Antimicrobial Activities Assessment of Cinnamon Bark

(Cinnamomum burmannii Nees & T. Nees) Extract against Caries

Factors

Prasetyorini

1

, Dian Indah W.

2

, Yulianita

2

, Novi F. U.

2

and Neng Rani

2

1

Biology Study Program, Faculty of Mathematics and Natural Science, Universitas Pakuan, Bogor, Indonesia

2

Pharmacy Study Program, Faculty of Mathematics and Natural Science, Universitas Pakuan, Bogor, Indonesia

Keywords: Cinnamon Bark Extract; Streptococcus Mutan, Staphylococus Aureus; Candida Albicans.

Abstract: This research was conducted to test the antimicrobial activity of cinnamon bark (Cinnamomum burmani

Nees & T. Nees Blume) against Streptococcus mutans, Streptococcus aureus, and Candida albicans. The

gradual extraction method was employed using 3 types of solvents which were n-hexane, ethyl acetate, and

70% ethanol. The obtained extracts were dried from their solvents by vacuum-drying and weighed to obtain

the extraction yield. The dried extracts were each characterized to gain information about color, aroma, and

water content. Further characterization was conducted to qualitatively measure the phytochemical contents

such as alkaloids, flavonoids, tannins, and saponin, then followed by growth inhibition tests such as

minimum inhibitory concentration (MIC) and inhibition zone test. The result showed that the obtained

yields of n-hexane, ethyl acetate, and 70% ethanol were 3.75%, 3.70%, and 32.47%, respectively. All

extracts were brown-colored with a distinctive cinnamon aroma. The qualitative phytochemical

measurements were as follows: n-hexane extract showed the presence of tannins, ethyl acetate extract

showed the presence of flavonoids, while the 70% ethanol extract showed the presence of alkaloids,

flavonoids, tannins, and saponin. The MIC test result for n-hexane, ethyl acetate, and 70% ethanol extracts

were, in order, 12%, 12%, and 8% against Staphylococcus aureus, 2.5%, 2.5%, and 25% against

Streptococcus mutan, and 2.5%, 2.5%, and 25% against Candida albicans. The best inhibition zone test

results against Staphylococcus aureus were exhibited by n-hexane, ethyl acetate, and 70% ethanol extracts

in following concentrations: 50% (3.16 mm), 50% (5.90 mm), and 32% (6.83 mm), respectively. Against

Streptococcus mutan, the best n-hexane concentration was 2.5% (3.83 mm), while ethyl acetate and 70%

ethanol extract exhibited relatively the same results in all of their measured concentrations, which were 2.00

mm and 5.30 mm, respectively. Against Candida albicans, the best n-hexane extract concentration was 10%

(14.5 mm), and the best ethyl acetate concentration extract was 10% (7 mm). The 70% ethanol extract

exhibited relatively same results (1.5 mm) in all measured concentrations.

1 INTRODUCTION

Oral microorganisms that cause dental caries and

thrush are Streptococcus mutans, Candida albicans,

and Staphylococcus aureus (Brotosoetarno, 1997).

Dental caries can cause the quality of life disorders

including limited dental function, physical disability,

and psychological discomfort. One of the plants that

have the potential to improve the dental and oral

health is cinnamon bark. Cinnamon is a plant in

which bark and branches are contain alkaloids,

flavonoids, tannins and essential oils consisting of

camphor, safrol, eugenol, sinamaldehid,

cinamilacetate, terpenes, cineol, citral, citronellal,

polyphenols and benzaldehyde (Perry & Metzger,

1980).

According to Anandito et al. (2012) the main

components of cinnamon bark essential oils are

sinamaldehid (63.12%), p-Cineole (17.37%), benzyl

benzoate (11.65%), linalool (8.57%), α-Cubebene

(7.77%), and α-Terpineol (4.16%). According to

Bisset & Wichtl (2001), cinnamon bark essential oils

contain cinnamicaldehyde, whereas the leaves

contain more eugenol. According to Rismunandar &

Paimin (2001), in cinnamon bark, there are also

chemical components such as dammar, adhesive,

tannin, tanners, sugar, calcium oxalate, two types of

insecticide cinnzelanin and cinnzelanol, cumarin.

494

Prasetyorini, ., W., D., Yulianita, ., F. U., N. and Rani, N.

Antimicrobial Activities Assessment of Cinnamon Bark (Cinnamomum burmannii Nees T. Nees) Extract against Caries Factors.

DOI: 10.5220/0010205500002775

In Proceedings of the 1st International MIPAnet Conference on Science and Mathematics (IMC-SciMath 2019), pages 494-501

ISBN: 978-989-758-556-2

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Cinnamon bark has a sweet and slightly spicy,

fragrant and warm nature. Cinnamon contains

including essential oils of eugenol, safrole, tannins,

calcium oxalate, dammar and tanners.

Susanti et al. (2013) reported that cinnamon bark

essential oil is widely used as raw material for the

industry of making fragrance oil, cosmetics,

pharmaceuticals, and other industries. The cinnamon

essential oil can also be used as a mouthwash and

paste, refreshment, aroma soap, detergent, lotion,

perfume, and cream (Rismunandar & Paimin, 2001).

