Container Yard Allocation under Uncertainty

Yue Wu

Southampton Business School, University of Southampton, Univesity Road, Southmapton, SO17 1BJ, U.K.

Keywords: Container Terminal, Yard Space Allocation, Stochastic Programming.

Abstract: This paper investigates allocation of space in storage yard to export containers under uncertain shipment

information. We define two types of stacks: one is called the dedicated stack and the other is called the shared

stack. Since containers meant for the same destination are assigned to dedicated stacks in the same block, no

re-handling is required for containers in dedicated stacks. However, containers in shared stacks have different

destinations; re-handling is required. We develop a two-stage stochastic recourse programming model for

determining an optimal storage strategy, called the dual-response storage strategy. The first-stage response,

regarding the allocation of containers to dedicated stacks, is made before accurate shipment information

becomes available. The second-stage response, regarding allocation of additional containers to shared stacks,

is taken after realization of stochasticity. Then, the unused spaces in the yard area can be released for other

purposes. Computational results are provided to demonstrate the effectiveness of the proposed dual-response

storage strategy obtained from the stochastic model.

1 INTRODUCTION

Containers were first used for international sea

transportation in the 1950s, and the proportion of

containerized items has been steadily increasing since

then. Today, over 60% of the world deep sea cargo is

transported in containers, where some routes,

especially between economically strong and stable

countries, are containerized up to 100% (Steenken et

al., 2004). Containers are standardized steel boxes in

three lengths, 20, 40 and 45 feet, and 8 feet wide and

either 8.5 or 9 feet high. This standardization offers

advantages of simplified discharging and loading of

containers, protection against weather and pilferage

and improved process of scheduling and controlling

facilities, etc. Container terminals are places where

containerized cargo is temporarily stored, before

being shipped to the destination. The increased

volume of container shipments has resulted in

increased demand for seaport container terminals,

container logistics and management, and the related

technical equipment. Heightened competition

between seaports, especially between geographically

close ports, is a result of this development.

The container storage area in the terminal is

usually separated into rectangular regions, called

blocks, which are further segmented into rows, bays

and tiers. The width of a block is typically divided

into several rows, one for trucks that interact with

yard cranes and others for storing containers. Blocks

are divided along their length into bays. Each bay is

made up of several container stacks of a certain height

(3 ~ 6 tiers). Containers are stored one on top of

another to form a stack. The blocks are usually

separated into areas allocated for export, import,

special (such as reefer, dangerous, overweight/over

width), and empty containers (Steenken et al., 2004).

A vessel normally visits a sequential list of ports,

called the shipping route. A number of containers are

discharged from the vessel to the port terminals along

its shipping route. The locations occupied by these

import containers on the vessel become available for

loading new export containers from the terminals to

the vessel. Export containers are assigned to specific

locations on the vessel such that they can be easily

discharged when the vessel arrives at the ports where

they are to be discharged. However, for container

terminals, decisions are different from the vessels.

Containers pass through a terminal in three ways:

imported, exported and transhipped. Import

containers arrive in batches, in vessels, and leave the

terminal by truck or rail, while export containers

normally come at the terminals one-by-one, by trucks,

in a random manner, and leave by vessels.

Transhipped containers arrive and leave terminals in

vessels. In practice, accurate shipment information,

30

Wu, Y.

Container Yard Allocation under Uncertainty.

DOI: 10.5220/0007253700300036

In Proceedings of the 8th International Conference on Operations Research and Enterprise Systems (ICORES 2019), pages 30-36

ISBN: 978-989-758-352-0

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

particularly for export containers, is usually difficult

to obtain because of the uncertainty involved in the

process of delivering the containers to the yard (for

example, truck delay and urgent shipment

requirement, etc.). Yard managers are increasingly

challenged by limited yard capacities, and the

uncertain and dynamic information involved in the

decision-making process. Therefore, yard managers

need new methodologies to help them make better

decisions about allocation of yard space.

