Inventory Replenishment Planning of a Distribution System with

Warehouses at the Locations of Producers and Minimum and

Maximum Joint Replenishment Quantity Constraints

Bo Dai

1

, Haoxun Chen

1

, Yuan Li

2,*

, Yidong Zhang

2

, Xiaoqing Wang

2

and Yuming Deng

2

1

Industrial Systems Optimization Laboratory, Charles Delaunay Institute and UMR CNRS 6281,

University of Technology of Troyes, 12 Rue Marie Curie, CS 42060, Troyes 10004, France

2

Alibaba Supply Chain Platform (ASCP), Alibaba (China) Co., Ltd, 969 West Wen Yi Road,

Yu Hang District, Hangzhou 311121, China

{tanfu.zyd, robin.wxq, yuming.dym}@alibaba-inc.com

Keywords: Inventory Management, Distribution Systems, Joint Inventory Replenishment, Warehouses at the Locations

of Producers, Optimization, e-Commerce.

Abstract: In this paper, an inventory replenishment planning problem in a three-echelon distribution system of

Alibaba is studied. In addition to central distribution centers and front distribution centers, this system also

has warehouses at the locations of producers. Multiple products are jointly replenished with minimum and

maximum joint replenishment quantity constraints. Transshipments between distribution centers/warehouses

are allowed. This problem, which is to determine the replenishment quantity of each product between any

two inventory locations in the system, is formulated as a bi-objective optimization model that aims at

finding a tradeoff between overall service level and total logistics cost of the system. This model is solved

by applying an augmented ɛ-constraint method. The effectiveness of the model is demonstrated by

numerical experiments generated from the data of Alibaba. The results show that having warehouses at the

locations of producers can lead to lower logistics costs with a given customer service level.

1 INTRODUCTION

In today’s society, e-commerce has entered the daily

life of most people. To deliver goods to customers

quickly at lower costs and increase market shares, e-

commerce companies have to efficiently manage

inventories in their distribution systems.

As a quickly emerged e-commerce giant with a

very large market share in China, Alibaba is trying

to improve the inventory management of its supply

chain to gain its competitive advantages over other

e-commerce companies. For this reason, we study a

replenishment planning problem in a distribution

system of Alibaba in this paper. Except for central

distribution centers (CDCs) and front distribution

centers (FDCs), the distribution system also has

warehouses at the locations of producers which are

the most upstream suppliers in the system. These

suppliers produce goods and sometimes send them

to the warehouses for temporary storage. The CDCs

get products from the warehouses and distribute

them to the FDCs which serve customers directly.

Hereafter, the warehouses are referred to as

producers distribution centers or PDCs for short.

Each PDC is located at the same location of its

suppliers or near them. It collects products from the

suppliers, and then sends the products to CDCs or

FDCs. The introduction of PDCs can help to reduce

logistics costs in the system that will be investigated

in this paper.

In this study, we consider a single period

inventory replenishment planning problem occurred

in the three-echelon distribution system of Alibaba.

Such inventory replenishment was usually made by

Alibaba before its promotion activities, which is

called “early product pushing down replenishment”.

For example, the well-known annual promotion

activity called ‘double 11 promotion’ has been

successfully held for nine years in Chinese e-

commerce market, which was created by Alibaba in

2009. In 2018, the transaction volume of Alibaba in

‘double 11 promotion’ reached 213.5 billion RMB.

To assure a high on-time delivery rate to customer

orders in such a promotion with huge demand, e-

Dai, B., Chen, H., Li, Y., Zhang, Y., Wang, X. and Deng, Y.

Inventory Replenishment Planning of a Distribution System with Warehouses at the Locations of Producers and Minimum and Maximum Joint Replenishment Quantity Constraints.

DOI: 10.5220/0007356902770284

In Proceedings of the 8th International Conference on Operations Research and Enterprise Systems (ICORES 2019), pages 277-284

ISBN: 978-989-758-352-0

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

277

commerce companies like Alibaba adopt a strategy

of early product pushing down replenishment, where

products are sent to the stocks of a multi-echelon

distribution system in advance for the sales of a

single promotion period. Since the inventory

replenishment is made in advance and for only one-

period sales, the replenishment lead time can be

neglected. The inventory replenishment of each

stock in this distribution system has two important

features: multiple products are replenished jointly,

there are minimum and maximum replenishment

quantity constraints for each replenishment, and

transhipment between two stocks is allowed.

In the literature, both single-period inventory

models (Khouja, 1999) with zero lead time like news

boy model and multi-period inventory models

(Aharon et al., 2009) with positive lead time are

comprehensively studied. These two types of models

have different application fields. Single-period

models deal with one time ordering problems,

whereas multi-period models deal with repetitive

ordering problems. The latter models are usually

more complex than the former ones. In this paper,

we focus on the early product pushing down

replenishment of e-commerce companies introduced

above, so a single period model is adopted.