Kadek (2011) mentioned the ethanol extract

compound of cinnamon bark has the antibacterial

power of Streptococcus mutans with a Minimum

Inhibition Concentration (MIC) of 5% and Inhibition

Zone of 5 mm. The content of cinnamon bark extract

compounds has the antifungal activity of Candida

albicans with a MIC of 1% and an inhibition zone of

25.5 mm. Nuryanti et al. (2015) stated that cinnamon

bark extract with n-hexane solvent had greater

inhibitory growth of Candida albicans when

compared to other solvents. Research by Puspita

(2014) stated that 96% ethanol extract of cinnamon

can reduce the growth of Staphylococcus aureus

bacteria with inhibitory zones of 20% (6.14 mm),

40% (13.01 mm), 80% (21, 04 mm), 100%

(23.61mm).

Cinnamon bark can be used as an antidiarrheal

drug, stomach cramps, and to reduce intestinal

secretions. Pharmacological effects of cinnamon are

carminative, diaphoretic, antirheumatic, stomachic

and analgesic pain relievers. Cinnamon bark can

also be used for medicinal ingredients; essential oils

can be used in the industry of perfume, cosmetics,

pharmaceutical, and food or beverage (Inna et al.,

2010; Shekar et al., 2012). Cinnamon bark is known

as one of the plants that have active compounds of

cinnamaldehyde and eugenol which has antibacterial

properties (Inna et al., 2010). In this research, the

extraction of active ingredients will use a multilevel

maceration method with three different solvents. The

first solvent is n-hexane, a type of nonpolar solvent

that can dissolve compounds that are nonpolar

(Maulida et al., 2010). The second solvent is ethyl

acetate, a semi-polar solvent that can dissolve semi-

polar compounds in the cell (Harborne, 1996). The

third solvent is ethanol, a polar solvent that can

dissolve polar compounds such as phenol groups

(Kusumaningtyas et al., 2008). The purpose of this

study was to obtain cinnamon bark extract with

different polarity solvents and test the extract as an

anti-bacterial and anti-fungal cause dental caries and

canker sores. Extract activity as antibacterial and

antifungal will be determined by measuring MIC and

inhibition zone on bacteria and fungus test.

2 METHODS

The study used a complete Randomized Design,

carried out in March to May 2019 in the Pharmacy

Laboratory, Faculty of Mathematics and Natural

Sciences at Pakuan University and in the

Microbiology Laboratory, Department of Biology,

Bogor Agricultural University. The tools utilized

include digital scales (LabPRO®, Kern®) grinders

(Zeppelin®), autoclaves (All American®), ovens

(Memmen®), test tubes (Pyrex®), test tube racks, 10

ml vials, dishes Petri (Pyrex, ose, beaker glass

(Pyrex), measuring glass (Pyrex), volume pipette

(Pyrex®), incubator (nuve®), stir bar, spirtus burner,

Laminar Air Flow (LAF), Vacuum Dry (Ogawa®) ,

furnace, Waterbath (Memment®), Hot plate stirrer

(Termo Scientific Cimarec®), magnetic bars and

other glassware. The ingredients utilized are 11000g

cinnamon bark, culture of Streptococcus mutans,

Staphylococcus aureus and Candida albicans, PDB

(Potato Dextrose Broth), BHI (Brain Heart Infusion),

70% Ethanol, N-hexane, Ethyl Acetate, Physiological

NaCl, Whatman paper disks, Clindamycin

antibiotics, Nystatin, 1% DMSO and other chemicals.

2.1 Extraction

Cinnamon bark used was obtained from the

Research Institute for Medicinal Herbs (Balitro) at

Jalan Tentara N0.3, Cimanggu, Central Bogor,

Ciwaringin, Bogor, West Java 16124 and has been

determined at the LIPI Bogoriense Hebarium Bogor.

Next, 1100g of cinnamon bark was made into

powder simplicia and measured the yield, moisture

content, and ash content. Water content is measured

by the gravimetric method and ash content is

measured by heating the powder simplicia in the

furnace at 6000C. 1000g extraction of cinnamon

barks powder using a multilevel maceration method

with three solvents, n-hexane, ethyl acetate, and 70%

ethanol. Initially, 500g of cinnamon powder was

macerated using 5 L n-hexane solvent for 3x24

hours, by putting 500g of cinnamon bark powder into

a brown bottle with capacity of 5 L, then adding 2.5

L of n-hexane, and shook. The solution allowed to

stand for 18 hours while occasionally shaken, then

the filtrate and residue are separated by filtering. In

the same way, the residue was re-macerated twice of

each using the remaining 1.5 L n-hexane.

Antimicrobial Activities Assessment of Cinnamon Bark (Cinnamomum burmannii Nees T. Nees) Extract against Caries Factors

495

The maceration filtrate was collected, poured for

± 24 hours, and the filtrate that had been poured was

then concentrated with vacuum dry until a dry

extract was obtained, then characterized for the

organoleptic character, water content and ash

content. Meanwhile, the residue is dried in an oven

at 50

0

C and then in the same way the residue is re-

macerated with different solvents of ethyl acetate

and 70% ethanol. Thus, three kinds of extracts will

be obtained, namely n-hexane extract, ethyl acetate

extract and 70% ethanol extract. The yield of the

extract obtained then calculated.

