A Stochastic Optimization Approach of Flow Shop Sequencing

Problem for On-time Delivery of Precast Components

Mohamed Mamdouh Yusuf

1

, Ahmed Karam

2

and Amr B. Eltawil

1

1

Industrial Engineering and Systems Management, Egypt-Japan University of Science and Technology (E-JUST),

PO box 179, New Borg Elarab City, Alexandria 21934, Egypt

2

Mechanical Engineering Department, Faculty of Engineering at Shoubra, Benha University, 108, Cairo, Egypt

Keywords: Precast Industry, Discrete Event Simulation, Flow Shop Sequencing, Stochastic Processing Times,

Simulation-based Optimization, Optquest

®

for Arena

®

.

Abstract: Recently, the flow shop sequencing problem in precast plants has been witnessing remarkable interest from

many researchers. This paper contributes to recent literature by providing a simulation-based optimization

approach to solve the precast flow shop sequencing problem taking into account the uncertainty of processing

times of precast production operations. The proposed approach is developed by integrating a Discrete Event

Simulation (DES) model, which is built to capture the realistic features of precast production activities, and

OptQuest

®

to find the optimum sequencing of Precast Components (PCs). The proposed approach is validated

against another approach from literature. In addition, its practicability is put to the test by applying the

proposed approach to a real case study. The obtained results indicated that pre-casters can use this approach

to attain better PCs sequences than that based on a rule of thumb.

1 INTRODUCTION

Precasting is a kind of industrialized building system

which refers to the process of shifting some

construction operations from the field to off-site

workshops, where construction components can be

produced with higher quality, in less time, lower

prices and in a leaner and greener way than the

traditional construction practice (Sacks et al., 2004).

By virtue of their advantages, Precast Components

(PCs) were used by 56% of construction projects in

Finland, and by 28% in Germany, 26% in Britain, and

about 20% in Spain (Sacks et al., 2004).

However, the precast industry faces many

challenges which can be cushioned by proper

management of its multi-echelon supply chain,

starting from material supplying and ending with

installation at construction sites (Wang et al., 2018b).

This paper focuses only on production scheduling in

precast plants where production managers shoulder

ordering of PCs to be processed through a number of

sequential operations to ensure on-time delivery of

PCs to the construction sites. So, it is a typical

flowshop sequencing problem. Early delivery of PCs

leads to higher inventory costs and double handling

of PCs at the construction site. However, lateness of

PCs causes higher direct and indirect costs due to

project delay. The problem is worsened by the fact

that each type of PC has different processing times on

the different production operations, and the managers

only depend on know-how and hands on experience

to tackle this problem, which in turn leads to

suboptimal PCs sequences (Wang et al., 2018a). So,

there exists a need to provide the production

managers with a decision support tool to help them in

scheduling of PC production efficiently in order to

meet due dates and maximize resource utilization to

achieve satisfactory return on investment.

until now, a plethora of researchers addressed the

precast production scheduling problem by using

different techniques such as mathematical

programming methods and simulation models. Most

of these studies considered the processing times of PC

production operations as deterministic times.

Recently, the stochastic nature of precast processing

times was claimed to be considered in the precast

flow shop sequencing problem only by (Wang et al.,

2018a). They developped a two-phase sequential

approach which firstly generates near optimal PCs

schedules obtained by a Genetic Algorithm (GA), and

then a DES model is used to evaluate performance of

these PCs schedules under stochastic processing

Yusuf, M., Karam, A. and Eltawil, A.

A Stochastic Optimization Approach of Flow Shop Sequencing Problem for On-time Delivery of Precast Components.

