, so the probability of the

reaction occurring in the active site is greater. How-

ever, in CoMo/ZY Catalyst, it provides a larger gas

product than Co/ZY catalyst. This was considered

from the role of the combination of Mo metal as a

catalyst promoter which showed a performance in

increasing catalyst activity in the MEFA hy-

drocracking reaction of rubber seed oil. The conver-

sion of liquid products produced from each ZY,

Co/ZY and CoMo/ZY catalysts were 39%, 32.4%

and 26.4% respectively. The selectivity of liquid

products to the gasoline and diesel fractions is dis-

played in Figure 6.

Figure 4: The SEM analysis result of (a) ZY, (b) Co/ZY

and (c) CoMo/ZY catalysts.

Figure 5: The catalytic activity of MEFA hydrocracking of

rubber seed oil with ZY, Co/ZY and CoMo/ZY catalyst at

a temperature of 450 oC with the ratio of 1:4.

Hydrocracking of Mefa Rubber Seed Oil into Biofuels Fraction with Co and CoMo Metals Supported on Zeolite Catalyst

283

Figure 6 shows that the ZY catalyst produced by

liquid hydrocarbons is dominated by diesel fractions

with 74.18%. However, for both the Co/ZY and

CoMo/ZY catalysts, the selectivity of liquid hydro-

carbon products produced on the gasoline fraction

increased significantly with the percentage of selec-

tivity to gasoline with 55.58% and 59.45% respec-

tively. The metal catalyst system of Co/ZY and

CoMo/ZY is able to increase the product selectivity

to the gasoline fraction to be more than 2 times that

of using a metal-free catalyst (ZY). This is due to the

increase in catalyst surface area and pore volume.

Trisunaryanti et al. (2013) reported that by using

zeolites which is containing metal, it will produce

liquid products with the C7-C12 fuel fractions. This

phenomenon may occur due to the presence of the

Bronsted acid site and as an active metal site causing

the solids to have catalytic properties. The empty d

orbitals owned by the metal, is functioning as Lewis

acid sites which can accept electron pairs from the

reactants. Therefore, the breakdown of the C-C

bonds occurs through the carbocation mechanism.

The CoMo/ZY catalyst shows the role of a combina-

tion of Co and Mo metals, where Mo acts as a pro-

moter on the catalyst which contributes to the in-

crease in catalyst activity in the MEFA rubber seed

oil hydrocracking reaction. This causes the Co-

Mo/ZY catalyst to produce gas and gasoline prod-

ucts that are larger than the ZY and Co/ZY catalysts.

