A Cuckoo Search Algorithm for 2D-cutting Problem in Decorative

Ceramic Production Lines with Defects

Javier Monzon

1

, Rony Cueva

1

, Manuel Tupia

1

and Mariuxi Bruzza

2

1

Department of Engineering, Pontificia Universidad Catolica del Peru, Av. Universitaria 1801 San Miguel, Lima, Peru

2

Faculty of Tourism and Hospitality, Universidad Laica Eloy Alfaro de Manabi, Manta, Ecuador

Keywords: Cuckoo Search Algorithm, 2D-Cutting Problem, Optimization, Bio-Inspired Algorithms.

Abstract: The residues generated from ceramic cuttings are one of the major causes of waste in the ceramic

production industry, with losses being around 40% of the used material. Hence, reducing residues from

materials used is critical for lowering the production cost. It is worth mentioning that in this industry the

material also shows high rates of defects, a constraint which most researches dealing with the 2D-cutting

problem lack. This paper develops a bio-inspired metaheuristic called Cuckoo Search to solve the problem

of exposed material cutting as an alternative solution to the genetic algorithm already developed by the

authors, which will also be used to measure the Cuckoo Search algorithm performance.

1 INTRODUCTION

Ceramic listels are generally rectangular-shaped

decorative products obtained from larger ceramic

cuttings. These laths can be previously decorated or

can be decorated after the cutting. They are used in

any home setting such as floors, bathrooms,

kitchens, so that their use and production is largely

widespread in the sector. Due to the components’

properties in ceramic products, cracks may appear in

these products which may result in damages to the

material overtime and because of environmental

conditions such as temperature fluctuations (Pastor,

2002). Likewise, these materials show a fragile

breakage degree so that this type of failures by

breaking is common.

For the manufacture of ceramic listellos, cutting

ceramic pieces of different sizes (40x40, 45x45,

60x60, etc.) is necessary. Hence, determining the

manner of obtaining listellos through the cutting of

one ceramic piece of larger size is pivotal, in such a

way that the loss resulting from the cutting is

minimized and thus total demand is met (Talbi,

2009) (Tupia, Cueva and Guanira, 2013), (Tupia,

Cueva and Guanira, 2017).

The emergence of variations of this problem –

many of them very similar– urged Dyckhoff to put

forward a typology to classify cutting and packaging

issues (Dyckhoff, 1990). Based on said research, an

improved typology is proposed in (Wäscher,

Haußner and Schumann, 2007) to identify some

shortcomings and deal with the variations required

in our research. The characteristics of ceramics to be

considered are as follow:

1) Dimensionality: Sizes established for the

production line.

2) Type of assignment: Maximization,

minimization.

3) Range of small objects: Identical, slightly

heterogeneous, strongly heterogeneous.

4) Range of large objects: Identical, slightly

heterogeneous, strongly heterogeneous.

5) Shape of final small items: Rectangles, circles,

boxes, cylinders

Additionally, other characteristics were proposed

to the problem regarding orientation and cutting

patterns (Lodi, Martello and Vigo, 1999), (Du and

Swamy, 2016):

6) Orientation: Items may require a fixed

orientation or may be rotated 90°.

7) Guillotine cuttings: Cuttings may either

require or not end-to-end cuttings in parallel to

both sides: that is to say, if this is done in a

rectangular piece, only two rectangles would be

obtained.

Proposed constraints to be considered within the

problem in this research are as follows (Booth,

2017), (Arbib et al, 2018):

Monzon, J., Cueva, R., Tupia, M. and Bruzza, M.

A Cuckoo Search Algorithm for 2D-cutting Problem in Decorative Ceramic Production Lines with Defects.

DOI: 10.5220/0007346705470553

In Proceedings of the 11th International Conference on Agents and Artificial Intelligence (ICAART 2019), pages 547-553

ISBN: 978-989-758-350-6

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

547

RF: Pieces may rotate 90º (R) and not all cuttings

are required to be made with guillotine (F).

RG: Pieces may rotate 90º (R) and all cuttings

are required to be made with guillotine (G).

OF: Direction of pieces is fixed (O) and not all

cuttings are required to be made with guillotine

(F).