In this paper, we assume that yard managers can

obtain uncertain shipment information from their

customers regarding destinations and quantity of

containers to be shipped. The yard managers have to

determine the storage yard plan before accurate

shipment information is available. One of the

methods that the yard managers adopt in practice is to

place the containers heading for the same destination

in the same block. Therefore, the number of blocks is

equal to the number of destinations/ports, where the

containers are to be discharged. The advantages of

this strategy is that containers can be easily loaded

from the yard to the ship without re-handling.

However, some spaces may not be occupied at all

because of the uncertain shipment information. This

is particularly true when the possibility of high

shipment demand is low. In this paper, it is assumed

that the yard is divided into different blocks, and each

block has the same size/capacity. We conceptually

divide each block into two portions: a set of dedicated

stacks and a set of shared stacks. Containers in

dedicated stacks within the same block have the same

destination (i.e. they will go to the same port).

Containers in shared stacks have different

destinations. Therefore, rehandling or reshuffling

may be required in shared stacks. Rehandling

happens when containers placed on the top of the

required one have to be removed first. Rehandling is

one of the most unproductive operations in the yard

area. The workload at the terminals can be

significantly reduced if no or limited number of

rehandling occurs. However, containers assigned to

dedicated stacks can be loaded to the ship

sequentially, without the need of rehandling. It is

noted that dedicated and shared stacks are not divided

physically. In each block, there are two portions: one

is for dedicated stacks and the other is for shared

stacks. In addition, each block has a special stack to

be used for re-handling containers in shared stacks;

this stack can store no more than one container so that

other containers in shared stacks of this block can be

temporarily placed in the stack during the process of

re-handling.

Since only containers in the shared stacks require

re-handling, the number of containers that require re-

handling in each block is limited. Therefore,

managers reserve only one stack in each block for re-

handling. However, the traditional sharing strategy, in

which all containers are mixed up, may require more

than a stack in each block for re-handling, since re-

handling happens frequently. Sometimes, a stack in

each bay is reserved for re-handling in practice

because frequent movement within a block might

cause safety concerns.

Although the concept of separate dedicated and

shared portions has already been used in some

terminals, yard managers are increasingly facing the

challenge of determining the split between dedicated

and shared stacks under uncertain shipment

information. Steenken et al. (2004) state that the need

for optimization of container terminal operations has

become an important issue in recent years. In this

paper, we propose a dual-response storage strategy to

deal with uncertain shipment information for export

containers. At the first stage, before the accurate

shipment information is available, yard managers

need to make the first response by determining how

the dedicated stacks in each block should be allocated

for storage of containers. At the second stage, when

the uncertain shipment information is realized, yard

managers need to respond to the situation by

determining the size of the shared stacks in each block

to store extra containers. As a result, spaces still left

in the blocks will be free for use.

The main problem considered in this paper is to

determine the optimal size of spaces to be reserved

for the dedicated stacks, as well as the shared stacks,

such that the total operational cost can be minimized.

In order to obtain an optimal dual-response storage

strategy, we formulate a two-stage stochastic recourse

programming model. The rest of the paper is

organized as follows. Section 2 provides the literature

review on storage management at container terminals

and stochastic modelling for allocation problems at

container terminals. Section 3 provides notations and

definitions for modelling the storage problem.

Section 4 presents a two-stage stochastic model for

storage management under uncertainty. Section 5

shows computational results and analysis. The final

section gives the conclusions of this paper and

recommendations for future research.

