Image-based Discrimination and Spatial Non-uniformity Analysis of

Effect Coatings

Ji

ˇ

r

´

ı Filip

1

, Radom

´

ır V

´

avra

1

, Frank J. Maile

2

and Bill Eibon

3

1

The Czech Academy of Sciences, Institute of Information Theory and Automation, Prague, Czech Republic

2

Schlenk Metallic Pigments, GmbH, Roth-Barnsdorf, Germany

3

PPG Industries, Cleveland, Ohio, U.S.A.

Keywords:

Effect Coating, Pigment, Discrimination, Cloudiness, Non-uniformity.

Abstract:

Various industries are striving for novel, more reliable but still efficient approaches to coatings characteri-

zation. Majority of industrial applications use portable instruments for characterization of effect coatings.

They typically capture a limited set of in-plane geometries and have limited ability to reliably characterize

gonio-apparent behavior typical for such coatings. The instruments rely mostly on color and reflectance char-

acteristics without using a texture information across the coating plane. In this paper, we propose image-based

method that counts numbers of effective pigments and their active area. First, we captured appearance of

eight effect coatings featuring four different pigment materials, in in-plane and out-of-plane geometries. We

used a gonioreflectometer for fixed viewing and varying illumination angles. Our analysis has shown that the

proposed method is able to clearly distinguish pigment materials and coating applications in both in-plane and

out-of-plane geometries. Finally, we show an application of our method to analysis of spatial non-uniformity,

i.e. cloudiness or mottling, across a coated panel.

1 INTRODUCTION

Coating industry uses a wide range of pigment materi-

als in combination with physical principles to achieve

eye-catching appearance of the coated surfaces that

stand out from the crowd (Maile and Reynders, 2010).

Metallic pigments rely mainly on geometrical proper-

ties of flakes and their reflectance, interference pig-

ments introduce effects due to light wave interference

with transparent substrate coated with materials of

high refractive indices, and diffraction pigments de-

compose light at a diffraction grating of a frequency

close to the wavelength of the incoming light. Note

that in practice many effect coatings are often combi-

nations of the above classes.

Majority of industrial and refinish aftermarket ap-

plications use portable instruments for characteriza-

tion of effect coatings. They typically capture be-

tween 3 and 6 standard in-plane geometries for fixed

illumination and variable observation angles. Such a

limited set of capturing geometries restricts their abil-

ity to reliably characterize gonio-apparent behavior

typical for effect coatings.

As an example can serve a car body refinishing

in Fig. 1, where coating appearance of the front and

Figure 1: Example of a car body part visually different from

the rest of body due to an insufficient number of illumina-

tion/viewing validation angles.

rear doors is not matched due to insufficient angular

sampling.

Therefore, industries are striving for novel, more

reliable but still efficient approaches to coatings char-

acterization (H

¨

ope et al., 2014). Majority of the meth-

ods rely mostly on color and reflectance characteris-

tics. Spatial information is not commonly used in in-

dustrial instruments. Currently, only two of them can

capture texture maps and use proprietary algorithm to

derive the levels of sparkliness and graininess refer-

ring to coating properties under directional and dif-

fuse illumination; however, their definitions and their

relation to typical user observations are unknown.

One of the promising approaches to effect pig-

Filip, J., Vávra, R., Maile, F. and Eibon, B.

Image-based Discrimination and Spatial Non-uniformity Analysis of Effect Coatings.

DOI: 10.5220/0007413906830690

In Proceedings of the 8th International Conference on Pattern Recognition Applications and Methods (ICPRAM 2019), pages 683-690

ISBN: 978-989-758-351-3

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

683

ments characterization is using complementary in-

formation about pigment flakes density, distribution

and orientation in the coating layer. To this end,

we perform this analysis using a gonioreflectome-

ter for in-plane and out-of-plane geometries of fixed

viewing and varying illumination angles. Next, we

propose image-based coating characterization method

that counts numbers of effective pigments and their

coverage area. Our method allows robust discrimina-

tion of different pigment materials as well as the same

material with different coating technology.

Our paper first discusses a prior work in the field

in Section 2. Then the analyzed coating samples

and acquisition method are introduced in Section 3.