OG: Direction of pieces is fixed (O) and all

cuttings are required to be made with guillotine

(G)

2 CUCKOO SEARCH

ALGORITHM

This is a search metaheuristic algorithm for

optimization problems. It can be classified as a

“swarm intelligence algorithm” since this is inspired

by the cuckoo bird’s collective reproductive

behavior in which some species usually lay their

eggs in other birds’ nests. If one of the host birds

discovers an alien egg, the bird can either throw said

egg away or abandon the nest and build another one

elsewhere. However, many of these eggs are very

similar to the hosts’ eggs, and as they are placed in

several nests the likelihood of being abandoned is

reduced (Yang and Deb, 2009).

Those nests that are “discovered” by the host

birds are left and removed from the population and

replaced with new nests (with new random

solutions). The following idealized rules are taken

into account (Yang and Deb, 2009):

Each cuckoo may lay one single egg at a time

and place it in a nest (solution) selected

randomly.

Nests sheltering better quality eggs (solutions)

will be transferred giving birth to new

generations of cuckoo birds.

The host bird may detect a cuckoo egg (that

doesn’t belong) with a probability P [0, 1].

The bird may either throw the cuckoo’s egg

away from the nest or abandon the nest (put it

simply, this is equal to replacing P ratio of the

worst nests)

Below is the pseudo code of a Cuckoo Search

algorithm in the version to be implemented in our

research (Iglesias et al, 2018):

Figure 1: Cuckoo search algorithm general approach.

3 CONTRIBUTION

3.1 Objective Function

To minimize the residue generated from cutting

material as the primary objective, the percentage of

material considered as a defect must be minimized.

For this article, the stock region that was not used is

regarded as residue as well as the pieces located on

the region with defects. It is worth mentioning that

the objective function to be put forward favours

pieces that are not found on faulty regions and, but if

they are, the pieces would be smaller, as they would

generate more residue otherwise. This statement can

be formalized in the following objective function

(called FO):

(1)

In the equation (1):

N: The number of stocks used to fulfill the order.

The minimum value to be taken is 1 (all the order

is fulfilled with one stock) and the maximum

value is equal to the quantity of pieces requested

(one piece per stock).

Stock

i

: This is the i-nth stock with a width,

height related to a list of defects represented by

defined pieces.

areaPieces_(stock_i): This is the addition of the

areas of all pieces in each stock_i, that would be

equal to all the pieces of the order. This is

ICAART 2019 - 11th International Conference on Agents and Artificial Intelligence

548

calculated internally by multiplying width and

height of each piece.

area_(stock_i): This is the addition of the area

occupied by each stock_1. It is calculated

internally by multiplying the width and height

of each stock.

3.2 Constrains

The number of available stocks must be higher or

equal to the number of pieces requested: Constraint

indicating that the quantity of available stocks must

be sufficiently large to cover any solution to the

problem in the best and worst scenarios. Likewise,

the quantity of pieces must be 1 as a minimum to be

considered an order.

The rectangle covering the pieces must cover the

piece to be cut: Constraint indicating that there is a

rectangle capable of covering each of the pieces (not

sticking out of said rectangle). It is preferred that

such rectangle is minimum as at first the stock is

considered as the union of all possible stocks

(regarded as infinitum) both in width and height

before dividing them into multiple stock.

Pieces cannot overlap: The constraint sought is

that no overlapping of pieces in the arrangement

occurs. Pieces must not cover regions with defects.

The purpose is that no overlapping occurs of pieces

requested with the regions with defects, represented

as pieces.

3.3 Data Structures

To represent data structures in the algorithm

proposed, the following variables will be used:

3.3.1 List Solution

The structure will allow representing a solution

considering a large stock, which will consist of a

chain of numeric characters and letters for which a

list of chains has been used for convenience so they

can support numbers, letters and empty chains. Then

an example of the solution to the problem is

introduced, which has a N size (occupied by pieces

and operators).

Table 1: Example of a solution to the problem.

Position

0

1

2

3

4

5

6

Value

1

R

5

N

H

7

N

6

N

V

2

N

where the value of the list, depending on its type,

represents the following:

Numeric type value: Represent the identifier of a

piece and its orientation, that is to say the

value “1R” refers to piece 1 with rotation of

90° while the value “5N” refers to piece 5

without rotation of 90°.

