The Sloshing Test of the Bilobe Tank Type Due to LNG Ship Motions

in Regular Wave

Aries Sulisetyono

1,a

,

Aditya P. Wibawa

1

,

Yoyok S. Hadiwidodo

2

1

Department of Naval Architecture, Institut Teknologi Sepuluh Nopember, Indonesia

2

Department of Ocean Engineering, Institut Teknologi Sepuluh Nopember, Indonesia

Keywords: Bilobe Tank, Buffle, LNG Ship, Sloshing.

Abstract: This paper describes the sloshing test of the Bilobe LNG tank type due to the LNG ship’s motion in regular

wave. Two-dimensional sloshing of the transverse tank was analysed due to the considered rolling excitation.

The experimental device developed with a principal work to oscillate the filling liquid tank under the

controlled amplitude and period of platform motion. Three variations of the LNG filling level inside the tank

which were an empty condition, 10%, a half condition, 50%, and a full condition, 90%, considered to be

investigated the occurred maximum pressure on the inner wall of LNG tank for certain amplitude and period

of times. The test results represented in terms of free surface patterns that its compared with the simulation

results which computed by the computational fluid dynamics approach for all cases of liquid filling level of

the tank. The comparison results of the sloshing test and the numerical simulation had shown a close with the

root mean square (RMSE) about 4%. Furthermore, the effect of baffle in reducing the sloshing pressure on

the inner wall of tank was also investigated numerically.

1 INTRODUCTION

The sloshing can be interpreted as all movements of

a fluid free surface inside a container, occur as a result

of container’s interference with a fluid partially filled

in a container. The sloshing phenomenon was source

of concern because the pressure that arises can cause

result in destructive stresses (Ibrahim, 2005), as well

as the ship motion stability (Hu et. all, 2017).

The study of sloshing had been carried out by

several researchers using the numerical CFD

approaches such as conducted by (Hou et. all, 2012)

and the testing approaches as conducted by (Brar and

Sigh, 2014). Sloshing tests in the laboratory were

generally intended to validate the results of CFD

simulations (Sinaga, 2014). The way to validate

numerical results could be done by comparing the

pressure value on the numerical results with the test

results under the same tank excitation conditions as

conducted by (Xue et. All, 2017). And another way

of validation was to compare the surface shape of the

numerical liquid results with the results of the tank

test when given the same tank oscillation conditions

as performed by (Chen, 2018). In this last method, the

sloshing was done in 2 dimensions due to the single

motion of ship.

The sloshing test on a box-shaped tank under the

sinusoidal motion performed by author (Pradana and

Sulisetyono, 2018), wherein the test also proposed to

investigate the effect of baffles on the magnitude of

pressures due to sloshing. The results shown that the

addition of a buffer could reduce the pressure on the

tank significantly. The same method was also shown

by (Coulibal et. all, 2018) with a CFD simulation

which states the baffle could reduce the pressure due

to sloshing in the same case of a box tank.

Generally, sloshing studies on LNG tanks were

mostly done for the case of the rectangular tanks

(Coulibal et. all, 2018), or moss tank (Hasheminejad

et. all, 2014), but few study for the cases of Bilobe

tank (Sulisetyono, 2017). Bilobi shape was a type C

of LNG tank or an independent tank which was

formed by the merge of two circular cross section

tank, and it had a certain length.

This paper discusses sloshing testing on the Bilobi

type tank that were originally designed for LNG

vessel tanks (Sulisetyono, 2018). The tank motion

would follow the ship's motion in regular or

sinusoidal waves. The test results were represented in

terms of some snapshot images per time step which

were the shape of the water surface in the tank. These

results were compared with the CFD simulation

Sulisetyono, A., Wibawa, A. and Hadiwidodo, Y.

The Sloshing Test of the Bilobe Tank Type Due to LNG Ship Motions in Regular Wave.

DOI: 10.5220/0010854000003261

In Proceedings of the 4th International Conference on Marine Technology (senta 2019) - Transforming Maritime Technology for Fair and Sustainable Development in the Era of Industrial

Revolution 4.0, pages 91-96

ISBN: 978-989-758-557-9; ISSN: 2795-4579

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

91

results under the same conditions of the filled water,

the motion period, and the motion amplitude. The

sloshing tests were performed with three different

filling levels including 10% h, 50% h and 90% h (h is

of the water surface height from the bottom of tank).