Method of pigment flakes detection is outlined in Sec-

tion 4 and its results are given in Section 5. Applica-

tion of the method to spatial uniformity analysis of

coatings is presented in Section 6, while the Section 7

concludes the paper.

2 RELATED WORK

One of the first survey works on application of angle-

dependent optical effects deriving from submicron

structures of films and pigments was presented in

(Pfaff and Reynders, 1999). A detailed overview of

special effect pigments is given in (Maile et al., 2005)

and (Pfaff, 2008).

Before considering to use any novel measure-

ment geometries, one can validate current industrial

standards (DIN (DIN, 1999) and ASTM (E2194-12,

2012),(E2539-12, 2012) used for the measurement

of appearance stemming from past research of gloss

and chromatic appearance (Hunter, 1937), (McCamy,

1996). This led to development of industrial multi-

angle gonioreflectometers: MA68 and MA98 by X-

rite, BYK-mac by Gardner, and MultiFX10 by Dat-

acolor as described more in detail in (Perales et al.,

2013). These devices typically capture between 5–12

in-the-plane geometries and BYK-mac even allows

pigment texture measurement using a built-in camera.

However, when it comes to effect coatings character-

ization, these devices, due to limited set of measure-

ment geometries, often struggle to identify individual

coatings reliably (G

´

omez et al., 2016).

A wide body of research work has been devoted to

analysis of bidirectional reflectance distribution func-

tions (BRDF) (Nicodemus et al., 1977) and chromatic

properties of effect coatings. Different measurement

geometries were analyzed in (Kirchner and Cramer,

2012), (Ferrero et al., 2015). A BRDF characteri-

zation of effect coatings using a half-difference pa-

rameterization of individual flakes was presented in

(Ferrero et al., 2013). The same parameterization was

applied in (Strothk

¨

amper et al., 2016) to predict the

global color appearance of coated surfaces and to an-

alyze color estimation using multi-angle spectropho-

tometers (Ferrero et al., 2015). Characterization of

diffraction pigments was studied in (Ferrero et al.,

2016).

Method of BRDF measurement and modelling

of effect coatings was introduced in (Mih

´

alik and

ˇ

Durikovi

ˇ

c, 2013). Kim et al. (Kim et al., 2010)

proposed a novel image-based method of pearlescent

paints spectral BRDF measurement using a dedicated

goniometric setup relying on a spherical sample and

derived a non-parametric bivariate reflectance model.

Lans et al. (Lans et al., 2012) presented an empiri-

cal approach to the realistic modelling of special ef-

fect flakes fitting patch-based model parameters us-

ing sparse texture data obtained by a portable multi-

angle spectrophotometer. In (Rump et al., 2009) were

presented extensions towards gonioapparent coatings

texture measurement and modelling using bidirec-

tional texture function (BTF) (Dana et al., 1999).

Although this research advanced considerably an

understanding of the processes driving the reflectance

and chromatic appearance of effect coatings, we are

not aware of any technique simultaneously analyzing

both spatial and gonioapparent appearance of effect

coatings at pigment size level.

3 COATING SAMPLES

ACQUISITION

Effect pigments can be, based on the principle of

chroma and sparkling effect generation, roughly di-

vided into three categories (Maile et al., 2005): metal-

lic , interference, and diffractive pigments. We tested

eight effect coatings featuring four different pigment

materials and different coating technology as shown

in inset images in Fig. 2:

• Polychromatic (MultiFlect

R

) – a polychromatic

coating including a diffraction pigment varying

in liquefying agent (water - poly1,poly3, solvent

- poly2) and its density (medium - poly1, poly2

and high - poly3).

• Ultra thin pigment (Zenexo

R

) a high-sparkle con-

trast, pearlescent coating including an ultra-thin,

colored aluminium pigment: UTP.

• Aluminum – coating including aluminum flakes

of silverdollar morphology: solvent (alu1) and

water-based (alu2).

• Mica – coating including white mica flakes flakes:

solvent (mica1) and water–based (mica2).

