Simulation of Vehicle Movements for Planning Construction Logistics

Centres

Fei Ying

1

, Mike O’Sullivan

2

and Ivo Adan

3

1

Department of Built Environment Engineering, Aucland University of Technology, Auckland, New Zealand

2

Department of Engineering Science, University of Auckland, Auckland, New Zealand

3

Department of Industrial Engineering, Eindhoven University of Technology, Eindhoven, The Netherlands

Keywords: Construction Logistics, Simulation.

Abstract: Materials supply is one of important elements in construction operation and a major factor affecting the quality

of construction projects. With materials accounting for 60% of the on-site cost of a typical construction

project, effective management of this vital resource is essential. Logistics processes, being crucial for

successful completion of the project, are often entrusted to external professionals specialized in logistic

services, such as logistics centres. However, this tendency is yet to be developed in construction. The purpose

of this paper is to examine the potential of managing logistics costs by planning construction logistics centres.

The planned centres are then evaluated using vehicle movement simulations. The enclosed results from the

simulations indicate that using a logistics centre will have reduced waste for the construction project

considered. A literature review and case study analysis are employed, with simulation results using Flexsim.

The paper emphasizes that creating a logistics centre for a project at its early stages of planning and then

designing an integrated logistics service for that project may help find ways of making the overall construction

project more effective by improving management of materials.

1 INTRODUCTION

Lean construction is an attempt to apply lean

principals that originate form Toyota Production

System (TPS) to construction, aiming at managing

and improving construction processes with minimum

cost and maximum value by considering customer

needs (Gao and Low, 2014). Following years of

developing, there have emerged significant studies

that have correlated lean principals with construction.

Lean construction alters the traditional view of the

project as transformation and have changed the way

constructors manage the operations (Jorgensen and

Emmitt, 2008). Lean tools and techniques come into

helping identify and eliminate the waste that adds no

value. In practice, Construction Supply Chain

Management (CSCM) is one of the systems to

implement lean construction philosophy.

CSCM is defined as “the network of facilities and

activities that provide customers with economic value

to the functions of design development, contract

management, service and material procurement,

material manufacture and delivery, and facilities

management” (Love et al., 2004). The term

“logistics”, as used in the title of the paper, is related

to the term “supply chain”. Logistics is defined as

“the process of strategically managing the

acquisition, movement and storage of materials, parts

and finished inventory (and the related information

flows) through the organisation and its marketing

channels, in such a way that current and future

profitability is maximised through the cost-effective

fulfilment of orders” (Gattorna and Day, 1993). For

the construction industry, logistics comprise

planning, organisation, coordination, and control of

the materials flow from the procurement of raw

materials to the incorporation into the finished

building (Agapiou et al., 1998).

Building materials and construction components,

along with human resources, are the first and most

important requirements for construction. Materials

supply is thus a factor affecting the quality of

construction projects and the profitability for

construction firms. With materials accounting for up

to 60% of the on-site cost of a typical construction

project (Song et al., 2005) and between 15 and 30 per

cent of urban waste (Formoso et al., 2002), effective

258

Ying, F., O’Sullivan, M. and Adan, I.

Simulation of Vehicle Movements for Planning Constr uction Logistics Centres.

DOI: 10.5220/0007346802580263

In Proceedings of the 8th International Conference on Operations Research and Enterprise Systems (ICORES 2019), pages 258-263

ISBN: 978-989-758-352-0

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

management of this vital resource is essential.

Furthermore, research suggests that improved

logistics will attain monetary and schedule savings,

reduce material waste, increase productivity and

safety (Jang et al., 2003; Poon et al., 2004; Shakantu

et al., 2003; Spillane and Oyedele, 2013). Thus,

effective construction logistics should provide

appropriate trade-offs involving costs and service in

the supply chain by integrating materials supply,

storage, processing and handling; site infrastructure

and equipment location; physical site flow

management and information management (Shakantu

et al., 2008).

