Formation of Low Resistance Contacts to p-type 4H-SiC

using Al-Film Source Laser Doping

Kento Okamoto

1

, Toshifumi Kikuchi

1

, Akihiro Ikeda

2

, Hiroshi Ikenoue

1

and Tanemasa Asano

1

1

Graduate School of Information Science and Electrical Engineering, Kyushu University, 744 Motooka,

Nishi-ku, Fukuoka, Japan

2

Department of Computer and Information Sciences, Sojo University, 4-22-1 Ikeda, Nishi-ku, Kumamoto, Japan

{okamoto@fed., asano@}ed.kyushu-u.ac.jp

Keywords: 4H-SiC, Ohmic Contact, Laser Doping, Specific Contact Resistance, Aluminum, p-type, Ti/Al.

Abstract: Impact of laser doping on the formation of ohmic contacts to 4H-SiC has been investigated. The laser doping

was performed by irradiating pulse-width stretched KrF excimer laser to an Al film coated on the surface of

4H-SiC. Doping and contact formation on the carbon face of 4H-SiC were investigated. The doping was

carried out while keeping the sample at room temperature. It is found that the laser doping is able to introduce

Al up to a concentration as high as 5×10

21

cm

-3

. As a result of heavy doping, the contact made of Ti/Al

metallization provides the ohmic contact whose specific contact resistance as low as 4.0×10

-6

Ωcm

2

without

additional heat treatment. The specific contact resistance is lower than that reported for ohmic contacts formed

by using ion implantation.

1 INTRODUCTION

The electric power consumption is expected to

increase significantly, due to the rise of electric

vehicles and artificial intelligence. Development of

low-loss power devices is, therefore, highly

demanded. Although silicon (Si) power devices have

been mainstream, they are facing the physical limit of

Si. Wide-gap semiconductors such as silicon carbide

(SiC) and gallium nitride are attracting great attention

for next-generation power devices.

4H-SiC (hexagonal silicon carbide) has the figure

of merit due to its superior physical properties such as

high breakdown voltage, excellent thermal

conductivity, and high saturation drift-velocity of

electrons. Therefore, it is regarded as one of the most

promising materials of power devices. Processing

technology of 4H-SiC devices has been well

advanced as they become of practical use. However,

the formation of low resistance contacts to 4H-SiC

remains as a challenge. Because the bandgap of 4H-

SiC is much wider than that of Si, the potential barrier

becomes large at the interface between the metal and

the semiconductor and, consequently, the carriers

(electrons and holes) hardly flows across the

interface. On the other hand, devices made of 4H-SiC

such as insulated gate bipolar transistors (IGBTs) are

expected to carry a much higher current than those

made of Si (Usman and Nawaz, 2014). Therefore,

very-low resistance contacts are highly demanded.

To reduce the ohmic contact resistance, reduction

of the barrier height at the metal/semiconductor

interface and/or an increase in doping concentration

near the semiconductor surface is needed. Reduction

of barrier height suffers from the constraint of metal

work function. p-type heavy-doping of 4H-SiC has

remained as one which we should develop since the

acceptor energy level is extremely large (0.29 eV for

B and 0.18 eV for Al) and, therefore, the activation

ratio is small. Ion implantation is widely used as the

doping method to form a heavily doped layer at the

semiconductor surface (Frazzetto et al., 2011).

However, it requires high temperature annealing at

about 1700ºC to activate the implanted dopant atoms

(Ito, Tsukimoto and Murakami, 2006). This high

temperature annealing induces undesirable

phenomena such as generation of 3C polytype crystal

structure and deterioration in yield. Therefore, low-

temperature processing is preferred. Low temperature

processing is also mandatory to form ohmic contacts

to the back side of the wafer where the device active

region has fabricated on the front side.

We have shown that a heavily doped layer can be

formed by laser irradiation to an Al film deposited on

the 4H-SiC surface. A generation of Al plasma during

294

Okamoto, K., Kikuchi, T., Ikeda, A., Ikenoue, H. and Asano, T.

Formation of Low Resistance Contacts to p-type 4H-SiC using Al-Film Source Laser Doping.