2.2 Phytochemical Test of Extracts

The three types of extracts were carried out by

phytochemical screening for alkaloids, flavonoids,

saponins, tannins, and steroids/terpenoids. Alkaloids

test using Dragendrof reagents, Mayer test and

Bouchardat test (Ministry of Health of the Republic

of Indonesia, 1995). Flavanoid test using Mg powder

with a few drops of 5 M hydrochloric acid and Zn

powder with a few drops of 5M hydrochloric acid.

The tannin test uses 1% of gelatin in 10% NaCl and

with a solution of FeCl3. Tannin test carried out by

shaking for 10 minutes. Steroid and terpenoid tests

using chloroform of concentrated H2SO4 (Kumoro,

2015).

2.3 Media Making

Weighed 20g for each medium of GDP and BHI,

and 23g for NA media, then each of media was

dissolved in 1 L of water, then placed in an

Erlenmeyer and heated using a hot plate equipped

with a magnetic stirrer until boil and clear. Then the

media was covered with cotton and aluminum foil

(Hidayat & Sutarma, 1999), and sterilized in an

autoclave at 121

o

C with a pressure of 1 atm for 20

minutes (Waluyo, 2008). After the heat is reduced,

near the Bunsen burner was poured in a Petri dish

and test tube (tilted) @ 5 ml. After the media has

frozen, the sterilization test was done by putting it

into a 37

o

C incubator for 24 hours before the media

is used. Each batch of media that has been tested for

sterilization and quality then stored at 5

o

C-8

o

C

(Hidayat & Sutarma, 1999).

2.3.1 Preparation of Bacteria and Fungus

One ose pure Candida albicans culture was

inoculated on slanted solid PDB (Potato Dextrose

Broth) media, while the pure culture of

Streptococcus mutans in BHI (Brain Heart Infusion)

media and Staphylococcus aureus was inoculated in

slanted solid Nutrien Agar (NA) media. Then each

test tube is closed with a plug (Waluyo, 2008). All

the media then incubated at 37

0

C and 20-25

0

C for 24

hours. Bacteria and fungi that have been grown are

then stored in a refrigerator at 4

O

C as stock. The

colonies of bacteria and fungi that have grown on

each tilted media then made a suspension on a test

tube containing 0.9% NaCl (physiological Na) by

using ose, then homogenized. The turbidity of the

suspension is likened to the standard solvent of Mc

Farland 1 and then dilution is carried out up to 10

-6

.

2.3.2 Test of Minimum Inhibitory

Concentration (MIC)

The MIC test for the three types of extract produced

was carried out by the dilution method, the

concentration of the extract tested was presented in

Table 1, and all treatments were duplicated.

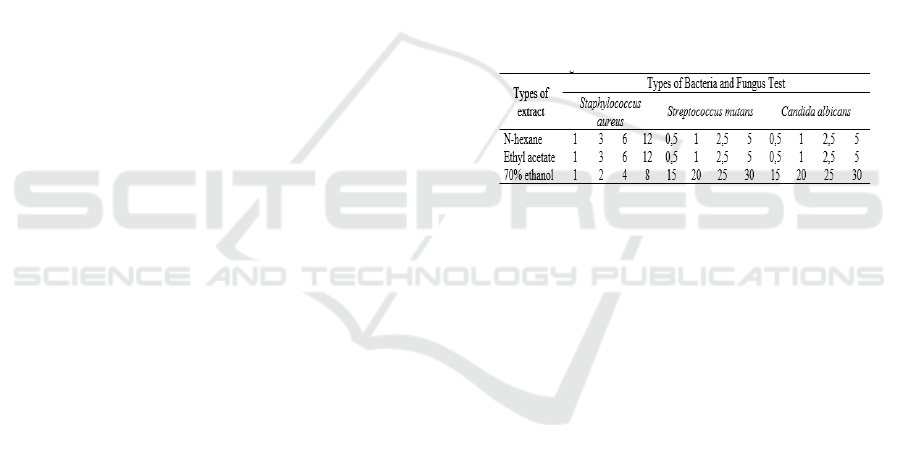

Table 1: Extract concentration treatment (%) in testing the

minimum inhibitory concentrations of bacteria and fungi.

2.3.3 Test of Inhibition Zone

The inhibition zone test is carried out using the Paper

Disc Diffusion method. The active ingredient in the

form of an extract is placed in a 6 mm diameter disc

aseptically, then placed on a media that has been

inoculated with bacteria or fungi. The inhibition zone

is measured by measuring the clear zone that occurs

around the disc paper. This test is done in duplicate.

For the inhibition zone test, the concentrations tested

are based on the results of the MIC test. The positive

control for Staphylococcus aureus bacteria is 10 ppm

amoxicillin, mutant Streptococcus is 10 ppm

clindamycin, Candida albicans used Nystatin 100.000

IU/ml, and all negative controls are DMSO 1%. The

making of extract test solution is done by making 50%

concentrated parent dissolve of each dry extract. The

making of the test solution is carried out with a

dilution formula based on concentration. The making

of the paper disc was done by soaking the Whatman

filter paper with a 6 mm diameter in extracts according

to concentration for 30 minutes. Then dried in the

oven for 24 hours in a Petri dish container at 40-50

o

C

until dry and ready for use. The concentrations used in

the inhibition zones test are presented in Table 2 and

each with 3 replications.