Most studies on inventory management of

distribution systems deal with a single product (De

Kok et al., 2018). The management of such systems

has to address two issues, one is to choose an

optimal inventory policy for each stock, and the

other is to make an inventory allocation decision

when the on-hand inventory of an upstream stock is

not sufficient to satisfy all replenishment

requirements of its immediate downstream stocks

(Van der Heijden et al., 1997). These papers only

consider single product, two-echelon distribution

systems and do not take into account of any

constraint on replenishment quantity of products in

each stock. In this paper, we study multi-echelon

multi-product joint replenishment planning problem

with constraints on the replenishment quantity of

each stock.

Joint replenishment was usually studied for a

single stock with only few exceptions. A two-

echelon inventory system with a central warehouse

and multiple identical retailers was investigated by

Axsäter and Zhang (1999). In this system, if the sum

of the inventory positions of all retailers reaches a

joint reorder point, the retailer with the lowest

inventory position orders a batch quantity. They

assumed that the inventory position of each stock

was supplied infinitely by the warehouse. Wang and

Axsäter (2013) studied a distribution system with a

central warehouse and multiple retailers with

stochastic demands. They developed a time based

joint replenishment policy. However, they did not

consider replenishment quantity constraints and

transshiplments. Zhou et al. (2012) considered a

multi-product multi-echelon inventory system with

multiple suppliers, one producer, and multiple

distributors and buyers. A joint replenishment and

(T, S) inventory control strategy was proposed,

which orders multiple products in one order cycle.

Besides, most papers studying lateral

transhipments consider stocks at the same echelon

(level) (De Kok et al., 2018). Kukreja and Schmidt

(2005) studied multiple stocks in a single echelon

inventory system with Poisson demand, where

lateral transhipments among stocks are allowed.

Yang et al. (2013) investigated a customer-oriented

service measure which takes into account pipeline

stocks and lateral transshipments in a single-echelon

inventory system. Fattahi et al., (2015) studied a

multiple period inventory system with one

manufacturer and one retailer. The systems studied

in above cited papers involve only a single product

without considering joint replenishment and are

simpler than the multiple echelon distribution

system studied in this paper.

To the best of our knowledge, no paper has

studied an inventory replenishment problem with all

of the following features we consider.

a. The joint inventory replenishment of multiple

products is considered for a multi-echelon

distribution system.

b. A three-echelon distribution system with

warehouses at the locations of producers is

investigated.

c. The minimum and maximum joint replenishment

quantity constraints are considered for each

replenishment.

d. Both vertical and horizontal inventory

replenishments are considered.

e. Two objectives, service level and cost, are

considered in the inventory replenishment planning.

The rest of this paper is organized as follows.

Section 2 describes the optimization problem

studied. Section 3 proposes relevant mathematical

models. Section 4 presents a model reformulation of

the bi-objective problem. Section 5 evaluates the

performances of the models by numerical

experiments. Section 6 concludes this paper with

remarks for future works.

ICORES 2019 - 8th International Conference on Operations Research and Enterprise Systems

278

2 PROBLEM DESCRIPTION

A three-echelon distribution system operated by

Alibaba is considered. As shown in Figure 1, this

system is composed of multiple stocks with multiple

suppliers, one PDC (Producers Distribution Center)

and multiple CDCs (Central Distribution Centers)

and multiple FDCs (Front Distribution Centers).

Each stock holds multiple products which are fast

moving goods. The demand of each stock is

assumed to be subject to a normal distribution.

Figure 1: A three-echelon distribution system with

warehouses at the locations of producers.

Figure 1 provides an illustrative example for the

studied system. Previously, the CDCs were supplied

directly by external suppliers (stock 1 and stock 2).

In recent years, a producers distribution center

(PDC, stock 3) was introduced in the system. The

PDC is located near its suppliers (producers)

geographically where suppliers’ goods can be

transported to the PDC very quickly. In contrast, the

PDC is far away from the CDCs (stocks 4-7) but it

can provide frequent replenishments to CDCs (as

indicated by the solid line from stock 3 to stock 4) in

small batches, which can help to increase the service

level, shorten the replenishment lead time of its

successors, and reduce the logistics cost of the

distribution system. This effect of cost reduction due

to the introduction of PDCs will be further

investigated in section 5. In the system, each FDC

(stocks 8-13) can be supplied directly by the

suppliers (as indicated by the dashed line from stock

1 to stock 9), by the PDC (as indicated by the solid

line from stock 3 to stock 11), or by the CDCs (as

indicated by the solid line from stock 5 to stock 10)

that supply the FDCs directly. Lost sales may

happen at the FDCs. Both vertical replenishment (as

indicated by the solid line from stock 4 to stock 9)

and horizontal replenishment (as indicated by the

solid line from stock 10 to stock 12) are possible,

whereas reverse replenishment from any stock to

any other stock at a higher level (echelon) is not

allowed.

In this paper, we assume that the inventory

replenishment of each stock is made in advance for

the sales of a single period, with minimum and

maximum joint replenishment quantity constraints.

These minimum and maximum joint replenishment

quantities may be different for different distribution

channels, as the suppliers of some products such as

fruits are located in isolated agricultural areas where

transportation capacity is much smaller than that in

economically well developed industrial areas.