ICPRAM 2019 - 8th International Conference on Pattern Recognition Applications and Methods

684

(a) polychromatic1 (b) polychromatic2 (c) polychromatic3 (d) UTP

(e) aluminum1 (f) aluminum2 (g) mica1 (h) mica2

Figure 2: Photos (insets) of the tested coatings and their appearance captured as BTF visualized on a sphere: three samples

containing polychromatic effect pigments (a,b,c), one sample with ultra-thin pigment (d), two samples using aluminum flakes

(e,f), and two samples featuring white mica pigment (g,h).

All samples have comparable mean particle sizes ≈25

µm.

To capture the appearance of the tested effect coat-

ings we used UTIA gonioreflectometer (Filip et al.,

2013). It has four degrees of freedom (DOF) realized

by a turntable with the measured sample (1 DOF) and

by two arms: one holding a RGB camera (1 DOF),

and one holding a LED light (2 DOF). The inner arm

holds the LED light source 1.1m from the sample

and produces a narrow and uniform beam of light.

The outer arm holds an industrial, full-frame 16Mpix

RGB camera AVT Pike 1600C. The sensor’s distance

from the sample is 2m. By combination of camera

exposures and lighting intensities we capture high-

dynamic-range RGB images of the coating, where a

single pixel occupies approximately 46µm. The an-

alyzed coating area was approximately 6x6mm. Ap-

pearance of the test coating captured as BTF is shown

in Fig. 2

4 SPATIAL ANALYSIS OF

EFFECT COATINGS

In order to identify the number of visible, i.e. active

pigment flakes, in each image I, we performed the fol-

lowing analysis in each RGB channel. We decided to

use RGB instead of common L*a*b as it is native col-

orspace of our camera and to avoid possible errors due

to a conversion process. First, we selected a candidate

whose image pixels had distinct color in the particular

color channel, e.g., for the red channel, the following

conditions had to apply

(P

R

> P

G

+ d) & (P

R

> P

B

+ d) , (1)

where P are pixel intensity values, d = 0.2, i.e., 20%

of the image dynamic range and subscripts

R,G,B

de-

note individual color channels.

However, these conditions are insufficient in the

center of the high-reflectance pigments, whose values

often tend to be achromatic. Therefore, we extended

the color information from the pixel’s neighborhood

by filtering the image I using a Gaussian filter (width

10 pixels, standard deviation σ = 1.0) to produce a fil-

tered image I

F

. The following alternative conditions

were used

(P

R

> m) & (P

G

> m) & (P

B

> m) & . . .

& (P

F

R

> P

F

G

) & (P

F

R

> P

F

B

) , (2)

where P

F

are pixels from filtered image and m = 0.9,

i.e., 90% of the image dynamic range. The equations

for the other two channels are similar.

If any of the above conditions for the tested pixel

apply, the pixel becomes a candidate for a respective

color channel. To remove visual noise outliers result-

ing from possible flakes interreflections, the image is

the subject of a morphological opening operator, dis-

Image-based Discrimination and Spatial Non-uniformity Analysis of Effect Coatings

685

poly1 poly2 poly3 alu1 alu2 mica1 mica2 UTP

original Red Green Blue

Figure 3: Example of identified flakes in individual RGB color channels for seven effect pigments (out-of-plane geometry and

illumination azimuthal angle 230

◦

, area 6×6 mm).

carding all elements with a size smaller than 3 x 3 pix-

els. Finally, the number of the remaining connected

regions and their pixel area are counted. Fig. 3 shows

examples of identified pigments in each color chan-

nel. The original image is on the bottom.

Once individual pigments are identified in each

color channel, we can use this information to derive

several computational features. The most straightfor-

ward one is the count of isolated pigments. The sec-

ond one is percentage of sample surface the coverage

by the segmented pigments, while the third one is the

average intensity of segmented pigments.

Our method depends on three parameters: chan-

nels difference threshold d, pixel intensity m, and

Gaussian filter variance σ. The first two related to a

dynamic range of all acquired images. Their settings

was relatively stable in the proximity of the values

given above, but they can be adjusted when different

coating types or different effect particle sizes are ana-

lyzed.

(a) (b)

Figure 4: The tested (a) in-plane and (b) out-of-plane illu-

mination/viewing geometry configurations.

5 RESULTS

We performed in-plane and out-of-plane analyses.

