A Simulation based Optimization Study for Optimum Sequencing of

Precast Components Considering Supply Chain Risks

Mohamed Mamdouh Yusuf

1

, Ahmed Karam

2

and Amr B. Eltawil

1

1

Industrial Engineering and Systems Management, Egypt-Japan University of Science and Technology (E-JUST),

POBox 179, New Borg Elarab City, Alexandria 21934, Egypt

2

Mechanical Engineering Department, Faculty of Engineering at Shoubra, Benha University, 108, Cairo, Egypt

Keywords: Precast Supply Chain, Risk Management, Discrete Event Simulation, Flow Shop Sequencing, Stochastic

Optimization.

Abstract: Unquestionably, Precast Supply Chain (PSC) abounds with many risks distributed along its echelons. Despite

that there is a wide consensus among the previous studies about the negative impact of these risks on the PSC

performance, its effect on making operational decisions in precast plants such as scheduling of Precast

Components (PCs) is still ambiguous. So, this study aims at exploring and quantifying the effect of

considering PSC risks on the optimum PCs sequences. To accomplish this, different processes of the PSC

with their associated risks are modelled via a discrete event simulation model. Then, the developed simulation

model is linked with an optimizer to generate PCs sequences that achieve on-time delivery of PCs with

minimum production costs. This optimization process is conducted twice, with and without considering

supply chain risks. Interestingly, the optimum PCs sequences generated in both cases are totally different.

More importantly, the optimized PCs sequences produced without considering risks may backfire and cause

higher production and penalty costs if they are applied to a PSC exposed to risk. So, investing in making a

reliable risk management plan of the PSC not only can cushion the risks impact but also can lead to better

sequences of PCs.

1 INTRODUCTION

By virtue of their benefits, construction by using

precast components is adopted increasingly all over

the world (Sacks et al., 2004). Moreover, this

construction method is fostered to be adopted in the

near future not only in public housing but also in

infrastructure projects by many countries (Wang et

al., 2018a). Owing to the fact that the precast

construction method is an integration between

construction and manufacturing domains (Wang et

al., 2018b), risks are divided between the construction

site and the precast plant, where production managers

shoulder delivery of Precast Components (PCs)

according to contracted due dates so as not to cause

delay in installation of PCs at construction sites. To

accomplish this target, pre-caster makes some

operational decisions such as resource allocation,

inventory management and sequencing of required

PCs. However, there are risks embedded in the

different echelons of the Precast Supply Chain (PSC)

starting from material supplying and followed by

production, transportation and approval of PCs at

construction site (Wang et al., 2018b). The PSC is a

unique multi-echelon supply chain that is different

from other supply chains because the precast

production alters between push (repetitive

production) and pull (on-time delivery to construction

sites) production all the time. This makes the PSC

more susceptible to risks which cause more costly

supply chain and handicap on-time delivery of PCs,

and as a result the advantages of using the precast

construction method can be easily wiped away (Wang

et al., 2018b). So, there exists a need to understand

how PSC risks can influence the operational decisions

of the pre-casters. Sequencing of PCs is one of the

most important operational decisions in precast

plants. It aims at ordering different types of PCs on a

number of sequential operations in order to meet the

contracted due dates, and meanwhile reducing

production costs. To date, literature is riddled with

studies on sequencing of PCs; diverse issues had been

addressed in these studies such as mold planning and

leveling (Hu, 2007), available space between

330

Yusuf, M., Karam, A. and Eltawil, A.

A Simulation based Optimization Study for Optimum Sequencing of Precast Components Considering Supply Chain Risks.

DOI: 10.5220/0007373303300337

In Proceedings of the 8th International Conference on Operations Research and Enterprise Systems (ICORES 2019), pages 330-337

