Thermal Analysis for Quantum Cascade Lasers using Experiments,

Simulations and Structure Function Obtained by Static Measurement

Shigeyuki Takagi

1

, Hirotaka Tanimura

1

, Tsutomu Kakuno

2

, Rei Hashimoto

2

and Shinji Saito

2

1

School of Engineering, Tokyo University of Technology, 1404-1, Katakura-cho, Hachioji city, Tokyo, Japan

2

Coporated Manufacturing Center, Toshiba Corporation, 8 Shinsugita-cho, Isogo Ward, Yokohama-city, Japan

Keywords: Quantum Cascade Lasers, QCLs, Statics Method, Dynamic Method, Heat Resistance, Three-dimensional

Simulation.

Abstract: In order to increase the output of quantum cascade lasers (QCLs), it is important to improve the heat

dissipation. For investigating the relationship between the device structure and heat dissipation properties,

three kinds of different QCL devices were prepared as follows. One is a device which has the ridge covered

with SiO

2

and thin Au, another is a device which has the ridge covered with SiO

2

embedded with Au, and the

other is a device which has the ridge covered with SiO

2

embedded with Cu. The temperature distributions

was measured with a thermos-viewer. In addition, relationship between structure and heat dissipation

properties in these structure devices are analysed with a three-dimensional model. As a result, it was clarified

from experiments and simulations to improve heat dissipation properties by embedding ridge with Au or Cu.

Furthermore, the thermal properties of the QCL device was measured by the statics method to separate the

thermal resistance of the ridge, that of substrate, and that of mount parts. It was shown that the thermal

resistance improves by more than 2 K/W from 9.3 K/W to 6.9 K/W by embedding ridge with Au or Cu.

1 INTRODUCTION

Quantum cascade lasers are n-type semiconductor

lasers in which two types of semiconductor films are

alternately stacked, and the laser light in the infrared

region can be obtained (Faist et al., 1994).

Conventional semiconductor lasers (LD) are limited

to visible wavelengths below 3 μm, and

semiconductor type lasers do not exist in the infrared

region beyond that. QCLs oscillate in this region, and

desired wavelength can be obtained just by changing

the film thickness of the multilayer film using two

kinds of materials.

In the latter half of the 2000s, commercially

available lasers have been provided, and steadily

commercialization is progressing with the detection

of trace substances and gas detection in the distance.

Particularly in the field of detection of trace

substances, since the oscillation wavelength of QCLs

is in the infrared region, it is possible to measure

many gases with high sensitivity. With such trace

substance detection and gas detection in the distance,

higher sensitivity is expected by increasing the output.

Since the amount of the laser absorption is measured

in the detection of trace substances, it is necessary to

propagate a long optical path length. Also, in far-field

gas detection, a high-power laser is required since it

detects weakly reflected light during laser light

propagation.

As a high-power laser, watt-class laser oscillation

has been reported by A. Evans et al., (2007; Bai et al.,

2008). In order to further increase the laser output, a

film structure with high oscillation efficiency and a

device structure with high heat dissipation property

are important. In this report, we focused on heat

dissipation in QCLs. As a method for evaluating the

heat dissipation property of QCLs, a method of

embedding a ridge with InP has been adopted.

Several reports on the heat distribution of QCLs

have been made. Sood et al. systematically measured

the relationship between film thickness and thermal

conductivity in super lattices of InGaAs and InAlAs

(Sood et al., 2014). Evans et al. reported the analysis

for temperature dependence of waveguide loss of

QCLs (Evans et al., 2012). G. K. Veerabathran et al.

have measured the thermal resistance by inputting

pulsed power to QCL, which is called Dynamic

method (Veerabathran et al., 2017).

On the other hand, V. Székely proposed a new

method of extracting the thermal resistance from the

Takagi, S., Tanimura, H., Kakuno, T., Hashimoto, R. and Saito, S.

Thermal Analysis for Quantum Cascade Lasers using Experiments, Simulations and Structure Function Obtained by Static Measurement.

DOI: 10.5220/0007612903030307

In Proceedings of the 7th International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS 2019), pages 303-307

ISBN: 978-989-758-364-3

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

303

voltage-current characteristics at the time of cooling

has been introduced (Székely, 1997). This method is

called the Statics method, and is widely used for

measuring the thermal resistance of power devices. In

this method, by using the inflection point of the

thermal resistance (structure function), it is possible

to separate the thermal resistance of the ridge, that of

substrate, and that of mount parts.