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

496

Table 2: Treatment of extract concentrations (%) tested on

the inhibition zone test of bacteria and fungus.

3 RESULTS AND DISCUSSION

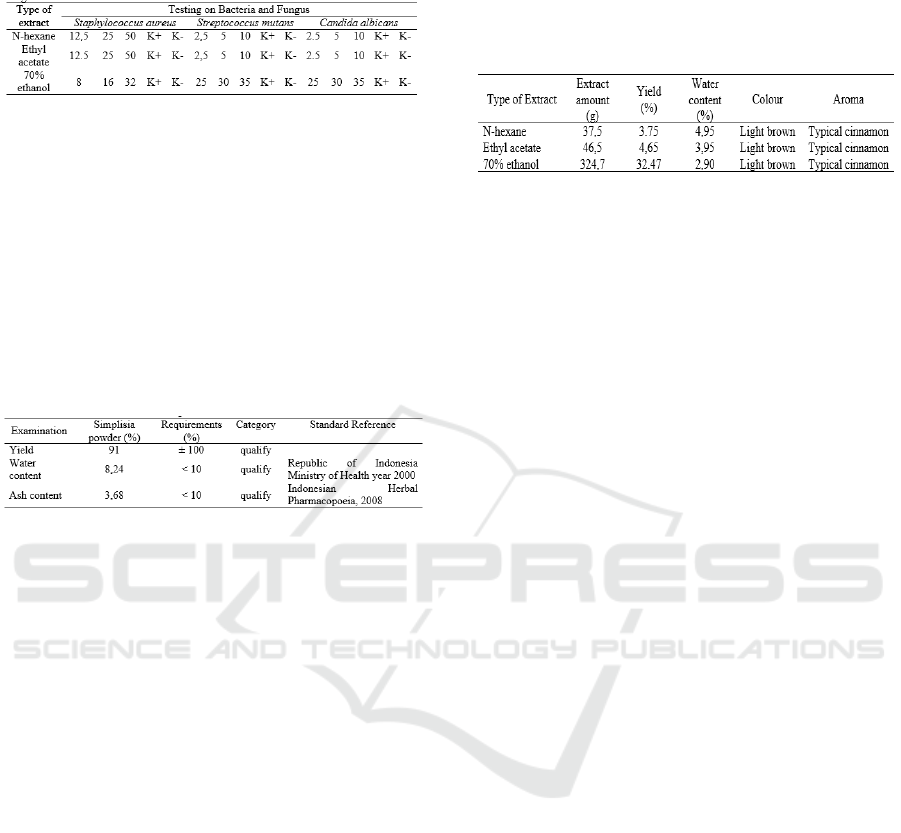

From 1100g cinnamon bark produces 1000g of

simplicia cinnamon bark powder, brownish-colored

simplicia powder, a slightly spicy-sweet taste with a

characteristic aroma of cinnamon. The yield, water

content and ash content are all meet the applicable

requirements (Table 3).

Table 3: Characterization results of Simplisia Cinnamon

Bark Powder.

Water content is a quality indicator of the simplicia

powder that needs to be known because water is a

good medium for microbial growth so that it can

result in decreased quality of simplicia. Low water

content in simplicia can extend the shelf life of

simplicia powder. The ash content of the simplicia

powder of cinnamon bark obtained was 5.21%. The

qualified determination of ash content was less than

10.5% (Ministry of Health of the Republic of

Indonesia, 2008). The determination of ash content

aims to determine levels of inorganic substances and

minerals contained in simplicia originating from

plants or contaminants during the manufacturing

process of simplicia (Ministry of Health of the

Republic of Indonesia, 1995). Ash levels in

cinnamon bark powder simplicia still meet the

Indonesian Herbal Pharmacopeia of 2008, which is

3.68% (˂ 10%).

3.1 Extraction Results

Multilevel maceration was carried out with a

simplicia powder of 1000g, using three different

solvents namely n-hexane, ethyl acetate and ethanol

70%, each solvent used in a ratio of 1:10.

Maceration results obtained 3 filtrates with different

solvents, and then each filtrate was vacuum dried

until a dry extract of cinnamon bark was obtained.

The results of the characteristics of n-hexane extract,

Ethyl acetate extract, and 70% ethanol extract of

cinnamon bark can be seen in Table 4.

Table 4: Characterization extracts Results of Multilevel

Maceration Results of 1000g Simplisia Powder.

The water content obtained in the n-hexane

extract of cinnamon bark was 4.95%, ethyl

acetate extract was 3.95% and 70% ethanol

extract was 2.90%. The results of the water

content of cinnamon bark extract meet the

requirements of the dry extract water content of

<5%. Different types of solvents affect the amount

of extract produced. Ethanol (polar) extract has the

highest yield because ethanol has a polar group that

is stronger than non-polar groups; this can be seen

from the chemical structure of ethanol containing

hydroxyl (polar) groups and carbon (nonpolar)

groups.