For in-plane analysis, we used the geometry shown

in Fig. 4-a, i.e., with the camera fixed at an elevation

angle 45

◦

from the surface normal, while the illumi-

nation elevation angles covered the whole plane from

-90

◦

to 90

◦

. In the case of the out-of-plane analy-

sis, we had the camera fixed at the same elevation an-

gle 45

◦

from surface normal (Fig. 4-b). The sampling

step of measurement for all three geometries was one

degree. Please note that both geometries have a blind

spot of a span of around 25

◦

due to occlusion of the

camera’s view by the arm with the light.

The captured in-plane data consisted of 180 im-

ages while the out-of-plane data consisted of 360 im-

ages of resolution 140×140 pixels corresponding to

sample size 6 × 6 mm.

The results of in-plane analysis are shown in

Fig. 5-a. The polar graph represents 180

◦

(-90

◦

,90

◦

)

covered by images taken over in-plane geometry. For

each image the values of pigments count, coverage,

and intensity are computed across seven tested ma-

terials. The polar plots visualize in-plane geometry

laterally and the camera observes material from ele-

vation angle 45

◦

(angle 135

◦

in polar plots). From

the plots we can immediately observe noisy behav-

ior of the pigment count (left), which is due to union

of isolated pigment flakes, when their intensity in-

creases towards specular highlight. In contrast, the

coverage feature (middle) produces more smooth re-

sults across entire in-plane geometry, thus allowing

clear distinguishing between the tested coatings. By

analysis of coverage one can observe that near 20

◦

as-

pecular (light elevation angle 25

◦

) is a promising can-

didate for coatings discrimination (shown as angular

range denoted as A); however, it should be sampled

together with around 55

◦

aspecular (light elevation

angle -10

◦

) to detect presence of the first order diffrac-

tion highlight present for polychromatic coatings (an-

gular range B). Further, although the intensity feature

ICPRAM 2019 - 8th International Conference on Pattern Recognition Applications and Methods

686

(a)

(b)

Figure 5: Results of (a) in-plane analysis of seven samples and (b) out-of-plane analysis of eight samples. Segmented pigments

count (left), their percentage of sample area coverage (middle), and average intensity (right).

(right) shows relatively noisy behavior too, the angles

close to specular reflection allow discrimination be-

tween the water/solvent-based coatings technologies

(angular range C).

The results of out-of-plane analysis are shown in

Fig. 5-b. The polar graph represents 360

◦

covered by

images taken over out-of-plane geometry. Again, for

each image the values of pigments count, coverage,

and intensity are computed across eight tested mate-

rials. In this case, we observe the geometry from the

overhead, where the camera is at azimuth 0

◦

. Differ-

ent azimuthal illumination directions produce the be-

havior very similar to the one for the in-plane geome-

try. Again, the percentage of area coverage produces

the smoothest results and optimal discrimination az-

imuthal angles are near 160

◦

and 200

◦

(denoted by

areas A) in combination with 100

◦

and 260

◦

(denoted

by areas B) from a camera azimuth. The intensity

image shows a again promising range of angles for

coating technologies discrimination denoted as C.

In both cases, it is clear that the coverage and in-

tensity features are able clearly separate not only dif-

ferent coating materials, but also their different vari-

ants due to coating technology.

6 SPATIAL UNIFORMITY OF

EFFECT PIGMENTS

Finally, we applied the proposed pigment segmenta-

tion results to analysis of a spatial uniformity of effect

Figure 6: An example of cloudiness / mottling visible as

spatial nonuniformity on: (left) a set of coated panels,

(right) a part of car body.

coatings. These visually disturbing non-uniform arti-

facts (see Fig. 6) are in coating industry denotes as

cloudiness or mottling. Therefore, their reliable de-

tection is crucial for quality control of coating pro-

duction process, where non-uniform coating applica-

tion produces cloudy artifact visible at specific, typ-

ically diffuse, illumination conditions. The cloudi-

ness is caused by a coating composition, movement of

spray-gun over the coated object, shape of the nozzle,

air pressure and other parameters in painting applica-

tion and solidification process. As such artifacts are

often barely visible, one can either rely on a dedicated

hardware for cloudiness evaluation or on knowledge

of a trained expert. Based on this, the parameters of

the coating process are iteratively adjusted till an ac-

ceptable coating uniformity is reached.