Character type value: Represent one operator,

represented by characters H(horizontal) or

V(vertical).

3.3.2 Class Rectangle

This class will allow to define a piece or set of

pieces (block) from the two coordinates x, y which

are interpreted with respect to the origin (0, 0) and

width and height represented by variables w and h.

Likewise there is a rotation variable, which will

indicate if the piece is rotated 90° with respect to

that originally recorded.

3.3.3 List Pieces

This structure will allow to represent the demand of

pieces, which will be indicated by a list of pieces

(using the rectangle class). An example of a list of

pieces is shown in the table below:

Table 2: Example of List of Pieces.

Position

id

X

Y

W

H

0

1

0

0

40

8

1

5

0

0

40

25

Where variables represent the following:

Id: The identifier of pieces: [piece_1, piece_2,…

piece_N].

x, y: Coordinates of pieces with respect to the

origin (0, 0). Initially all of them will occupy

the position (0, 0).

w, h: The width and height of pieces

3.3.4 Class Stock

This stock class will allow to represent stock

material which has a width and height with the

peculiarity that unlike any piece, the stock is related

to a list of defects which will be indicated by a list of

pieces. Additionally, prior to the fitness calculation,

an algorithm is run in which the solution is divided

into multiple stocks so that each stock will be related

to a list of pieces, initially empty.

3.3.5 List of Stocks

This structure will allow to represent the available

stock material expressed as a list of stocks. Then, an

example of a list of N stocks available is introduced

A Cuckoo Search Algorithm for 2D-cutting Problem in Decorative Ceramic Production Lines with Defects

549

with each showing a maximum of M defects:

Table 3: Example of List of Stocks.

Position

id

X

Y

Defect

1

Defect

2

0

1

10

20

Piece

1

Piece

2

1

2

30

50

Piece

1

Piece

2

Where variables represent the following:

Id: The identifier of the stock:

[stock_1,stock_2,… stock_N].

w, h: The width and height of the stock.

Defect

i

: It represents a region with defects, which

will be represented by the same structure than a

piece (see Rectangle class in previous section),

indicating the position relative to the stock they

belong to.

3.3.6 Class Node

This class will allow to define a binary tree in which

post-fixed notation may be represented in the

algorithm representation. It has two attributes of the

same kind that represent left and right children.

Besides, it has a rectangle variable, which will

indicate the occupied area and the position of a piece

(if this is a leaf) or a block (if this is the union of

several pieces). The latter will be defined through

the integration type variable, which may be “H” o

“V”.

3.4 Integration Operators

The representation of the solution in a problem

influences on the complexity and implementation of

the solution. For this work, a post-fixed

representation will be used through a list of

characters, as proposed in (Leon et al, 2007). To

define such structure, two integration operators will

be used:

Operator H: Receives two pieces as an argument

and produces the minimum rectangle capable

of covering such pieces, horizontally arranged,

side by side. The dimensions of such possible

minimum rectangle (L_h and W_h) are

obtained as follows:

L_h=large (p_1 )+large_(p_2 )

W_h =max (width_(p_1 ),width_(p_2 ))

Operator V: Receive two pieces as an argument

and produces the minimum rectangle capable

of covering such pieces, vertically arranged,

side by side. The dimensions of such possible

minimum rectangle (L_h and W_h) are

obtained as follows:

L_h=max(large (p_1 ),large_(p_2 ))

W_h = width_(p_1 ) + width_(p_2 )

Graphically, both operators can be understood in

the following manner:

Figure 2: Pieces after applying the p1p2H and p1p2V

operation respectively.

3.5 Interpretation of a Solution

This structure will serve both for definition of the

solution known as “nest’s egg” in the Cuckoo

Search algorithm and for “individual chromosome”

in the genetic algorithm. Using the operators of the

previous section, the solution of a real case can be

determined.

For example, if the solution is “1 5 H 7 6 V 2 H

4 H V 9 8 V 3 V H,” start by taking the components

from left to right in a stockpile until the emergence

of a V and H operator, which will be responsible for

integrating said components (i.e., pieces). See the

figure below:

Figure 3: Pieces after applying the p1p2H and p1p2V

operator simultaneously.

