Isolation and Determination of Amylase Enzyme Activity from

Durian Seed Sprouts

M. Zulham Efendi Sinaga

1,2

, Cut Fatimah Zuhra

1,2

, Emma Zaidar

1,2

, Firman Sebayang

1

,

Rumondang Bulan

1

and Dea Rahmadana

1

1

Department of Chemistry, Universitas Sumatera Utara, Medan, Indonesia

2

Pusat Unggulan Iptek (PUI) Kitosan dan Material Maju

Keywords: Enzyme, Amylase, Germination, Durian Seed Sprouts.

Abstract: One of the favorite fruits in Medan-Indonesia is durian. The number of fruit is comparable to the most waste

of durian seed produced. Seeds are one of the ways to breed through the process of germination. In the

process of germination which plays an important role is the enzyme amylase. Based on this, the research

aims to isolate the enzyme amylase found in durian seed sprouts on the fifth day through dialysis with

ammonium sulfate and then determined its activity against temperature, pH, substrate concentration.

Through this research, the enzyme amylase has been isolated from the sprouts of durian beans with the best

activity at temperature 40 oC (36.87 U/ml), pH 7 (36.86 U/ml), substrate concentration 1% (26.36 U/ml).

The best ammonium sulfate saturation in the dialysis process is 60% acquired enzyme activity of 58.59

U/ml.

1 INTRODUCTION

Enzyme is a biocatalyst which can accelerate the

process of a reaction. Currently, the use of enzymes

in an industrial field is increasing. Some industries

that use enzymes among others are pharmaceutical

industry, food and beverage industry, and energy

sector (Chapman et al., 2018). One of the most

widely used enzymes is the amylase enzyme.

Amylase enzyme is an enzyme that hydrolyzes

starch to dextrin, maltose and glucose units by

cutting glycosidic bonds α- 1,4 and α- 1,6 in starch

(Mohanan & Satyanarayana, 2018; Simair et al.,

2017). In the food industry, amylase enzymes play

an important role in producing syrups and

sweeteners, in baking, in cereals and also in

beverage production. The wide use of amylase

enzymes in industry makes this amylase enzyme

take up 25% of the world's market enzymes (Naili et

al., 2016; Sindhu et al., 2017). The large enzyme

needs make researchers have to find new sources to

produce the enzyme amylase.

One of the process which requires amylase

enzymes is the germination process, in the

germination process the amylase enzyme is needed

to produce energy that will be used for the growth

process (Joshi, 2018). Based on these reasons, the

potential for durian seed sprouts as a source of

amylase enzymes is considered to have great

potential. In this study the age of durian seed sprouts

used as a source of the amylase enzyme was 5 days

old. Some factors that determine enzyme activity are

enzyme purity, pH, temperature and substrate

concentration of the enzyme. Therefore in this study

the parameters to be tested are the activity of the

amylase enzyme isolated from durian seed sprouts

on variation of temperature, pH and substrate

concentration. After the optimum conditions are

obtained then it will be applied to determine the

enzyme activity after the purification process by

using several variations of ammonium sulfate.

The success of this research is expected to add

new information on the source of the amylase

enzyme from durian seed sprouts. The potential of

durian is very much in Medan will add another

advantage of the waste produced by the durian fruits.

Sinaga, M., Zuhra, C., Zaidar, E., Sebayang, F., Bulan, R. and Rahmadana, D.

Isolation and Determination of Amylase Enzyme Activity from Durian Seed Sprouts.

DOI: 10.5220/0010199800002775

In Proceedings of the 1st International MIPAnet Conference on Science and Mathematics (IMC-SciMath 2019), pages 413-417

ISBN: 978-989-758-556-2

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

413

2 MATERIALS AND METHODS

2.1 Isolation of Amylase Enzyme from

Durian Seed Sprouts

Durian seeds are washed with running water and

then put into a container for the germination process,

prepared by growing media and then waited for

durian seed germination for 5 days. 150 grams of 5

days durian seed sprouts obtained were

homogenized with 250 ml of 1% Isotonic NaCl

solution in a cold state. Then mashed and filtered

until the filtrate and pulp separate. The filtrate was

centrifuged at 10,000 rpm at 20C for 10 minutes.