Many industries attempt to integrate logistics

processes into logistics chains of suppliers and

customers, from obtaining raw material, through

manufacturing, distribution and final sale and service

to the end-users. Logistic processes, which are crucial

for successful completion of the project, are often

entrusted to external professionals specialised in

logistics services, such as logistics centres (Sobotka

and Czarnigowska, 2005). However, in the field of

construction, this tendency is to be developed.

Moreover, recent research has shown that, in the

management of material deliveries, an ad hoc,

intuitive approach is often adopted (Spillane and

Oyedele, 2017; Ying et al., 2014). Consequently,

there appears to be a significant need for an enhanced

understanding of transportation in a construction

context in order to deliver the full benefits from the

adoption of efficient construction logistics. The

purpose of this research is to address how the

efficiency of construction logistics can be improved

by using logistics centres. In order to evaluate the

effect of using a logistics centre, we provide a

simulation case study that measures logistics waste

with and without a logistics centre.

Next section surveys the related literature. It

follows by defining the problem environment and the

research methodology. The mathematical models and

scenario considered are then described. The paper

ends with conclusions and further research directions.

2 LOGISTICS ISSUES IN

CONSTRUCTION

2.1 Lack of Supply Chain Innovations

While many industries have experienced

performance improvements through supply chain

management initiatives, the construction industry is

yet to realise these improvements to the same extent.

Several researchers have explained the particular

features of the industry that hinder these potential

benefits, such as the fragmented structure of the

industry (Fadiya et al., 2015), the negative

consequence of arm-length relationships (Briscoe and

Dainty, 2005), and the lack of trust and commitment

among the firms involved in the process (Gadde and

Dubois, 2010).

Determining project logistics process requires a

wide range of construction project management

knowledge, such as knowledge of the building

materials market, financing, and managing

contractors’ approaches to supply. It also demands a

deep understanding of the impact of logistics on

project efficiency in terms of cost, quality and time.

Furthermore, it is of great impact to be aware of

logistics costs and their relationship to variables such

as batch size, place and time of the delivery, and

required storage conditions.

2.2 On-site and off-Site Logistics

Efficiency and effectiveness of a construction project

heavily depend on the integration between on-site and

off-site logistics. However, a lack of planning of

materials deliveries and unloading among

subcontractors and their site workforce causes

significant issues in this interface (Ying et al., 2014).

Previous research shows that substantial benefits can

be attained through the rearrangement of on-site

logistics (Lindén and Josephson, 2013). Off-site

logistics refers to supply logistics involving suppliers

of building materials.

The aim of logistics customer service is to ensure

that construction materials are appropriate and

available for construction operations. Thus, service

related factors affecting vehicle movements are

planning, training, loading and the logistics

management strategy. It is widely recognised that the

troublesome logistics in the construction industry is

influenced by the characteristics of the industry,

including the fragmentation of the construction

industry supply chain, lack of coordination and

communication among actors, inefficient planning

both on-site and off-site. From the project managerial

perspective, the real-time scheduling of materials

planned and keyed to the master plan for material

delivery is highly desirable. However, frequently this

is unachievable because of many factors, such as

inadequate detailed information at the

commencement of a contract, and considerable

variations during the construction stage.

Simulation of Vehicle Movements for Planning Construction Logistics Centres

259

3 RESEARCH METHODOLOGY

The guiding purpose of this study was to develop a

simulation framework for analysis of potential

improvements of logistics performance using

logistics centres. The focus of the work is to identify

achievable benefits through optimising off-site

logistics. The studies in this work were carried out as

a case study with simulation modelling. The case

study described in this paper has been developed from

a commercial project hosted by a university. The

$100 million project consists of a 13 level tower block

with a roof top plant room surrounded with lecture

theatres and student facilities. The new construction

integrates several existing buildings on campus. The

construction has three stages: ground works,

structure, and fit-out.

Special attention has been paid to the numbers and

patterns of vehicle movements, since it was expected

that appropriate interventions to improve

construction logistics could be identified through

analysing these elements. The vehicle movements

were recorded by the gates-person on the site. Details

such as delivery company name, date, time, truck

type, materials, and activities were noted on printed

tables.

3.1 Flexsim

The simulation case study has been developed in the

Flexsim environment. “Flexsim is an object-oriented

software environment used to develop, model,

simulate, visualize, and monitor dynamic-flow

process activities and systems” (Nordgren, 2003).