If we follow the steps through the end, we will

obtain the following arrangement (in a binary tree

format) where arrows indicate the order in which

guillotine cuttings will be made:

ICAART 2019 - 11th International Conference on Agents and Artificial Intelligence

550

Figure 4: Representation as a binary tree.

3.6 Treatment of Defects in Pieces

Once the pieces are distributed in stocks, the main

idea of this algorithm is to follow/walk through each

of the stocks to verify that none has fallen in the

regions with defects. If this is the case, the piece

affected must be placed in one stock, so as to fulfil

the order. Immediately the algorithm’s pseudo code

is shown for the stock’s distribution:

Figure 5: Representation as a binary tree.

Each of the pieces of the stocks is followed to

verify their positions. Absolute positions are

calculated from pieces in a stock until the moment

they were located in a relative manner (with respect

to another block). The binary tree is

followed/walked through again, in any order. The

pieces in one stock are converted into a list. For each

piece a list of defects related is obtained in a loop. It

is verified that one piece is not intersected with one

stock (both represented as pieces), comparing their

absolute positions. If a piece falls into a region with

defect, this is inserted in the stock immediately

available.

3.7 Proposed Algorithm

The algorithm is based on the following main rules:

Each cuckoo lays one single egg at a time and

place it on the nest chosen randomly.

The best nests with the highest egg quality will

pass to the next generation.

The number of nests available in each generation

(n) is predefined, and eggs will be assessed

(discovered) and removed if a pa probability is

lower than the total nests. These nests

(containing the eggs removed) will be replaced

with new eggs each generation (iteration).

The proposed algorithm may be expressed as

follows:

Figure 6: Algorithm Proposed.

Detail explanation:

Line 1: A list of initial nests is calculated

randomly.

Line 2: An i variable is created to iterate each

generation.

Line 2-a: A random nest is selected from the list

of nests.

Line 2-b: A modification is done to the selected

nest by means of a function following the

Levy distribution.

Line 2-c: A random nest is selected from the list

of nests.

Line 2-d: If the nest modified is better than the

other nest, then keep the modified nest.

Line 2-e: A fraction (p_a) of the worst nests is

removed because they have been found.

Line 2-f: The list is arranged by fitness from the

lowest to the highest. Remember that this

function of the case we are proposing is as

follows:

(2)

Line 3: Return the main nest, which is the one

occupying the first position.

A Cuckoo Search Algorithm for 2D-cutting Problem in Decorative Ceramic Production Lines with Defects

551

4 EXPERIMENTATION

As previously indicated, a comparison was made

with a genetic algorithm also developed by the

authors in an attempt to try the quality of results

yielded by the Cuckoo algorithm.

For 40 test instances taken from a real Peruvian

ceramic manufacturer, the following table shows the

results of total waste in units of area (square

meters/centimeters), a value resulting from the

respective objective function of each of the

algorithms:

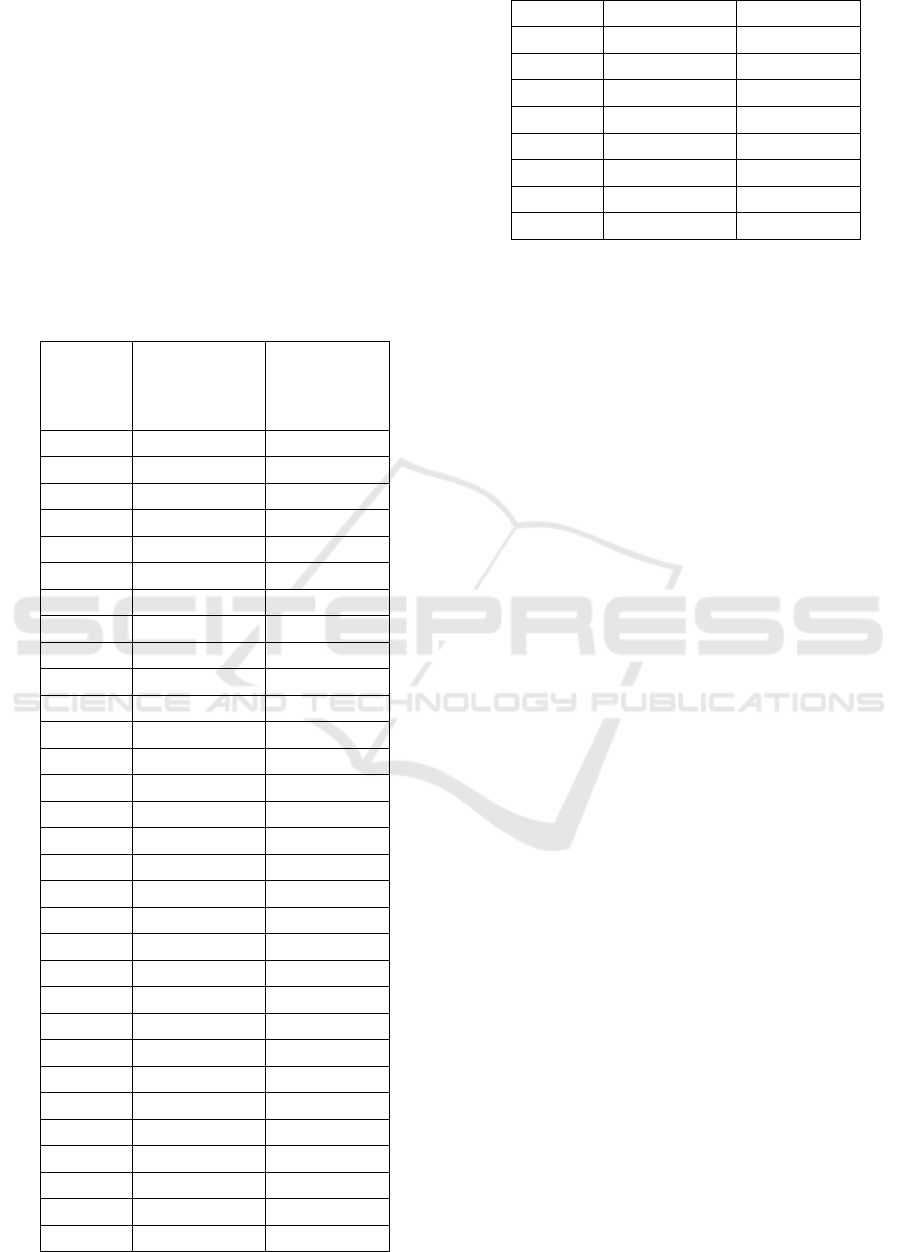

Table 4: Example of List of Stocks.

Sample

Objective

function

Genetic

Algorithm

Objective

function

Cuckoo Search

Algorithm

1

46.07

55.06

2

36.67

50.72

3

40.00

43.29

4

28.15

31.06

5

43.98

46.37

6

29.51

30.16

7

34.63

38.08

8

36.24

47.24

9

40.49

51.71

10

38.22

48.19

11

45.73

46.85

12

39.18

52.63

13

39.67

48.23

14

37.78

51.55

15

49.31

57.23

16

41.62

52.62

17

41.51

41.64

18

35.18

40.45

19

46.55

51.77

20

37.02

38.05

21

39.84

47.27

22

38.05

40.84

23

41.25

53.88

24

45.50

53.97

25

39.46

43.26

26

40.60

49.41

27

35.02

44.60

28

48.41

52.29

29

45.18

51.86

30

36.13

47.49

31

47.18

54.70

32

36.87

41.59

33

45.32

50.05

34

40.10

40.21

35

45.22

51.33

36

45.80

48.61

37

49.99

53.09

38

36.22

46.70

39

43.04

53.31

40

46.39

59.30

5 CONCLUSIONS

Although it is possible to find accurate algorithms in

the literature allowing for the solution of the 2D

cutting problem, most of said algorithms are

computationally infeasible with large instances of

the problem. According to Kallrath, who made

experiments in production lines of the paper sector

for 25 types of pieces (molds), the algorithm is

unfeasible (Kallrath et al, 2014).