ISBN: 978-989-758-352-0

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

production processes (Ko and Wang, 2011), multiple

production lines (Yang et al., 2016), incorporating of

mold manufacturing, storage and transportation

processes (Wang and Hu, 2017), demand fluctuations

of PCs (Wang and Hu, 2018) and considering

stochastic processing times (Wang et al., 2018a). On

the other hand, literature lacks studies that investigate

how multiple risks can impact the performance of the

PSC, which aims at on-time delivery of PCs with the

required quality at lowest cost incurred by supply

chain members (Tuncel and Alpan, 2010). (Wang et

al., 2018b) was the pioneer in meeting this need by

using discrete event simulation to evaluate the

performance of the PSC under multiple risks from

pre-casters’ perspective. Their conclusions

illuminated pre-casters to the criticality of each risk

embedded in different stages of the PSC. Despite this,

the question of whether considering risks in the PSC

can affect operational decisions such as PCs

sequencing, is yet to be answered. So, this study is

intended to provide numerical justification of the

value of considering the PSC’s risks in determination

of optimum PCs sequences in precast plants. This is

done by using a simulation optimization approach to

compare between the optimum PCs sequences

generated with and without considering risks in the

PSC. But before applying this approach, different

risks propagated through echelons of the PSC are

identified and assessed by using information from

literature. These risks are then incorporated into

different operations of the PSC in a discrete event

simulation model. Thereafter, this simulation model

is integrated with an optimization package to search

for the optimum PCs sequence which minimizes both

penalty and production costs.

The reamaining parts of this paper are organized

as follows. Section 2 is the literature review. Section

3 discusses the integration between the risk

managemnt and the PSC. The DES model of the PSC

is explained in Section 4. The developed simulation-

based optimization approach is illustrated in section

5. Results of the study are presented and discussed in

section 6. Finally, conclusions are drawn in section 7.

2 LITERATURE REVEW

Due to the fact that the production stage of PCs is at

the core of the PSC, many researchers addressed the

precast production planning by using either

mathematical modeling or Discrete Event Simulation

(DES). Regarding using mathematical modeling,

(Chan and Hu, 2001) was the first to indicate that the

precast production system resembled the traditional

flow shop sequencing problem where n jobs have to

be processed in the same sequence on all m machines,

and the objective is to minimize the makespan using

the appropriate order for these jobs. Despite that

literature is full of studies on flow shop sequencing

(Yenisey and Yagmahan, 2014), these studies cannot

be applied directly to the precast industry because of

the specific nature of precast production. So, (Chan

and Hu, 2001) formulated a tailored flow shop

sequencing model for precast production by

considering the realistic nature of the precast

production activities. They classified these activities

into preemptive or non-preemptive activities and

sequential or parallel activities. Their objective was

to minimize Tardiness and Earliness (T&E) penalty

costs or reduce makespan. More and more scholars

enhanced the model proposed by (Chan and Hu,

2001) by incorporating more factors. For instance,

(Ko and Wang, 2011) considered the waiting times

due to restricted buffer size between production

processes. To be closer to the realistic precast

production environment, (Yang et al., 2016)

enhanced the previous model to consider multiple

production lines as well as additional types of

production resources such as pallets and curing

machine. Despite these improvements, (Wang and

Hu, 2017) contended that addressing the precast

production problem in isolation from its supply chain

would not inevitably lead to on-time delivery of

precast components, and hence they added three

processes to the precast flow shop sequencing model.

One of them is mold manufacturing prior to

production processes, and the others are storage and

transportation to the construction sites, after

production processes. Recently, (Wang and Hu,

2018) extended their model used in (Wang and Hu,

2017) to address demand variability issue by

assignment of PCs to proper production line and

reordering of PCs. Interestingly, genetic algorithms

were a common method used in the previous studies

by virtue of its performance to tackle such

nondeterministic polynomial (NP)-hard problems.

However, academics often resort to simulation

modeling due to its superiority over mathematical

modeling to imitate complex stochastic systems

(Law, 2007), such as the PSC. To support this, (Wang

et al., 2018a) claimed to be the first to consider

stochastic processing times within PSC by using

simulation modeling to evaluate pre-optimized PCs

sequences generated in advance from mathematical

optimization. Moreover, (Wang et al., 2018b)

developed a DES model to evaluate multiple risks in

PSC. Their model was used to prioritize risks under

study based on their impact on economic and tech-

A Simulation based Optimization Study for Optimum Sequencing of Precast Components Considering Supply Chain Risks

331

nical factors. After reviewing the aforementioned

studies, it is noticed that researchers had not, as yet,

addressed precast flow shop sequencing problem

while considering multiple risks identified in the

PSC. In this work, a DES model is developed to study

the different stages of the PSC while considering the

associated risks. The simulation environment is used

to identify the optimum PCs sequences with

considering several real aspects such as the

uncertainty of PCs processing times and different

operational risks in the PSC. This simulation

optimization approach is conducted twice, with and

without considering risks in the PSC, and the

optimum PCs sequences generated in the two cases

are compared and analysed to study the effect of

considering PSC risks on the developed optimum

precast production schedules.

3 PRECAST SUUPLY CHAIN

MANAGEMENT WITH RISK

CONSIDERATIONS

This section aims at applying the risk management

procedure to the PSC management. But firstly, the

definition of PSC management should be clarified.