DOI: 10.5220/0007309602450252

In Proceedings of the 8th International Conference on Operations Research and Enterprise Systems (ICORES 2019), pages 245-252

ISBN: 978-989-758-352-0

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

245

times. In other words, it is a simulation based

evaluation approach which does not guarantee full

integration between simulation and optimization, as

explicitly mentioned by (Wang et al., 2018a). To

improve, this paper presents a simulation-based

optimization approach to obtain optimum PCs

production schedules with consideration of the

stochastic nature of the problem to achieve just in

time delivery of PCs. In doing so, a DES model is

integrated with an optimization module. After

verification and validation of the proposed approach,

it is used to find the near optimum PCs production

schedules in a real case study.

The rest of the paper is organized as follows,

previous studies of precast production planning are

reviewed and related research gaps are identified in

section 2. Section 3 illustrates the operations to

produce and deliver PCs to construction sites while

section 4 provides a detailed explanation of the

developed simulation-based optimization approach.

Numerical experiments are elaborated in section 5.

Finally, conclusions are discussed in section 6.

2 LITERATURE REVIEW

The literature on precast production planning is

plentiful, and previous researchers dealt with it by

using either mathematical programming methods or

discrete event simulation models as will be illustrated

later in sections 2.1 and 2.2, respectively. Finally,

research gaps are identified in section 2.3.

2.1 Precast Production Scheduling

using Mathematical Programming

Despite that literature is riddled with many studies on

production scheduling (Yenisey and Yagmahan,

2014), these studies did not fit the precast production

scheduling problem (Chan and Hu, 2001). So,

numerous academics are avid for solving this problem

by means of mathematical modeling. (Chan and Hu,

2001) was the first to model the precast sequencing

problem as a flow shop sequencing problem with the

objective of minimizing the makespan or Tardiness

and Earliness (T&E) penalty cost. They made it more

realistic by distinguishing between daily working and

non-working hours, and classifying production

activities into interruptible or uninterruptible and

sequential or parallel activities, as will be illustrated

in section 3. Their model was deemed to be a

stepping-stone because subsequent researchers

enhanced it by considering ignored resources or

adding other objectives. For example, moulds were

considered by the same authors in (Chan and Hu,

2002), however, the competition between PCs on

limited moulds was simulated by (Benjaoran et al.,

2005) who calculated the PC waiting times due to

mould scarcity; they used a multi-objective function

to minimize the total flow time, machine idle time and

T&E penalty cost. Moreover, mould planning was

addressed carefully by (Hu, 2007), who sought for

minimizing the number of required moulds and

levelling its usage. To improve the models, the buffer

capacity between production processes as a limited

resource was added by (Ko and Wang, 2011), who

used a multi-objective function to minimize the

makespan and T&E penalty cost. By the same token,

(Yang et al., 2016) not only considered the previous

resources but also included pallets, capacity of the

curing chamber and the number of production lines to

the model. Their objective was to reduce idle time,

T&E penalty cost, inventory cost, makespan and PC

changeover, simultaneously. Recently, (Wang and

Hu, 2017) expanded this model by including three

ignored stages in the precast supply chain which are,

mould manufacturing, storage and transportation to

construction sites, with the objective of cutting T&E

penalty costs.

With respect to the applied optimization

algorithm, a Genetic Algorithm (GA) was used in the

previous studies, by virtue of its performance to find

near-optimal solution for such nondeterministic

polynomial (NP)-hard problems, except (Chan and

Hu, 2002) who applied constrained programming

method.

2.2 Discrete Event Simulation-based

Approaches Applied to Precast

Production

Simulation modelling is preferred over mathematical

modelling in analysing large problems of real and

complex systems characterized with uncertainty

(Law, 2007). Moreover, the ability to conduct

different scenarios and check their performance is

another advantage over analytical methods (Law,

2007). This fact conduced to the adoption of

simulation modelling to tackle precast production

planning issues in many studies. Based on the purpose

of using simulation, these studies can be categorized

into two types: studies applied simulation based

evaluation approach and others used simulation based

optimization approach.