Ethanol can extract phytochemical compounds in

higher amounts. The high yield in the ethanol

solvent shows that the solvent was able to extract

more bioactive components that have higher polarity

properties. This is probably because the cinnamon

bark component contains many polar compounds.

The yield of ethyl acetate solvent is smaller than the

ethanol solvent but larger than the n-hexane solvent;

it is suspected that there is a methoxy group

contained in the chemical structure of ethyl acetate.

The presence of the methoxy group in the hydrogen

bond sample formed in the ethyl acetate solvent is

weaker than the hydrogen bond formed in the

ethanol solvent; so that it can affect the yield of less

solvent of the ethyl acetate.

3.2 Phytochemical Screening

This test was conducted to determine the class of

compounds contained in extracts of n-hexane, ethyl

acetate and ethanol of cinnamon bark after

extraction. Tests carried out are alkaloid, flavonoid,

tannin, and saponin. Phytochemical test results of n-

hexane extract, ethyl acetate and ethanol of

cinnamon bark can be seen in Table 5.

Antimicrobial Activities Assessment of Cinnamon Bark (Cinnamomum burmannii Nees T. Nees) Extract against Caries Factors

497

Table 5: Results of Qualitative Phytochemical Tests of

Extracts.

Phytochemical test results indicate the presence

of tannin compounds in n-hexane extract. The

tannins contained in the n-hexane solvent are

hydrolyzed tannins because it has a polyester

structure that is easily hydrolyzed by acids or

enzymes, and as a result of its hydrolysis is a

polyphenic acid and simple sugar (Maldonado,

1994). Hydrolyzed tannins are present in non-food

ingredients (Makkar et al., 1993). The positive ethyl

acetate extract contains alkaloids because alkaloids

can dissolve in semi-polar solvents. Alkaloids in

plants are generally in the form of salts so that only

soluble in inorganic solvents (chloroform, ethyl

acetate, acetone, benzene, alcohol, ethanol, and

methanol). In the 70% ethanol extract contains

alkaloid, flavonoid and saponin compounds because

the 70% ethanol is polar in nature so that it can

attract polar compounds. From these results, it can

be seen that there are other compounds that have

efficacy as antimicrobials other than essential oils

revealed by the research of Kadek (2011).

Alkaloids are the largest group of secondary

metabolites and are mostly sourced in plants

(Ningrum et al., 2016). Alkaloid compounds which

have basic groups containing nitrogen will react with

amino acid compounds that make up bacterial cell

walls and bacterial DNA. This reaction results in

changes in the structure and composition of amino

acids. So it will cause changes in genetic balance in

the DNA chain that will be damaged and encourage

bacterial cell lysis that will cause death in bacterial

cells. Flavonoids are polar compounds that are

usually spread in plants and belong to the phenol

group. Flavonoids are polar so it is easier to penetrate

the peptidoglycan layer which is also polar in gram-

positive bacteria than in the nonpolar lipid layer

(Dewi, 2010). The mechanism of action of

flavonoids as antimicrobials is by binding to

extracellular proteins and dissolved proteins so that

they lose their normal function, deactivate enzymes,

and damage cell walls and bacterial cell membranes.

Some flavonoids are bactericidal, bacteriostatic,

fungicidal, and deactivate the lipophilic virus.

Saponin is a secondary metabolite compound that

functions as an antiseptic so that it has the ability as

an antibacterial. The presence of these antibacterial

substances will inhibit the formation or transport of

components to the cell wall which results in the

weak structure of the cell wall accompanied by loss

of cell walls and release of cell contents which will

ultimately kill or inhibit the growth of the bacterial

cell. In addition, saponin compounds cause a

decrease in cell surface tension and cause cells to

become lysis.