2 LITERATURE REVIEW

Due to the growing importance of maritime

transportation, operations of sea container terminals

have received increasing attention from researchers

Container Yard Allocation under Uncertainty

31

(Froyland et al., 2008). Excellent review papers about

detailed descriptions and classification of operations

of container terminals are provided by Vis and De

Koster (2003), Steenken et al. (2004), and Stahblock

and Voß (2008). The problem to be discussed in this

paper belongs to the category of storage yard

management in the literature. Storage management

addresses the assignment of locations to containers,

which includes space allocated to containers moving

into and out of storage yards as well as

reshuffles/rehandles (Froyland et al., 2008). Chen

(1999) investigates yard operations in Taiwan, Hong

Kong, Korea and UK. Kim and Park (2003) study

storage space allocation for export containers. A

mixed-integer programming model is proposed for

efficient utilization of storage space and efficient

loading. Two heuristics approaches are designed for

solving this problem. Lee and Hsu (2007) propose an

integer programming model for the container pre-

marshalling problem with a vessel and a rail mounted

gantry crane. Jin et al. (2016) study the daily storage

yard manage problem arising in maritime container

terminals, which integrates the space allocation and

yard crane deployment decisions together with the

consideration of container traffic congestion in the

storage yard. Lin and Chiang (2017) investigate the

storage space allocation problem at a container

terminalgantry crane in Taiwan. A decision rule-

based heuristic is proposed. Extant literature on

storage management problems has mainly discussed

deterministic situations where all accurate

information is available at the time when decisions

are made. Unfortunately, storage planning based on

available (at the time of decision-making)

information seldom matches the real situation

because container delivery is a stochastic process that

cannot be exactly foreseen (Steenken et al., 2004).

Zhen et al. (2011) propose stochastic programming

models for managing container terminal operations.

A meta-heuristic approach is proposed to solve the

above problem in large-scale real environments. Zhen

(2013) exams sstorage allocation in transshipment

hubs under uncertainties and proposes a real-time

decision support system (DSS) which can act as an

ultimate solution for coping with uncertainties in yard

storage allocation process.

3 NOTATIONS AND

DEFINITIONS

3.1 Known Parameters

It is assumed that there are a total of N destinations,

indexed by n. Since the yard area is equally divided

into N blocks according to containers’ destination, n

also represents the index of blocks. Each block

consists of dedicated and shared stacks. Containers in

dedicated stacks (within the same stack) have the

same destination, while containers in shared stacks

may have different destinations. Parameters R, B, H

represent the maximum numbers of rows, bays and

tiers for any block. C represents the maximum

capacity of yard. Since each block has (H-1) spaces

for reshuffling, we have:

C = N*[R*B*H-(H-1)].

It is also assumed that the total capacity of the

storage yard is adequate to accommodate the total

quantity of export containers under any possible

scenario. If the total capacity of the yard is fully used,

further demand from customers will be either

rejected, or handled by other terminal operators. The

cost of handling these extra containers is not

considered in our model.

3.2 Stochastic Parameters

is a random vector, which represents the

stochastic nature of arrivals of export containers.

is a probability space. Let represent

the probability density function of , , for

all ,

.

is a random vector, where

represents the

random shipment demand in the nth destination

.

3.3 Decision Variables

Under uncertain shipment information, yard

managers have to decide how many containers should

be assigned to the dedicated stacks in each block.

Therefore, we have a set of decisions to be taken

without accurate information on the stochastic

demand. These decisions are called the first stage

decisions, which are represented by vector:

,

where

represents the quantity of containers to be

assigned to the dedicated stacks in the nth block

. When the full information is received on

realization of random vector , the second stage ac-

ICORES 2019 - 8th International Conference on Operations Research and Enterprise Systems

32

tions are taken, which are represented by vector:

,

where

represents the quantity of container to be

assigned to the shared stacks in the nth block

.

3.4 Costs

The unit cost of handling containers in the dedicated

and shared stacks plays an important role in the

model. We use the following parameters to represent

some crucial factors that have impact on handling

cost:

represents the average cost of assigning

and holding a container in the nth block. Note

that in some container terminals, the cost of

using a container location in a dedicated stack

can be bid by yard managers. It can also be

considered as the unit cost of storing containers.