The comparison results had clarified the level

accuracy of the numerical set up which was

quantified in terms of the Root Mean Square Error

(RMSE). Using the same set up running of software,

the sloshing test able to compute the pressure values

in the inner tank. Furthermore, the effects of the

baffle, which was placed inside the tank, was

discussed in this paper.

2 METHODOLOGY

2.1 Dimension of Ship and Tank

The LNG vessel was operating in the Makassar

waters as shown in Figure 1. The ship had a waterline

length (LWL) 103.26 m, width (B) 16.8m, draft (T)

3.4 m, displacement of 5257.62 tons with service

speed of 11 knots.

Figure 1: The LNG Vessel (Sulisetyono, 2018).

Figure 2: Transverse section of bi-lobe tank.

Inside the ship, there were 3 (three) distinct type C

tanks also known as Bilobe tanks. each tank on the

vessel had a capacity of 1270 m

3

with a length of 17.2

m, height of 6.9 m and half the width of the tank of

6.65 m. In this study, a tank in the middle of the ship

was used to be analysed, and it was located the centre

of gravity of ship longitudinally. The transverse

section of tank is presented in Figure 2 since the only

ship rolling motion was considered discuss in this

paper.

2.2 Experimental Setup

The equipment test was developed to oscillate the

model tank for some difference of periods and

amplitudes. This equipment had four main

components, namely docking plate, DC motor low

rpm, motion converter, and model tank. The plate

docking was built to place the model tank in which it

could be rotated by the DC motor with respect to the

axes. Another component was the motion converter

which was to change the rotational of motor into the

translation motion on the edge docking plate. The

advantages of this equipment were the period, and the

amplitude of motion might be controlled by adjusting

the RPM of motor and setup motion converter,

respectively. The sloshing equipment test was shown

in Figure 3.

Figure 3: The sloshing equipment test.

The transverse tank was a symmetrical shape, and

the half tank might be possibly used for a sloshing test

as well as a numerical simulation. The Froude

similitude approach was adopted to set up a

dimensional of tank, an angular velocity, and an

amplitude of motion. The tank model was built with

scale of 1:50 from the full-scale tank which is the

width of 13.3 cm, and the height of 13.8 cm. Length

of the model tank did not follow the scale, because it

did not have any influences to the 2D sloshing

analysis.

The procedure in carrying out the sloshing test

was determined to produce a fluid surface motion in

the tank. The sloshing test procedures included: (i)

filling the bilobe tank with water at the specified

filling level, (ii) put the bilobe tank on the docking

plate by paying attention to the midpoint location, (iii)

adjust the bolt position on the converter wheel to

adjust the amplitude of motion, (iv) adjust the motion

period by the speed controller, (v) use the camera

senta 2019 - The International Conference on Marine Technology (SENTA)

92

recorder to produce the video of sloshing, and the

location of camera must be adjusted, and (vi) sloshing

test with the specified filling level variation had been

recorded with the camera.

The experiment set up were determined such as,

(i) the filing level were variated in 10%, 50%, and 90

% of the tank height, (ii) the variations of amplitude

were obtained such as 2, 3, and 4 cm, and (iii) the

rolling period were including 2, 4, 6, and 8 second,

(iv) the data were taken for 5 second at each filling

level condition.