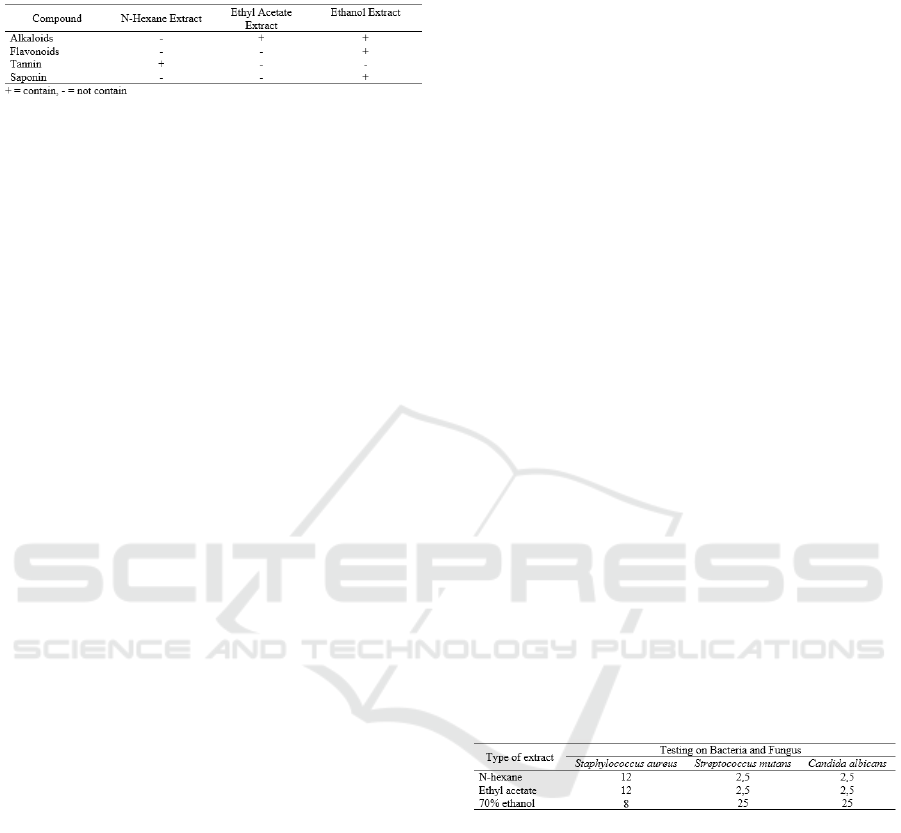

3.3 Test Results of MIC

Test results on Streptococcus mutans and Candida

albicans showed that n-hexane and ethyl acetate

extracts had the same MIC at 2.5% concentration,

and at 70% ethanol extract had 25% higher marked

by the absence of a growing bacterial colony. In

Staphylococcus aureus, on the contrary, n-hexane

extract and ethyl acetate have the same MIC

(12%), but the concentration is higher than ethanol

extract, 8% ethanol extract in Staphylococcus

aureus has shown no bacterial colonies. The results

of the MIC test for 70% ethanol on Staphylococcus

aureus get lower concentrations compared to n-

hexane and ethyl acetate because the ethanol

extract contains alkaloids, flavonoids, and tannins.

Whereas in ethyl acetate and n-hexane the

concentration used is higher because in ethyl

acetate only contains flavonoid compounds and in

n-hexane only contains tannin compounds. The

MIC values for each microorganism are presented

in Table 6.

Table 6: Test Results of MIC Extract (%) on

Staphylococcus aureus, Streptococcus mutans, and

Candida albicans.

3.4 Test Results of Inhibiton Zone

Antimicrobial testing was carried out to see the

concentration of each extract that had the greatest

antimicrobial activity. This test is carried out using

the Paper Disc Diffusion method. This method is

used because it is more sensitive to new

antimicrobial compounds whose activity is

unknown. The inhibition of growth in the method is

shown by the wide clear area (inhibition zone) that

forms around the paper disk (Brander et al., 1999).

(Davis & Stout, 2009) divides the strength of

antibacterial power into four categories, namely

inhibition weak (<5mm), moderate (5-10mm),

strong (10-20mm), and very strong (> 20mm).

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

498

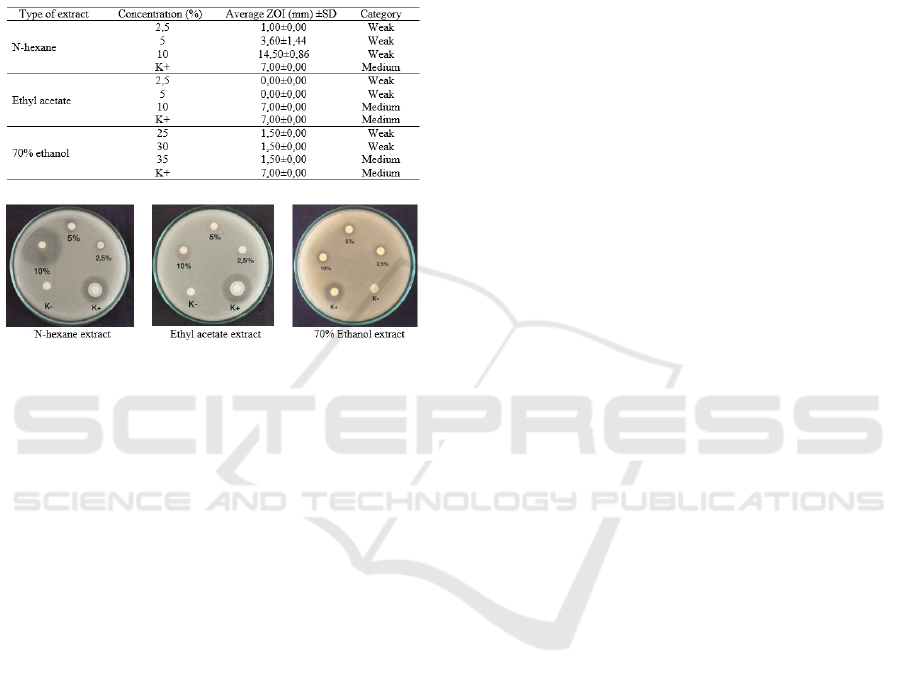

3.5 Staphylococcus aureus

Inhibition zone test results of ethanol extract, ethyl

acetate and n-hexane extract in Staphylococcus

aureus bacteria can be seen in Table 7.

Table 7: Average Test Results of Inhibition Zone (mm)

Extracts on Staphylococcus aureus Bacterial Growth.

Figure 1: Inhibition Zone Test Results of Cinnamon bark

extract against bacteria Staphylococcus aureus.