In this paper, we applied this method to three

kinds of QCLs with different structures, and

separated the resistance for each constituent element

such as ridge, substrate, and mount. In addition, we

report on the thermal analysis using three-

demensionsl simulations which reproduce the

thermal characteristics of actual devices.

2 DEVICE STRUCTURE AND

CHARACTERISTICS

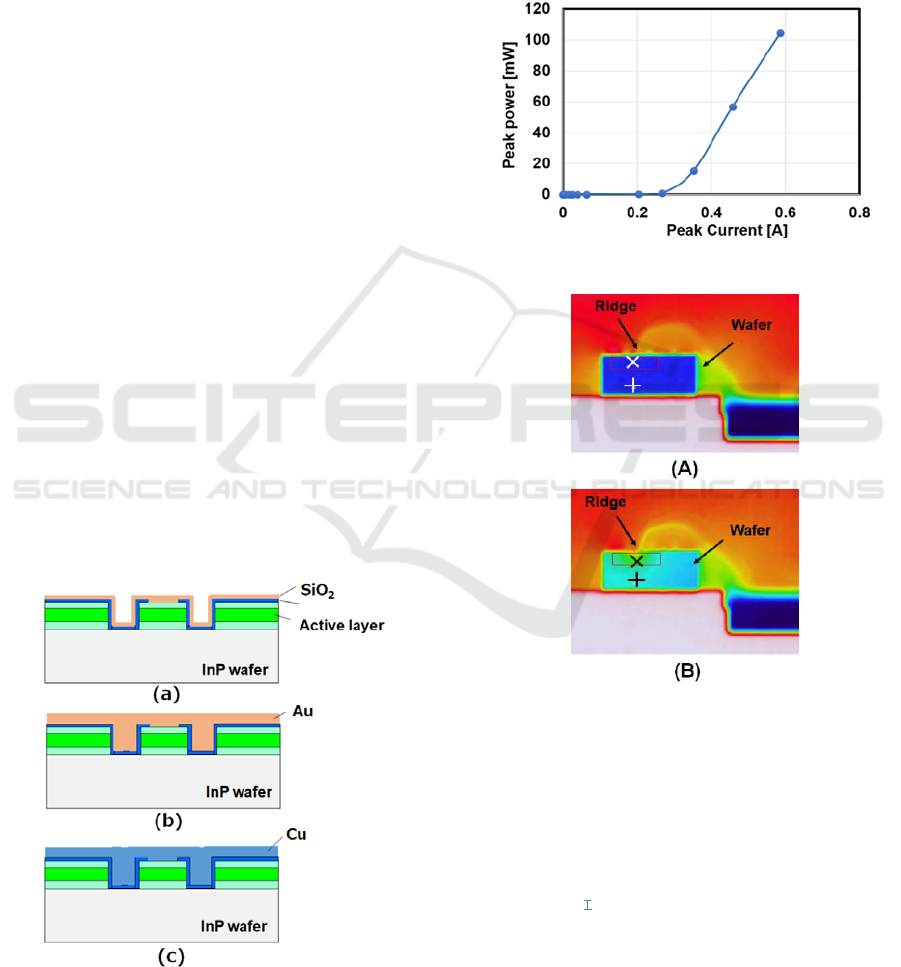

Figures 1 (a) - (c) show three kinds of device

structures comparing the temperature characteristics.

In all devices, the QCL device forms an active layer

(ridge portion) in which 22 layers of alternating layers

in the device structure (a), thin SiO

2

and Au film are

formed on the cladding layer. In the structure (b), gold

of 10µm in thickness is plated on the structure (a). In

the structure (c), Cu of 10 μm in thickness is plated

on the SiO

2

film of (a). The result of laser operation

for the device in the structure (c) is shown in Fig.2.

At an operating temperature of 0 ℃, an oscillation

wavelength of 4.41 µm and a laser peak output of

100mW have been obtained.

Figure 1: Devices structures. (a) Ridge covered with thin

SiO

2

and thin Ti/Au, (b) Ridge embedded with Au, and (c)

Ridge embedded with Cu.

In structures (a) - (c), the CuW mount was cooled

to 10℃. Power up to 4 W was applied and the device

temperature was measured with a thermos-viewer.