The crude of enzyme produced was tested for its

activity against temperature variations (30, 35, 40,

45 dan 50C), pH (3, 5, 7, dan 9) and Substrate

concentration (0,5; 1; 1,5; 2; dan 2,5% w/v). The

resulting enzyme crude is purified by varying the

saturation level of ammonium sulfate (20, 40, 60 dan

80% w/v) then the purification results of each

variation were tested their activity back to the

optimum temperature, pH and substrate

concentrations to determine the activity of the

resulting amylase enzyme after purification.

2.2 Crude Amylase Enzyme Activity

Test on Variation of Temperature

0.5 mL of 1% starch solution was put into the test

tube then added 5 mL of buffer phosphate pH 7.

Added 1 mL of crude amylase enzyme extract and 1

ml of 1% NaCl. Then incubated at temperature

variations (30, 35, 40, 45 and 50 0C) for 1 hour.

After that, 1 mL of 0.1N NaOH was added and

centrifuged at 3400 rpm for 20 minutes. 1 ml of the

supernatant is taken and then diluted in 10 ml

measuring flask and then homogenized. Put 1 ml of

dilution results into the test tube then add 1 ml of

Nelson’s reagent and heated in a water bath for 20

minutes. Then removed and cooled until the

temperature 25 0C. 0.5 mL of arsenomolybdate was

added and then shaken until all the sediment

dissolved. Then added 7 mL of distilled water and

then shaken until homogeneous. Its absorption is

measured at a wavelength of 645 nm.

2.3 Crude Amylase Enzyme Activity

Test on Variation of pH

0.5 mL of 1% starch solution was put into the test

tube then added 5 mL of buffer phosphate pH 3, 5, 7

and 9. Added 1 mL of crude amylase enzyme extract

and 1 ml of 1% NaCl. Then incubated at optimum

temperature for 1 hour. After that, 1 mL of 0.1N

NaOH was added and centrifuged at 3400 rpm for

20 minutes. 1 ml of the supernatant is taken and then

diluted in 10 ml measuring flask and then

homogenized. Put 1 ml of dilution results into the

test tube then add 1 ml of Nelson’s reagent and

heated in a water bath for 20 minutes. Then removed

and cooled until the temperature 25C. 0.5 mL of

arsenomolybdate was added and then shaken until

all the sediment dissolved. Then added 7 mL of

distilled water and then shaken until homogeneous.

Its absorption is measured at a wavelength of 645

nm.

2.4 Crude Amylase Enzyme Activity

Test on Variation of Substrate

Concentrations

0.5 mL of starch solution variation (0,5; 1; 1,5; 2;

dan 2,5%) was put into the test tube then added 5

mL of buffer phosphate optimum pH. Added 1 mL

of crude amylase enzyme extract and 1 ml of 1%

NaCl. Then incubated at optimum temperature for 1

hour. After that, 1 mL of 0.1N NaOH was added and

centrifuged at 3400 rpm for 20 minutes. 1 ml of the

supernatant is taken and then diluted in 10 ml

measuring flask and then homogenized. Put 1 ml of

dilution results into the test tube then add 1 ml of

Nelson’s reagent and heated in a water bath for 20

minutes. Then removed and cooled until the

temperature 25C. 0.5 mL of arsenomolybdate was

added and then shaken until all the sediment

dissolved. Then added 7 mL of distilled water and

then shaken until homogeneous. Its absorption is

measured at a wavelength of 645 nm.

2.5 Crude Amylase Enzyme Activity

Test after Purification with

Ammonium Sulfate

0.5 mL of starch solution optimum variation was put

into the test tube then added 5 mL of buffer

phosphate optimum pH. Added 1 mL of crude

amylase enzyme extract after purification with

variations in the saturation level of ammonium

sulfate (20, 40, 60 dan 80%) and 1 ml of 1% NaCl.

Then incubated at optimum temperature for 1 hour.