PSC management can be defined as the applied

techniques to link between suppliers, manufacturers,

transporters and contractors, so as to deliver PCs on

time with required quality and quantity, in a way to

reduce system costs incurred by the supply chain

members, (Simchi-Levi et al., 2000). However,

(Tuncel and Alpan, 2010) argued that overlooking of

disturbances across any supply chain can impact its

performance. Owing to this fact, contractors are used

to procure raw materials as early as possible in

traditional construction projects in order to mitigate

the consequences of supply chain uncertainties.

Unfortunately, the large sizes and heavy weights of

PCs hamper stacking them on construction sites

surrounded by urban areas, (Wang et al., 2018a). So,

integrating risk management with supply chain

management is of utmost importance for optimal PSC

management. To accomplish this integration, risks

pertained to the different parts in the PSC should be

firstly identified. Risk identification is an iterative

process that needs collaboration between different

stakeholders of the PSC. Documentation review is

one of many methods that can be used to accomplish

this process (Guide, 2001). After determination of

different risks that might impact the PSC, assessing

the identified risks is the second step in the risk

management procedure (Guide, 2001). During this

stage, many techniques can be used to assess

numerically the likelihood and impact of the

identified risks. Despite that there are many risks

associated with the different echelons of the PSC, as

documented by (Pheng and Chuan, 2001), no much

information about their probability and impact is

available in literature. Hence, only five main risks in

the PSC are considered and summarized in Table 1. It

is worth mentioning that the impact of these risks is

represented by the time delay they may impose on the

system. After risk identification and risk assessment,

the third process in the risk management procedure is

the risk response, where the risk management team

tries to reduce the probability and impact of each risk

by using different techniques such as risk aviodance,

risk mitigation, risk transfer and risk acceptance. The

risk responses mentioned in Table 1 are classified as

risk acceptance where there are no other suitable risk

responses available for the team to deal with such

risks. To sum up, Table 1 represents the output from

applying the risk identification, risk assessment and

risk response processes to the PSC. This table

identified five risks which are poor-quality materials,

machine breakdown, truck failure, poor-quality PCs

and rejection of PCs at the construction site. These

Table 1: Identified risks in PSC with its probability and impact, (Michalska and Mazurkiewicz 2011) and (Wang et al.,

2018b).

Echelons of PSC

Identified risks

Probability

Impact (hours)

Risk response

Material supplying

Low quality of

materials

22%

EXPO(15)

Reordering

materials

Precast plant

Machine breakdown

28%

EXPO(50)

Machine repairing

Logistics

Truck failure

EXPO (1000)

hrs*

Norm(2,0.71)

Truck repairing

On-site checking

Imperfections in

delivered PCs

27%

EXPO(15)

PC repairing

Rejection of PCs

after repairing

19%

Deduced from

simulation model

Reproduction of

rejected PCs

* Time between failures obeys exponential distribution.

ICORES 2019 - 8th International Conference on Operations Research and Enterprise Systems

332

risks disrupt different echelons of the PSC which are

material supplying, PC production, logistics and on-

site checking. These five risks and different

operations of the PSC will be incorporated in a

developed simulation model, as will be illustrated in

the next section.