Flexsim models consist of a tree of individual nodes

that contain model objects, library objects,

commands, and all model information. Within this

tree are flowitems which are simple objects that are

created to move through the model. Flowitems can

represent actual objects, or they can be representative

of a more abstract concept.

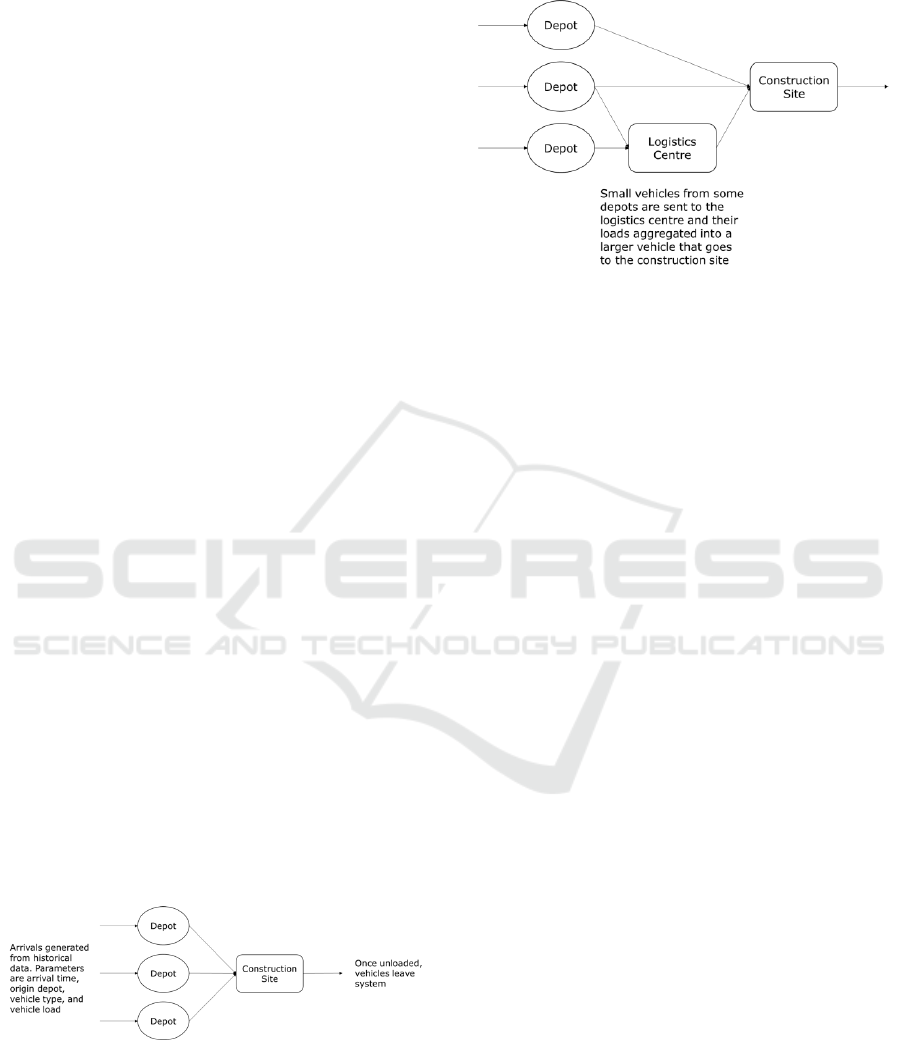

Figure 1: Simulation pathway without a logistics centre.

(a) Simulation pathway without a logistics centre.

Vehicles arrive to depots according to historical data

(which is also used to determine the vehicle size and

load), travel to the construction site, are unloaded

according to triangular distributions and leave the

system

Figure 2: Simulation pathway with a logistics centre.

(b) Simulation pathway with a logistics centre.