After that, 1 mL of 0.1N NaOH was added and

centrifuged at 3400 rpm for 20 minutes. 1 ml of the

supernatant is taken and then diluted in 10 ml

measuring flask and then homogenized. Put 1 ml of

dilution results into the test tube then add 1 ml of

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

414

Nelson’s reagent and heated in a water bath for 20

minutes. Then removed and cooled until the

temperature 25C. 0.5 mL of arsenomolybdate was

added and then shaken until all the sediment

dissolved. Then added 7 mL of distilled water and

then shaken until homogeneous. Its absorption is

measured at a wavelength of 645 nm.

3 RESULTS AND DISCUSSIONS

Durian seeds used in this study were obtained from

durian traders around Medan, North Sumatera,

Indonesia. Durian seeds that have been cleaned are

then germinated, after 5 days the resulting sprouts

will then be processed as a source of the amylase

enzyme. Germination carried out in this study after 5

days as in Figure 1 below.

Figure 1: Durian Seed Sprouts.

Based on Figure 3.1 above durian seed sprouts

after 5 days have an average height of 2.5 cm - 2.8

cm. Some factors that can affect the process of

germination development are temperature, water

potential, nutrition, light and humidity (Joshi, 2018;

Shaban, 2013). These factors must be conditioned to

obtain sprouts with a uniform height.

Amylase enzyme isolation process carried out on

150 grams of durian seed sprouts, at this stage

obtained an orange solution, which will then be

tested for its activity against variations on

temperature, pH and substrate concentration before

and after purification.

3.1 Crude Amylase Enzyme Activity

Test on Variation of Temperature

One of the main determinants of enzyme activity is

temperature. This is because enzymes are part of

proteins that are sensitive to extreme changes in

temperature (Mohanan & Satyanarayana, 2018). In

this study the temperature range used is 30 – 50

0

C

with a range of 5

0

C. The amount of crude amylase

enzyme activity obtained in accordance with Figure

2

Figure 2: Activity of Crude Enzyme on Variation of

Temperature.

Based on Figure 2 above, it can be seen that the

activity of crude amylase enzyme produced is

influenced by temperature. At temperature of 30-40

0

C the enzyme activity has increased and the

optimum temperature is seen at a temperature of 40

0

C with value of activity is 36.87 U/ml and will

further decrease its activity until a temperature of 50

0

C. Temparature value of the activity of enzyme is

also influenced by the source of the enzyme

obtained. Asrat et al 2018 has isolated enzyme

amylase from Aspergillus Niger FAB-211, the

optimum temperature of enzyme amilase is 45 0C.

Several studies have reported that the optimal

activity for the amylase enzyme is at temperature

40°C if the enzyme is isolated from H.

bacteriophora, A. suum and S. Litorallis and 50°C

for α -amylases from C. flavus, S. alluvius

ATCC 26074, L. kononenkoae and C. antarctica

CBS 667 (Wanderley et al., 2004).

3.2 Crude Amylase Enzyme Activity

Test on Variation of pH

Besides temperature, another factor that determines

the activity of an enzyme is pH. The crude amylase

enzyme activity test results obtained in this study are

shown in Figure 3 below.