The results showed ethanol extract was an

extract with inhibition zone results that were

stronger than ethyl acetate extracts and ethyl acetate

showed inhibition zone results that were stronger

than n-hexane. Among the three solvents, extract

with 70% ethanol solvent produced an average

inhibition zone that was closer to positive control at

32% extract concentration. From the observations, it

can be seen that the antibacterial activity of n-

hexane extract produces a weak inhibitory power at

the three concentrations used against Staphylococcus

aureus. These results indicate that n-hexane extract

has less antibacterial activity compared to ethyl

acetate and 70% ethanol solvent. In observing the

antibacterial activity of ethyl acetate extract at a

concentration of 50%, it produces an inhibition zone

with a moderate category of 5.9 mm, but when

compared with 70% ethanol extract with a

concentration of 32% it produces an inhibition zone

of 6.83%. These results showed that extracts with

70% ethanol solvent had better antibacterial activity

on Staphylococcus aureus than ethyl acetate or n-

hexane solvents. According to other research

conducted shows that the difference in the level of

the polarity of the solvent affects the antibacterial

properties. The research of S. muticum extract on S.

aureus has the highest antibacterial properties in

extracts using 96% ethanol solvent followed by ethyl

acetate and n-hexane solvents according to the

decrease in polarity. The higher the level of polarity,

the better the antibacterial activity (Hidayah, 2016).

3.6 Staphylococcus mutans

The inhibition zone test results on Streptococcus

mutans can be seen in Table 8 and in Candida

albicans fungus can be seen in Table 9.

Table 8: Test Results of Inhibition Zone (mm) Cinnamon

Bark Extract against Streptococcus mutans Bacteria.

4 CONCLUSIONS

Figure 2: Inhibition Zone Test Results on Streptococcus

mutans bacteria.

The statistical analysis results of the inhibition

zone test on Streptococcus mutans showed that n-

hexane and ethyl acetate extracts for all

concentrations tested did not have a significant

effect. For the n-hexane and ethyl acetate extracts,

all the concentrations had inhibitory power with

weak categories (˂5mm). While the ethanol extract

of all concentrations has inhibition in the medium

category (5-10mm). This might be caused by the

compounds contained in ethanol extracts including

alkaloids, flavonoids, and saponins.

3.7 Candida albicans

The results of the inhibition zone test on Candida

albicans showed that n-hexane extract at a

concentration of 2.5% and 5% had inhibition zone of

the weak category (<5 mm), and the concentration of

10% is very strong that is 14.50mm (10-20mm). The

ethyl acetate extract with a 10% concentration has

inhibition zone with a medium category of 7 mm (5-

10 mm) equal to the positive control. The inhibition

Antimicrobial Activities Assessment of Cinnamon Bark (Cinnamomum burmannii Nees T. Nees) Extract against Caries Factors

499

zone test on ethanol extract of all concentrations

tested has a weak inhibition power of 1.5 mm. The

results of inhibition Test of cinnamon bark extract

against the fungus Candida albicans are presented in

Table 9.

Table 9: Test Results of Inhibition Zone (mm) on

Cinnamon Bark Extract against Candida albicans.

Figure 3: Inhibition Zone Test Results in Candida

albicans.

Statistical test results showed that there were no

significant differences in extract concentration on

the inhibition zone. Quantitatively showed that

inhibition zone extract of n-hexane 10% against the

fungus Candida albicans was greater than the

positive control, which is 14.5mm (2 times of the

positive control). This might be due to the tannin

content in n-hexane extract. Tannin is a complex

organic compound that acts as an antimicrobial. The

presence of tannin as an antibacterial will disrupt the

synthesis of peptidoglycan so that the formation of

cell walls becomes less perfect. Circumstances that

caused the bacterial cells to become lysis were due

to osmotic and physical pressure so that bacterial

cells became dead. In addition tannin compounds

work by binding to protein walls so that the

formation of bacterial cell walls is inhibited (Fahria

& Muktiana, 2007).

4 CONCLUSION

From this study can be concluded:

1. Different solvents produce different

antimicrobial effects. The effectiveness of

cinnamon bark extract against the antibacterial

Staphylococcus aureus and Streptococcus mutans

respectively are ethanol extract, ethyl acetate

extract, and n-hexane extract.

2. The effectiveness of cinnamon bark extract

against fungus Candida albicans respectively is

n-hexane extract, ethyl acetate extract, and

ethanol extract.

3. The 10% concentration of n-hexane ethanol

extract of cinnamon bark has strong

antimicrobial power against Candida albicans

with an inhibition zone of 14.50 mm over the

positive control.

REFERENCES

Anandito, B. K., Lia, U. K., & Fuki, T. . (2012). Pengaruh

Ukuran Bahan dan Metode Destilasi (Destilasi Air

Dan Destilasi Uap-Air) Terhadap Kualitas Minyak

Atsiri Kulit Kayu Manis (Cinnamomum burmani).

Journal of Teknosains Pangan, 1(1).

Bisset, N. G., & Wichtl, M. (2001). Herbal Drugs and

Phytopharmaceuticals (2nd ed.). Medpharm Scientific

Publishers.

Brander, G. ., Pough, D. M., Bywater, R. ., & Jenkins, W.