Vehicles arrive in the same way as without the

logistics centre, but now some of the smaller vehicles

travel to the logistics centre where their loads are

aggregated before being delivered in a larger vehicle

to the construction site. Other vehicles go directly to

the construction site as before. Some depots dispatch

both small and large vehicles, but only the small ones

go to the logistics centre

The movement of vehicles within the construction

logistics process is depicted in Figure 1, for the

scenario with no logistics centre, and Figure 2, for

the scenario with a logistics centre, respectively. In

the construction logistics model two different

flowitems library classes are used. The Box class is

used to represent the cargo of a vehicle and the Pallet

class is used to represent the vehicle. These classes

are used as they already contain the functionality for

loading and unloading required for simulating

construction logistics. Deliveries are simulated using

historical data by creating a delivery vehicle (a Pallet)

at a depot and creating the appropriate cargo (a

number of Boxes) and combining them together. Note

that the arrival time at the depots of the loaded

vehicles is calculated from their arrival time on-site

less the travel time from the depot to the site. This

combined flowitem can have its properties altered,

e.g., image type, colour, to enable the simulation’s

visualisation to be representative of the construction

site activities, which is useful for validating the

simulation via visual inspection. The delivery

flowitem then travels from its origin (e.g., the

supplier) to the construction site or (if it is being used)

the logistics centre. At the logistics centre smaller

vehicles can be unloaded, i.e., the underlying Pallet

and Box objects separated, and combined into a larger

vehicle, i.e., a new (higher capacity) Pallet is

ICORES 2019 - 8th International Conference on Operations Research and Enterprise Systems

260

combined with the Boxes from multiple (smaller)

Pallets, which then travels to the construction site.

This way transportation between suppliers, the

logistics centre (if it is being used) and the

construction site is visible. It is important to set the

correct speed between locations to get the desired

travel duration.

Once loaded vehicles arrive to the construction

site they are unloaded either by hand or using

equipment available on-site. In this model there are

two cranes that can be used for unloading along with

a hoist. If the unloading equipment is already busy,

then the vehicle needs to wait in the loading bay for

the appropriate equipment or, if the delivery area is

full, wait outside the site itself. Once unloaded both

vehicles and their load leave the system.

In the model, queues and queuing mechanisms are

used to model vehicles waiting to be unloaded. It is

possible to change the strategy of queueing from the

default of First-in First-Out (FIFO) to investigate

priority policies that may streamline deliveries. Once

the equipment required to unload a vehicle is

available, the vehicle is unloaded with the unloading

duration dependent on the type of load, the size of the

load, and the equipment being used. The load (the

Box objects) are separated from the vehicle (the

Pallet) and the vehicle leaves the site. At this point the

delivery is complete and box the load and the vehicle

are removed from the model.

By experimenting with the use of a logistics centre

and policies for unloading deliveries, the simulation

model can be utilised to evaluate the effect of a

logistics centre and also determine if similar

improvements could have been achieved by adopting

a less ad hoc approach to managing deliveries.

4 KEY FINDINGS

The main aim of this paper is to contribute to the

knowledge of setting up logistics centres to improve

construction logistics performance. The key findings

section of the paper is focused on where to locate the

logistics centre and the potential improvements that

can be achieved in practice by using this centre. The

improvements are measured by simulating vehicle

movements to the site and/or the logistics centre and

observing the effect on vehicle waiting time on-site.