Here, we write the coefficients

in a vector-

form as

.

represents the average cost of moving a

container in a dedicated stack in the nth block. The

movement includes lifting the container, putting it on

a trailer or an internal truck, and transporting it to the

quay side. This cost is calculated by yard managers

from the average movement cost for individual

containers. We write the coefficients

in a vector-

form as

.

represents the average cost of assigning and

holding a container in the shared stack. In some

container terminals, the cost of using a space in the

shared stack can be bid by yard managers. It can also

be regarded as the unit cost of storing a container in

the shared stack. One of the simplest methods to

estimate this parameter is to divide the annual cost of

assigning and holding space in the shared stacks by

the total number of all spaces used in the shared stacks

in a year.

represents the average cost of moving a

container in the shared stack. The movement includes

searching, re-handling, lifting of the container, and

then loading it on a trailer or internal truck, and

transporting it to the quay side. It is noted that the

average cost of moving a container in the shared stack

is significantly higher than the dedicated stack

because it involves searching and re-handling, which

does not occur in the dedicate stack. One of the

natural ways to estimate this parameter is to divide

the annual cost related to movements (such as

searching, re-handling, lifting, releasing and

transporting) of containers in the shared stacks by the

total number of containers stored in the shared stacks

per year

4 A TWO-STAGE STOCHASTIC

RECOURSE PROGRAMMING

MODEL FOR YARD STORAGE

ALLOCATION UNDER

UNCERTAINTY

4.1 A General Two-Stage Stochastic

Model for Uncertain Yard Storage

Allocation Problems

A two-stage stochastic recourse programming model

for determining a dual-response storage allocation

strategy is formulated as follows:

subject to

, integer for (1)

Where is the optimal solution of the

second stage problem:

In (1),

represents an appropriate

dimension. The first stage decisions (x

n

) are

independent of realization of the stochastic

variable. It means no matter what shipment demand

is realized (i.e. how containers will arrive), the first-

stage decisions remain the same. However, yard

managers can make different responses (the second

stage decision

) for any shipment situation that

might happen.

In (1), for vectors

and

, functions and

are defined in accordance with the following vector-

forms:

Here, we summarize explanations of the above

model as follows. In the objective function, a

T

x is the

total cost of assigning and holding containers in the

dedicated stacks.

represents the

Container Yard Allocation under Uncertainty

33

expectation of the overall cost caused by assigning,

holding and moving containers, plus the movement

cost in the dedicated stacks. The term

represents the expectation of the cost caused by

assigning and holding container space in the shared

stacks. The term,

, denotes the overall

expected cost of moving containers in the dedicated

stacks with the value of

being the

number of containers stored in the dedicated stacks of

the nth block. The term

,

is the cost of moving containers stored in the shared

stacks with the value of

being

the number of containers placed in the shared stacks

in the nth block.

Now, let us look at the constraints in (1). The

constraint

ensures that the quantum of

the dedicated stacks in each block does not exceed the

maximum capacity of the block, and the first stage

decision variables have to be non-negative integer.

The constraints

ensure that the total capacity of the yard is not

exceeded, and shipment demand has to be satisfied

for any scenario. It means all containers are assigned

to either the dedicated or shared stacks. The final

constraint is the non-negative and integer requirement

for all decision variables.

4.2 A Two-Stage Stochastic Model with

Finite Scenarios for Uncertain

Yard Storage Allocation Problems

In this subsection, we investigate a model (See (2)),

which is a simplified two-stage recourse model in (1)

for the uncertain storage problem. From the

definitions of

and in Section 3.4, we know that

and represent the average cost of moving a

container from the dedicated stacks and shared stack

to vessels at the quay side. It is natural to assume that

for planning purposes, both

and are dependent on

the basis of the overall capacity rather than the space

used for each individual container. In real-world

situations, both the labour costs (salary) and

equipment costs (for example, the cost of purchasing

and maintaining a vehicle) are almost fixed, even in

the case, where no service is performed in the yard

area. Compared to the cost of assigning and holding a

container, other costs related to the movement (for

example, fuel or gas used for lifting, trucking etc.) are

also relatively small. Therefore, we only focus on the

cost of assigning and holding in the yard area

(including the dedicated and shared stacks) in Model

(1).