DOI: 10.5220/0007583002940298

In Proceedings of the 7th International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS 2019), pages 294-298

ISBN: 978-989-758-364-3

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

laser irradiation was observed by using optical

emission spectroscopy (Ikeda et al., 2016). We

suppose that high temperature molten Al is formed on

the 4H-SiC surface by laser irradiation and it acts as

the dopant source and also as the heat reservoir.

In this paper, we show that very-low resistance

contacts can be formed by using the laser doping with

an Al film, which does not require high temperature

annealing. The carbon-face (C-face) of 4H-SiC is

used in the investigation since this face composes the

back side of conventional MOS-gated devices.

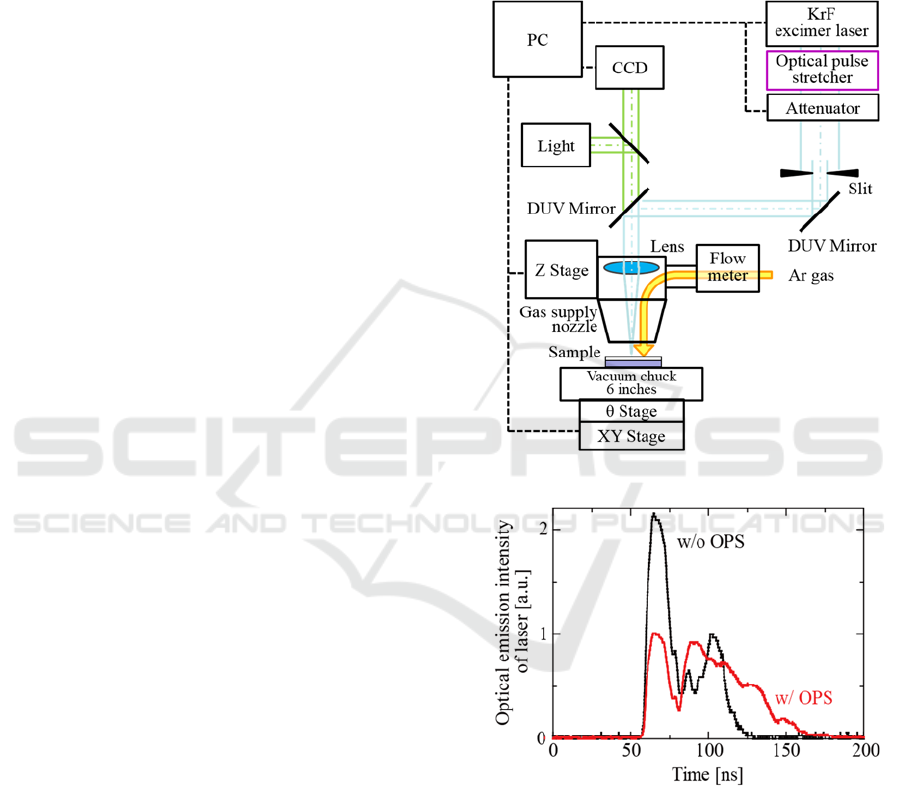

2 EXPERIMENTAL

A non-doped semi-insulating 4H-SiC substrate was

adopted in order to avoid the wraparound current at

the time of measurement. The experimental setup

used was schematically shown in Fig. 1. An Al thin

film (120 nm thick) was deposited on the C-face of

the substrate by DC magnetron sputtering. The Al-

coated 4H-SiC chip was chucked with a vacuum

pump to a computer-controlled mechanical scanning

stage and the KrF excimer laser (wavelength: 248

nm) was irradiated while scanning the stage. The laser

irradiation condition was as follows; fluence: 2-4

J/cm

2

, number of laser pulses: 1-36 shots, and

frequency: 100 Hz. The laser spot size was adjusted

with a slit to be ~300 µm in the direction

perpendicular to the scanning direction while the slit

was open along the scanning direction. The original

laser pulse was expanded by using an optical pulse

stretcher (OPS) to suppress laser ablation of the

surface and to increase the heat retention time by laser

irradiation (See Fig. 2) (Ikeda et al., 2017). Ar gas

blowing to the sample surface was employed to keep

the surface unreacted during irradiation. After the

laser irradiation, the Al film remained in the irradiated

area as well as the unirradiated area was etched with

phosphoric acid. The Al etching was followed by CF

4

plasma and O

2

plasma etchings to remove Si and C