L. (1999). Veterinary Applied Pharmacology and

Therapeutic (5th ed.). Brailler Tindal.

Brotosoetarno, S. (1997). Peran Serta Mikroorganisme

Dalam Proses Terjadinya Karies Gigi. Journal of

Dentistry Universitas Indonesia, 7.

Davis, & Stout. (2009). Disc Plate Method of

Microbiological Antibiotic Essay. Journal of

Microbiology, 22(4).

Dewi, F. K. (2010). Aktivitas Antibakteri Ekstrak Etanol

Buah Mengkudu (MorindaCitrifolia, Linnaeus)

Terhadap Bakteri Pembusuk Daging Segar. Sebelas

Maret University.

Fahria, & Muktiana, S. (2007). Ekstraksi Zat Aktif

Antimikroba danTanamanYodhium (Jatrophamultifida

L.) sebagai Bahan Baku Alternatif Antibiotik Alami.

Harborne, J. . (1996). Metode Fitokima Penuntun Cara

Modern Menganalisis Tumbuhan (K. Padmawinata

(ed.); II). Institut Teknologi Bandung.

Hidayah, N. (2016). Uji Efektivitas Ekstrak Sargassum

muticum Sebagai Alternatif Obat Bisul Akibat

Aktivitas Staphylococus aureus. Journal of Creativity

Students.

Hidayat, Y., & Sutarma. (1999). Teknik Pembuatan Kultur

Media Bakteri. Veterinary Research Institute.

Inna, M., Atmania, N., & Primasari, S. (2010). Potential

Use of Cinnamomum burmanii Essential Oil-based

Chewing Gum as Oral Antibiofilm Agent. Journal of

Dentistry Indonesia, 17(3), 81–82.

Kadek, R. . (2011). Daya Antibakteri Minyak Atsiri Kulit

Batang Kayu Manis (Cinnamomum burmannii BI.)

Terhadap Streptococcus mutans Penyebab Karies

Gigi. Sanata Dharma University.

Kumoro, A. C. (2015). Teknologi ekstraksi senyawa

bahan aktif dari tanaman obat. Plantaxia.

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

500

Kusumaningtyas, E., Widiati, R. R., & Gholib, D. (2008).

Uji Daya Hambat Ekstrak dan Krim Ekstrak Daun

Sirih (Piper betle) terhadap Candida albicans dan

Trichophytonmentagrophytes. Manuscript of Animal

Husbandry and Veterinary Technology, 805–812.

Makkar, H. P. S., Blummel, M., Borowy, N. K., & Becker,

K. (1993). Gravimetric determination of tannins and

their correlations with chemical and protein

precipitation methods. Journal of Science Food

Agriculture.

Maldonado, R. A. P. (1994). The Chemical Nature and

Biological Activity of Tannins in Forages Legumes

Fed to Sheep and Goat. University of Queensland

Australia.

Maulida, Dewi, Zulkarnaen, & Naufal. (2010). Ekstraksi

antioksidan (likopen) dari buah tomat dengan

menggunakan solven campuran, n – heksana, aseton,

danetanol. Diponegoro University.

Ministry of Health of the Republic of Indonesia. (1995).

Indonesian Pharmacopoeia fourth edition.

Ministry of Health of the Republic of Indonesia. (2008).

Indonesian Herbal Pharmacopoe.

Ningrum, R., Purwanti, E., & Sukarsono. (2016). Alkaloid

compound identification of

Rhodomyrtustomentosastem as biology instructional

material for senior high school X grade. Jurnal

Pendidikan Biologi Indonesia, 2(3), 231–236.

Nuryanti, S., Jura, R. M., & Nursucianti. (2015). Uji

Aktivitas Anti Jamur Ekstrak Kayu Manis

(Cinnamomum burmanii Blume) Terhadap Jamur

Candida albicans. Jurnal Pendidikan Kimia.

Universitas Tadulako.

Perry, L. ., & Metzger, J. (1980). Medicinal Plants of East

and Southeast Asia Attributed Properties and Uses.

The MIT Press.

Puspita, A. (2014). Pengaruh Konsentrasi Ekstrak Kayu

Manis Dalam Menurunkan Pertumbuhan Streptococus

mutans secara invitro. University of Muhammadiyah

Surakarta.

Rismunandar, & Paimin, F. B. (2001). Kayu Manis

Budidaya dan Pengolahan. Penebar Swadaya.

Shekar, M., Shetty, S., Lekha, G., & Mohan, K. (2012).

Evaluation of In Vitro Antioxidant Property and Radio

Protective Effect of The Constituent Medicinal Plants

of a Herbal Sunscreen Formulations. International

Journal of Pharmaceutical Frontier Research

(IJPFR), 2(2), 5.

Susanti, N., Gandidi, M., Indra, Dyan, M., & Susila.

(2013). Potensi Produksi Minyak Atsiri dari Limbah

Kulit Kayu Manis Pasca Panen. Journal of FEMA,

1(2), 45.

Waluyo, L. (2008). Teknik dan Metode Dasar dalam

Mikrobiologi. University of Muhammadiyah Malang

Press.

Antimicrobial Activities Assessment of Cinnamon Bark (Cinnamomum burmannii Nees T. Nees) Extract against Caries Factors

501