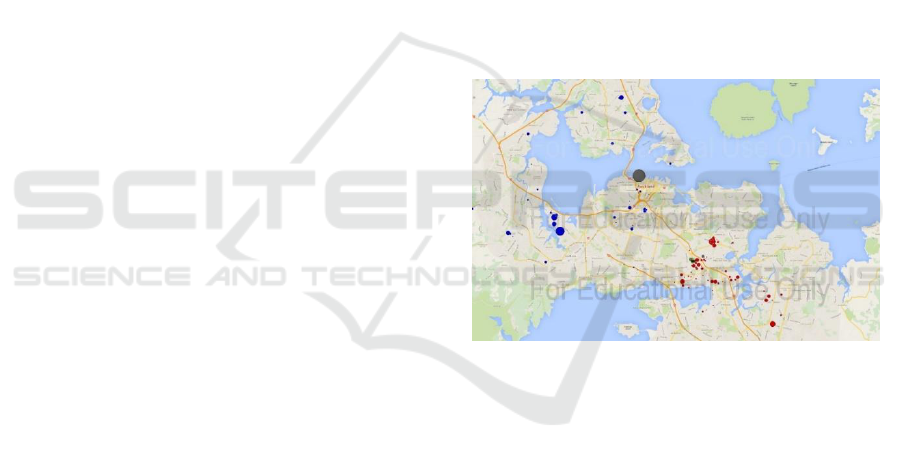

4.1 Locating Logistics Centre

In order to determine the best location for the logistics

centre, data from vehicle deliveries were used to

visualise the depots where each vehicle began its

delivery from. Google API was used for this

visualisation and travel durations between the depots,

the logistics centre, and the construction site were

also acquired via Google API. The depot address of

each subcontractor and material supplier were first

translated into longitude and latitude, visualised on a

background map, then used in the simulation model

for deliveries. The result of the visualisation, as

shown in Figure 3, can then be used to evaluate

potential locations for the logistics centre at which

delivery loads of vehicles could be merged. The size

of the circles in Figure 1 represents the amount of

deliveries that originated from this particular

company, hence its depot. The exception is the large

grey circle which the construction site itself. It is

obvious that a large percentage of deliveries

originated from certain suburbs. The simulation

model depicted in Figure 3 located the logistics centre

in one of these suburb, Penrose, and evaluated the

subsequent performance improvement. The logistics

centre location is shown as a small black rectangle

neat the centre of Figure 3.

Figure 3: Flexsim visualisation of companies.

4.2 Simulations of Vehicle Merging

One scenario simulated in this case study merges all

small vehicle loads, within the Penrose region (shown

in red in Figure 3), at the Penrose logistics centre and

the delivers the aggregated load of materials to the

construction site located in the Auckland CBD. In the

simulation model the assumption is that all small

vehicles go to the hoist with a mean process time of

30 minutes, while all large vehicles are directed to

one of the cranes (with equal probability) with a mean

process time of 45 minutes. The process times are

modelled using a Triangular distribution with

minimum value equal to 2/3 of the mean and

maximum value equal to 4/3 of the mean. Hence,

there are two symmetric distributions, with the

appropriate mean values, for unloading via either a

crane or the hoist

Simulation of Vehicle Movements for Planning Construction Logistics Centres

261

The number of total deliveries occurring during

construction is 6889 of which 2256 (33%) are made by

small vehicles. The total deliveries from the Penrose

region during construction is 2465 (36%) of which 857

(12% of total deliveries) are small vehicles. By

merging small vehicle deliveries from the Penrose

region each day the number of deliveries can be

reduced from 857 to 281, a reduction of 67%. Note,

however, that the new deliveries from the Penrose

logistics centre will require larger vehicles with more

load so that merged vehicles use a crane with a mean

process time of 60 minutes.