We tackle this problem by proposing a technique

relying on behavior of isolated pigments contours in

each captured image described in Section 4. Let

I be a single RGB image from out-of-plane geom-

Image-based Discrimination and Spatial Non-uniformity Analysis of Effect Coatings

687

etry, f

B

(I

s

(i), d, m, σ) is a function generating bi-

nary image containing only pixels indicating pres-

ence of segmented flakes in a selected RGB chan-

nel s, where d, m, σ are segmentation parameters, and

i ∈ {0

◦

, 360

◦

} is azimuthal angle across out-of-plane

geometry. First, we sum up the detected flakes con-

tribution across all RGB channels to obtain a single

binary image

A

i

=

∑

s={R,G,B}

f

B

(I

s

(i);d, m, σ) . (3)

Then, a density map of pigment flakes is obtained as

D =

360

◦

∑

i=1

◦

A

i

. (4)

As we want also evaluate differences due to non-

uniform orientation of pigment flakes we compute

also pixel-wise standard variance of pigments pres-

ence across different azimuthal angles, we compute a

variation map as

V =

1

360

360

◦

∑

i=1

◦

(A

i

− D)

2

. (5)

We apply these two features (density D and vari-

ance V) on two effect coatings mica1, mica2. As we

want to capture also non-uniformity due to pigment

disorientation, we decided to use out-of-plane geom-

etry described in Fig. 4-b. Due to optical diffraction

effect resulting in limited depth of field for viewing el-

evation angle 45

◦

, we restricted the region-of-interest

in camera direction to guarantee sharp texture across

entire analyzed area as shown in Fig. 7-a. The size of

analyzed image is 1300×717 pixels corresponding to

area 60×30 mm.

(a) (b)

Figure 7: (a) A region of interest selection on the sample

plane and its relation to measured out-of-plane geometry,

(b) an overhead scheme of illumination and viewing condi-

tions for obtaining cloudiness reference images.

The obtained uniformity maps using both pro-

posed features side-by-side with enhanced photo-

graph of the coated panels are shown in Fig. 8.

These reference images (left) were obtained by using

quarter-hemisphere diffuse illumination and nearly

retro-reflective viewing angle as shown schematically

in Fig. 7-b (light and camera elevation angles are 45

◦

and their distances from the sample are 0.7 m). The

original feature images are rather noisy, so we fil-

tered these images using a median filter with a ker-

nel size 100×100 pixels. The filtered images on the

right can be regarded as uniformity maps, highlight-

ing differences between spatial locations due to a dif-

ferent density of detected pigment flakes. The black

banding is due to the filter kernel size. When compar-

ing the results to the reference image on the left, we

can observe, that although both features correlate with

the reference, a slightly better performance in non-

uniformity prediction was obtained using the density

feature. Fig. 8 also shows a dynamic range of values

in non-uniformity maps for both tested materials and

features. Higher values for mica1 are due to a higher

contrast in flakes structure.

7 CONCLUSION

We proposed a gonioapparent effect coatings charac-

terization method based on using a total area occupied

by pigment flakes at a given image threshold level.

Our analysis has shown that the proposed method is

able to clearly distinguish pigment materials and coat-

ing applications in both in-plane and out-of-plane ge-

ometries. Results also revealed that one can identify

a sparse set of geometries that perform the best in

differentiation of the coatings materials and different

coating technology. These geometries can be used to

obtain complementary information to that obtained by

commercial instruments and can be regarded as pos-

sible measurement geometry candidates for future in-

struments. Finally, we have shown application of our

image segmentation results over out-of-plane geome-

try, to assessment of coating spatial non-uniformity,

i.e. cloudiness or mottling, of effect coatings. To

sum up, our results show that using gonioapparent

image-based data is a promising way of effective and

reliable characterization of effect coatings as well as

for pigment spatial uniformity analysis. In future, we

plan to derive a computational measure of spatial non-

uniformity of effect coatings based on combination of

uniformity map histogram and frequency analysis.

ACKNOWLEDGMENT

This research has been supported by the Czech Sci-

ence Foundation grant GA17-18407S.