In the first type, simulation models were used to

evaluate some predetermined scenarios and as a result

a conclusion can be drawn according to the purpose

of study. For instance, (Chen et al., 2016) used a DES

ICORES 2019 - 8th International Conference on Operations Research and Enterprise Systems

246

model, as an evaluation tool, to validate the

advantages of a proposed precast production method

over the traditional one in terms of minimizing the

makespan and maximizing resource utilization. A

DES model was used by (Wang et al., 2018a) to

compare between ten PCs production schedules pre-

generated by optimizing a mathematical model using

GA. The same authors enhanced their model to

simulate different risks which disturb the precast

supply chain, (Wang et al., 2018b). By using an

applied simulation based evaluation approach, they

prioritized the identified risks based on their

detrimental impact.

In the second type of these studies, the researchers

fully integrated simulation with search techniques, to

generate a new set of solutions after evaluating an

objective function defined in the simulation model.

This process continues until a predefined stopping

criteria is met. For example, (Cheng and Yan, 2009)

coupled a messy GA and CYCLic Operation

NEtwork (CYCLONE), a simulation language, to

search for optimum resource allocation in order to

both minimize hiring cost and maximize production

rate of a precast plant. Different kinds of production

resources were simulated in this study such as molds,

labors, trucks, cranes, hydraulic jacks and truck

mixers. Also, (Al-Bazi and Dawood, 2018) integrated

GA and simulated annealing, respectively with

Arena

®

simulation model; the purpose was to find the

optimum allocation of multi skilled labors in a precast

plant with the objective of reducing crew allocation

costs. Arena

®

is a simulation software enables both

discrete and continuous simulation simultaneously.

Moreover, (Arashpour et al., 2016) used Tabu search

and Arena

®

model to meet contracted due dates of

PCs by finding the optimum PCs production sequence

while considering multi-skilled resources and wasted

time due to switching from one PC type to another.

However, the realistic nature of the precast

production activities, identified by (Chan and Hu,

2001) and mentioned in section 2.1, was not

considered in their model.

2.3 Research Gaps

After reviewing the aforementioned studies, some

research gaps can be deduced and discussed along the

following fronts.

Despite the superiority of simulation modelling

over mathematical modelling in capturing the

characteristics of complex systems and incorporating

uncertainty, precast production planning issues

addressed by using mathematical models were more

diverse than that addressed by simulation models. So,

a research gap needs to be filled by applying

simulation modelling not only to consider uncertainty

but also to regard other important factors in the

precast industry such as inventory management,

logistics, multiple production lines, buffer space

between workstation, materials supply, coordination

with contractors at construction sites, risk

management, incorporation of valuable assets such as

trucks, cranes and steamers.

In addition to that, the realistic nature of precast

production activities was simulated only by (Wang et

al., 2018a), who built their model based on the

mathematical formulation illustrated in (Chan and

Hu, 2001) and (Wang and Hu, 2017). This

formulation does not reflect other realistic conditions

in precast production such as waiting time due to

shared resources like moulds, cranes and multi-

skilled labours, hiring additional crews at each

process, limited capacity of curing and storing

processes, limited production space between

processes and specifying failure data for each type of

production resources. So, there exists a need to

develop a more general model to enable practitioners

to experience the different production conditions

without the need to reformulate the mathematical

model to suit each condition.

Besides, reviewing the studies in section 2.2

shows that researchers used only metaheuristics in

their simulation based optimization methodology due

to their advantages. However, other simulation

optimization methods may be more beneficial than

metaheuristics to deal with noisy functions and

correlated decision variables in case of applying

cross-entropy methods, or to reduce computational

time by using the Response Surface Methodology

(RSM) which will be of great importance in case of

more complex models of precast production planning

in the future. In a similar vein, commercial

optimization toolboxes can be used due to its

capability, credibility and usability.

To bridge these gaps, this paper is intended to

develop a more general simulation model to reflect

the nature of precast production activities without the

need to use case dependent mathematical equations.

This model is linked with an optimizer to solve the

precast flow shop sequencing problem with

considering uncertainty in processing times of precast

production activities.