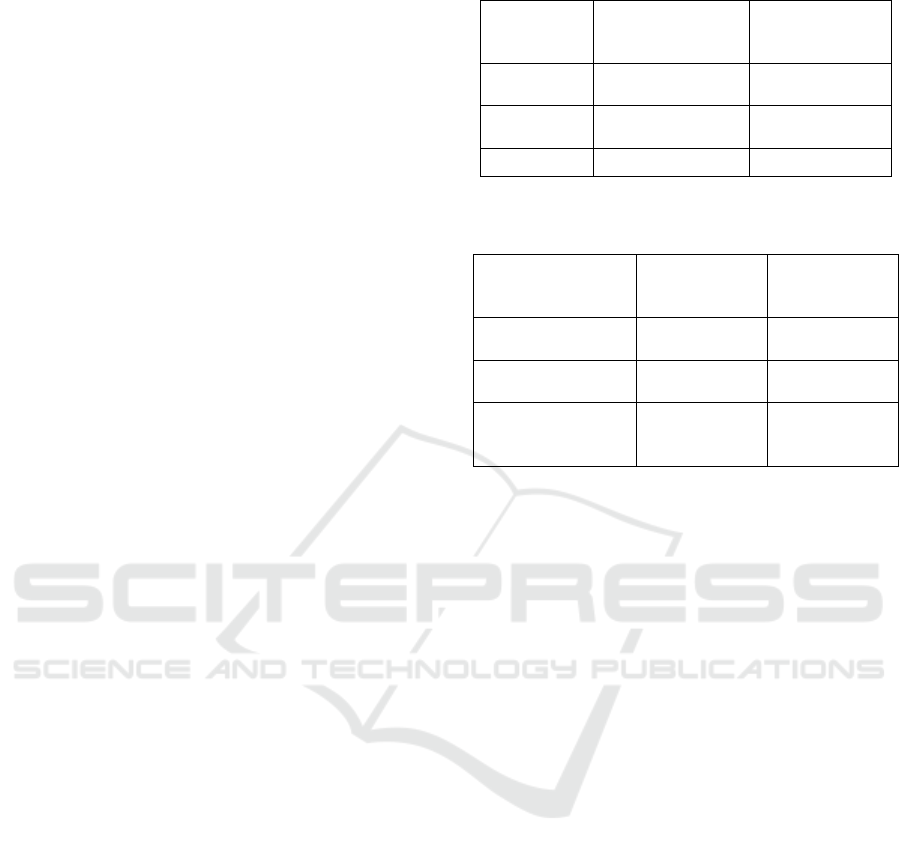

A comparison of the system with and without the

logistics centre is now possible via the Flexsim

simulation (running 20 replications for 468 days each).

Table 1 shows the number of small vehicle, large

vehicle, and merged vehicle deliveries. Table 2 shows

the expected waiting time (in minutes) for the cranes

and the hoist with and without the Penrose logistics

centre. Note that the waiting time for the hoist

demonstrates a clear difference and is almost halved

when the Penrose logistics centre is used. However, the

waiting time for the crane also demonstrates a clear

difference with the waiting time being slightly worse

when the Penrose logistics centre is used.

Although waiting time is one key measure of waste,

a better comparison between the systems is that of total

unloading time on-site. Aggregating the loads of small

vehicles from the Penrose region onto larger vehicles

means that the cranes are used more (281 more times)

and for longer each time (mean process time of 60

minutes), but there are far less small vehicle deliveries

on-site. While the average waiting time (for a crane or

the hoist) is the time vehicles waste while idle, the total

time spent unloading on-site measures the “busy-ness”

caused by deliveries. If aggregating loads at a logistics

centre causes more total on-site busy-ness, even if it

reduces the average waiting time per vehicle, then its

efficacy is questionable. Table 2 shows that the total

time spent unloading on-site is reduced by

approximately 18 days over the duration of the

construction project. Note that this saving is offset by

unloading (and possibly waiting) tie at the logistics

centre, but time spent at the logistics centre does not

reduce productivity at the construction site so it is not

measured.

Table 1: Number of each type of delivery vehicle.

Delivery

Vehicle

Type

No Logistics

Centre

Penrose

Logistics Centre

Small

2256

2256 – 857 =

1399

Large

6889 – 2256 =

4633

4633

Merged

0

281

Table 2: 95% confidence interval for expected waiting time

(minutes).

Measure

No Logistics

Centre

Penrose

Logistics

Centre

Waiting time for

Hoist (mins)

[29.4, 30.1]

[16.1, 16.6]

Waiting time for

Crane (mins)

[41.6, 49.3]

[46.4, 49.0]

Total on-site

unloading time

(days)

[191.5, 191.7]

[173.6, 173.9]

5 CONCLUSIONS

The simulation confirms that using logistics centres

can improve construction logistics performance.

Through logistics centres, off-site logistics are

consolidated and optimized. This in turn will

stimulate the planning of on-site logistics

performance. This approach could solve previously

observed problems identified in relation to

insufficient planning, limited storage capacity, waste

in extra material handling, and low delivery

reliability.

When the principles of logistics centres are

applied, the interface between off-site and on-site

logistics could be connected seamlessly. The main

findings in relation to reduced waiting time to be

unloaded, the number of vehicle movements on-site,

and total on-site unloading time are encouraging. This

would significantly increase the efficiency of cranes

and hoists utilization, which are the most expensive

equipment on construction sites.