Furthermore, multiple products may be replenished

simultaneously. Because the inventory

replenishment of each stock is made in advance with

a quite short lead time, we assume in our model that

all replenishments are carried out immediately with

zero lead time. In addition, for a stock which may

both receive and deliver goods, it is assumed that

goods are received first from its supplier stocks

before the goods can be delivered to its customer

stocks.

The replenishment decision is made based on

demand forecast and historitical demand data

especially historial demand forecast errors. Before

the replenishment, each stock holds a certain on-

hand inventory of each product. The shipping costs,

maximum and minimum joint replenishment

quantity between any two stocks are given. During

the replenishment, the products of suppliers will be

transported to FDCs directly or through PDCs and

CDCs with possible transhipments between them at

the same level (echelon). The objectives of this

distribution system are to maximize the service

levels at the FDCs and minimize total replenishment

cost. All products at all FDCs are expected to have

the same service level and inventory holding costs

are not considered. As the above two objectives are

in conflict with each other, so we formulate this

replenishment planning problem as a bi-objective

optimization problem, which aims at finding a

tradeoff between the two objectives by providing a

set of Pareto optimal replenishment plans for the

distribution system.

3 PROBLEM FORMULATION

Before presenting the model, we first introduce the

following notations.

Indices

i,j: stock index, i,j N, where N is the set of all

stocks in the distribution system

k: product index, k K, where K is the set of all

p

roducts in the distribution s

y

ste

m

Inventory Replenishment Planning of a Distribution System with Warehouses at the Locations of Producers and Minimum and Maximum

Joint Replenishment Quantity Constraints

279

Parameters

SS

: set of stocks at the supplier echelon of the

distribution system

SO

: set of stocks at the PDC echelon of the

distribution system

SC

: set of stocks at the CDC echelon of the

distribution system

SF

: set of stocks in the FDC echelon of the

distribution system

N: set of all stocks in the distribution system, N =

SS SO SC SF

K: set of all products in the distribution system

0

ki

I

: initial on-hand inventory of product k at

stock i at the beginning of replenishment, k K,

iN

ki

: demand forecast of product k at stock i

ki

: standard deviation of demand forecast of

product k at stock i

ki

d

: real demand of product k at stock i,

ki

d

is a

random variable. It is assumed that

ki

d

is subject

to a normal distribution with mean value

ki

and

standard deviation

ki

ij

s

c

: shipping cost from stock i to stock j, where

ij ji

s

csc

and the triangle inequality,

in nj ij

s

csc sc

, holds for any i, j, n with

,nin j

max

ij

C

: maximum joint replenishment quantity

from stock i to stock j (

,ij N

) for each

replenishment

min

ij

C

: minimum joint replenishment quantity

from stock i to stock j (

,ij N

) for each

replenishment

M: a big positive number

Decision Variables

ki

I

: on-hand inventory of product k at stock i

after replenishment

α: common service level of each product at

each stock

z

α

: z-value corresponding to the service level α

k

ij

x

: replenishment quantity of product k from

stock i to stock j

ij

y

: if the replenishment of products happens

from stock i to stock j,

1

ij

y

, otherwise

0

ij

y

With the above notations, the single period

replenishment planning problem of the three-echelon

distribution system can be formulated as the

following mixed-integer programming model

SPRPP.

Model SPRPP:

,

1

SPR k

ij ij

kKiN

P

jNji

P

Z

M

in x sc

(1)

2 1

SPRPP

Z Min

(2)

Subject to:

0

,,

,,

kk

ki ki ji ij

jNji jNji

iN

I

IxxkK

(3)

,,

ki ki ki

iSF

I

zkK

(4)

0

,

,,

k

ij ki

jNji

iSSkKxI

(5)

,0, ,

k

ji

iSSjN

x

kK

(6)

min max

,,

k

ij ij ij ij

kK

iCy xC jN

(7)

,,

k

ij ij

kK

i

x

yM jN

(8)

0, ,

k

ii

x

iNkK

(9)

,0,0 1, 0,1, ,

k

ki ij ij

Ix y ijNkK

(10)

The objective function (1) seeks to minimize the

total replenishment cost. The objective function (2)

aims to maximize the common service level α of all

products at all FDCs in the distribution system.

Constraints (3) are the inventory balance constraints

of each product at each stock. Constraints (4) ensure

that the same service level α of each product at each

stock can be achieved after replenishment. These

constraints are derived from the probability

constraints

P{ } , ,

ki ki

iSF

I

dkK

, where

z is

the z-value corresponding to the service level α, with

the relationship between them given by

P{ }

xz

,

~(0,1)xN

, i.e.,

z

, where

.

is the cumulative distribution function of

(0 ,1)N

. Constraints (5) ensure that the total

replenishment quantity of product k from supplier i

to all stocks in the distribution system does not

exceed the on-hand inventory of the product

available in the supplier. Constraints (6) ensure that

no product will be replenished between supplier

stocks or send back to a supplier. Constraints (7)

guarantee that the replenishment quantity of all

products from one stock to another is subject to

ICORES 2019 - 8th International Conference on Operations Research and Enterprise Systems

280

minimum and maximum joint replenishment

quantity constraints. Constraints (8) indicate the

relationship between

k

ij

x

and

ij

y

. Constraints (9)

mean that each stock is not replenished by itself.