based materials produced at the surface by the laser

irradiation. The CF

4

plasma etching condition was as

follows; the pressure was 30 Pa, the etching time was

10 min, and the discharge power was 100 W. The O

2

plasma etching condition was as follows; the pressure

was 100 Pa, the etching time was 5 min, and the

discharge power was 400 W. Furthermore, the oxide

film at the surface was etched with buffered

hydrofluoric acid (BHF, 6%). The above cleaning

processes by plasma and BHF were repeated several

times. A 100 nm-thick Ti film and a 400 nm-thick Al

film were sequentially deposited on the treated

surface by using a sputtering system to form a metal

contact of Al/Ti/p-SiC structure. The Ti/Al electrode

is one of the promising contact metals to p-type SiC

(Crofton et al., 2002), (Ito, Tsukimoto and Murakami,

2006). The deposited metal electrode was patterned

by using photolithography. The electrode size is 400

× 100 µm. Five sets of test patterns whose electrode

spacing was modulated were prepared on a test chip.

Figure 1: Schematic of the experimental setup.

Figure 2: Waveforms of laser pulse intensity produced with

and without optical pulse stretcher (OPS).

The sample surface was observed with a scanning

electron microscope (SEM). The current-voltage (I-

V) characteristic was evaluated by a semiconductor

parameter analyzer, Agilent 4156C. The depth profile

of aluminum from the doped layer surface was

obtained by secondary ion mass spectrometry

(SIMS). The specific contact resistance was evaluated

by the transfer length method (TLM) based on a

transmission line model (Crofton et al., 2002).

Formation of Low Resistance Contacts to p-type 4H-SiC using Al-Film Source Laser Doping

295

3 RESULTS AND DISCUSSION

3.1 Al Doping

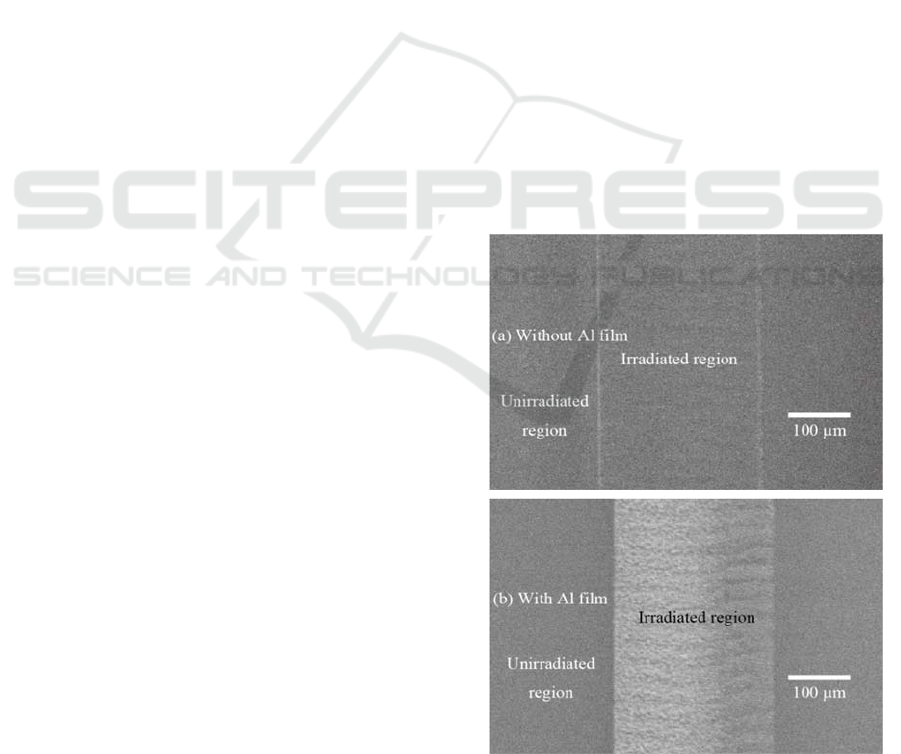

Figures 3(a) and 3(b) show the SEM images of the

sample surfaces irradiated without and with the Al

film, respectively. The laser scanned area of the

sample irradiated with the Al film (Fig. 3(b)) shows a

brighter contrast than the other areas, while the laser

scanned area in the sample without the Al films (Fig.

3(a)) shows a similar brightness to the other areas.