Likewise, based on the results of the numerical

experimentation, the mean of the objective function

and the solution generated by the genetic algorithm

have proven to be significantly lower than the mean

of the objective function of solutions generated by

the Cuckoo Search algorithm. It must therefore be

concluded that for the set of data used the genetic

algorithm has a better performance than the Cuckoo

Search algorithm. This can be explained bearing in

mind that the latter algorithm has random movement

(Levy’s flight) as the phase of improvement that in

most cases do not improve the real solution, unlike

the phase of improvement of the genetic algorithm

in which crossing, and mutation operations are

indeed enhanced.

Finally, the genetic and Cuckoo Search

metaheuristic algorithm designed in this research to

solve the cutting problem may be easily adjustable

to other cutting problem variants (properly

modifying the structure of the solution).

REFERENCES

Moore, R., Lopes, J., 1999. Paper templates. In

TEMPLATE’06, 1st International Conference on

Template Production. SCITEPRESS.

Smith, J., 1998. The book, The publishing company.

London, 2

nd

edition.

Arbib, C., Marinelli, F., Pizzuti, A., and Rosetti, R., 2018.

A Heuristic for a Rich and Real Two-dimensional

Woodboard Cutting Problem. In 7th International

ICAART 2019 - 11th International Conference on Agents and Artificial Intelligence

552

Conference on Operations Research and Enterprise

Systems (ICORES 2018), pages 31-37.

Booth, R., 2017. Procesamiento y caracterización de

materiales cerámicos refractarios del sistema ZrO

2

-

CaO-MgO-SiO

2

. Doctoral thesis. Universidad

Nacional de La Plata, Buenos Aires.

Du, K., and Swamy, M., 2016. Search and Optimization

by Metaheuristics. Springer, Basel.

Dyckhoff, H., 1990. A typology of cutting and packing

problems. In European Journal of Operational

Research, volume 44, pages 145–159.

Iglesias, A., Gálvez, A., Suárez, P., Shinya, M., Yoshida,

N., Otero, C., Manchado, C., and Gomez-Jauregui, V.,

2018. Cuckoo Search Algorithm with Lévy Flights for

Global-Support Parametric Surface Approximation in

Reverse Engineering. In Symmetry, volume 10, page

58.

Kallrath, J., Rebennack, S., Kallrath, J., and Kusche, R.,

2014. Solving real-world cutting stock-problems in the

paper industry: Mathematical approaches, experience

and challenges. In European Journal of Operational

Research, volume 238, pages 374–389.

León, C., Miranda, G., Rodríguez C., and Segura, C.,

2007. 2D-cutting stock problem: a new parallel

algorithm and bounds. In European Conference on

Parallel Processing (EURO-PAR 2007), pages 795-

804.

Lodi, A., Martello, S., and Vigo, D., 1999. Heuristic and

metaheuristic approaches for a class of two-

dimensional bin packing problems. In INFORMS

Journal on Computing, volume 11, pages. 345-357.

Pastor, J., 2002. Fractura de materiales cerámicos

estructurales avanzados. Doctoral thesis. Universidad

Complutense, Madrid.

Talbi, E., 2009. Metaheuristics: from design to

implementation. John Wiley & Sons, New Jersey.

Tupia, M., Cueva, R., and Guanira, J., 2017. A bat

algorithm for job scheduling in ceramics production

lines. In 2017 International Conference on Infocom

Technologies and Unmanned Systems (Trends and

Future Directions) (ICTUS 2017), pages 266-270.

Tupia, M., Cueva, R., and Guanira, J., 2013. A GRASP

algorithm with 2-opt improvement for job scheduling

enviroment in ceramics production lines. In AISS:

Advances in Information Sciences and Service

Sciences, volume 5, number 15, pages 1-10.

Wäscher, G., Haußner, H., Schumann, H., 2007. An

improved typology of cutting and packing problems.

In European Journal of Operational Research, volume

183, pages 1109–1130.

Yang, X., and Deb, S., 2009. Cuckoo search via Lévy

flights. In IEEE Nature & Biologically Inspired

Computing, pages 210-214.

A Cuckoo Search Algorithm for 2D-cutting Problem in Decorative Ceramic Production Lines with Defects

553