Constraints (10) indicate the types and the domains

of all decision variables.

As the z-value

z

α

is a monotone increasing

function of α, we can replace objective function (2)

of the above model by an equivalent objective

function (11) below.

2

SPRPP

Z

M

in z

(11)

4 SOLUTION APPROACH

To solve the bi-objective model SPRPP, an

augmented ɛ-constraint method (Mavrotas, 2009) is

employed. This method is a revised version of ɛ-

constraint method (Chankong and Haimes, 1983),

which can avoid the generation of weakly Pareto

optimal solutions and accelerates the whole

computation process without redundant iterations.

Firstly, we introduce some new parameters and

variables required for the description of this method

as follows.

Parameters

f

1

(x): objective function (1) of model SPRPP

f

2

(α): objective function (2) of model SPRPP

lb

2

: upper bound of the objective function f

2

(α),

which is obtained by solving the model with single

objective function f

2

(α) and constraints f

1

(x) = f

1

*

,

where f

1

*

is obtained by optimally solving the model

with single objective function f

1

(x).

r

2

: range of the objective function value f

2

(α), which

is the difference between its best value and upper

bound. The best value can be obtained by optimally

solving the model with single objective function

f

2

(α).

Ng

2

: number of grid points in the range of objective

function value f

2

(α)

gi

2

: grid point index, gi

2

= 0, 1, … , Ng

2

eps: a small positive number, which is usually taken

from 10

-6

to 10

-3

2

: a variable parameter depending on gi

2

,

22 2 22

()

lb gi

N

gr

Decision Variables

s

2

: slack variable of the objective function f

2

(α)

With the above notations, a model SPRPP2

modified from model SPRPP can be formulated as

following.

2

122

()

SPRPP

ZMin

f

xepssr

(12)

Subject to constraints (3) to (10) and:

222

()

fu s

(13)

2

0s

(14)

By taking Ng

2

sufficiently large and iteratively

solving model SPRPP2 for different values of

2

generated by taking the grid point index gi

2

from 0

to Ng

2

, representative Pareto optimal solutions of the

original model SPRPP can be found. These solutions

provide multiple choices for the decision-maker of

replenishment planning of the distribution system

under different customer service levels.

5 NUMERICAL EXPERIMENTS

In this section, we report and analyze the results of

our numerical experiments conduced to evaluate the

models proposed in this paper. Twenty instances

generated partially based on Alibaba’ data were used

to validate the models and evaluate the performances

of distribution systems with PDCs. For the sake of

confidentiality, some data of the instances will be

not presented hereafter.

The initial inventory of each PDC, CDCs, and

FDC stock is set to zero, and the initial inventory of

each supplier is randomly generated and is high

enough to ensure that an expected service level at

FDCs can be achieved.

Based on the data of Alibaba, the maximum joint

replenishment quantity is set as a multiple of the

minimum joint replenishment quantity for the

replenishment between any two stocks. After the

coordinates of all nodes are given, the Euclidean

distance c

ij

(shipping cost) between any two stocks i

and j is calculated.

In addition, the demand forecast and its standard

deviation of each product at each FDC are also

generated based on data of Alibaba. For all

instances, the number of products is set to 3 (K = 3).

For the first ten instances, the number of stocks

is set to 10 with 4 suppliers, 1 PDC, 1 CDC, and 4

FDCs. For the second ten instances, the number of

stocks is set to 18 with 8 suppliers, 1 PDC, 1 CDC,

and 8 FDCs. All models involved in the instances

were solved by using the solver of Cplex 12.8 on a

personal PC with i7-8650U CPU and 16GB RAM.

The computation time of each instance is very small,

which is usually in several seconds.