The mechanism of the hydrocracking reaction on the

metal-carrying system catalyst (bifunctional cata-

lyst) has been described by Weitkamp (2012), as

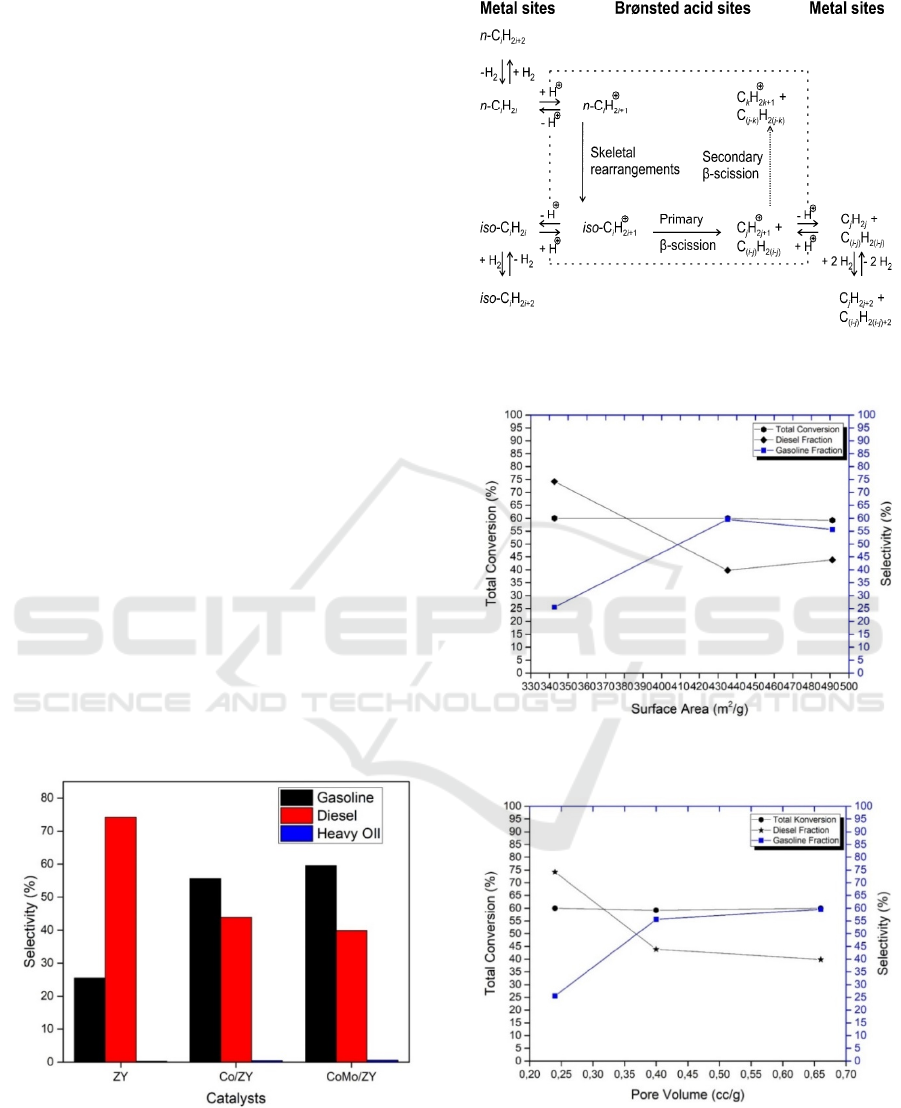

described in Figure 7.

Figure 6: The selectivity of liquid product of MEFA hy-

drocracking of rubber seed oil with ZY, Co/ZY and Co-

Mo/ZY catalyst at a temperature of 450

o

C with the ratio of

1:4.

Figure 7: The classical reaction mechanism of n-alkane

hydrocracking process on metal addition catalytic system.

Figure 8: The relation between surface area of catalyst to

the total conversion and selectivity level.

Figure 9: The relation between pore volume of catalyst to

the total conversion and selectivity level.