Since the potential increase due to p-type formation

results in the enhanced emission of secondary

electrons in SEM, these results indicate that p-type

doping of 4H-SiC can be performed by the laser

irradiation to an Al film deposited on the 4H-SiC

substrate.

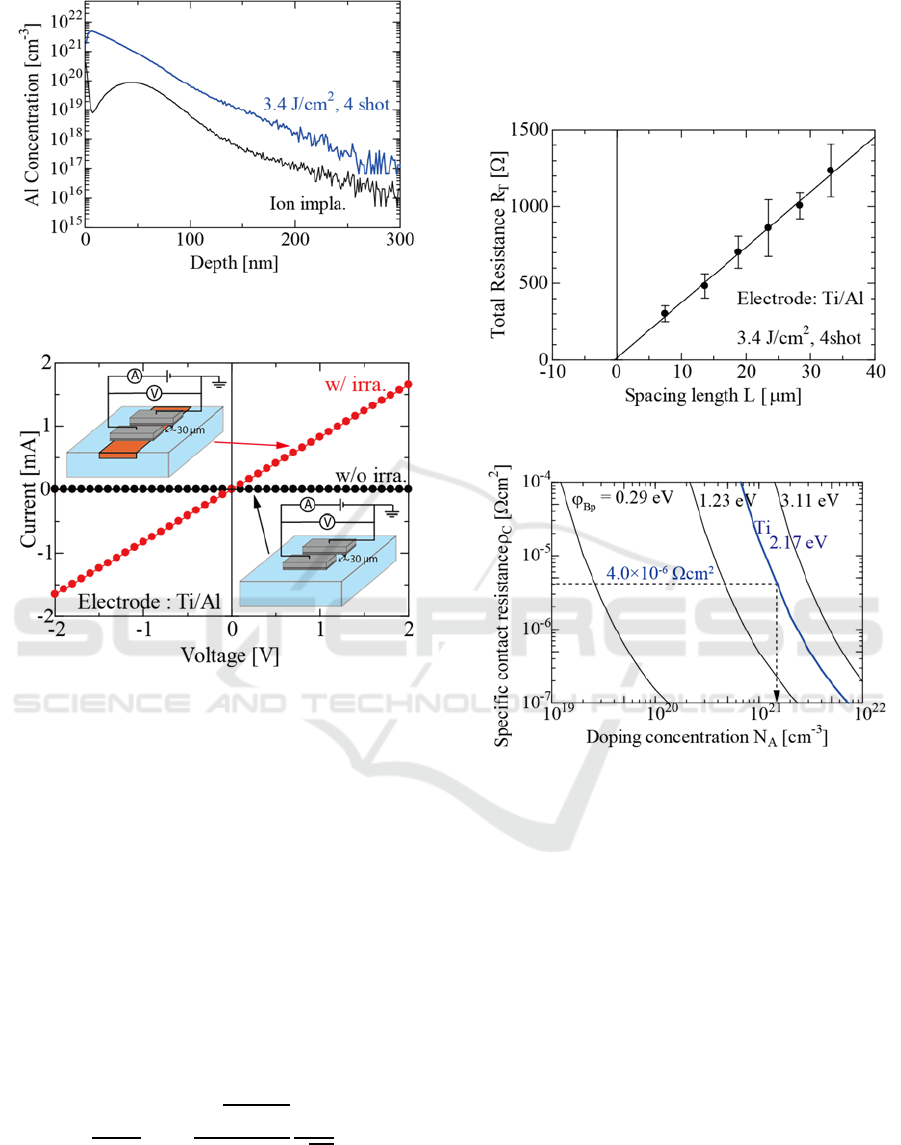

In order to verify the doping of Al, the presence

of Al in 4H-SiC and depth distribution were measured

by using SIMS. Figure 4 shows the depth profiles of

Al concentration obtained by laser doping at 3.4 J/cm

2

with 4 shots. We find that Al as high as 5×10

21

cm

-3

in concentration is introduced by the laser doping. In

the figure, the depth profile of Al ion-implanted at 40

keV to a dose of 5.0 ×10

14

cm

-2

was also plotted as a

reference. The profile of implanted Al well agrees

with the theoretical prediction, which indicates that

the SIMS measurement gives accurate concentration

and profile of Al. We find from a comparison of the

two profiles shown in Fig. 4 that the laser doping

produces a highly Al-doped layer particularly in the

vicinity of the surface.