ICPRAM 2019 - 8th International Conference on Pattern Recognition Applications and Methods

688

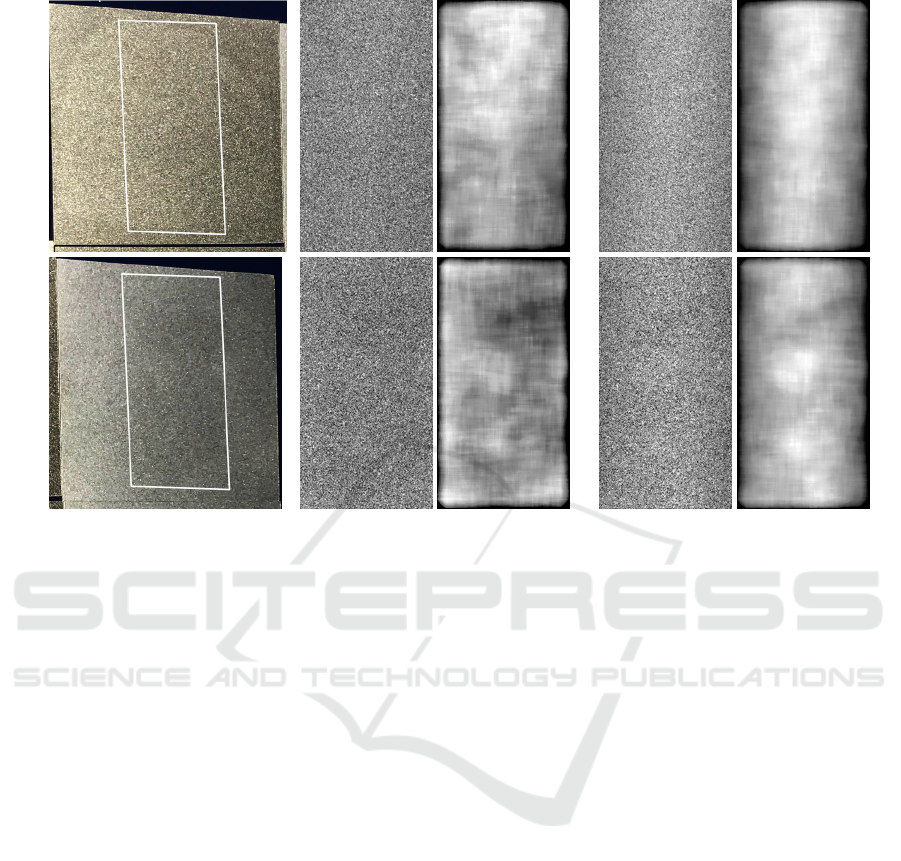

(a) reference photo (b) density filtered (c)variance filtered

mica1

dynamic range 8.65

dynamic range 0.038

mica2

dynamic range 6.03

dynamic range 0.027

Figure 8: Results of out-of-plane spatial uniformity analysis of samples mica1 and mica2: (a) reference cloudiness obtained

by SW enhancement of the coated panel photograph, (b,c) results of the density D and variance V features, respectively, and

their filtering using median filter. Dynamic ranges of individual features are included.

REFERENCES

(1999). Deutsches Institut f

¨

ur Normung e.V., DIN 55945.

Dana, K., van Ginneken, B., Nayar, S., and Koenderink, J.

(1999). Reflectance and texture of real-world surfaces.

ACM Transactions on Graphics, 18(1):1–34.

E2194-12, A. (2012). Standard practice for multiangle

color measurement of metal flake pigmented materi-

als. West Consh. PA: ASTM Inter., 2012.

E2539-12, A. (2012). Standard practice for multiangle color

measurement of interference pigments. West Con-

shohocken PA: ASTM Inter., 2012.

Ferrero, A., Bernad, B., Campos, J., Perales, E., Vel

´

azquez,

J. L., and Mart

´

ınez-Verd

´

u, F. M. (2016). Color charac-

terization of coatings with diffraction pigments. JOSA

A, 33(10):1978–1988.

Ferrero, A., Campos, J., Perales, E., Mart

´

ınez-Verd

´

u, F. M.,

Van der Lans, I., and Kirchner, E. (2015). Global color

estimation of special-effect coatings from measure-

ments by commercially available portable multiangle

spectrophotometers. Journal of the Optical Society of

America A, 32(1):1–11.