The sloshing test results were obtained in form of

video, and it was needed to be processed into

snapshot picture at each second. The free surface

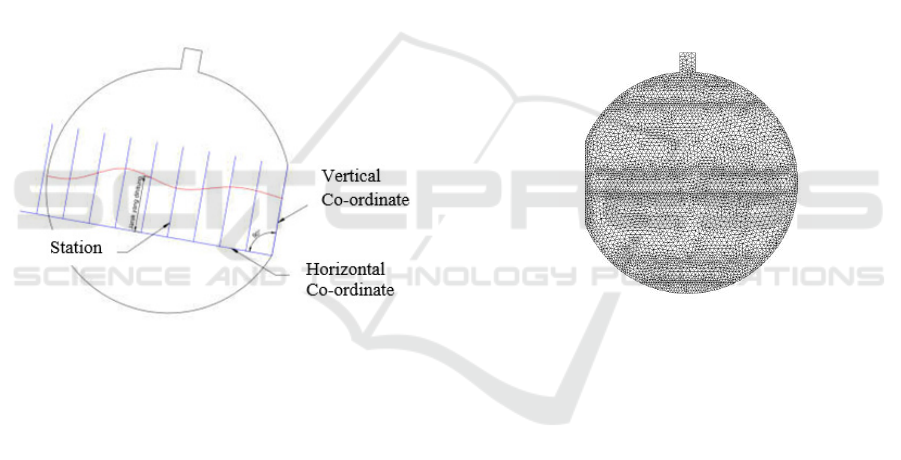

pattern was analysed. Figure 4 explained the

measurement way of the free surface elevation, while

obtaining the base line. The elevation of free surface

was measured from the base line for each station of

13 station lines.

Figure 3: Validation process.

2.3 Numerical Setup

Numerical analysis was performed by using

Computational Fluid Dynamic (CFD) that consider to

rolling motion. The numerical procedures were

developed using a modified version of the approach as

described by (Sulisetyono, 2017) in the UDF program.

The Bilobe tank was modeled numerically using

GAMBIT in a triangular meshing, and the number of

meshing was determined based on the study of grid

independence. It known to the optimum number for

the simulation was about 8192 panels. The meshing

was modeled evenly and equally throughout the fluid

and gas portions in the tank. The sloshing simulation

was conducted using the FLUENT software by first

importing model from GAMBIT. The FLUENT was

a popular CFD application program with the approach

of Fluid Volume Method (VOF).

The simulations used solver-based pressure

solving model with set up of implicit, unsteady, and

non-iterative time advancement formula. The fluid

flow was modelled in two phases with the Volume of

Fluid method. The parameters were explicitly

determined, and the implicit body force formula was

selected. The flow type was assumed turbulent with

k-epsilon, and standard model with standard wall

function. The density of two-phase materials which

were water and air, were specified. The operational

conditions including pressure, gravity, density, and

temperature were determined according to fluid

characteristics. Fluid boundary condition of tank wall

was specified as a zero-velocity condition. User

defined was determined by uploading the libudf

(library user defined function) file into the UDF

library which was a ship rolling code, and compiled

it. Meshing was modelled in dynamic mesh using

layering method and set dynamic mesh zone in the

rigid body of the tank wall.

Figure 5: Meshing with 8192 panels.

2.4 Validation Setup

Validation of the numerical simulation method would

be conducted by comparing the shape of the water

surface due to sloshing tank which produced by the

numerical simulations and the tank tests at the same

conditions of filling level, period, and amplitude. The

comparison of both results carried out under

conditions of filling levels 10%, 50%, and 90% of the

tank height.

For validation, the surface motion of the water

were considered at time steps of 3, 4, 5, 6, 7, and 8

second. The results at time step of 1 and 2 second

were not used since the inert force still influence the

surface motion and it could affect to the accuracy of

results. The results of surface pattern which come

from the CFD analysis and test were expected to give

the same trend, so that the numerical set up obtained

could be said valid. For validation purposed, the

equipment was set up at an amplitude of 5.7o and a

The Sloshing Test of the Bilobe Tank Type Due to LNG Ship Motions in Regular Wave

93

period of 5.98 second. And the different between both

results were expressed in terms of Root Mean Square

Error (RMSE) as formulated in Equation 1.

𝑅𝑀𝑆𝐸

1

𝑛

𝐶𝐹𝐷 𝑇𝑒𝑠𝑡

(1)

After the numerical setup was declared valid, then

the numerical approach was used further to find the

effect of the buffle on sloshing phenomenon. The

existence of the buffle was expected to reduce the

amount of sloshing pressure. In this case, the buffle

was placed at the middle of the bottom tank as shown

in Figure 6 for tank with and without baffles.

Figure 6: Tank without and with buffle.

