Study on Contamination Control of Optical Thin Films with First

Contact

TM

Yan Baozhu, Yuan Shengfu, Zhou Qiong, Sun Quan and Yang Yi

College of Advanced Interdisciplinary Studies, National University of Defense Technology, Changsha, Hunan, P. R. China

Keywords: Laser, Optical Thin Films, Contamination Control, Intra-Cavity Device.

Abstract: In high power laser system, it is very lethal of contamination on the surface of optical thin films. The

contamination can be heated and burn rapidly under high power laser irradiation, which would result in

damage to the optical thin films or even the whole optical component. Therefore, it is the key to control the

contamination on the surface of optical thin films. First Contact

TM

can be used to clean the surface of optical

thin films, remove fingerprints, dust and other contamination attached to the surface of optical thin films. It

has been applied in many important projects such as aLIGO. In this paper, the First Contact

TM

was used to

clean the optical thin films for chemical lasers. A microscope was used to test the appearance of the optical

thin films before and after cleaning, which showed that, the First Contact

TM

is able to remove

contamination, such as fingerprints and dust, attached to the surface of optical thin films for chemical lasers.

The absorption coefficients of the optical thin films before and after cleaning were measured by an intra-

cavity device, which is 286.5ppm and 216.9ppm respectively. The absorption coefficient was decreased by

24.3% after cleaning. The above results show that, the First Contact

TM

can effectively clean the optical thin

films for chemical lasers, and there is no First Contact

TM

remain on the surface of optical thin films. It is

found that the shortcoming of the First Contact

TM

is that, it cannot repair the defects in the substrates or

optical thin films of the optical components, and cannot clean the optical thin films online. Finally, the use

of First Contact

TM

was optimized, and the optimized method is conducive to the long-term preservation of

optical components.

1 INTRODUCTION

The control of contamination on the surface of

optical thin films has always been the concern of the

researchers in the field of high power laser (Raman

R N, et al., 2016; Xiaofeng Cheng, et al., 2014; Kai

Han, et al., 2016).

.

In the process of high power laser

system, the power density on the optical thin films is

very high. Then, the presence of contamination is

fatal. Irradiated by the high power laser,

contamination will be heated, even burning, and

causing a damage of optical thin film. This is a

serious threat to the stability and security of the

system.

First Contact

TM

is a kind of cleanser for optical

surface, which is produced by a company called

Photonic Cleaning Technology. It is a mixture of

solvent and polymer in liquid form. When it is

painted or sprayed on the optical surface, a soft layer

of film is formed, and there is not any damage to the

optical surface. When it is dry, it can be torn down

easily. At the same time, the contamination on the

optical surface is taken away, such as dust and

handprint, then a clean optical surface is left. First

Contact

TM

is used for removing contamination on

the surface of optical thin films in many projects,

such as aLIGO, which is short for advanced Laser

Interferometer Gravitational-Wave Observatory

(Margot H. Phelps, et al., 2013; Photonic Cleaning

Technologies, LLC, 2018). But there are no

applications in chemical lasers. In this paper, the

cleaning method of optical thin films used for

chemical lasers was studied experimentally, and the

cleaning effect is tested by means of microscope and

an intra-cavity device (Xiaoting Fang, et al., 2015;

Yan Baozhu, et al., 2015).

2 CLEANING METHOD

As shown in Fig.1, the steps of cleaning the surface

of the optical thin films with First Contact

TM

are:

Baozhu, Y., Shengfu, Y., Qiong, Z., Quan, S. and Yi, Y.

Study on Contamination Control of Optical Thin Films with First Contact TM.

DOI: 10.5220/0007357601250128

In Proceedings of the 7th International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS 2019), pages 125-128

ISBN: 978-989-758-364-3

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

125

a) Firstly, one layer of First Contact

TM

is sprayed

on the surface of the optical thin films, as

Fig.1a;

b) 15 minutes later, a sticker is pasted on the layer

of First Contact

TM

, then another layer of First

Contact

TM

is sprayed on them, as Fig.1b;

c) Another 15 minutes later, by tearing the sticker,

double layers are torn off simultaneously. The

surface of optical thin film is very clean as

Fig.1c, and the tearing film of First Contact

TM

is

shown as Fig.1d.

a)

b)

c)

d)

Figure 1: The cleaning process.