Future research will investigate the feasibility of

establishing logistics centres, especially determining

any impediments to implementing this concept in the

construction industry. The improvement of

construction logistics efficiency will not be realised

without commitment that is initiated from within the

construction industry and application of logistical

expertise. Further research will focus in identifying

the financial costs and benefits logistics centres could

ICORES 2019 - 8th International Conference on Operations Research and Enterprise Systems

262

bring to various actors, such as main contractors,

subcontractors and material suppliers.

REFERENCES

Agapiou A, Clausen LE, Flanagan R, et al. (1998) The role

of logistics in the materials flow control process.

Construction Management and Economics 16: 131-

137.

Briscoe G and Dainty A. (2005) Construction supply chain

integration: an elusive goal? Supply Chain

Management: An International Journal 10: 319-326.

Fadiya O, Georgakis P, Chinyio E, et al. (2015) Decision-

making framework for selecting ICT-based

construction logistics systems. Journal of Engineering,

Design and Technology 13: 260-281.

Formoso CT, Soibelman L, Cesare CD, et al. (2002)

Material waste in building industry: main causes and

prevention. Journal of Construction Engineering and

Management 128: 316-325.

Gadde L-E and Dubois A. (2010) Partnering in the

construction industry -- Problems and opportunities.

Journal of Purchasing and Supply Management 16:

254-263.

Gao S and Low SP. (2014) Impact of Toyota way

implementation on performance of large Chinese

construction firms. Journal of Professional Issues in

Engineering Education and Practice 140: 1179-1183.

Gattorna J and Day A. (1993) Strategic issues in logistics.

International Journal of Physical Distribution and

Logistics Management 16: 3-42.

Jang H, Russell JS and Yi JS. (2003) A project manager's

level of satisfaction in construction logistics. Canadian

Journal of Civil Engineering 30: 1133-1142.

Jorgensen B and Emmitt S. (2008) Lost in transition: the

trasfer of lean manufacturing to construction.

Engineering, Construction and Architectural

Management 15: 383-398.

Lindén S and Josephson P-E. (2013) In-housing or out-

sourcing on-site materials handling in housing? Journal

of Engineering, Design and Technology 11: 90-106.

Love PED, Irani Z and Edwards D. (2004) A seamless

supply chain management model for construction.

Supply Chain Management: An International Journal 9:

43-56.

Nordgren WB. (2003) Flexible simulation (Flexsim)

software: Flexsim simulation environment. 35th

conference on Winter simulation: driving innovation.

New Orleans, LA, USA, 197-200.

Poon CS, Yu ATW, Wong SW, et al. (2004) Management

of construction waste in public housing projects in

Hong Kong. Construction Management and Economics

22: 675-689.

Shakantu W, Muya M, Tookey J, et al. (2008) Flow

modelling of construction site materials and waste

logistics: A case study from Cape Town, South Africa.

Engineering, Construction and Architectural

Management 15: 423-439.

Shakantu WM, Tookey JE and Bowen PA. (2003) The

hidden cost of transportation of construction materials:

An overview. Journal of Engineering, Design and

Technology 1: 103-118.

Sobotka A and Czarnigowska A. (2005) Analysis of supply

system models for planning construction project

logistics. Journal of Civil Engineering and Management

XI: 73-82.

Song J, Haas CT, Caldas Ch, et al. (2005) Locating

materials on construction site using proximity

techniques. ASCE Construction Research Congress

Proceedings of the Construction Research Congress.

San Diego, CA.

Spillane JP and Oyedele LO. (2013) Strategies for effective

management and safety in confined site construction.

Australasian Journal of Construction Economics and

Building 13: 50-64.

Spillane JP and Oyedele LO. (2017) Effective material

lobistics in urban construction sites: a structural

equation model. Construction Innovation 17: 406-428.

Ying F, Tookey J and Roberti J. (2014) Addressing

effective construction logistics through the lens of

vehicle movements. Engineering, Construction and

Architectural Management 21.

Simulation of Vehicle Movements for Planning Construction Logistics Centres

263