Ferrero, A., Rabal, A., Campos, J., Mart

´

ınez-Verd

´

u, F.,

Chorro, E., Perales, E., Pons, A., and Hernanz, M. L.

(2013). Spectral brdf-based determination of proper

measurement geometries to characterize color shift of

special effect coatings. Journal of the Optical Society

of America A, 30(2):206–214.

Filip, J., V

´

avra, R., Haindl, M., Zid, P., Krupicka, M.,

and Havran, V. (2013). BRDF slices: Accurate adap-

tive anisotropic appearance acquisition. In Conference

on Computer Vision and Pattern Recognition, pages

4321–4326.

G

´

omez, O., Perales, E., Chorro, E., Burgos, F. J., Viqueira,

V., Vilaseca, M., Mart

´

ınez-Verd

´

u, F. M., and Pujol, J.

(2016). Visual and instrumental assessments of color

differences in automotive coatings. Color Research &

Application, 41(4):384–391.

H

¨

ope, A., Koo, A., Verdu, F. M., Leloup, F., Obein, G.,

W

¨

ubbeler, G., Campos, J., Iacomussi, P., Priit, J., and

K

¨

allberg, S. (2014). Multidimensional reflectometry

for industry (xd-reflect) a european research project.

In Electronic Imaging, number 9018-04, pages 1–11.

Hunter, R. S. (1937). Methods of determining gloss. NBS

Research paper RP, 958.

Kim, D. B., Seo, M. K., Kim, K. Y., and Lee, K. H. (2010).

Acquisition and representation of pearlescent paints

using an image-based goniospectrophotometer. Opti-

cal engineering, 49(4):043604.

Kirchner, E. and Cramer, W. (2012). Making sense of mea-

surement geometries for multi-angle spectrophotome-

ters. Color Research & Application, 37(3):186–198.

Lans, I. v. d., Kirchner, E., and Half, A. (2012). Accurate

appearance-based visualization of car paints. In Pro-

ceedings of International Conference on Computer

Graphics, volume 2012, pages 17–23.

Maile, F. J., Pfaff, G., and Reynders, P. (2005). Effect pig-

Image-based Discrimination and Spatial Non-uniformity Analysis of Effect Coatings

689

ment – past, present and future. Progress in Organic

Coatings, 54(3):150 – 163.

Maile, F. J. and Reynders, P. (2010). A colorful menagerie

of platelets for transparent effect pigments. Asia Pa-

cific Coatings Journal, 23(1):14–17.

McCamy, C. (1996). Observation and measurement of the

appearance of metallic materials. part i. macro appear-

ance. Color Research & Application, 21(4):292–304.

Mih

´

alik, A. and

ˇ

Durikovi

ˇ

c, R. (2013). Metallic paint

appearance measurement and rendering. Journal

of Applied Mathematics, Statistics and Informatics,

9(2):25–39.

Nicodemus, F., Richmond, J., Hsia, J., Ginsburg, I., and

Limperis, T. (1977). Geometrical considerations and

nomenclature for reflectance. NBS Monograph 160,

pages 1–52.

Perales, E., Chorro, E., Viqueira, V., and Mart

´

ınez-Verd

´

u,

F. M. (2013). Reproducibility comparison among

multiangle spectrophotometers. Color Research &

Applications, 38(3):160–167.

Pfaff, G. (2008). Special effect pigments: technical basics

and applications. Vincentz Network GmbH & Co KG,

Hannover.

Pfaff, G. and Reynders, P. (1999). Angle-dependent opti-

cal effects deriving from submicron structures of films

and pigments. Chemical reviews, 99(7):1963–1982.

Rump, M., Sarlette, R., and Klein, R. (2009). Efficient re-

sampling, compression and rendering of metallic and

pearlescent paint. In Magnor, M., Rosenhahn, B., and

Theisel, H., editors, Vision, Modeling, and Visualiza-

tion, pages 11–18.

Strothk

¨

amper, C., Hauer, K.-O., and H

¨

ope, A. (2016).

How to efficiently characterize special effect coatings.

Journal of the Optical Society of America A, 33(1):1–

8.

ICPRAM 2019 - 8th International Conference on Pattern Recognition Applications and Methods

690