A Stochastic Optimization Approach of Flow Shop Sequencing Problem for On-time Delivery of Precast Components

247

3 DESCRIPTION OF THE

PRECAST PRODUCTION

PROCESS

To be ready for installation on the construction site,

PCs have to be processed through nine sequential

operations (from M1 to M9), (Wang and Hu, 2017).

M1- Mould manufacturing: Due to lack of

standardization, pre-casters may receive PC orders

inconsistent with their own moulds. If that is the case,

new moulds should be manufactured.

M2- Mould assembling: assemblers have to prepare

moulds by fastening, cleaning and oiling its sides to

ensure smooth PCs surface and effortless

demoulding.

M3- Reinforcement setting: reinforcement and other

predetermined parts are placed in their locations

according to shop drawings.

M4- Casting: ready mix concrete is poured,

compacted and levelled.

M5- Curing: PCs are either transferred to the steam

curing chamber or covered by water proof membrane,

to ensure its strength development and durability.

M6- Demoulding: stripping moulds and extracting

PCs.

M7- Finishing and repairing: after taking out PCs,

they should be checked and any imperfections have

to be fixed.

M8- Storing: the PCs are stored at the stockyard to

ensure delivery strength.

M9- Transportation: in this process, the PCs are

transferred to the construction sites by using trucks.

These nine processes can be classified into

interruptible and sequential (M1, M2, M3, M6 and

M7), uninterruptible and sequential (M4),

uninterruptible and parallel activities (M5, M8 and

M9), (Wang and Hu, 2017). With respect to

interruptible activities, it is not permitted that

working on the PCs exceeds an allowable working

time denoted by H

w

. If working on a PC needs time

beyond H

w

, it will be continued on the next day, as

shown in Figure 1.a. However, in case of

uninterruptible activities, labors are allowed to work

overtime hours denoted by H

A

if they can finish

working on a PC. If they cannot, the whole working

on this PC is delayed to the next day, as shown in

Figure 1.b. In parallel activities, more than one PC

can be processed, simultaneously. On the contrary,

only one PC can be processed in sequential activities.

Moreover, PC curing and storing can be extended

overnight in case of requiring time beyond H

w

in

contrast to transportation activity, as shown in

Figures 2.c and 2.d, respectively.