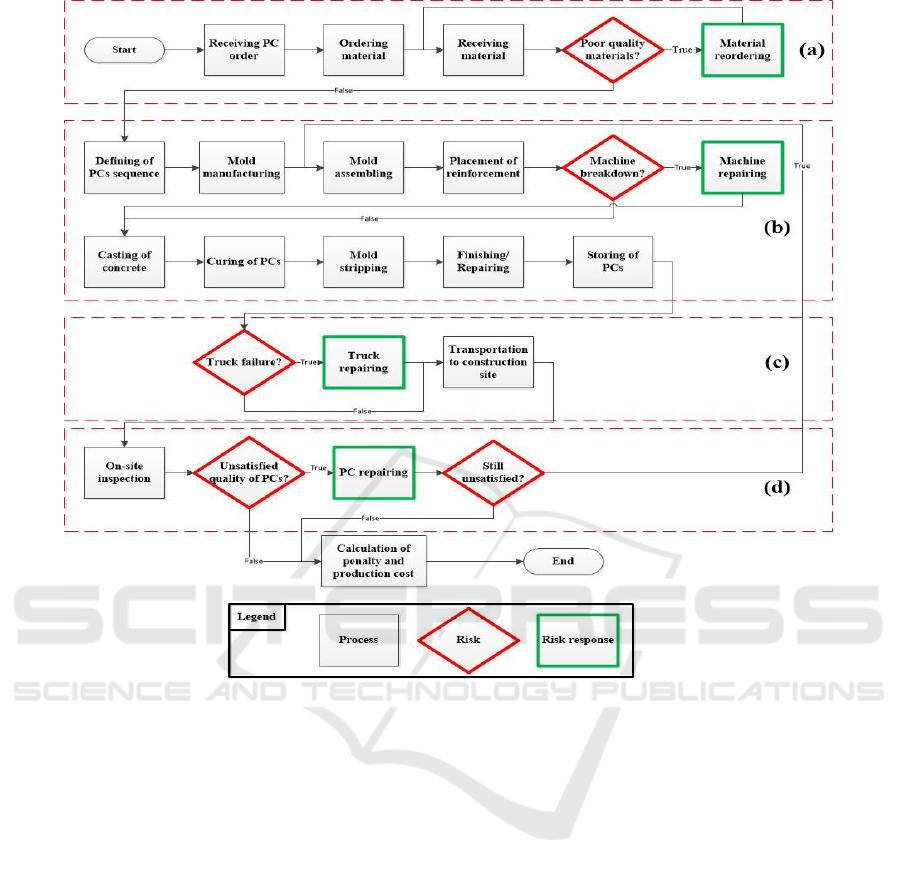

4 DEVELOPMENT OF

SIMULATION MODEL

In this section, a DES model is developed to represent

the operations at different echelons of the PSC and its

embedded risks aforementioned in Table 1. The

developed model considers the whole supply chain of

the PCs starting from processes of material supplying

to PC inspection on-site with their related risks, as

discussed in the previous section. Figure 1 shows the

different processes at each echelon of the PSC with

their corresponding risks, starting from material-

supplying stage and ending with on-site checking of

delivered PCs. During the supplying stage, PCs

orders are registered and raw materials are solicited.

After arrival of the materials, if the precast plant

rejects the delivered materials due to their poor

quality, the production of PCs will be delayed until

inventory is replenished with another shipment of

good-quality materials. After that, the production

process can start with the identified PCs sequence.

The production process begins with mold

manufacturing, followed by mold preparation and

reinforcement setting. But before proceeding to the

casting and curing processes, there is a probability

that the machines used in these processes break down,

and as a result, the repairing activities will halt the

production process. After casting and curing

processes, PCs are extracted from molds, finished and

stored at the stockyard of the precast plant. The third

stage in the PSC is logistics, where the PCs are carried

Figure 1: Schematic of PSC with multiple risks in its echelons; (a) Material supplying, (b) Precast plant, (c) Logistics and

(d) On-site checking.

A Simulation based Optimization Study for Optimum Sequencing of Precast Components Considering Supply Chain Risks

333

to the construction sites by trucks or trailers. Delivery

of PCs to the construction sites can be delayed due to

truck failure. Eventually, PCs arrive at the

construction sites; but before hoisting them to their

final destination, the responsible site engineer

scrutinizes the delivered PCs to ensure that they are

matching with construction drawings. In case of

finding defects that cannot be overlooked, the PCs are

repaired and installed at their positions. However, if

the repaired PC is still rejected by the site engineer,

an alternative PC is ordered from the precast plant.

Finally, the incurred penalty cost and production

costs are recorded for the purpose of decision making.

The processing times of the different operations of the

PSC are taken from (Wang et al., 2018b) and

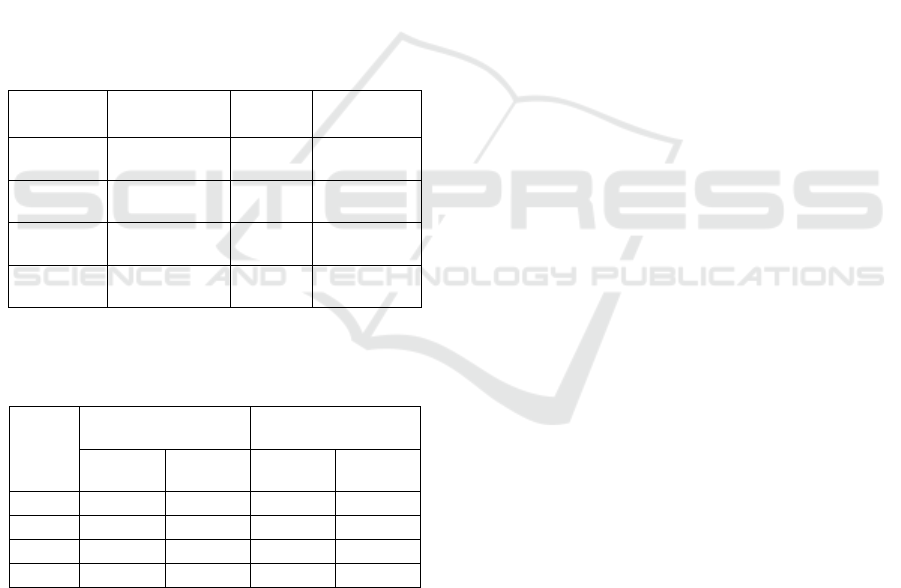

summarised in Tables 2 and 3.