3 RESULTS

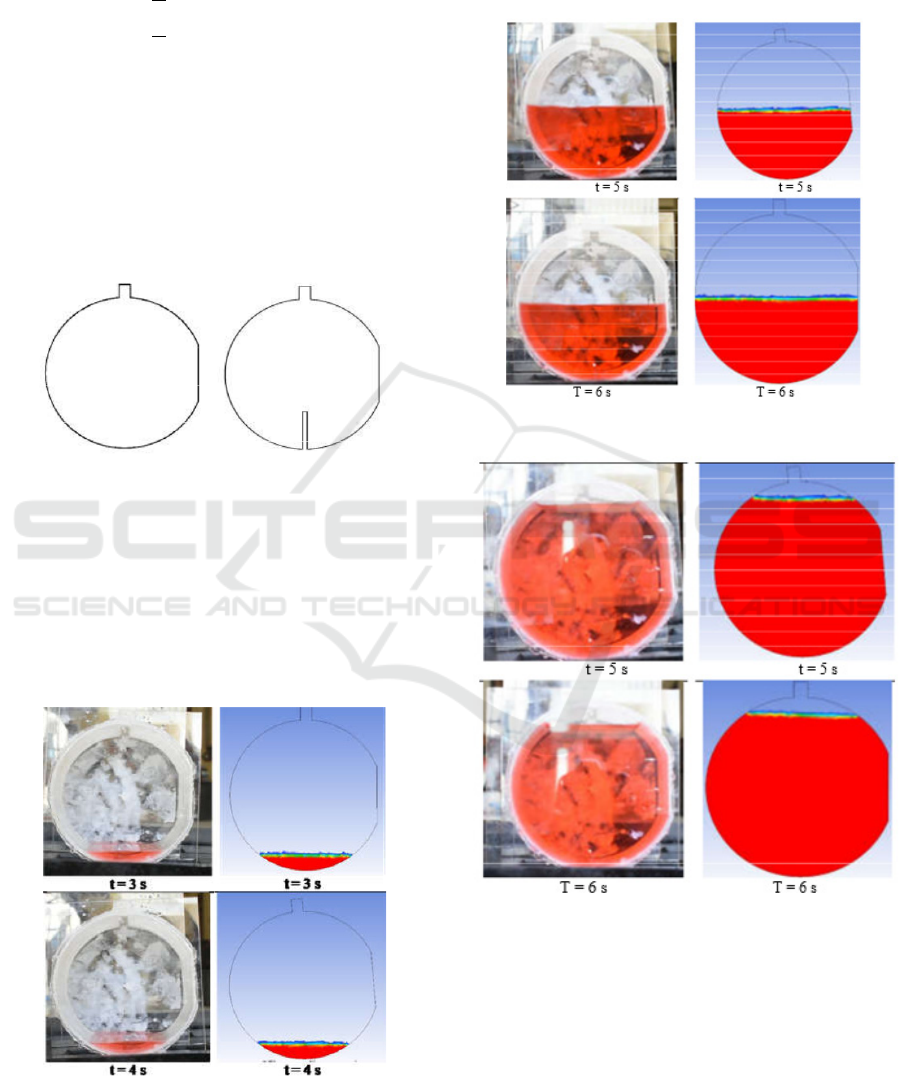

Figure 7 illustrates the comparison between the

surface shape of the test results with the CFD results

at the condition of filling level 10% of the tank height

for time steps 3 and 4 seconds.

Figure 7: Comparison sloshing test and CFD in 10% h.

Figure 8 and 9 explained the comparison between

the surface shape of the test and the CFD results at the

condition of filling level 50% and 90% of the tank

height for time steps 5 and 6 seconds, respectively.

Figure 8: Comparison sloshing test and CFD in 50% h.

Figure 9: Comparison sloshing test and CFD in 90% h.

To determine the amount of error that occurs

between the test results and CFD results, were first

calculate an average difference between the elevation

of the test results with the CFD results, and secondly

to calculate the RMSE using Equation (1) for all time

steps. Table 1 shown the results of RMSE calculation

for a case of 50% filling level. The same procedure

was applied for the case of 10% and 90% filling level,

and the RMSE of 4.13% and 1.74% respectively.

senta 2019 - The International Conference on Marine Technology (SENTA)

94

Based on the RMSE, it could be stated the setup of

CFD simulation was suitable used for further sloshing

analysis.