In addition, we notice that one of the difficulties in

solving the two stage stochastic programming model

(See (1)) is the continuity of the scenario set Ω. There

are three reasons for the difficulties caused: 1) It is

almost impossible to obtain a continuous distribution

of the uncertainty in a real-world process. However,

in most of cases, a set of finite scenarios and

approximate discretized distribution functions can be

easily obtained from historical data; 2) In a real-world

situation, the number of containers is normally finite,

and hence it is reasonable to use a finite scenario

model to capture uncertain situations that might

happen in the future. 3) Even for the case where the

number of scenarios is infinite and the distribution is

available, it is difficult to integrate the expectation of

the objective function, due to the complexity of the

distribution function. Therefore, in this subsection,

we proceed to analyse a variation of stochastic model

with a finite scenario set. It is assumed that a support

set Ω with finite number of scenarios, denoted by

, where

,

, and K is the maximum number of

scenarios. Note that this assumption holds true in the

real problem, where the number of containers arrived

is normally finite. We have the following notation

related to a finite set of scenarios:

k: Index different scenarios for demand. (

: Probability of scenario k.

: Realization of demand for containers in the

nth destination under scenario k.

: Number of containers in the shared stacks of

the nth block under scenario k.

We write the second stage decision variables

in vector-form, as

. Now, the two

stage stochastic optimisation for the storage

management problem in Model (1) can be

equivalently reformulated as the following algebraic

equivalent linear programming form:

subject to

, for

(2)

, for

ICORES 2019 - 8th International Conference on Operations Research and Enterprise Systems

34

and integer for

5 COMPUTATIONAL RESULTS

AND ANALYSIS

In order to illustrate the effectiveness of the proposed

two stage model in Section 4 for the uncertain storage

management problem of container terminals, we use

data provided by a container terminal in Hong Kong.

Located at the mouth of the Pearl River with a deep

natural harbour, Hong Kong is geographically and

strategically important as a gateway to China and

trans-shipment port for intra-Asian and world trade.

Hong Kong is the largest container port serving

southern China and one of the busiest ports in the

world. Consider export containers stacking for a

vessel visiting 10 ports for discharge of containers.