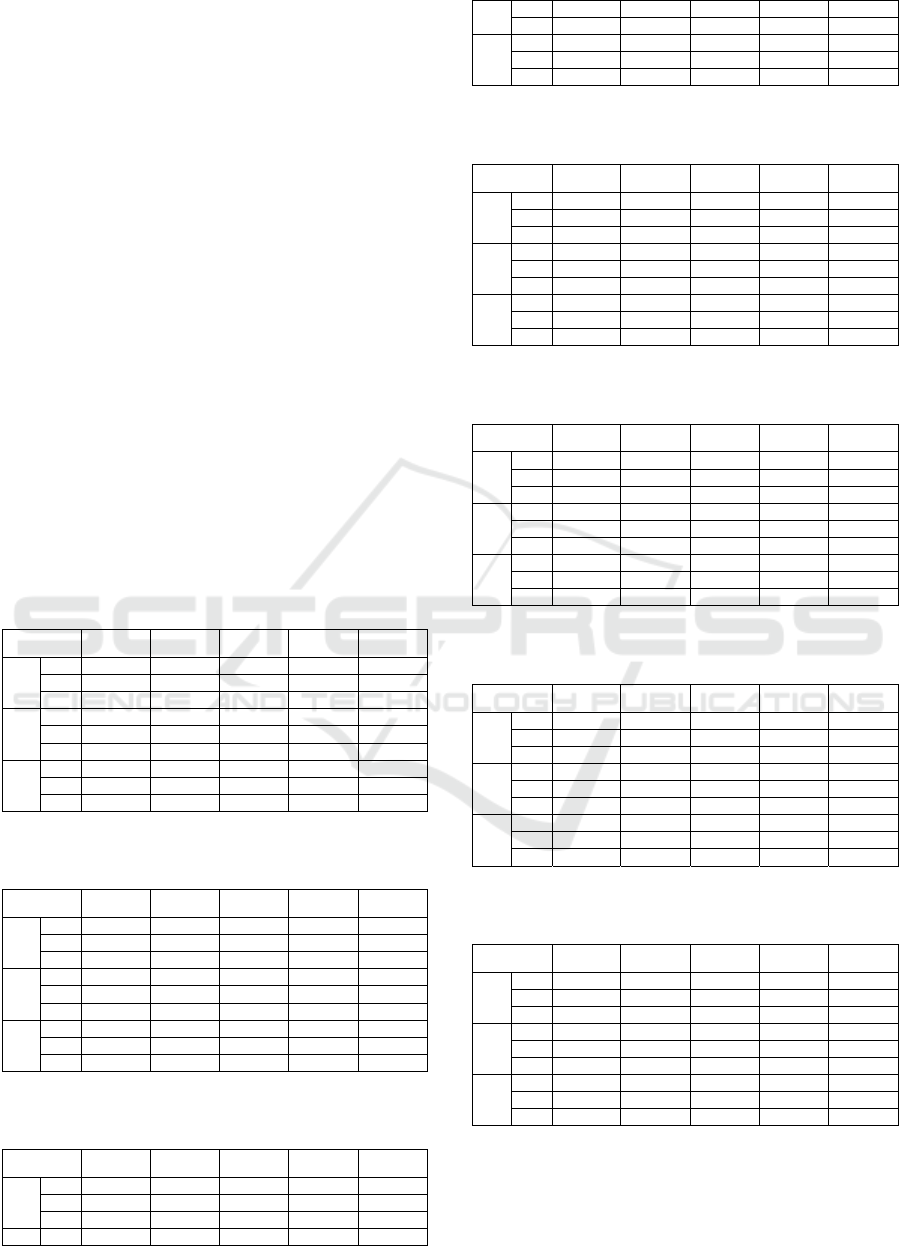

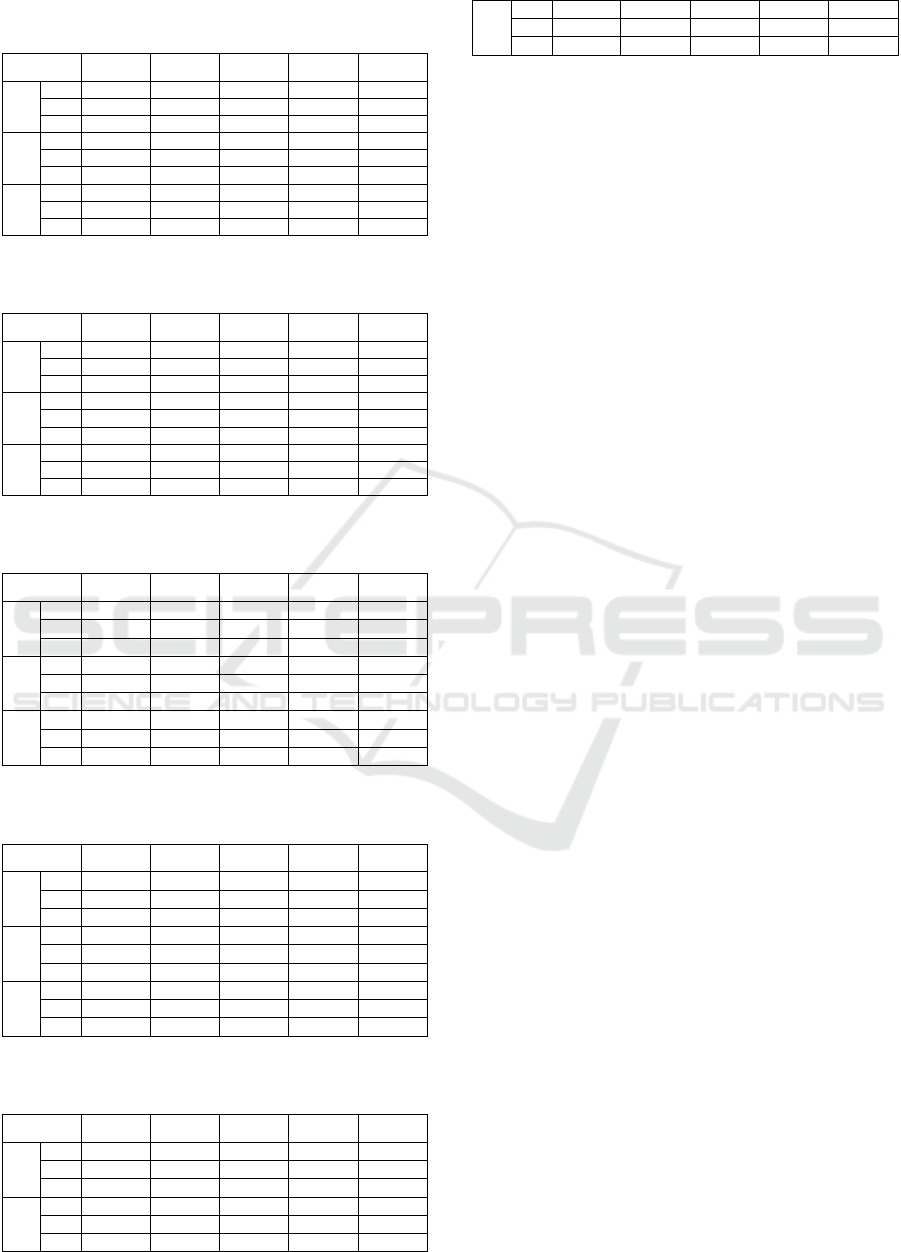

The computational results are given in Table 1 to

Inventory Replenishment Planning of a Distribution System with Warehouses at the Locations of Producers and Minimum and Maximum

Joint Replenishment Quantity Constraints

281

Table 12. To evaluate the influence of the minimum

and maximum joint replenishment quantity

constraints on the replenishment plan, we tested

three scenarios denoted by MR1, MR2, and MR3

respectively for each instance. For scenario MR1,

the minimum and maximum joint replenishment

quantities are set based on real data of Alibaba. For

scenario MR2 and MR3, the minimum and

maximum joint replenishment quantities are set as

two and four times of those in the first scenario

respectively.

For each instance, we consider three cases with

different service levels to examine different

situations of the distribution system. In Case 1 (C1)

the service level α is set to 0.92 with z

α

is equal to

1.41, in Case 2 (C2) the service level α is set to 0.95

with z

α

is equal to 1.65, and in Case 3 (C3) the

service level α is set to 0.98 with z

α

is equal to 2.06.

Furthermore, in the following tables, CA

represents the replenishment cost of the distribution

system without PDCs, CB represents the

replenishment cost of the system with PDCs, and CR

indicates the cost reduction in percentage of CB with

respect to CA, i.e., CR = (CA - CB)/CA.

Table 1: Computational results of the instances 1 to 5

(scenario MR1).

Instance 1 2 3 4 5

C1

CA 946378 855362 879649 869401 865940

CB 887305 799543 822589 812915 807978