The tearing film of First Contact

TM

is about 0.2

millimeter in thickness. This thickness is more

suitable. If too thin, the First Contact

TM

film is not

strong enough; if too thick, the First Contact

TM

film

will not be dry inside. In these two cases, the film

will be easy to break and can not be tearing clean.

3 CLEANING EFFECT

Two methods are used to test the cleaning effect.

The first way is to compare the state of optical film

surface before and after cleaning by microscope. As

shown in Fig.2a and Fig.2c, there are handprints and

a lot of micron scale white spots on the surface of

optincal thin film before cleaning. After cleaning,

the handprints are removed completely (as Fig.2b),

and the number of white spots is reduced

significantly (as Fig.2d).

It is found that some of the white spots are

contamination, and the others are defects in the

substrate or optical thin film. Contamination, such as

dust, can be removed by the First Contact

TM

, and

this is the reason for the decrease of white spots. But

defects in the substrate or optical thin film can not

be repaired, so there are still some white spots after

cleaning.

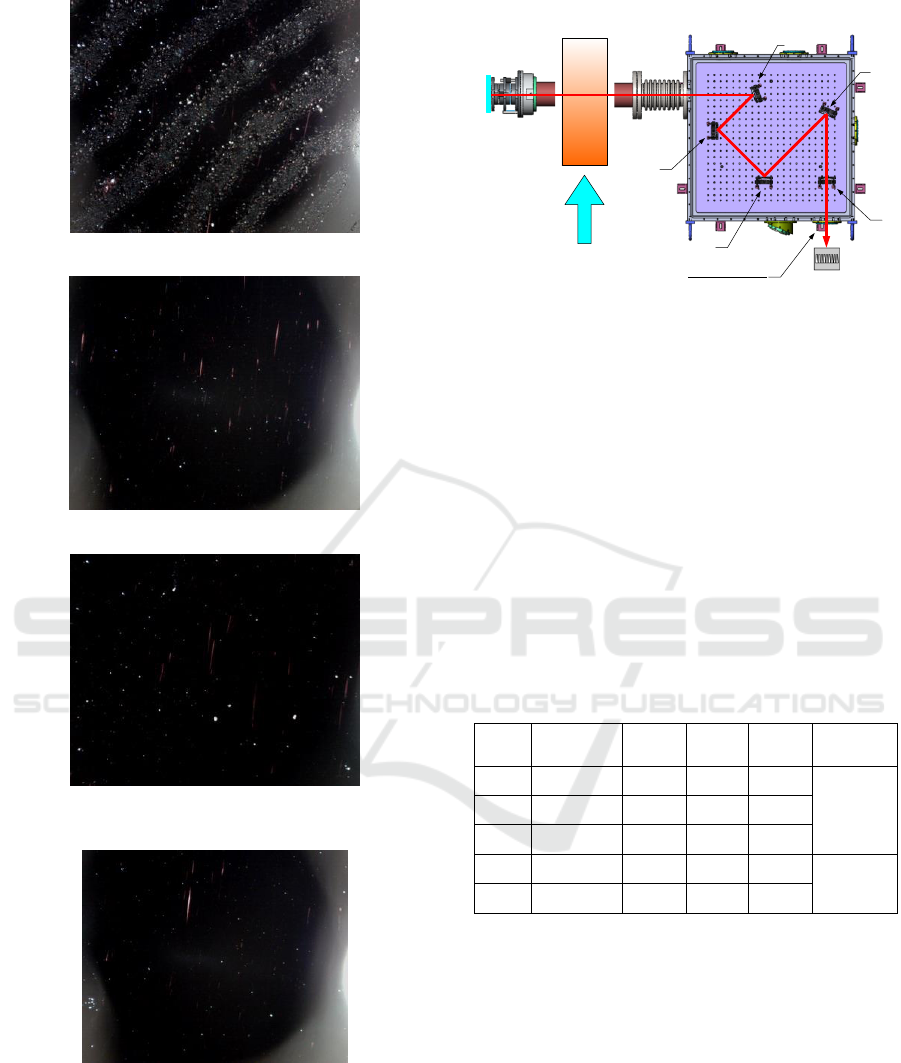

Another way is to measure the absorption

coefficient of optical thin film before and after

cleaning by an intra-cavity device (Xiaoting Fang, et

al., 2015; Yan Baozhu, et al., 2015). As is shown in

Fig.3, an intra-cavity device is established based on

a discharge-drived CW DF chemical laser of

hundred watt level. The center wavelength is about

3.8μm. Utilizing an output mirror M2 with a low

output coupling ratio (τ=0.03), the intra-cavity

device could produce a laser beam of about 2.5-

6.5kW/cm

2

and 1 cm

2

in the resonant cavity. When

placed in the resonant cavity, the testing mirrors

S1~S4 are irradiated by the laser beam of high

power density.

In the test, the irradiation is lasting 100 seconds

continuously, and the equilibrium temperature rise

of the substrate after the irradiation can be measured

by temperature sensors, which are pasted at rear

surface of testing mirrors S1~S4. The output power

is measured by power sensor. Then, the absorption

coefficient of optical thin film can be calculated by

calorimetry.