There are 10 blocks are reserved to hold the

containers in the yard area. Each block has 6 rows and

8 bays. Since the maximum height for stacking is 5

tiers, saving (5-1) = 4 free spaces for re-handling, the

maximum number of containers that can be

accommodated is C = 10*[6*8*5-4] = 2360. It is

assumed that the demand for containers is uncertain

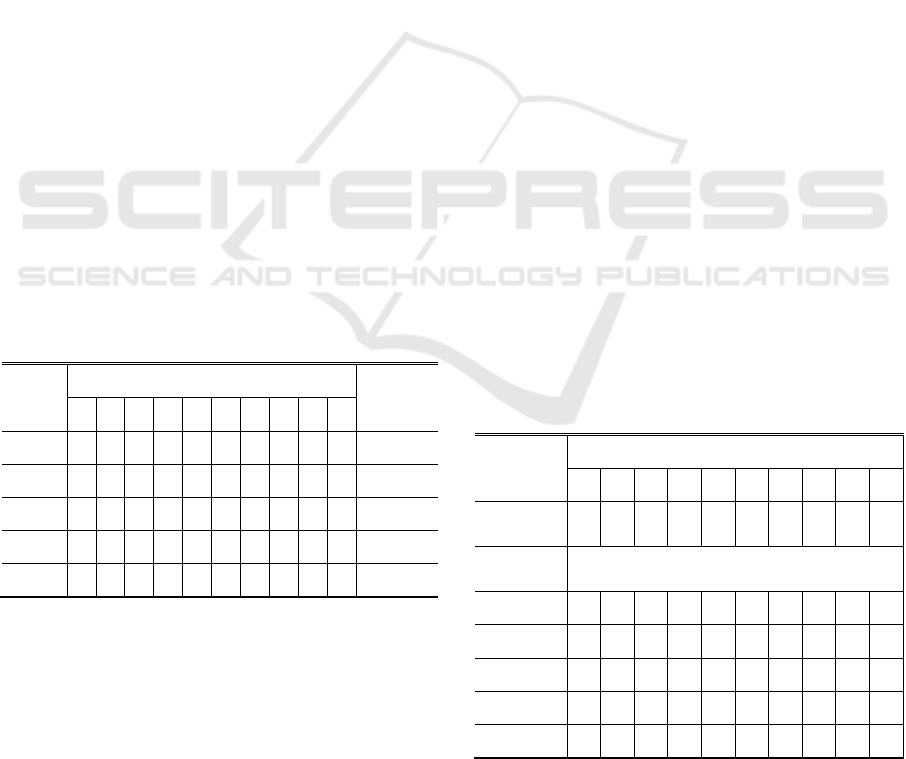

for different ports (See Table 1). In general, there are

five different scenarios representing the trend for the

shipment demand in the future. The demand

quantities and likelihood of each scenario are

estimated by a yard storage planner (Table 1).

Table 1: Known data.

Scenario

Port

Likelihood

1

2

3

4

5

6

7

8

9

10

1

200

150

270

200

240

220

180

150

160

140

0.1

3

200

250

160

245

280

180

180

120

250

240

0.3

4

240

180

270

240

260

250

180

200

250

210

0.1

5

200

100

250

260

240

230

200

240

270

260

0.2

The data in Table 1 pertain to a real situation. For

simplicity, we assume the cost of assigning and

holding a container in the dedicated stacks is 1 unit,

while the cost in the shared stacks it is 3.5 units. We

run the two stage stochastic programming model in

(1) with optimization software Xpress IVE. The

results of yard space allocation are as shown in Table

2. The total cost of the dual-response storage plan is

2570.25 units. Table 2 gives the dual-response

storage strategy. The row “Dedicated Stack” indicates

the first-stage response, which is the predetermined

number of containers for dierent destinations to be

allocated to the dedicated stacks. The row “Shared

Stack” under “Scenario k” indicates the second-stage

response, which is the reactive number of containers

for dierent destinations to be allocated to the shared

stacks according to the real demand under scenario k.

From the results in Table 2, we can see that only 35

spaces in Block 2 and 10 spaces in Block 5 are

required for storing containers in the shared stacks if

Scenario 1 happens. The capacity for each block is

236. 235 spaces in Block 3 and 230 spaces in Block 5

are allocated to the dedicated stacks. Therefore, the

managers can use 35 spaces in Block 1, 5 spaces in

Block 4, and 5 spaces in Block 5 for storing extra

containers in the shared stacks. As a result, the spaces

that have not been allocated to either the dedicated or

shared stacks are free for other purposes. For

example, there are total 135 spaces left if Scenario 1

happens. By adopting the dual-response strategy, the

managers do not need to hold all spaces until the

containers are loaded into the ship. As soon as the

managers have full information about the shipment

demand, i.e. the stochastic demand is realized, the

managers can make the corresponding response by

deciding the size of the shared stacks and releasing

the spaces that will not be required, simultaneously.

Releasing the unused space is very important in

practice because the unused spaces make no profit,

which will potentially increase the total operations

cost of the terminal. This is particularly true for

terminals with limited yard space, like the Hong Kong

container terminal.

Table 2: Yard Allocation under Uncertainty.

It is noted that when the number of containers

cannot be divided by the number of tiers, which is five

Port

1

2

3

4

5

6

7

8

9

10

Dedicated

Stack

200

210

235

230

230

230

180

195

235

235

Shared

Stack

Scenario 1

0

0

35

0

10

0

0

0

0

0

Scenario 2

20

40

65

0

0

0

0

0

5

15

Scenario 3

0

40

0

15

50

0

0

0

15

10

Scenario 4

40

0

35

10

30

20

0

5

15

0

Scenario 5

0

0

15

25

10

0

20

45

35

25

Container Yard Allocation under Uncertainty

35

in this example, we need to move some containers

(less than five) from the dedicated stacks to the shared

stacks so that re-handling is not required in the

dedicated stacks. Whereas, if there are no dedicated

stacks allocated, all containers will be mixed in the

shared stacks. This is a traditional sharing strategy.