3.2 Electrical Characteristics

Figure 5 shows the change in I-V characteristic

between two electrodes formed on the samples with

and without laser irradiation. The gap spacing

between the electrodes was about 30 µm. The probe

voltage was swept from -2 to 2 V. In the sample

without laser irradiation, the current hardly flows.

The current value was several pA at the maximum.

On the other hand, in the sample with laser irradiation

using the Al thin film, current up to several mA flows,

which indicates that the resistance markedly

decreased in the laser irradiated region. Besides, the

I-V curve shows a good linear relation, suggesting

that a highly doped p-type layer was formed by the

laser doping.

Figure 6 shows the total resistance (R

T

) between

two electrodes as a function of the

spacing

length

(L)

between the two electrodes. R

T

was calculated from

the slope of the I-V characteristic from which a linear

relation

was

obtained.

In

order

to

accurately

derive

the specific contact resistance, TLM characteristic

shown in Fig. 6 was adopted. From the TLM

characteristics, an effective transfer length (L

T

) and

contact resistance (R

C

) can be obtained from the x-, y-

intercept of straight line approximated from the plot,

respectively. L

T

corresponds to the distance at which

the voltage or current attenuates to 1/e. The specific

contact resistance (ρ

C

) is derived by multiplying R

C

,

L

T

, and the width (W) of the doping region:

.

(1)

From the experimental results, ρ

C

is evaluated to be

approximately 4.0×10

-6

Ωcm

2

. This value is

significantly lower than the value of the contact

resistance obtained by the ion implantation method as

follows. In case of Ti/Al contacts to p-type 4H-SiC

doped to a concentration of ~10

19

cm

-3

, ρ

C

=2×10

-3

-

8×10

-4

Ωcm

2

(Ito, Tsukimoto and Murakami, 2006). In

case of Ti/Al/Ni contact to p-type 4H-SiC doped to a

concentration of 10

20

cm

-3

, ρ

C

=2.3×10

-4

Ωcm

2

(Vivona

et al., 2017). In case of Ni/Al contacts to p-type 4H-

SiC doped to a concentration of 10

19

cm

-3

, ρ

C

= 3×10

-5

-

8×10

-6

Ωcm

2

(Vang et al., 2006). In addition, high-

temperature post-deposition annealing (PDA) at about

1000°C is usually required to form a good ohmic

contact on 4H-SiC. The PDA causes chemical

reactions between 4H-SiC and the metals at the

interface to form silicide and carbide alloys.

Figure 3: SEM images of the surfaces of SiC samples (a)

irradiated without the Al film and (b) irradiated with the Al

film.

PHOTOPTICS 2019 - 7th International Conference on Photonics, Optics and Laser Technology

296

Figure 4: Depth profiles of Al introduced in 4H-SiC by

using laser doping and ion implantation.

Figure 5: Change in I-V characteristic between the

electrodes formed on samples with and without laser

irradiation.

3.3 Theoretical Consideration

Specific contact resistance is a function of the

potential barrier height at the interface. In addition, it

is known that the specific contact resistance strongly

depends on the doping concentration and is reduced

with the increase of doping concentration. In a contact

of very heavily doped semiconductor, the flow of

carriers across the interface is dominated by the field

emission (FE). That is, for N

A

≥10

19

cm

-3

, ρ

C

is

dominated by the tunneling process and decrease

rapidly with increased doping. Theoretical analysis of

FE gives the specific contact resistance described by

the following equation: (Sze, 2007)

∗∗

exp

2

∗

ħ

√

(2)

where k is the Boltzmann constant, q is the

elementary charge, A

**

is the effective Richardson

constant, T is the absolute temperature,

is the

permittivity of 4H-SiC (Saito et al., 2004),

∗

is the

effective mass of the light hole (Lindefelt, 1998),

is barrier height, ħ is the reduced Planck constant, and

N

A

is the doping concentration of acceptor.

Figure 6: Resistance values of a TLM pattern.

Figure 7: Doping concentration dependence of specific

contact resistance calculated for various barrier height.