CR 6.24% 6.53% 6.49% 6.5% 6.69%

C2

CA 1038930 939450 964502 946854 939234

CB 979322 881588 905372 889462 880951

CR 5.74% 6.16% 6.13% 6.06% 6.21%

C3

CA 1197490 1084290 1109760 1079190 1064470

CB 1137910 1026420 1050630 1021780 1006170

CR 4.98% 5.34% 5.33% 5.32% 5.48%

Table 2: Computational results of the instances 1 to 5

(scenario MR2).

Instance 1 2 3 4 5

C1

CA 682239 613529 630274 623977 611243

CB 617991 562506 576774 570291 566934

CR 9.42% 8.32% 8.49% 8.6% 7.25%

C2

CA 768727 688948 707926 694107 680734

CB 669265 608242 619727 609836 604172

CR 12.94% 11.71% 12.46% 12.14% 11.25%

C3

CA 921745 828128 847817 821704 803534

CB 809473 716824 731208 710968 690256

CR 12.18% 13.44% 13.75% 13.48% 14.1%

Table 3: Computational results of the instances 1 to 5

(scenario MR3).

Instance 1 2 3 4 5

C1

CA 613015 556239 571134 564595 564530

CB 612830 556229 571051 564518 564530

CR 0.03% 0.002% 0.01% 0.01% 0%

C2 CA 659466 598809 613673 603500 601206

CB 659273 598761 613590 603359 601206

CR 0.03% 0.01% 0.01% 0.02% 0%

C3

CA 738924 671868 686366 670040 663870

CB 738689 671568 686272 669744 663870

CR 0.03% 0.04% 0.01% 0.04% 0%

Table 4: Computational results of the instances 6 to 10

(scenario MR1).

Instance 6 7 8 9 10

C1

CA 798457 888181 872951 898750 931109

CB 740557 833167 816825 841345 875136

CR 7.25% 6.19% 6.43% 6.39% 6.01%

C2

CA 869174 969267 954169 964632 1019340

CB 810531 913780 897866 907227 962056

CR 6.75% 5.72% 5.9% 5.95% 5.62%

C3

CA 990081 1107880 1092920 1077190 1170140

CB 931514 1052460 1036650 1019780 1112760

CR 5.92% 5% 5.15% 5.33% 4.9%

Table 5: Computational results of the instances 6 to 10

(scenario MR2).