4 THE PROPOSED

SIMULATION-BASED

OPTIMIZATION APPROACH

The proposed approach is based on iterative

interaction between a DES model and OptQuest

®

which is a commercial optimization software fully

integrated with Arena

®

. The integration mechanism is

as follows: OptQuest

®

finds trial schedules for the

simulation model. The quality of the schedules is

evaluated through running the simulation model. The

evaluation of the schedules is feedback to OptQuest

®

in order to search for new trial schedules. Once, a

termination condition is held true, the iterative

process is stopped and the best schedule is output. In

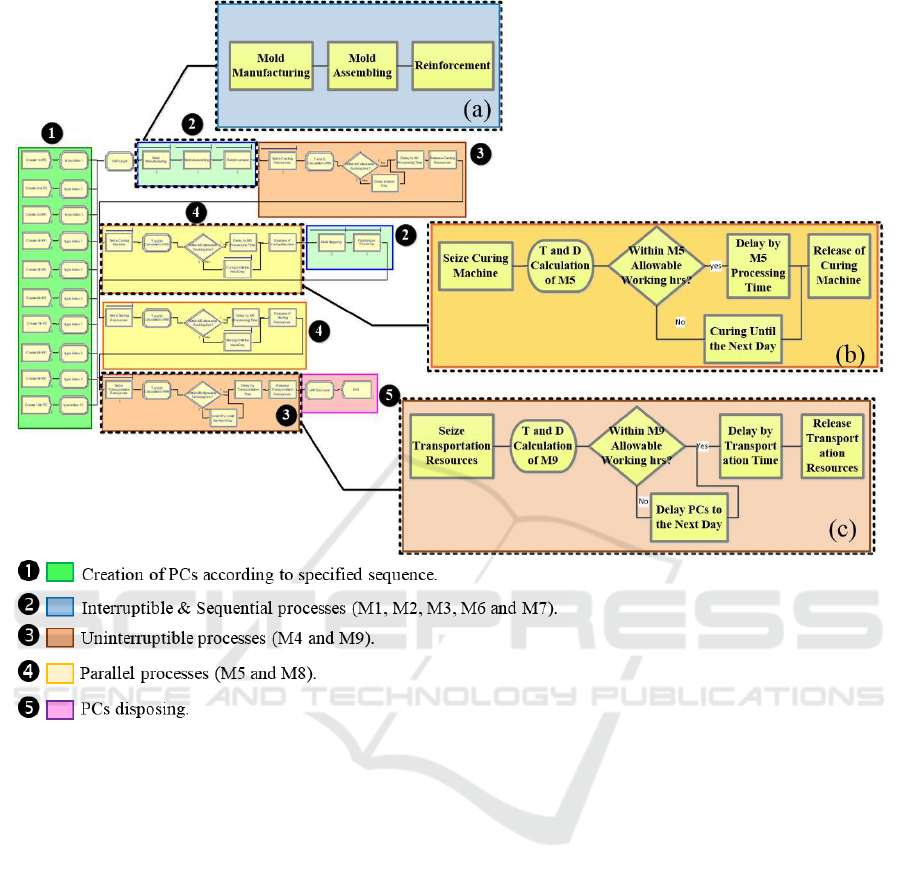

Figure 1: Completion Time (CT) in different classes of precast production activities.

ICORES 2019 - 8th International Conference on Operations Research and Enterprise Systems

248

the following sections, the simulation model and the

optimization procedure are described in detail.

4.1 The Simulation Model of the

Precast Production Activities

The realistic nature of each precast production

activity is simulated in a more general model than that

of (Wang et al., 2018a), as shown in Figure 2. For

instance, interruptible and sequential activities such

as mold manufacturing (M1), mold assembling (M2),

reinforcement (M3), mold stripping (M6) and

finishing/repairing (M7) can be modeled by using

only Arena

®

’s “Process” modules, as shown in Figure

2.a, and identify a resource schedule with unit

capacity and “Preempt Rule”, available during

normal working hours (H

w

). Regarding the parallel

activities (curing M5 and storing M8) and the

uninterruptible activity (casting M4), they are

modeled by using “Seize”, “Delay” and “Release”

modules, as shown in Figures 3.b and 3.c. After

seizing the respective resources, the completion time

of each PC until this stage must be examined to decide

whether this PC can be processed during the

remaining hours of a typical working day (normal

working hours (H

w

) for M5 and M8; normal working

hours (H

w

) + allowable overtime (H

A

) for M4). If it is

not the case, the PC is delayed to the next day for the

casting process, as shown in Figure 2.c. As for the

curing or storing processes, the PC is left in the curing

machine or the storage yard until the next day, as

depicted in Figure 2.b. The resources’ schedules with

unlimited capacity during 24 hours are identified for

the M5 and M8 processes, but only a unit resource

Figure 2: Arena simulation model of precast workshop; (a) The representation of the interruptible and sequential activity

by using Arena

®

’s “Process” module; (b) The representation of the parallel activity by using Arena

®

’s “Seize”, “Decide”,

“Delay” and “Release” modules; (c) The representation of the uninterruptible activity by using Arena

®

’s “Seize”, “Decide”,

“Delay” and “Release” modules.

A Stochastic Optimization Approach of Flow Shop Sequencing Problem for On-time Delivery of Precast Components

249

capacity is available during (H

W

+ H

A

) hours for the

M4 process. It is worth mentioning that all the

scheduling rules are set to “Preempt” for all activity

types. Finally, the transportation process (M9) is an

uninterruptible activity with unlimited capacity.