Table 3: Processing times of tasks at the echelons of

material supplying and construction site.

Process

Duration (hour)

Receiving PC order

TRIA (0.05, 0.1, 0.15)

Ordering material

TRIA (0.05, 0.1, 0.15)

On-site inspection of PCs

TRIA (0.15, 0.35, 0.55)

5 THE SIMULATION-BASED

OPTIMIZATION APPROACH

The developed simulation model is integrated with an

optimization package in order to find the optimum

PCs sequences. The inputs, decision variables and

objective function are elucidated along the following

subsections.

5.1 Objective Function

Commonly, pre-casters are contemplating

minimization of production cost and penalty cost, as

reducing the first one enables them to repay financing

costs while minimizing the second one promotes their

reputation. The two objective functions are adopted

from (Wang and Hu, 2017) and (Wang et al., 2018b),

respectively. The penalty cost,

is represented

by equation (1) while the production cost,

is

represented by equation (2).

(1)

Where is the sequence of precast components;

is completion time of each job (PC) at the last

process;

is contracted due date for each job (PC) ;

and

are the tardiness and earliness penalties per

unit

= LC(s) + IC(s)

(2)

=

Where LC(s) is labor cost at sequence s; IC(s) is

inventory cost at sequence s;

and

are empirical

cost coefficients equal 3$/(labor*hour) and

12.3$/day;

is number of labours;

is time in

hours spent by precast components, ordered in a

sequence , from receiving the order to be approved

on site.

However, summing the two objectives into one

objective function may be unsuitable as the

production cost is often higher than the penalty cost,

and therefore it is expected that the production cost

will dominate the penalty cost. This situation might

lead to solutions focus only on minimizing production

costs at the expense of penalty cost. So, the two

objectives are combined into one non-dimensional

fitness function with equal weights by using a

function transformation method, mentioned in

Table 2: Processing times (hours) of the production and transportation processes in the PSC, and the due date (hours)

associated with each PC type.

PC

type

Processing times of production and transportation processes (triangular distribution (Min, Mode, Max))

Due

date

M1

M2

M3

M4

M5

M6

M7

M8

M9

1

(10.2,11,11.5)

(1.3,1.5,1.7)

(1.2,2,2.5)

(0.3,0.5,0.7)

8

(0.8,1,1.2)

(0.3,0.5,0.7)

10

(1.2,1.5,1.6)

164

2

(10,11,11.8)

(0.8,1,1.2)

(1.8,2,2.5)

(0.2,0.4,0.6)

8

(0.8,1,1.2)

(0.3,0.5,0.8)

10

(1.2,1.5,1.6)

140

3

(9,10,10.5)

(0.8,1,1.2)

(1,1.5,1.8)

(0.3,0.5,0.7)

8

(0.3,0.5,0.7)

(0.3,0.5,0.7)

10

(0.8,1,1.2)

164

4

(7.8,8,8.2)

(0.2,0.5,0.8)

(0.8,1,1.2)

(0.1,0.3,0.5)

8

(0.1,0.3,0.5)

(0.3,0.5,0.7)

10

(1.2,1.5,1.6)

160

5

(3.8,4,4.5)

(0.5,1,1.2)

(0.6,0.8,1)

(0.5,1,1.2)

8

(1.2,1.5,1.7)

(0.3,0.5,0.7)

10

(1.2,1.5,1.6)

160

6

(7.5,8,8.5)

(0.3,0.5,0.7)

(1.5,2,2.2)

(0.2,0.4,0.6)

8

(0.3,0.5,0.7)

(0.3,0.5,0.7)

10

(1.2,1.5,1.6)

164

7

(4,5,5.8)

(1.3,1.5,1.7)

(1.5,2,2.2)

(0.2,0.5,0.6)

8

(0.5,1,1.2)

(0.2,0.4,0.6)

10

(0.3,0.5,0.7)