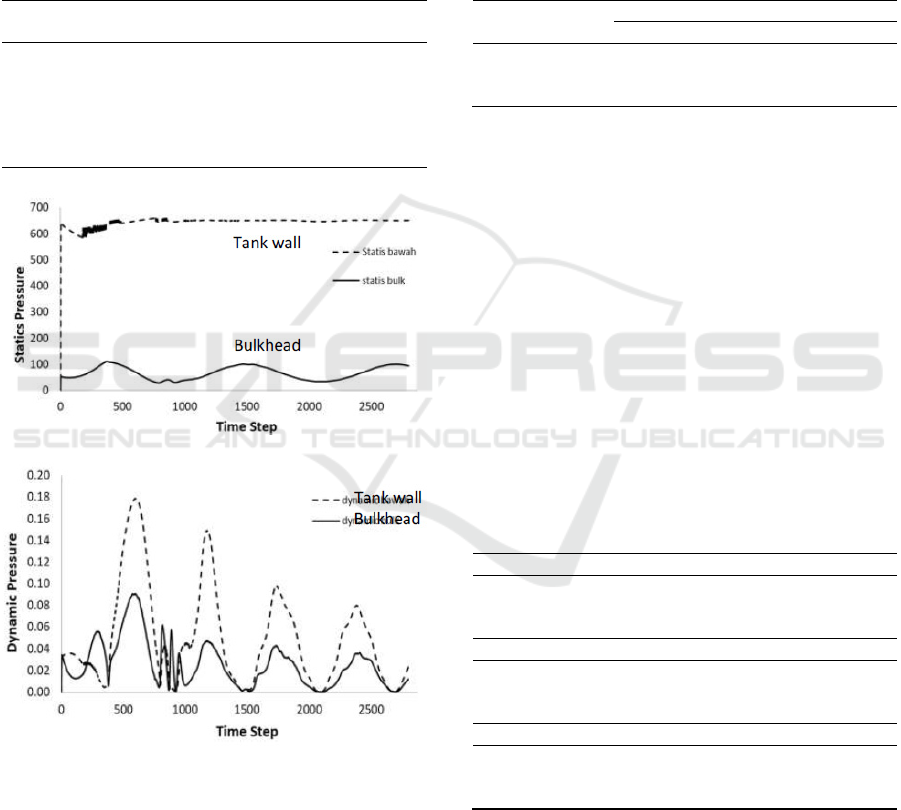

The CFD simulation results were recorded for the

filling level case of 50% h presented in terms of static

and dynamic pressure values. Figure 10 explain the

pressure of static and dynamic in the internal of bilobe

tank for all filling level cases using time step of 0.005

second with the total number of 4000.

Table 1: RMSE of sloshing test and CFD for 50%.

Filling

Level

Time Step

(second)

Error (%) RMSE

(%)

50% 3 2.26 2.1

4 2.72

5 1.45

6 4.58

7 3.52

8 0.71

Figure 10: Static and dynamic pressures filling level 50%h.

Figure 10 shown that the static pressure give more

contribute to the total pressure than the dynamic

pressure, and it shown also for the other cases of filling

level. The value of dynamic pressure was always

different for all the time, and it shown the bottom area

gave more pressure than the other location.

Table 2 explained the recapitulation of dynamic

pressure results for different level filling such as 10%,

50%, and 90% which were located at the Tank

Longitudinal Bulkhead (TLB) and Tank Wall (TW).

Basically, the dynamics pressure on the inner tank

were occurred because of the sloshing on the liquid,

and it was becoming a parameter used to quantify the

sloshing effect. Table 2 shown the most sloshing

effect occurred while the filling level of liquid was

50%h, and it explained that the sloshing effect had

linear with the surface are of liquid.

Table 2: Recapitulation of maximum dynamic pressure.

Filling Level D

y

namic Pressure (Pa)

Tank Wall Lon

g

Bulkhea

d

10%h 0.143 0.000

50%h 0.051 0.066

90%h 0.045 0.053

Table 3 explored the difference of the maximum

dynamic pressure between the sloshing results on the

tank without and with buffle for the filling level case

of 10%, 50% and 90% respectively. All figures

shown the baffle installed on the inner bottom tank

could reduce the maximum pressure on longitudinal

bulkhead up to 50%, 33%, and 30% for filling level

of 10% h, 50% h, and 90% h respectively. The most

contribution of baffle was in filling level 10%

because of the free surface area was reduced by buffle

significantly. Although the free surface area of the

filling level 50% and 90% did not reduced, but the

buffle had contribute increasing the viscous damping.

It was correlation with other research for the case of

rectangular tank (Xue et. all., 2017).

Table 3: Recapitulation of the maximum dynamic pressure

for case with and without buffle.