The developed simulation model is built on some

assumptions illustrated through the following points:

1- Every PC has to be processed throughout all of the

operations starting from mold manufacturing (M1)

and ending with transportation (M9).

2- It is not possible that a PC is processed on more

than one operation simultaneously.

3- Every process can work only on one PC within a

time period except curing (M5) and storing (M8)

which have an unlimited capacity.

4- Rescheduling of PCs is not allowable. In other

words, the PCs processing sequence will not be

manipulated until the exit of the last PC even if it

could improve objective function.

5- The considered resources are the molds and labors

only, and there are no shared resources. To clarify,

each process has its own crew and each PC has its

specific mold.

6- The storing and transportation processes (M8 and

M9) are considered under daytime scenario, as

illustrated in (Wang and Hu, 2017).

7- Ramifications of resources breakdown are not

taken into consideration.

8- First-In-First-Out (FIFO) is adopted as a priority

rule at each task.

4.2 The Optquest® Optimization

Module

OptQuest

®

depends mainly on scatter search, and

Tabu search as a secondary algorithm. In addition, it

uses neural network to speed up searching process.

By using these techniques, OptQuest

®

establishes a

new set of decision variables after evaluating value of

objective function retrieved from Arena

®

simulation

model (Bradley, 2007). This process is iterated in a

cyclic manner until a predefined stopping criteria is

achieved; more details on how it works can be found

in (Laguna and Marti, 2003). In order to commence

the optimization process, decision variables,

constraints and objective function need to be

identified to OptQuest

®

. As for the constraints, they

are formulated to guarantee that each PC has a unique

ordering. For more clarification, suppose that there a

number of PCs and each PC must be processed with

a sequence number where . We define

a bianry variable,

which is one if the PC , where

, is processed in

th

order and zero

otherwise.

(1)

Constraint set (1) ensures that in any

th

order, one

and only one PC is processed.

(2)

Constraint set (2) ensures that each PC must be

processed in only one

th

order.

OptQuest

®

generates new sets of feasible

sequences of PCs after evaluating the objective

function though running the simulation model. The

objective function aims at minimizing tardiness and

earliness penalty cost, as defined in equation (3).

(3)

Where

is the total tardiness and earliness

penalty costs for PCs of sequence of precast

components ;

is completion time of each PC at

the last process;

is contracted due date for each PC

;

and

are tardiness and earliness penalties for

each PC .

5 NUMERICAL EXPERIMENTS

In this section, numerical experiments are carried out

to investigate the performance of the proposed

approach. Firstly, section 5.1 shows the validation of

the proposed approach by making a comparison with

an approach existing in literature. In section 5.2, the

proposed approach is applied to a case study.

5.1 Validation of the Proposed

Approach

The developed approach was validated by comparing

its results with that provided by (Chan and Hu, 2001).

In their work, they proposed a GA to solve the precast

flow shop sequencing problem. The objective was to

minimize makespan by sequencing six PCs on six

operations, starting from mold assembling (M2) and

ending with finishing/repairing (M7), and compared

their results with heuristic rules from literature. In

order to compare our approach with the approach of

(Chan and Hu, 2001), we modified our objective

function into theirs and also, we conducted a purely

ICORES 2019 - 8th International Conference on Operations Research and Enterprise Systems

250

Table 1: Comparison of our approach with the results reported by (Chan and Hu, 2001).

deterministic run of our approach by considering the

deterministic times as in the work of (Chan and Hu,

2001). In other words, their example is replicated by

using the proposed approach and a comparison is

made between the results, as shown in Table 1. It can

be noticed that the proposed approach could obtain

optimal solution that is as good as that provided by

the GA proposed by (Chan and Hu, 2001). In

addition, the optimal solution of the proposed

approach outperforms the other heuristic rules.