Five times of measurements are carried out by

use of the intra-cavity device in this paper, and the

absorption coefficients of optical thin film are listed

in Tab.1. The Pd, E, △T and α represent power

density of laser beam in the resonant cavity, energy

PHOTOPTICS 2019 - 7th International Conference on Photonics, Optics and Laser Technology

126

a) Handprints on the surface before cleaning.

b) The position of handprints after cleaning.

c) White spots on random area outside of the handprints

before cleaning.

d) Random area outside of the handprints after cleaning.

Figure 2: The cleaning effect of First Contact

TM

.

radiated on the optical thin film, equilibrium

temperature rise of the substrate after the irradiation,

and absorption coefficient respectively.

M1

M2

S1

S2

S3

S4

Gain

region

Power sensor

Intra-cavity box

Flow

Output window

Figure 3: Layout of intra-cavity device.

The first three times of measurements are carried

out before cleaning, and the average value of

absorption coefficients is 286.5ppm. After cleaning

by First Contact

TM

, other two measurements are

made. The average absorption coefficient is

216.9ppm, which is 24.3% less than the value before

cleaning. The reason for the decline is the removal

of dust and other contamination on the surface of

optical thin film. On the other hand, the results

reveal that the layer of First Contact

TM

is torn off

completely, and there are no residue on the surface

of optical thin film. There is no new pollution to the

optical film, which is of great practical significance.

Table 1: The absorption coefficients measured by the

intra-cavity device.

Num

Pd /

(kw/cm

2

)

E /

kJ

△T /

℃

α /

ppm

Status

1

3.45

328.0

5.71

295.8

Before

cleaning

2

2.88

368.1

6.47

298.7

3

2.92

472.8

7.37

264.9

4

3.80

547.2

6.95

215.8

After

cleaning

5

4.02

579.1

7.43

218.0

4 PROTECTION OF OPTICAL

COMPONENTS

One layer film is formed when First Contact

TM

is

sprayed on the surface of the optical thin film. The

layer of First Contact

TM

can isolate optical thin films

from water vapor and prevent it from being damaged

by other things. So First Contact

TM

can be used for

protecting optical components during preservation

and transportation.