Filling Level 10%h

Baffle Tank Wall Long Bulkhead (Pa)

With 0.049 0.000

Without 0.199 0.000

Fillin

g

Level 50%h

Baffle Tank Wall Lon

g

Bulkhead

(

Pa

)

With 0.040 0.062

Without 0.177 0.092

Fillin

g

Level 90%h

Baffle Tank Wall Long Bulkhead (Pa)

With 0.032 0.148

Without 0.369 0.212

4 CONCLUSIONS

The innovation equipment was developed to

numerically validate the sloshing simulation that was

conducted by the CFD approach. Results were

The Sloshing Test of the Bilobe Tank Type Due to LNG Ship Motions in Regular Wave

95

validated by looking at the surface water pattern.

Validation was done by comparing the numerical

result with the tank test results with the RMSE

method, and the different was less than 5% for all

cases of filling level. It is shown that the numerical

set up on the FLUENT was made to utilize the

simulation of sloshing. The most sloshing effect

occurred while when the liquid filling level of liquid

was 50% h, and it explained the sloshing effect had

linear to the liquid surface area The use of baffle on

the tank model resulted in a reduction in the

maximum value of dynamic pressure for all cases of

filling level carried out up to 50%. However, the

irregular motion of ship’s sloshing must be performed

in future work complete this work.

ACKNOWLEDGEMENT

The authors wish to thank the RISTEKDIKTI of

Indonesian Government for awarding the scheme of

Basic Research 2019

REFERENCES

Brar, G.S., and Singh, S., 2014. An Experimental and CFD

Analysis of Sloshing in a Tanker. 2nd International

Conference on Innovations in Automation and

Mechatronics Engineering, ICIAME, Procedia

Technology 14 (2014) 490 – 496.

Chen, Y., and Xue, M.A., 2018. Numerical Simulation of

Liquid Sloshing with Different Filling Levels Using

OpenFOAM and Experimental Validation. Water, 10:

1752.

Coulibaly, N., Dosso, M., and Danho, E., 2014. Numerical

simulation of sloshing problem in rectangular tank.

Advances and Applications in Mechanical Engineering

and Technology, 5(1): 1-26.

Hasheminejad, S.M., Mohammadi, M.M., and Jarrahi, M.,

2014. Liquid sloshing in partly-filled laterally-excited

circular tanks equipped with baffles. Journal Fluids and

Structures, 44: 97-114.

Hou, L., Li, F., and Wu, C., 2012. A Numerical Study of

Liquid Sloshing in a Two-dimensional Tank under

External Excitations. Journal Marine Science and

Application, 11: 305-310.

Hu, Z.Q., Wang, S.Y., Chen, G., Chai, S.H., and Jind, Y.T.,

2017. The effects of LNG-tank sloshing on the global

motions of FLNG system. International Journal of

Naval Architecture and Ocean Engineering ,9: 114-125.

Ibrahim, R.A., 2005. Liquid Sloshing Dynamics Theory

and Applications. New York Cambridge University

Press.

Perdana, M.A., and Sulisetyono, A., 2018. Study of

Sloshing LNG Tanks with and without Baffle by

Computational Fluid Dynamic (CFD) Method.

Proceedings of the 3rd International Conference on

Marine Technology (SENTA 2018), Surabaya,

Indonesia.

Sinaga, L.T.P., Utama, I.K.P., and Sulisetyono, A., 2014.

Experimental and numerical of sloshing effect on heave

and pitch Motions of FLNG vessel, Applied Mechanics

and Materials, 664: 153-157.

Sulisetyono, A., 2018. Sloshing Analysis of The

Independent Tank Type C Due to The LNG Ship

Motions Using Computational Fluid Dynamic.

Proceedings of the 9th International Conference on

Thermofluids IX, AIP Conference Proceedings 2001,

010001.

Sulisetyono, A., 2012. Seakeeping analysis of the trimaran

ferry ship in short crested sea for a case of east java

water condition. RINA, Royal Institution of Naval

Architects - International Conference on Ship and

Offshore Technology, ICSOT 2012: Developments in

Ship Design and Construction, Ambon, Indonesia.

Xue, M.A., Zheng, J., Lin, P., Yuan, X., 2017.

Experimental study on vertical baffles of different

configurations in suppressing sloshing pressure. Ocean

Engineering, 136: 178–189.

senta 2019 - The International Conference on Marine Technology (SENTA)

96