5.2 Case Study

The purpose of this section is to test the performance

of the proposed approach within a realistic problem

taken from literature (Wang et al., 2018a). In this case

study, it was required to order ten PCs on nine

processes (from M1 to M9) with the objective of

minimizing T&E penalty costs. Since the processing

times of the production operations are stochastic (the

processing times obey triangular distribution), ten

replications are used based on preliminary analysis to

achieve reasonable half-width of the 95% confidence

intervals of the resulted penalty cost. Before starting

the optimization process, the initial solution is

selected to be 7-9-2-5-4-10-8-6-3-1. This solution is

based on a heuristic rule often used by pre-casters in

reality, (Chan and Hu, 2001). The penalty cost that

resulted from applying this heuristic sequence is

229.6$. Table 2 lists the optimum solutions of the

case study obtained by applying the proposed

approach under different number of simulation

iterations, accompanied by the average penalty costs

and the half-width of the 95% confidence intervals.

These simulation experiments were conducted by

using a laptop with Intel(R) Core(TM) i7-6500U 2.50

GHz processor, 8.00 GB of RAM and running a

Windows 10 Education 64-bit operating system.

Obviously, the adoption of the proposed approach can

lead to better PCs production sequences than that

based on the heuristic rule. Interestingly, the proposed

approach took only four minutes to provide a PC pro-

duction sequence (sequence obtained after 100

iterations) that saves about 11% of penalty costs in

comparison with the heuristic sequence, which in turn

proves the practicability of the proposed approach in

case of making such urgent operational decisions like

PCs sequencing. Figure 3 shows the fast convergence

of the proposed approach after 1000 simulation

iterations. This figure indicates that the penalty cost

was plunged during the first hundred iterations and

there was no improvement in the objective function

after 400th iteration.

Figure 3: Convergence of the proposed approach to solve

the case study.

Objective

function

The

proposed

approach

Heuristic algorithms used in (Chan and Hu, 2001)

Palmer’s

heuristic

Gupta’s

heuristic

CDS

heuristic

RA

heuristic

EDD

rule

GA

Minimize

Makespan

(Hours)

48.5

50.6

50

50

49.4

51

48.5

Table 2: Results of the case study after applying the proposed approach.

No. of

simulation

iterations

Solution time

(Min)

Optimum PCs sequence

Average

penalty cost

($)

Half-width

penalty cost ($)

1000

32

3-2-9-7-4-5-10-8-6-1

195.2

1.35

500

16

2-1-9-7-4-5-8-10-3-6

196

0.17

100

4

1-9-2-4-7-5-8-10-3-6

203.9

0.22

A Stochastic Optimization Approach of Flow Shop Sequencing Problem for On-time Delivery of Precast Components

251

6 CONCLUSION

Previous studies addressed precast production

planning by using either mathematical programming

methods or simulation models. However, the

uncertainty of processing times when determining

optimum PCs schedules to achieve on-time delivery

of PCs was seldom addressed. To fill this gap, a

simulation-based optimization approach is developed

in which a discrete event simulation model was

developed by using Arena

®

software based on precast

flow shop sequencing formulation. Then, the

developed model is linked with OptQuest

®

(an

optimization package) to search for optimum PCs

sequences that minimize deviation from the

contracted due dates of PCs. Thereafter, the proposed

approach was validated by comparing its results with

a published approach from literature. To test its

practicality, the developed approach was applied on a

case study with the objective of minimizing the

tardiness and earliness penalty costs. The obtained

results indicated that the optimum sequence can save

about 15% of penalty costs in comparison with the

results of a heuristic rule.

In future work, multi-objective function to

minimize both the penalty cost and production costs

can be applied while considering other realistic

features of the precast production such as buffer space

between production stages and multiple production

lines. However, the computation time will be longer

due to the complexity of the simulation model. This

might call for using other simulation optimization

methods such as the response surface methodology to

reduce the time needed to make urgent operational

decisions in precast plants such as PCs sequencing.