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

284

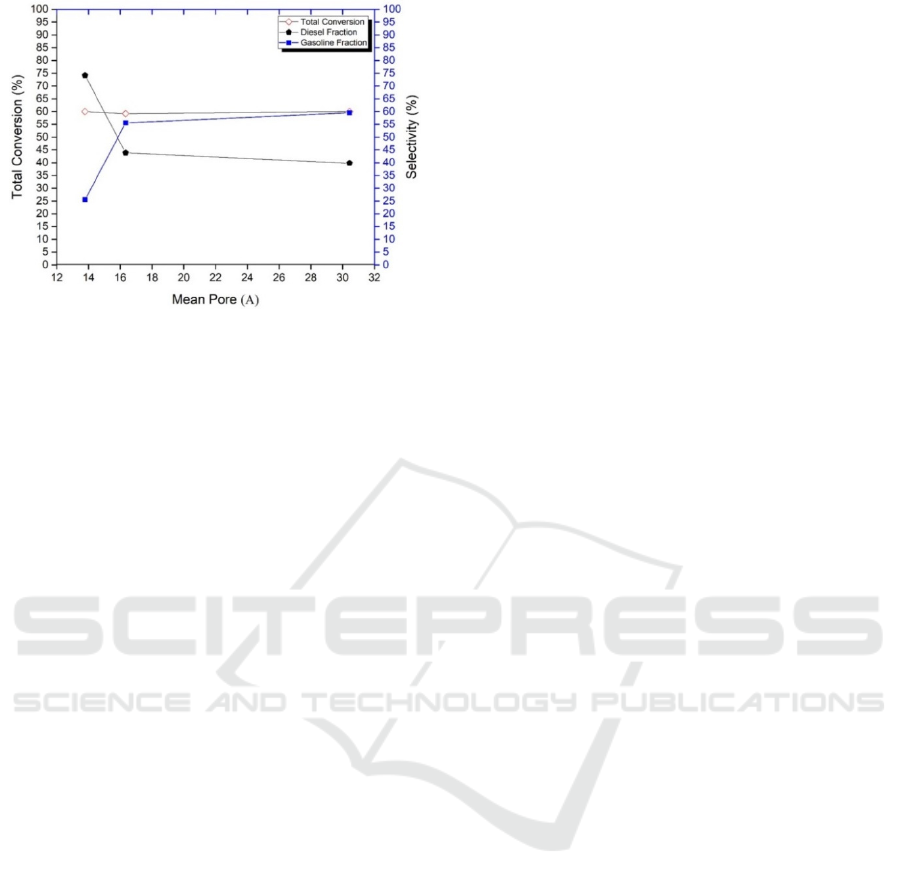

Figure 10: The relation between mean pore of catalyst to

the total conversion and selectivity level.

The relationship between specific surface area,

pore volume and mean of pore catalyst to the total

conversion and product selectivity are shown in

Figure 8, 9 and 10. Figure 8 shows that the increase

in catalyst surface area, will not giving a significant

effect on the total conversion results. In the other

hand, increasing the catalyst surface shows a ten-

dency to produce a higher gasoline fraction. This

condition is inversely proportional to the selectivity

of the diesel fraction. This is possible since the wide

catalyst surface provides a higher chance of adsorp-

tion and cracking reactions to produce lighter frac-

tions of gasoline or hydrocarbons. The same trends

are also shown in Figure 9 and 10. In Figure 9 and

10, it can be observed that the increase in pore vol-

ume and the mean of the catalyst pore range does

not contribute large influence on the total conversion

value, but shows the trend of increasing the selec-

tivity of liquid products to the gasoline fraction.

Increased pore volume as a result of the widening of

the pore size of the catalyst, so that the diffusion

process of the molecules resulting from cracking

MEFA can penetrate the pore, no further reaction

occurs, resulting in hydrocarbon compounds which

is equal to gasoline fractions in higher amounts. This

phenomenon may also be caused by the suitability of

the pore size of the catalyst at the time of cracking

reaction, including the process of reactant adsorp-

tion, catalytic cracking process, and desorption of

cracking molecules from the catalyst surface.

4 CONCLUSIONS

The Co and CoMo metal supported on ZY carriers

exhibit characteristics in increasing catalyst specific

surface area, total pore volume and mean catalyst

pore rate. The data obtained illustrate that Co metal

and CoMo metal presences do not damage the crys-

tal structure of ZY and are evenly distributed on the

pore surface of the carrier. From the processing of

XRD data using expo-2014 method, it was found

that ZY and Co/ZY catalysts were formed with a

triclinic crystal system, while for CoMo/ZY cata-

lysts showed a monoclinic crystal system. Moreover,

in the rubber seed oil MEFA hydrocracking reaction,

ZY catalyst showed a 74.18% higher selectivity for

biodiesel products. The presence of Co and CoMo

metals loaded on ZY increases the activity and se-

lectivity to the formation of the gasoline fraction. To

sum up, the highest gasoline product was produced

by CoMo/ZY catalyst with 59.45% w/t, followed by

Co/ZY catalyst with 55.58% w/t.

ACKNOWLEDGEMENT

Authors would like to acknowledge Rector Universi-

tas Negeri Medan and LPPM-Unimed for financial

support via “Hibah Penelitian KDBK-2019” scheme.

Moreover, a grateful acknowledgement is addressed

to Universitas Negeri Medan Research Center, Indo-

nesia, for facilitating the research.

REFERENCES

Bezergianni, S., Kalogianni, A., & Vasalos, I. A. (2009).

Hydrocracking of vacuum gas oil-vegetable oil mix-

tures for biofuels production. Bioresource Technology,

100(12), 3036–3042.

Choi, M., Na, K., Kim, J., Sakamoto, Y., Terasaki, O., &

Ryoo, R. (2009). Stable single-unit-cell nanosheets of

zeolite MFI as active and long-lived catalysts. Nature,

471(7261).

Da Silva, A. C. V. (2014). Study of the liquid activation of

CoMo and NiMo cat-alysts.

De Jong, K. P., Zečević, J., Friedrich, H., de Jongh, P. E.,

Bulut, M., Van Donk, S., & Fajula, F. (2010). Zeolite

Y crystals with trimodal porosity as ideal hy-

drocracking catalysts. Angewandte Chemie

International Edition, 49(52), 10074–10078.