Figure 7 shows the doping concentration

dependence of specific contact resistance calculated

from Eq. (2) for various barrier height. The barrier

height calculated from the work function of Ti (4.33

eV) (Huang et al., 2012) and the electron affinity of

4H-SiC is 2.17 eV. The specific contact resistance

calculated for this value is shown by the solid line in

Fig. 7. The theory suggests that doping concentration

of about 10

21

cm

-3

is required to obtain 4.0×10

-6

Ωcm

2

.

This doping concentration agrees with experimental

results of SIMS shown in Fig. 4.

4 CONCLUSIONS

We have investigated the formation of low resistance

p-type contacts by using laser doping with Al thin

film as the source on the C-face of 4H-SiC. Al doping

Formation of Low Resistance Contacts to p-type 4H-SiC using Al-Film Source Laser Doping

297

to the concentration as high as 5×10

21

cm

-3

can be

performed

by the irradiation of pulsed excimer laser

to the Al film coated 4H-SiC sample kept at room

temperature. Owing to the heavy doping, the contact

made of Ti/Al metallization provides an ohmic

contact whose specific contact resistance as low as

4.0×10

-6

Ωcm

2

without additional heat treatment.

This specific contact resistance is lower than that

reported for ohmic contacts formed by using ion

implantation. Thus the laser doping with Al thin-film

source is a promising candidate to form low

resistance ohmic contacts of 4H-SiC power devices.

ACKNOWLEDGEMENTS

This work is supported in part by Grants-in-Aid for

Scientific Research, KAKENHI, (No. JP17K06387

and No. JP16H02342) from Japan Society for the

Promotion of Science. A part of this work was carried

out by using the facility of Department of Gigaphoton

Next GLP.

REFERENCES

Crofton, J. et al., 2002. ‘Finding the optimum Al–Ti alloy

composition for use as an ohmic contact to p-type SiC’,

Solid-State Electronics. Pergamon, 46, pp. 109–113.

Frazzetto, A. et al., 2011. ‘Structural and transport

properties in alloyed Ti/Al Ohmic contacts formed on

p-type Al-implanted 4H-SiC annealed at high

temperature’, Journal of Physics D: Applied Physics,

44.

Huang, L. et al., 2012. ‘Low resistance Ti Ohmic contacts

to 4H-SiC by reducing barrier heights without high

temperature annealing’, Applied Physics Letters, 100,

pp. 1–5.

Ikeda, A. et al., 2017. ‘Increased doping depth of Al in wet-

chemical laser doping of 4H-SiC by expanding laser

pulse’, Materials Science in Semiconductor Processing.

Elsevier Ltd, 70, pp. 193–196.

Ikeda, A. et al., 2016. ‘Al doping of 4H-SiC by laser

irradiation to coated Al film and its application to

junction barrier Schottky diode’, Japanese Journal of

Applied Physics, 55.

Ito, K., Tsukimoto, S. and Murakami, M., 2006. ‘Effects of

Al ion implantation to 4H-SiC on the specific contact

resistance of TiAl-based contact materials’, Science

and Technology of Advanced Materials, 7, pp. 496–

501.

Lindefelt, U., 1998. ‘Doping-induced band edge

displacements and band gap narrowing in 3C–, 4H–,

6H–SiC, and Si’, Journal of Applied Physics, 84, pp.

2628–2637.

Saito, W. et al., 2004. ‘Theoretical limit estimation of

lateral wide band-gap semiconductor power-switching

device’, Solid-State Electronics, 48, pp. 1555–1562.

Usman, M. and Nawaz, M., 2014. ‘Device design

assessment of 4H-SiC n-IGBT - A simulation study’,

Solid-State Electronics. Elsevier Ltd, 92, pp. 5–11.

Vang, H. et al., 2006. ‘Ni-Al ohmic contact to p-type 4H-

SiC’, Superlattices and Microstructures, 40, pp. 626–

631.

Vivona, M. et al., 2017. ‘Electrical and structural properties

of surfaces and interfaces in Ti/Al/Ni Ohmic contacts

to p-type implanted 4H-SiC’, Applied Surface Science.

Elsevier B.V., 420, pp. 331–335.

Sze, S., 2007. Physics of Semiconductor Devices, Jhon

Wiley and Sons, Inc., Hoboken, New Jersey, 3

nd

edition.

PHOTOPTICS 2019 - 7th International Conference on Photonics, Optics and Laser Technology

298