The thermos-viewer FSV-210L (Apiste Corp.) is

used for the measurement, and it can be measured the

temperature with a space resolution of 12.5 μm or less

with 25 μm lens and digital zoom. Fig.3 (A) shows

the measurement results without operating, and (B)

shows the result in the case of inputting 3 W of power.

Figure 2: QCL output power.

Figure 3: Temperature measurement with thermo-viewer,

(A) without power and (B) input power of 3W.

Temperatures at two points “x” and “+” in Fig. 3

(A) were measured, and the supplied electric power

was varied to obtain the temperature difference ΔT

between “x” and “+”. “x” is just under the ridge

portion, and “+” is a position 50 μm above the lower

surface of the substrate. These results are shown in

Fig.4. The measured values fluctuated by about 10%

depending on the experimental setup. The variation

ranges are shown as error with error bar. In the

structure (a), the upper surface is covered with SiO

2

with a thickness of 0.2 μm and Au with a thickness of

0.5 μm, and the heat dissipation property for releasing

PHOTOPTICS 2019 - 7th International Conference on Photonics, Optics and Laser Technology

304

heat into the atmosphere is lowered, and ΔT is large.

On the other hand, in structures (b) and (c), heat is

released to the atmosphere via Au or Cu on SiO

2

, and

ΔT decreases.

Figure 4: Temperature difference ΔT between the ridge

bottom and the bottom of the wafer (Experiment).

3 THERMAL ANALYSIS

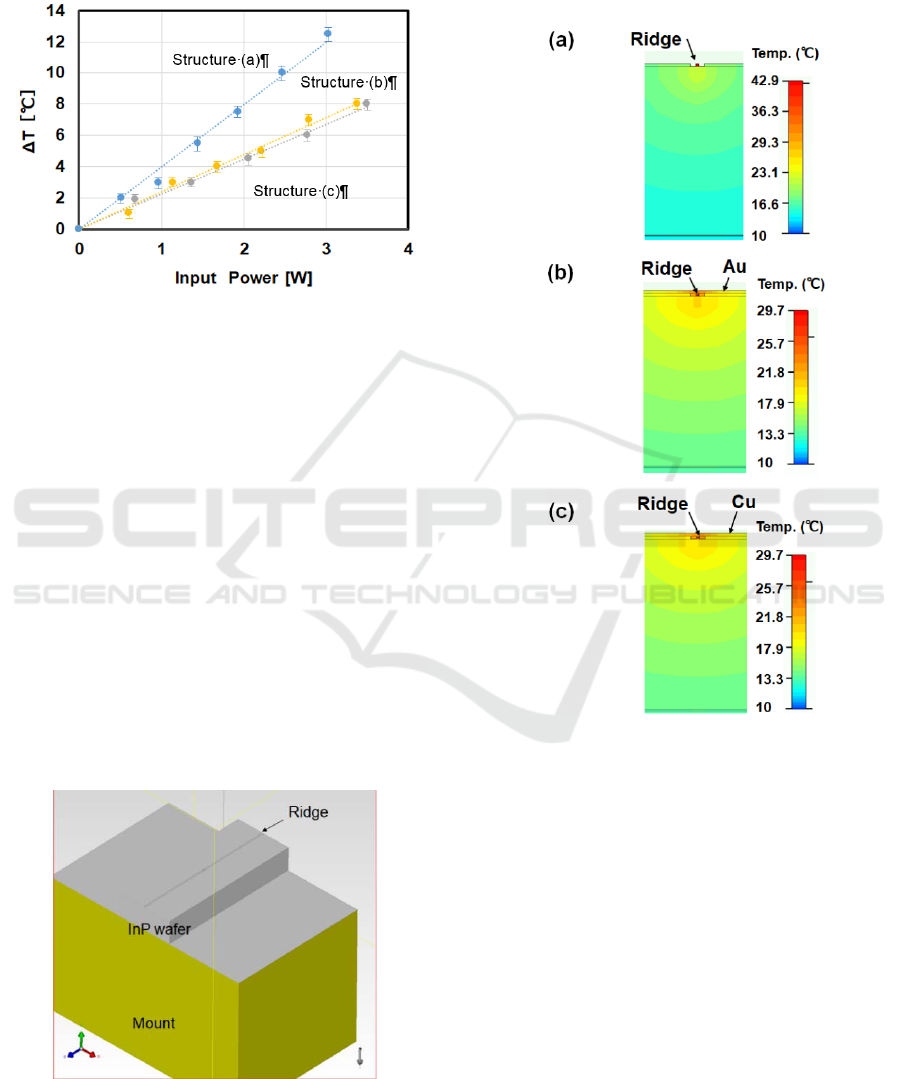

For thermal analysis inside the QCL element, a

thermal airflow analysis software FloTHERM

(Mentor Graphics Japan Co., Ltd.) was introduced to

calculate the temperature distribution in the structures

of (a), (b) and (c). 3-demensional model of the

structure (a) of is shown in Fig.5.