140

8

(4.8,5,5.5)

(0.3,0.5,0.7)

(1.8,2,2.5)

(0.1,0.3,0.5)

8

(0.4,0.6,0.8)

(0.2,0.3,0.5)

10

(1.2,1.5,1.6)

164

9

(7.5,8,8.2)

(1.3,1.5,1.7)

(1.6,1.8,2)

(1,1.2,1.8)

8

(1,1.5,1.8)

(1.2,1.5,1.6)

10

(0.8,1,1.2)

140

10

(3.8,4,4.5)

(0.2,0.4,0.8)

(0.2,0.5,0.7)

(0.4,0.6,0.8)

8

(0.3,0.5,0.7)

(0.2,0.5,0.7)

10

(1.5,2,2.2)

164

M1= mold manufacturing; M2 = mold assembling; M3 = placement of reinforcement; M4 = casting; M5 = curing; M6 = mold stripping; M7 =

finishing/repairing; M8 = storing; M9 = transportation.

ICORES 2019 - 8th International Conference on Operations Research and Enterprise Systems

334

(Marler and Arora, 2005). The Fitness function,

is represented by equation (3).

(3)

Where

and

are minimum or approximate

minimum values of penalty and production costs;

and

are relative weights of penalty and

production costs.

5.2 Decision Variables

The solution of the optimization procedure is the

sequence (s) of producing ten PCs. For example, 7-9-

2-5-4-10-8-6-3-1 is a PC production sequence where

the first PC to be processed is component 7; the

second one is component 9; and so forth.

Understandably, each PC may have a different

processing time at each process in the PSC, and all

jobs (PCs) have to be processed in the same operating

sequence of all machines (processes). So, it is a

typical flow shop sequencing problem.

5.3 Constraints

Any solution becomes feasible only if each PC has a

unique ordering from 1 to 10. For example, 7-9-2-5-

4-10-7-6-3-1 is an infeasible solution because

component 7 is processed twice and component 8 is

not scheduled at all. The following constraints ensure

the feasibility of the generated solutions. For instance,

if we have a number of PCs and each PC , where

, must be processed with a sequence

number , where . A binary variable

will equal one if the PC is processed in

th

order and

zero otherwise.

(4)

(5)

5.4 The Simulation Optimization

Technique

OptQuest

®

for Arena

®

is used for simulation based

optimization. OptQuest

®

is fully integrated with

Arena

®

; it utilizes scatter search, tabu search and

neural networks as search techniques. By using these

techniques, OptQuest

®

establishes a new set of

decision variables after evaluating the objective

function generated by the simulation model in a

cyclic manner until a predefined stopping criteria is

achieved (Automation, 2013).

6 RESULTS AND DISCUSSION

In this section, the aforementioned simulation

optimization approach is applied to find out whether

considering or ignoring risks in the PSC changes the

optimum PCs sequences generated from the

optimization process. For more clarification, this

approach is conducted twice, with and without

considering risks. The obtained results are discussed

and analyzed along the following sub-sections.

6.1 In Case of Considering Risks

To launch the optimization process, the number of

replications and stopping criteria have to be specified.

Regarding the number of replications, 800

replications are used to obtain solutions with avergae

half width less than 5%. It is worth mentioning that

(Wang et al., 2018b) used 1000 replications.

Secondly, the stopping criteria is determined to

terminate the optimization process when there is no

improvement in the fitness value for a consecutive

200 simulation iterations. This number of iterations is

determined after conducting some preliminary

analysis.

Finally, the optimization process is accomplished

in about 160 minutes with 250 simulation iterations

by using a laptop with Intel(R) Core(TM) i7-6500U

2.50 GHz processor, 8.00 GB of RAM and running a

Windows 10 Education 64-bit operating system. The

top near optimum PCs sequences are listed in Table 4

with their values of penalty and production costs.

Table 4: Near Optimum sequences produced when

considering risks with its penalty and production cost.