Degnan, T. F. (2000). Applications of zeolites in

petroleum refining. Topics in Catalysis, 13(4), 349–

356.

Htay, M. M., & Oo, M. M. (2008). Preparation of Zeolite

Y catalyst for petroleum crack-ing. World Academy of

Science, Engineering and Tech-Nology, 48, 114–120.

Khowatimy, F. A., Priastomo, Y., Febriyanti, E.,

Riyantoko, H., & Trisunaryanti, W. (2014). Study of

waste lubricant hydrocracking into fuel frac-tion over

the combination of Y-zeolite and ZnO cata-lyst.

Procedia Environmental Sciences, 20, 225–234.

Hydrocracking of Mefa Rubber Seed Oil into Biofuels Fraction with Co and CoMo Metals Supported on Zeolite Catalyst

285

Parkhomchuk, E. V., Lysikov, A. I., Okunev, A. G.,

Parunin, P. D., Semeikina, V. S., Ayupov, A. B., &

Parmon, V. N. (2013). Meso/macroporous CoMo

alumina pellets for hy-drotreating of heavy oil.

Industrial & Engineering Chemistry Research, 52(48),

17117–17125.

Pashigreva, A. V., Bukhtiyarova, G. A., Klimov, O. V.,

Chesalov, Y. A., Litvak, G. S., & Noskov, A. S.

(2010). Activity and sulfidation behavior of the

CoMo/Al2O3 hydrotreating catalyst: The effect of

drying conditions. Catalysis Today, 149(1–2), 19–27.

Perlack, R. D., Eaton, L. M., Turhollow Jr, A. F., Lang-

holtz, M. H., Brandt, C. C., Downing, M. E., &

Nelson, R. G. (2011). US billion-ton update: biomass

supply for a bioenergy and bioproducts industry.

Pulungan, A. N., Sihombing, J. L., Nasution, H. I., Evina,

R., Dibyantini, Selly, R., Trisunaryanti, W., &

Triyono. (2014). Preparation, Characterization and

Activity Assay of NiO-CoOMoO/Zeolite-Y Catalyst

on Hydrocracking of Casher Nut Shell Liquid in

Fixed-bed Reactor. The First International Seminar on

Trends in Science and Science Education.

Sato, K., Nishimura, Y., Honna, K., Matsubayashi, N., &

Shimada, H. (2001). Role of HY zeolite mesopores in

hydrocracking of heavy oils. Journal of Catalysis,

200(2), 288–297.

Schwarz, J. A., Contescu, C., & Contescu, A. (1995).

Methods for preparation of catalytic materials.

Chemical Reviews, 95(3), 477–510.

Sihombing, J. L., Gea, S., Kembaren, A., Pulungan, A. N.,

Wibowo, A. A., & Wirjosentono, B. (2018). Activity

assays of calcinated sarulla natural zeolite (snz-cal) in

catalytic hydrocracking rubber seed oil. Journal of

Physics: Conference Series, 1116(4).

Sihombing, J. L., Gea, S., Pulungan, A. N., Agusnar, H.,

Wirjosentono, B., & Hutapea, Y. A. (2018). The

characterization of Sarulla natural zeolite crystal and

its morphological structure. AIP Conference

Proceeding, 2049(1).

Sriningsih, W., Saerodji, M. G., Trisunaryanti, W.,

Armunanto, R., & Falah, I. I. (2014). Fuel production

from LDPE plastic waste over natural zeolite

supported Ni, Ni-Mo, Co and Co-Mo metals. Procedia

Environmental Sciences, 20, 215–224.

Trisunaryanti, W., Syoufian, A., & Purwono, S. (2013).

Characterization and modification of indonesian natu-

ral zeolite for hydrocracking of waste lubricant oil into

liquid fuel fraction. Journal of Chemistry and

Chemical Engineering, 7(2), 175.

Vinh, T. Q., Loan, N. T. T., Yang, X. Y., & Su, B. L.

(2011). Preparation of bio-fuels by catalytic cracking

reaction of vegetable oil sludge. Fuel, 90(3), 1069–

1075.

Weitkamp, J. (2012). Catalytic hydrocracking—

mechanisms and versatility of the process.

ChemCatChem, 4(3), 292–306.

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

286