Assuming that the electric power applied to the

active layer in the ridge is a heating source, the

inputting powers to the active layer were changed

from 0 to 4 W. In addition, the surrounding air current

is a natural convection model in which air is heated

and rises. Because we can assume that the Cu/W

mount was cooled to 10 ℃, the temperature of Cu/W

was fixed at 10 ℃.

Figure 5: 3-Dimensional simulation model.

Figure 6 shows the calculation results. The

temperature distributions at 3 W input power are

displayed as contours. The maximum temperatures of

the ridge portion in the structures of (a), (b), and (c)

are 42.9, 29.7, and 29.7 ℃, respectively.

Figure 6: Simulation results. (A) Ridge covered with SiO

2

and thin Ti/Cu, (B) Ridge embeded with Au and (C) Ridge

embeded with Cu.

In the three-dimensional simulation, the

temperature distribution in the QCL was calculated

by changing the input to the active layer. The

temperatures in the temperature distribution were

measured at the positions of “x” and “+”

corresponding to those of Fig. 3, and the temperature

difference ΔT was obtained. Fig. 7 shows the

relationship between the input and the temperature

difference ΔT. The ΔT in the structure (a) becomes

larger than the ΔT in the structures (b) and (c). This

tendency of the ΔT coincides with that of ΔT. It is

considered that the absolute value differs because the

measurement positions of the thermos-viewer does

Thermal Analysis for Quantum Cascade Lasers using Experiments, Simulations and Structure Function Obtained by Static Measurement

305

not accurately match the measurement positions in

the calculation.

Figure 7: Temperature difference between the ridge bottom

and the bottom of the wafer (Simulation).