We can still use the model proposed in Section 4 to

obtain the solution for the traditional sharing strategy.

Since no container is assigned to the dedicated stacks,

, for . We run this model again

with optimization software Xpress IVE and obtain the

cost of using the traditional sharing strategy as

7320.25 units. Compared with this traditional sharing

strategy, the average savings in cost for the dual

response-strategy proposed in this paper is 64.89%.

6 CONCLUSIONS

This paper investigates storage yard allocation

problems for export containers under uncertainty. The

yard storage is physically divided into blocks and

each block is conceptually divided into dedicated and

shared stacks. The dedicated stacks in the same block

have the same destination/port. The shared stack has

mixed containers, destined for dierent ports. As a

result, no re-handling is required for containers stored

in the dedicated stacks but containers in the shared

stacks need re-handling. We propose the dual-

response storage policy to decide how containers are

allocated to the two dierent types of stacks under

uncertain shipment information. At the first stage,

when accurate shipment information is not available,

we need to decide how containers are to be allocated

to the dedicated stacks. At the second-stage, when the

uncertainty is realized, we need to respond to the

dierent possible shipment scenarios that might

happen. The decision at the second stage includes

determining how additional containers are allocated

to the shared stacks. As only a small number of

containers are allocated to the shared stacks, re-

handling is significantly reduced. In addition, we

develop the two-stage stochastic recourse

programming model to obtain the optimal dual-

response storage plan. The computational results

show the eectiveness of the two-stage stochastic

model for storage problems under uncertain shipment

information. Compared with the traditional sharing

strategy (in which all containers are mixed up) and

the non-sharing strategy (in which no containers are

mixed up), the dual-response storage strategy can

significantly reduce operations cost and, therefore,

enhance productivity of container terminals. Future

research might consider a situation in which both yard

space and shipment demand are uncertain. In

addition, how to precisely determine the placement of

containers in the shared stacks is a potential area for

future research. The yard storage problem for import

containers under uncertainty is also a potential area to

explore.

REFERENCES

Chen, T., 1999. Yard operations in the container terminal -

A study in the “unproductive moves”. Maritime Policy

and Management 26: 27-38.

Froyland, G., Koch, T., Megow, N., Duane, E., Wren, H.,

2008. Optimizing the land operation of a container

terminal. OR Spectrum 30: 53-75.

Jin, J.G., Lee, D.H., Cao, J.X., 2017. Storage Yard

Management in Maritime Container Terminals.

Transportation Science 26: 93-116.

Kim, K.H., Park, K.T., 2003. A note on a dynamic space-

allocation method for outbound containers. European

Journal of Operational Research: 148: 92-101.

Lee, Y., Hsu, N.Y., 2007. An optimal model for the

container pre-marshalling problem. Computers and

Operations Research 34: 3259-3313

Lin, D.Y., Chiang, C.W., 2017. The Storage Space

Allocation Problem at a Container Terminal. Maritime

Policy and Management 44: 685–704.

Stahblock, R, Voß, S, 2008. Operations research at

container terminals: a literature update. OR Spectrum

30: 1-52.

Steenken, D., Voß, S., Stahlbock, R., 2004. Container

terminal operation and operations research - a

classification and literature review. OR Spectrum 26: 3-

49.

Zhen, L., Lee, L.H., Chew, E.P., 2011. A decision model

for berth allocation under uncertainty. European

Journal of Operational Research 212: 54-68.

Zhen, L., 2014. Storage allocation in transshipment hubs

under uncertainties. International Journal of

Production Research 52: 72-88.

ICORES 2019 - 8th International Conference on Operations Research and Enterprise Systems

36