Instance 6 7 8 9 10

C1

CA 555609 647823 632874 651628 685687

CB 529090 576119 566325 576504 598705

CR 4.77% 11.07% 10.52% 11.53% 12.69%

C2

CA 619808 724730 710581 716832 769287

CB 564730 623285 610943 613549 658509

CR 8.89% 14% 14.02% 14.41% 14.4%

C3

CA 737443 859343 847674 828682 917948

CB 629748 754111 737566 715203 803412

CR 14.6% 12.25% 12.99% 13.69% 12.48%

Table 6: Computational results of the instances 6 to 10

(scenario MR3).

Instance 6 7 8 9 10

C1

CA 527254 569731 559990 574277 592346

CB 527101 569701 559713 574136 592316

CR 0.03% 0.01% 0.05% 0.02% 0.01%

C2

CA 562685 610437 600679 607250 636521

CB 562527 610394 600427 607100 636490

CR 0.03% 0.01% 0.04% 0.02% 0.005%

C3

CA 623223 680031 670280 663613 712023

CB 623068 679948 670083 663447 711962

CR 0.02% 0.01% 0.03% 0.03% 0.01%

Table 7: Computational results of the instances 11 to 15

(scenario MR1).

Instance 11 12 13 14 15

C1

CA 1013390 1102040 1158610 1155320 1279270

CB 957531 1026230 1071180 1060360 1181500

CR 5.51% 6.88% 7.55% 8.22% 7.64%

C2

CA 1136720 1250040 1313900 1293050 1429550

CB 1044870 1149870 1216400 1194000 1330450

CR 8.08% 8.01% 7.42% 7.66% 6.93%

C3

CA 1360530 1512160 1587120 1540520 1694240

CB 1261720 1406960 1486670 1436560 1591650

CR 7.26% 6.96% 6.33% 6.75% 6.06%

ICORES 2019 - 8th International Conference on Operations Research and Enterprise Systems

282

Table 8: Computational results of the instances 11 to 15

(scenario MR2).

Instance 11 12 13 14 15

C1

CA 944804 1017380 1025400 1026850 1084460

CB 944729 1017200 1025160 1026650 1084360

CR 0.01% 0.02% 0.02% 0.02% 0.01%

C2

CA 1013540 1096050 1106860 1101450 1163300

CB 1013490 1095840 1106540 1101160 1163240

CR 0.005% 0.02% 0.03% 0.03% 0.01%

C3

CA 1135130 1232300 1249180 1230980 1301260

CB 1135050 1232050 1248830 1230670 1301150

CR 0.01% 0.02% 0.03% 0.03% 0.01%

Table 9: Computational results of the instances 11 to 15

(scenario MR3).

Instance 11 12 13 14 15

C1

CA 944362 1016430 1024750 1025310 1082640

CB 944362 1016430 1024670 1025300 1082600

CR 0% 0% 0.01% 0.001% 0.004%

C2

CA 1012950 1094910 1106020 1099720 1161050

CB 1012950 1094910 1105940 1099700 1161020

CR 0% 0% 0.01% 0.002% 0.003%

C3

CA 1134400 1230870 1248220 1229090 1298520

CB 1134380 1230850 1248140 1229070 1298460

CR 0.002% 0.002% 0.01% 0.002% 0.005%

Table 10: Computational results of the instances 16 to 20

(scenario MR1).

Instance 16 17 18 19 20

C1

CA

1310400 1143130 1263490 1276570 1181300

CB

1214280 1049400 1168190 1178210 1093050

CR

7.34% 8.20% 7.54% 7.71% 7.47%

C2

CA

1459840 1285920 1411980 1425210 1325780

CB

1360470 1187470 1309290 1322040 1231210

CR

6.81% 7.66% 7.27% 7.24% 7.13%

C3

CA

1731150 1536620 1673730 1688930 1587940

CB

1627500 1434010 1567610 1582810 1488360

CR

5.99% 6.68% 6.34% 6.28% 6.27%

Table 11: Computational results of the instances 16 to 20

(scenario MR2).

Instance 16 17 18 19 20

C1

CA

1106090 1017200 1100580 1091480 1028570

CB

1105810 1017030 1100560 1091440 1028510

CR

0.03% 0.02% 0.002% 0.004% 0.01%

C2

CA

1186440 1092170 1178760 1169920 1107760

CB

1186180 1091990 1178710 1169860 1107730

CR

0.02% 0.02% 0.004% 0.01% 0.003%

C3

CA

1326790 1221760 1312800 1304250 1243910

CB

1326510 1221540 1312690 1304200 1243770

CR

0.02% 0.02% 0.01% 0.004% 0.011%

Table 12: Computational results of the instances 16 to 20

(scenario MR3).