Isolation and Determination of Amylase Enzyme Activity from Durian Seed Sprouts

415

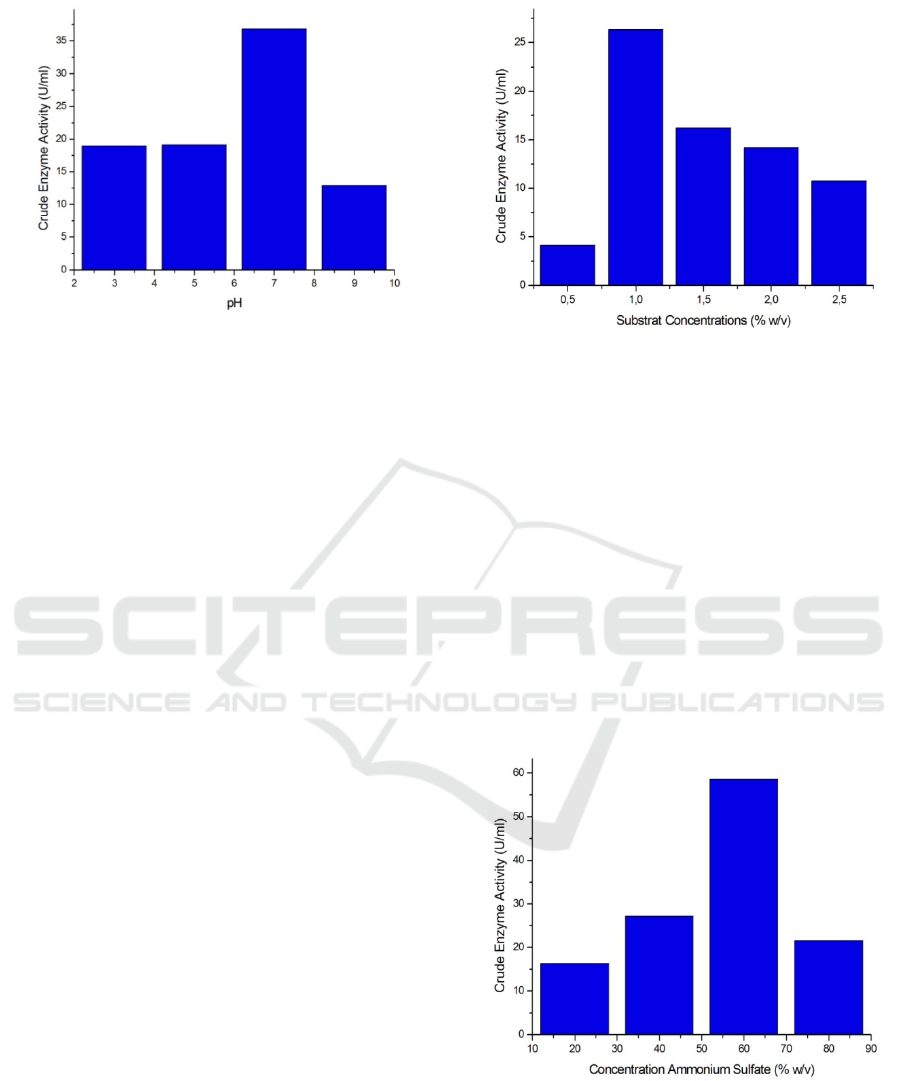

Figure 3: Activity of Crude Enzyme on Variation of pH.

Based on Figure 3 The following shows that at pH 3

and 5 the crude amylase enzyme activity shows no

difference, but when pH 7 shows the optimum

activity of crude enzyme amylase, the value of

activity ezymes is 36,86 U/ml and will decrease at

pH 9. Several studies have shown that the optimum

pH for several amylase enzymes is also in the pH

range of 6-6.5 (Asrat & Girma, 2018; Biazus et al.,

2009).

3.3 Crude Amylase Enzyme Activity

Test on Variation of Substrate

Concentrations

Comparison between enzymes and substrate

concentrations also needs to be considered because

if a comparison between enzymes and substrate is

appropriate a product with maximum hydrolysis

results will be obtained. In this study the results of

testing the activity of crude enzyme amylase on

substrate concentration are shown in Figure 4.

Based on Figure 4 below, it can be concluded

that the optimum substrate concentration that can be

hydrolyzed by the crude amylase enzyme isolated is

at a concentration starch solution 1%. This shows

that the ratio between enzymes and substrate is 1 ml

of enzyme with 0.5 ml of 1% starch substrate

obtained enzyme activity of 26.36 U/ml.

Figure 4: Activity of Crude Enzyme on Variation of

Substrat Concentration.

3.4 Crude Amylase Enzyme Activity

Test after Purification with

Ammonium Sulfate

The purity of enzymes is important because purer

enzymes will have better activity than before

purification. In this study crude enzyme amylase

was purified through a dialysis process that was

previously precipitated with ammonium sulfate at a

saturation level of 20% - 80% with range of 20%. At

this stage the enzyme activity measured was carried

out at the optimum temperature, pH and substrate

concentration that had been carried out previously.

The results obtained are shown in Figure 5 below.

Figure 5: Activity of Crude Enzyme on Variation of

Concentration Ammonium Sulfate.