Sequence

ID (s

ri

)

PCs sequence

Penalty

cost

Production

cost

s

r1

7-9-2-5-4-10-

8-6-3-1

479.0

10594.0

s

r2

10-9-2-5-4-7-

8-6-3-1

502.2

10636.8

s

r3

2-10-9-8-7-5-

3-6-1-4

511.9

10622.2

s

r4

7-9-2-6-4-10-

5-8-3-1

509.1

10730.3

A Simulation based Optimization Study for Optimum Sequencing of Precast Components Considering Supply Chain Risks

335

6.2 In Case of Ignoring Risks

The same procedure is repeated again, but this time

after discarding the risks. Eliminating the risks in the

developed DES model is simply done by setting the

probabilities of the five risks to zero. By trial and

error, ten replications are used to ensure generating

reliable solutions with about 5 percentage avergae

half width. Eventually, the optimization process is

completed after 500 generations and it took about 15

minutes by using the same hardware mentioned in

section 6.1. The top near optimum sequences are

listed in Table 5. To explore the penalty and

production costs of these schedules, in case of

applying them to a PSC suffered from the five

identified risks. Table 6 presents the values of the

penalty and production costs of these schedules if

they are applied to the PSC without eliminating the

original risks’ probabilities mentioned in Table 1.

Table 5: Near optimum sequences resulted in case of

ignoring risks with its penalty and production cost.

Sequence

ID (s

i

)

PCs

sequence

Penalty

cost

Production

cost

s

1

1-2-9-7-8-5-

10-6-3-4

200.4

9212.5

s

2

4-2-9-7-6-5-

10-8-3-1

203.1

9212.5

s

3

3-2-9-7-8-5-

10-4-6-1

203.3

9212.5

s

4

2-6-7-9-4-5-

8-10-3-1

204.7

9212.5

Table 6: Values of penalty and production cost when

applying near optimum schedules (s

1

to s

4

) on PSC with the

associated risks.

Seque

nce ID

With considering

risks

Percentage increase

Penalty

cost

Producti

on cost

Penalty

cost

Producti

on cost

s

1

537.4

10904.7

168%

18.4%

s

2

564.9

11128.7

178%

20.8%

s

3

525.2

10847.9

158%

17.8%

s

4

598.9

11198.5

193%

21.6%

Making a comparison between Tables 4 and 5

reveals that the near optimum PCs sequences

generated after risk consideration in PSC (schedules

from s

r1

to s

r4

) are totally different from those

obtained when neglecting the risks (schedules from s

1

to s

4

). More importantly, applying the PCs sequences

generated without considering risks (schedules from

s

1

to s

4

) to a PSC exposed to the predefined risks may

lead to poor performance in terms of both high

penalty and production costs, as shown from the

second column of Table 6. The third column of the

same table represents the percentage increase in

penalty and production costs in comparison with their

values in Table 5. These percentages illustrate how

production and penalty costs are escalated when

taking risks into consideration, and interestingly they

show that the penalty cost is more sensitive to these

risks than the production cost. This means that the

reputation and credibility of pre-casters to deliver PCs

on contracted due dates may be significantly harmed

if they ignore risks of PSC. In addition to that,

simulating PSC with risks requires a larger number of

replications (800 replications) than the number used

in case of ignoring risks (only 10 replications) and as

a result the optimization process takes longer time

when considering risks in the PSC. The long solution

time may pose a problem to production managers

who need faster ways to determine PCs sequences.

So, this might call for using other simulation

optimization methods to shorten the solution time

such as the response surface methodology.

7 CONCLUSION

Risks are ubiquitous and inevitable in the different

echelons of the PSC, and hence pre-casters need to

consider them when making operational decisions

such as sequencing of PCs. In spite of pernicious

effect of these risks propagating throughout the PSC,

as pointed in the previous studies, the effect of these

risks on determination of the optimum PCs sequences

has not yet been addressed. To bridge this gap, firstly,

echelons of the PSC accompanied by their risks are

simulated using a discrete event simulation model.

After that, it is linked with an optimization solver to

generate the optimum PCs sequences with and

without considering risks in the PSC. Making a

comparison between the optimum PCs sequences

generated with and without considering risks reveals

some remarkable points:

1- Near optimum PCs sequences obtained with

considering risks are totally different from that

produced in case of discarding risks.

2- Applying the generated near optimum PCs

sequences without considering risks on a PSC

plagued by risks causes high penalty and production

costs.

3- The penalty cost is escalated more than the

production cost in case of taking PSC risks into

consideration.

4- Considering risks in PSC increases variability

which in turn prolongs the computational time.

Having discussed all of this, this study provides

ICORES 2019 - 8th International Conference on Operations Research and Enterprise Systems

336

pre-casters with quantitative evidence for the

importance of integrating the risk management with

the PSC. Since allocating resources to conduct the

risk management procedures can help pre-casters not

only in minimizing the probability and impact of the

identified risks, but also in making better operational

decisions such as determining the optimum PCs

sequence to ensure higher service level with

minimum production cost. Hence, investing in

making a reliable risk management plan has dual

benefits to precasters. This can be backed by the study

findings that found that conducting simulation

optimization without considering risks in the PSC, to

find the optimum PCs sequence, may backfire and

lead to PCs sequences which cause high production

costs and vast deviations from the contracted due

dates. Moreover, this study provides the practitioners

with the way to link Arena

®

model with Optquest

®

to

solve precast flow shop sequencing problem.