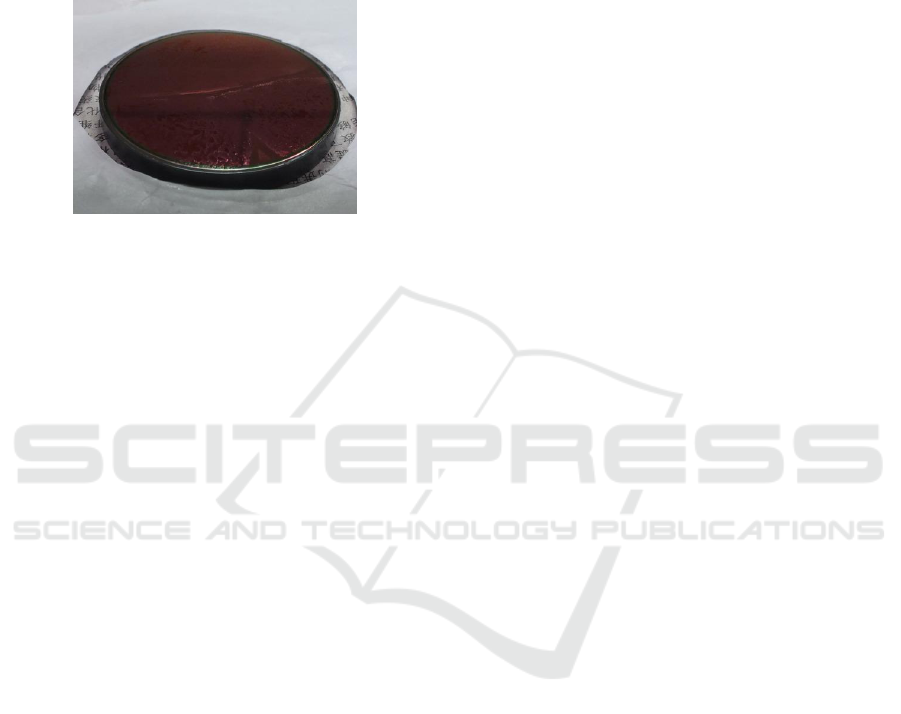

In order to explore the method of using First

Contact

TM

to protect optical thin films, two layers of

Study on Contamination Control of Optical Thin Films with First Contact TM

127

First Contact

TM

are sprayed on the surface as step a

and b in the part 2. One week later, double layers

can still be torn off completely, but a imprint like

watermark appeared on the surface of optical film,

as shown in Fig.4, and there is a clear boundary

around the sticker. The imprint can be removed by

using First Contact

TM

again, but the boundary can’t.

Figure 4: The optical film tearing down the First

Contact

TM

film after a week.

Thus, the spraying method need to be optimized.

After spraying the first layer of First Contact

TM

on

the surface of the optical thin films, the sticker is not

pasted immediately. When the optical component

need to be used, maybe a few days later, paste a

sticker, tear off the sticker and the layer of First

Contact

TM

. Tests verify that, using the optimized

method, the layer of First Contact

TM

can be torn off

completely even 3 months after spraying and there is

no boundary around the sticker. If there is a

watermark-like imprint on the surface of optical

film, it can be cleaned by use of the method in part 2

again.

5 CONCLUSIONS

In this paper, the cleaning method of First Contact

TM

to the surface of optical thin films is studied

experimentally. The test results of the microscope

and the intra-cavity device reveal that, the cleaning

effect of First Contact

TM

is perfect, and there are no

negative effects, such as pollution and damage. But

the defects of substrates or optical films can not be

repaired by First Contact

TM

. The layer of First

Contact

TM

can be torn off completely even 3 months

after spraying, so it may be used for protecting

optical components when preservation and

transportation.

REFERENCES

Raman R N, Demos S G, Shen N, et al., 2016. Damage on

fused silica optics caused by laser ablation of surface-

bound microparticles, Opt. Express, 24(3), 2634.

Xiaofeng Cheng, Xinxiang Miao, Hongbin Wang, et al.,

2014. Surface contaminant control technologies to

improve laser damage resistance of optics, Adv.

Condens, Matter Phys, 210.

Kai Han, Baozhu Yan, Xiaojun Xu, et al., 2016. Thermal

damage mechanism of the optical element used in

mid-infrared high power laser system, J. Infrared

Millim, Waves, 35(6), 741.

Margot H. Phelps, Kaitlin E. Gushwa, Calum I. Torrie,

2013. Optical contamination control in the Advanced

LIGO ultra-high vacuum system, Proc. of SPIE Vol.

8885, 88852E-1.

Photonic Cleaning Technologies, LLC, 2018,

http://www.photoniccleaning.com/.

Xiaoting Fang, Shengfu Yuan, Wenguang Liu, et al., 2015.

Absorption measurement of optical thin films under

high power density with a Closed Cavity, Chinese

Optics Letters, 13(3), 033101.

Yan Baozhu, Liu Wenguang, Zhou Qiong, et al., 2015. An

intra-cavity device with a discharge-drived CW DF

chemical laser, Proc. of SPIE Vol. 9513, 95131A-1.

PHOTOPTICS 2019 - 7th International Conference on Photonics, Optics and Laser Technology

128