Based on Figure 5 above it can be seen that after the

purification process the enzyme amylase activity has

increased than before the dialysis process. The

optimum activity of the amylase enzyme obtained at

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

416

60% ammonium sulfate concentration, the value of

activity enzyme is 58.59 U/ml. Based on this it can

be concluded that the purification process is one of

the important things that must be done to see the

activity of an enzyme.

4 CONCLUSIONS

Based on the research that has been done, it can be

concluded that durian seed sprouts can be used as a

source of amylase enzymes. Crude Activity The

amylase enzyme produced in this study before being

purified had optimum activity at a temperature of 40

0C, pH 7, and 1% substrate concentration obtained

activity values for each of 36.87 U/ml, 36.86 U/ml,

and 26.36 U/ml. The optimum conditions obtained

were then used to determine the crude activity of the

amylase enzyme after purification through dialysis

which was previously precipitated with ammonium

sulfate and obtained optimum results at a

concentration of 60% ammonium sulfate with

enzyme activity of 58.59 U/ml.

ACKNOWLEDGEMENT

The researcher would like to thank to Chancellor of

Universitas Sumatera Utara through the research

institution of Universitas Sumatera Utara for funding

this research with no contract

4167/UN5.1.R/PPM/2019. On April 2019

REFERENCES

Asrat, B., & Girma, A. (2018). Isolation, Production and

Characterization of Amylase Enzyme Using the

Isolate Aspergillus niger FAB-211. International

Journal of Biotechnology and Molecular Biology

Research, 9(2), 7–14.

Biazus, J. P. M., Souza, R. R. de, Márquez, J. E., Franco,

T. T., Santana, J. C. C., & Tambourgi, E. B. (2009).

Production and characterization of amylases from Zea

mays malt. Braz. Arch. Biol. Technol., 52(4), 991–

1000. https://doi.org/https://doi.org/10.1590/S1516-

89132009000400024

Chapman, J., Ismail, A. E., & Dinu, C. Z. (2018).

Industrial Applications of Enzymes: Recent Advances,

Techniques, and Outlooks. Catalysts, 8(6), 1–26.

https://doi.org/https://doi.org/10.3390/catal8060238

Joshi, R. (2018). Role of Enzymes in Seed Germination.

International Journal of Creative Research Thoughts,

6(2), 1481–1485.

Mohanan, N., & Satyanarayana, T. (2018). Amylases

Reference Module in Life Sciences. Elsevier Inc.

Naili, B., Sahnoun, M., Bejar, S., & Kammoun, R. (2016).

Optimization of submerged Aspergillus oryzae S2 α-

amylase production. Food Science and Biotechnology,

25(1), 185–192.

Shaban, M. (2013). Effect of Water and Temperature on

Seed Germination and Emergence as A Seed

Hydrothermal Time Model. International Journal of

Advanced Biological and Biomedical Research, 1(12),

1686–1691.

Simair, A. A., Qureshi, A. S., Khushk, I., Ali, C. H.,

Lashari, S., Bhutto, M. A., Mangrio, G. S., & Lu, C.

(2017). Production and Partial Characterization of α-

Amylase Enzyme from Bacillus sp. BCC 01-50 and

Potential Applications. BioMed Research

International, 2017, 1–9.

https://doi.org/https://doi.org/10.1155/2017/9173040

Sindhu, R., Binod, P., Madhavan, A., Beevi, U. S.,

Mathew, A. K., Abraham, A., Pandey, A., & Kumar,

V. (2017). Molecular improvements in microbial α-

amylases for enhanced stability and catalytic

efficiency. Bioresour Technol., 245, 1740–1748.

Wanderley, K. J., Torres, F. A. G., Moraes, L. M. P., &

Ulhoa, J. C. (2004). Biochemical characterization of α‐

amylase from the yeast Cryptococcus flavus. FEMS

Microbiology Letters, 231(2), 165–169.

https://doi.org/https://doi.org/10.1016/S0378-

1097(03)00955-8

Isolation and Determination of Amylase Enzyme Activity from Durian Seed Sprouts

417