Instance 16 17 18 19 20

C1

CA

1104940 1015320 1099930 1090210 1027320

CB

1104920 1015320 1099900 1090210 1027310

CR

0.002% 0% 0.003% 0% 0.001%

C2

CA

1185280 1090030 1178060 1168640 1106480

CB

1185260 1090030 1178050 1168610 1106480

CR

0.002% 0% 0.001% 0.003% 0%

C3

CA

1325600 1219060 1311900 1302920 1242460

CB

1325540 1219050 1311900 1302890 1242430

CR

0.005% 0.001% 0% 0.002% 0.002%

From the above tables, we can see, for each

given service level of FDCs, the replenishment plan

of the distribution system with PDCs can lead to a

smaller replenishment cost than that of the system

without PDCs for almost all instances and cases. For

the cases with smaller maximum joint replenishment

quantity (Table 1, 2, 4, 5, 7 and 10), the

replenishment cost of the system with PDCs is much

lower than that of the system without PDCs for all

instances. The reason is that some products are

consolidated in PDCs before they are transported to

FDCs in these cases. When the maximum joint

replenishment quantity is set larger (Table 3, 6, 8, 9,

11 and 12), the cost reduction of the system with

PDCs with respect to the system without PDCs

becomes smaller for all instances. The reason is that

more products are directly transported from

suppliers to FDCs due to a larger and almost

unconstrained maximum joint replenishment

quantity. Since the replenishment quantity between

two stocks is usually constrained by the maximum

joint replenishment quantity because of limited

transportation capacity, our numerical experiment

results show the introduction of PDCs in a

distribution system can significantly reduce

inventory replenishment costs.

Today, PDCs have been introduced by Alibaba

in its distribution system for some fresh products

(fruits), where a novel project called ‘Shen Nong

Plan of Alibaba’ is in the process of implementation.

The inventory replenishment via PDCs brings both

economic and social benefits to Alibaba. On the one

hand, it can lead to lower replenishment costs for a

given service level of FDCs. On the other hand, as

PDCs are located in the areas of producers that are

usually less developed, the project of

implementation of PDCs will provide jobs for

habitants in such areas, which can both reduce the

poverty in these areas and increase their local

industry incomes.

6 CONCLUSIONS

An inventory replenishment planning problem in a

three echelon distribution system with warehouses at

the locations of producers is studied in this paper.

This problem is formulated as a bi-objective

optimization problem. Numerical experiments on

instances generated based on the data of Alibaba

validate the proposed model and demonstrate the

Inventory Replenishment Planning of a Distribution System with Warehouses at the Locations of Producers and Minimum and Maximum

Joint Replenishment Quantity Constraints

283

advantage of having such warehouses in the system.

Our future work is to study a multi-period

replenishment planning problem of the system.

ACKNOWLEDGEMENTS

This study is supported by the Alibaba Innovative

Research Project entitled “Optimization of Safety

Stock Placement in Supply Chains with Demand and

Lead Time Uncertainty”.

REFERENCES

Aharon, B., Boaz, G., Shimrit, S. 2009 Robust multi-

echelon multi-period inventory control, European

Journal of Operational Research, 199, pp 922-935.

Axsäter, S., Zhang, W.F. 1999 A joint replenishment

policy for multi-echelon inventory control,

International Journal of Production Economics, 59,

pp 243-250.

Chankong, V., Haimes, Y.Y. 1983 Multiobjective

Decision Making: Theory and Methodology, North-

Holland, New York.

De Kok, T., Grob, C., Laumanns, M., Minner, S., Rambau,

J., Schade, K. 2018 A typology and literature review

onstochastic multi-echelon inventory models,

European Journal of Operational Research, 269, pp

955-983.

Fattahi, M., Mahootchi, M., Moattar Husseini, S.M.,

Keyvanshokooh, E., Alborzi, F. 2015 Investigating

replenishment policies for centralised and

decentralised supply chains using stochastic

programming approach, International Journal of

Production Research, 53, pp 41-69.

Heijden, M. C., van der Diks, E. B., de Kok, A. G. 1997.

Stock allocation in general multi-echelon distribution

systems with (R, S) order-up-to-policies, International

Journal of Production Economics, 49, pp 157-174.

Khouja, M. 1999 The single-period (news-vendor)

problem: literature review and suggestions for future

research, Omega, 27, pp 537-553.

Kukreja, A., Schmidt, C.P. 2005 A model for lumpy

demand parts in a multi-location inventory system

with transhipments, Computers & Operations

Research, 32, pp 2059-2075.

Mavrotas, G. 2009 Effective implementation of the e-

constraint method in multi-objective mathematical

programming problems, Applied Mathematics and

Computation, 213, pp 455-465.

Van der Heijden, M.C., Diks, E.B., De Kok, A.G. 1997.

Stock allocation in general multi-echelon distribution

systems with (R, S) order-up-to-policies, International

Journal of Production Economics, 49, pp157-174.

Wang, Q., Axsäter, S. 2013 Fixed-interval joint-

replenishment policies for distribution systems with

multiple retailers and stochastic demand, Naval

Research Logistics, 60, pp 637-651.

Yang, G., Dekker, R., Gabor, A. F., Axsäter, S. 2013

Service parts inventory control with lateral

transshipment and pipeline stock flexibility,

International Journal of Production Economics, 142,

pp 278-289.

Zhou, W.Q., Chen, L., Ge, H.M. 2012 A multi-product

multi-echelon inventory control model with joint

replenishment strategy, Applied Mathematical

Modelling, 37, pp 2039-2050.

ICORES 2019 - 8th International Conference on Operations Research and Enterprise Systems

284