4 MEASUREMENT OF

THERMAL RESISTANCE AND

STRUCTURE FUNCTION BY

STATICS METHOD

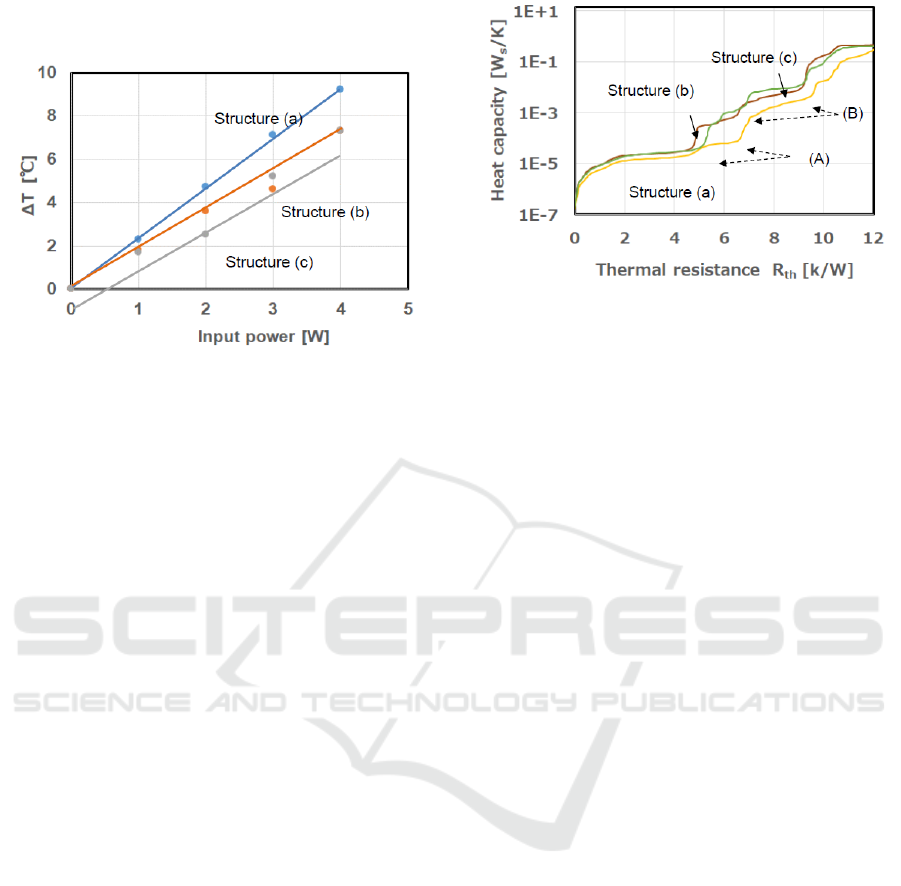

Dynamic method and statics method are available for

measuring thermal resistance of semiconductor

devices. In the dynamics method, pulsed electric

power is supplied to a semiconductor device to heat

it, and the thermal resistance is measured. On the

other hand, the statics method is a method in which a

device is heated and the thermal resistance is

measured from the voltage-current characteristic

during cooling (Székely, 1997). Compared with the

dynamics method, the measurement time is short, and

it is possible to obtain highly reproducible results, and

it has been widely used as a measurement method of

thermal resistance.

In order to measure the thermal resistance of QCL

accurately, statics method was adopted. For the

measurement, T3Ster (Siemens AG) was used. The

mounting part of the QCL device was cooled at 20 ℃

, and about 0.8 W of electric power was supplied to

the QCL device to heat it. After stopping the power

supply, the thermal resistance was calculated from the

voltage-current characteristic flowing in the device.

The measurement results are shown in Fig.8. In

the figure, the mark (A) shows the value of thermal

resistance to the periphery of the ridge. Also, the mark

(B) shows the thermal resistance value up to the InP

wafer edge. It suggests that the thermal resistance

improves by more than 2 K/W from 9.3 K/W to 6.9

K/W around the wafer edge of (B).

Figure 8: Thermal resistance vs. Heat capacity (Structure

function).

5 CONCLUSIONS

The relationship between the device structure and

heat dissipation were investigated in quantum

cascade lasers. Three types of devices were prepared

as follows. One is a device which has the ridge

covered with SiO

2

and thin Au, another is a device

which has the ridge covered with SiO

2

embedded

with Au, and the other is a device which has the ridge

covered with SiO

2

embedded with Cu.

From the results of the temperature measurement

with the thermos-viewer and the three-dimensional

thermal simulations, the effect of embedding Au and

Cu was clarified. Furthermore, the heat properties of

QCL devices were measured by the statics method

using T3Ster. As a result, the thermal resistance of the

ridge, that of InP wafer, and that of the mount were

separated from the total thermal resistance. The

improvement of thermal resistance with more than 2

K/W was attained by using Au or Cu embedding.

ACKNOWLEDGEMENTS

This work was supported by Innovative Science and

Technology Initiative for Security, ATLA, Japan.

REFERENCES

Bai, Y., Darvish, S.R., Slivken, S., Zhang, W., Evans, A.,

Nguyen, J., and Razeghi, M., 2008. Appl, Phys. Lett.,

92, 101105.

Evans, A., Darvish, S.R., Slivken, S., Nguyen, J., Bai, Y.,

and Razeghi, M., 2007. Appl. Phys. Lett., 91, 071101.

Evans, C.A., Indjin, D., Ikonic, Z., and Harrison, P., 2012,

J. Comput. Electron, 11, 137.

PHOTOPTICS 2019 - 7th International Conference on Photonics, Optics and Laser Technology

306

Faist, J., Capasso, F., Sivco, D.L., Sirtori, C., Hutchinson,

A.L., Cho, A.Y., 1994. Science, 264, 553.

Sood, A., Rowiette, J.A., Caneau, C.G., Bozorg-Graeli, E.,

Asheghi, M., and Goodeson, K.E., 2014. Appl. Phys.

Lett., 105, 051909.

Székely, V., 1997. Microelectronics Journal, 28, 277

Veerabathran, G., K., Sprengel, S., Kari, S., Andrejew, A.,

Schmelauch, H., and Amann, M., C., 2017. AIP

Advances, 7, 025208.

Thermal Analysis for Quantum Cascade Lasers using Experiments, Simulations and Structure Function Obtained by Static Measurement

307