REFERENCES

Al-Bazi, A., and Dawood, N., 2018. Simulation-based

optimisation using simulated annealing for crew

allocation in the precast industry. Architectural

Engineering and Design Management, 14(1–2), 109–

126. https://doi.org/10.1080/17452007.2017.1313721

Arashpour, M., Wakefield, R., Abbasi, B., Lee, E. W. M.,

and Minas, J., 2016. Off-site construction optimization:

Sequencing multiple job classes with time constraints.

Automation in Construction, 71(Part 2), 262–270.

https://doi.org/10.1016/j.autcon.2016.08.001

Benjaoran, V., Dawood, N., and Hobbs, B., 2005. Flowshop

scheduling model for bespoke precast concrete

production planning. Construction Management and

Economics, 23(1), 93–105.

https://doi.org/10.1080/0144619042000287732

Bradley, A., 2007. OptQuest for Arena User’s Guide. RS

Inc., Ed., Ed.

Chan, W.-T., and Hu, H., 2001. An application of genetic

algorithms to precast production scheduling.

Computers and Structures, 79(17), 1605–1616.

Chan, W. T., and Hu, H., 2002. Constraint programming

approach to precast production scheduling. Journal of

Construction Engineering and Management, 128(6),

513–521.

Chen, J. H., Yang, L. R., and Tai, H. W., 2016. Process

reengineering and improvement for building precast

production. Automation in Construction, 68, 249–258.

https://doi.org/10.1016/j.autcon.2016.05.015

Cheng, T. M., and Yan, R. Z., 2009. Integrating messy

genetic algorithms and simulation to optimize resource

utilization. Computer-Aided Civil and Infrastructure

Engineering, 24(6), 401–415.

https://doi.org/10.1111/j.1467-8667.2008.00588.x

Hu, H., 2007. A study of resource planning for precast

production. Architectural Science Review, 50(2), 106–

114. https://doi.org/10.3763/asre.2007.5016

Ko, C. H., and Wang, S. F., 2011. Precast production

scheduling using multi-objective genetic algorithms.

Expert Systems with Applications, 38(7), 8293–8302.

https://doi.org/10.1016/j.eswa.2011.01.013

Laguna, M., and Marti, R., 2003. The OptQuest callable

library. In Optimization Software Class Libraries (pp.

193–218). Springer.

Law, A. M., 2007. Simulation modeling and analysis,

McGraw-Hill New York, 4

th

edition.

Sacks, R., Eastman, C. M., and Lee, G., 2004. Process

model perspectives on management and engineering

procedures in the precast/prestressed concrete industry.

Journal of Construction Engineering and Management,

130(2), 206–215.

Wang, Z., and Hu, H., 2017. Improved Precast Production

– Scheduling Model Considering the Whole Supply

Chain. Journal of Computing in Civil Engineering,

31(4), 1–12. https://doi.org/10.1061/(ASCE)CP.1943-

5487.0000667.

Wang, Z., Hu, H., and Gong, J., 2018a. Framework for

modeling operational uncertainty to optimize offsite

production scheduling of precast components.

Automation in Construction, 86(April 2017), 69–80.

https://doi.org/10.1016/j.autcon.2017.10.026

Wang, Z., Hu, H., and Gong, J., 2018b. Simulation based

multiple disturbances evaluation in the precast supply

chain for improved disturbance prevention. Journal of

Cleaner Production, 177(March), 232–244.

https://doi.org/10.1016/j.jclepro.2017.12.188

Yang, Z., Ma, Z., and Wu, S., 2016. Optimized flowshop

scheduling of multiple production lines for precast

production. Automation in Construction, 72, 321–329.

https://doi.org/10.1016/j.autcon.2016.08.021

Yenisey, M. M., and Yagmahan, B., 2014. Multi-objective

permutation flow shop scheduling problem: Literature

review, classification and current trends. Omega, 45,

119–135.

ICORES 2019 - 8th International Conference on Operations Research and Enterprise Systems

252