However, using Optquest

®

for Arena

®

to solve this

problem when considering risks in the PSC took long

time due to high variability. This issue may be

worsened in case of using larger number of decision

variables and replications, which poses a problem for

pre-casters who need quicker way to make such

operational decisions. To remedy this, using another

simulation optimization methods such as response

surface methodology may be fruitful in order to

shorten the optimization time.

In line with this study, other research questions

need to be answered such as how considering the PSC

risks can influence other operational decisions such

as resource allocation and inventory management in

the precast plants.

REFERENCES

Automation, R., 2013. OptQuest for Arena, Rockwell

Automation.

Chan, W.-T., Hu, H., 2001. An application of genetic

algorithms to precast production scheduling.

Computers & Structures, 79(17), 1605–1616.

https://doi.org/10.1016/S0045-7949(01)00036-0

Guide, A., 2001. Project Management Body of Knowledge

(PMBOK® GUIDE). Project Management Institute.

Hu, H., 2007. A study of resource planning for precast

production. Architectural Science Review, 50(2), 106–

114. https://doi.org/10.3763/asre.2007.5016

Ko, C. H., Wang, S. F., 2011. Precast production scheduling

using multi-objective genetic algorithms. Expert

Systems with Applications, 38(7), 8293–8302.

https://doi.org/10.1016/j.eswa.2011.01.013

Law, A. M., 2007. Simulation modeling and analysis,

McGraw-Hill New York, 4

th

edition.

Marler, R. T., Arora, J. S., 2005. Function-transformation

methods for multi-objective optimization. Engineering

Optimization, 37(6), 551–570.

Michalska, K. Mazurkiewicz, J., 2011. Functional and

dependability approach to transport services using

modelling language. International Conference on

Computational Collective Intelligence, Springer, pp.

180–90.

Pheng, L. S., Chuan, C. J., 2001. Just-in-Time Management

of Precast Concrete Components. Journal of

Construction Engineering and Management, 127(6),

494–501. https://doi.org/10.1061/(ASCE)0733-

9364(2001)127:6(494)

Sacks, R., Easman, C. M., Lee, G., 2004. Process model

perspectives on management and engineering

procedures in the precast/prestressed concrete industry.

Journal of Construction Engineering and Management,

130(2), 206–215.

Simchi-Levi, D., Kaminsky, P., Simchi-Levi, E., 2000.

Designing and managing the supply chain. Concepts,

Strategies, and Case Studies.

Tuncel, G., Alpan, G., 2010. Risk assessment and

management for supply chain networks: A case study.

Computers in Industry, 61(3), 250–259.

https://doi.org/10.1016/j.compind.2009.09.008

Wang, Z., Hu, H., 2017. Improved Precast Production –

Scheduling Model Considering the Whole Supply

Chain. Journal of Computing in Civil Engineering,

31(4), 1–12. https://doi.org/10.1061/(ASCE)CP.1943-

5487.0000667.

Wang, Z., Hu, H., 2018. Dynamic response to demand

variability for precast production rescheduling with

multiple lines. International Journal of Production

Research, (January), 1–16.

https://doi.org/10.1080/00207543.2017.1414970

Wang, Z., Hu, H., Gong, J., 2018a. Framework for

modeling operational uncertainty to optimize offsite

production scheduling of precast components.

Automation in Construction, 86(April 2017), 69–80.

https://doi.org/10.1016/j.autcon.2017.10.026

Wang, Z., Hu, H., Gong, J., 2018b. Simulation based

multiple disturbances evaluation in the precast supply

chain for improved disturbance prevention. Journal of

Cleaner Production, 177(March), 232–244.

https://doi.org/10.1016/j.jclepro.2017.12.188

Yang, Z., Ma, Z., Wu, S., 2016. Optimized flowshop

scheduling of multiple production lines for precast

production. Automation in Construction, 72, 321–329.

https://doi.org/10.1016/j.autcon.2016.08.021

Yenisey, M. M., Yagmahan, B., 2014. Multi-objective

permutation flow shop scheduling problem: Literature

review, classification and current trends. Omega, 45,

119–135.

A Simulation based Optimization Study for Optimum Sequencing of Precast Components Considering Supply Chain Risks

337