Life Cycle-Oriented Evaluation of Cyber-Physical Systems

K. Höse and U. Götze

Faculty of Economics an Business Administration, Chair of Management Accounting and Control,

Technische Universität Chemnitz, 09107 Chemnitz, Germany

Keywords: Cps (Cyber-Physical Systems), Evaluation, Industrie 4.0, Life Cycle.

Abstract: Cyber-physical systems as technical enabler of “Industrie 4.0” (I4.0) have been discussed in many published

papers. The application of I4.0-technologies allows for an intelligent interconnection between product

development, logistics, customers and production. As a result, it is expected that the implementation of I4.0-

technologies contributes to the protection of economic wealth of companies and society. This trend enables

innovative processes and products right up to new business models. Nevertheless, companies often hesitate

to invest in I4.0-solutions. The uncertainty of the benefit of using I4.0 is one reason making an economic

consideration of I4.0-solutions necessary. Therefore, a structured analysis and evaluation of I4.0-solutions in

form of CPS is the topic of this paper. Firstly, the evaluation requirements are described. One main

requirement is the life cycle-oriented analysis of CPS, because not only the implementation costs and

expenditures are important, but also the prospective costs and benefits of the application of CPS. Afterwards,

a decision theory-based procedure model is suggested to handle the complexity of a life cycle-oriented

evaluation. Within the description of the steps of the procedure model, characteristics and challenges

regarding the evaluation of CPS are discussed. Additionally, instruments and methods, which support the

evaluation of CPS, are presented.

1 INTRODUCTION

The implementation of cyber-physical systems

(CPS), especially in value creation processes, has

become an often discussed topic for companies, since

the “Industrie 4.0” (I4.0)-development arised. I4.0 is

a term resulting from a project initiated by the

German government with the aim of protecting

Germany as competitive manufacturing base

(Sendler, 2013). The main objective of I4.0 was

considered to be the interconnection via internet,

which leads to a merger of the physical and virtual

world. The CPS are the technical enabler for this

connection (Kagermann, 2014). The implementation

of I4.0-solutions by means of CPS enables new

products, processes, business models and possibilites

to manage the value chain processes with new ideas

to organize the production (Kagermann, Wahlster,

Helbig, 2013).

The technical opportunities of the application of

I4.0/CPS have been discussed in many academic

papers. Nevertheless, many companies are hesitating

to invest in these solutions because of the fear of high

implementation costs and the uncertain benefit. Thus,

an economic consideration of I4.0 is necessary as

well. Some studies have been published discussing

the economic impact of I4.0-solutions, e. g.

Obermaier et al. conducted a process- and potential

analysis for an ex-ante assessment of investments in

I4.0 (Obermaier, et al, 2015). An ongoing research

project is examining this economic issue for the

intralogistics (IPRI, 2017). In other papers economic

influences of I4.0 are investigated as well (for an

overview see Braccini and Margherita, 2019), but

mostly for special purposes like the design and

examination of the productivity of a warehouse

management system for smart logistics (Lee, et al,

2017).

The model that is presented in this paper has an

universal character, it is not developed for a special

branch or scope. When examining the economic

impact of the application of I4.0-solutions, it is not

sufficient to analyse only the acquisition costs at the

beginning. Also the follow-up costs, e. g. for

maintenance and recycling, have to be analysed.

Additionally, the benefits of the usage of I4.0-

solutions by means of CPS have to be considered.

Thus, a life cycle-oriented analysis is essential.

332

Höse, K. and Götze, U.

Life Cycle-Oriented Evaluation of Cyber-Physical Systems.

DOI: 10.5220/0007746103320338

In Proceedings of the 4th International Conference on Internet of Things, Big Data and Security (IoTBDS 2019), pages 332-338

ISBN: 978-989-758-369-8

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Within this analysis, various challenges like the

complexity of CPS or the uncertainties, especially for

input data and the expected benefit, exist. Therefore,

a set of evaluation tools is necessary. Thus, the

objective of this paper is to present the draft of such a

one. A life cycle-oriented analysis is conducted by e.

g. Thiede, who presents the Life Cycle Assessment

(LCA) as a method to evaluate the environmental

sustainability of cyber-physical production systems –

but without considering the economic perspective

(Thiede, 2018).

The following paper is divided into four sections.

After the introduction, the terms I4.0 and CPS are

explained and the necessity of a life cycle-oriented

evaluation of CPS is justified in more detail.

Afterwards, model requirements are posed and

finally, a general structure for a procedure model for

a life cycle-oriented evaluation of CPS with

suggestions for single evaluation instruments and

methods that can be used within it, is presented as a

basis for following studies. The procedure model is

generally applicable for evaluating all dimensions of

sustainability – the economic, the ecological and the

social one, with the possibility to include existing

approaches like LCA for CPS. However, this paper

mainly focuses on the economic evaluation

considering technical aspects as a basis.

2 CYBER-PHYSICAL SYSTEMS

2.1 Cyber-Physical Systems as Enabler

of Industrie 4.0

CPS are the technical basis of I4.0-solutions, which

include the connection of the production with modern

information and communication technology on the

basis of internet technologies. Beyond the technical

controllability of more flexible production and

supplier industries a profound economical change is

possible. A shift of the classical customer-supplier-

relation is expected, as the traditional supply chains

are broken up. Different areas of industry, e. g.

machinery and plant engineering, have to be enabled

to develop new products and services as well as

business models with the help of digital technologies

(Drossel, et al, 2018).

For I4.0, no homogeneous definition exist.

Therefore, different interpretations of the term were

compared and the following definition was developed

(based on an analysis of different definitions for I4.0):

I4.0 is the utilization of the Internet of Everything in

the production domain. On the basis of real-time

available intelligent data, elements like humans,

things, and services are linked and exchange

information. The crosslinking in form of integration

of IT-systems occurs internet-based – in vertical as

well as in horizontal direction. The crosslinking takes

place within companies, but also cross-company and

leads to a merger of the physical and virtual world.

CPS technically enable this (based e. g. on Roy,

2017).

2.2 Cyber-Physical Systems and Their

Elements

As mentioned in chapter 2.1, CPS act as technical

enabler of I4.0. Thus, they form the technical base for

the realization of the visions and ideas within I4.0.

For CPS, heterogeneous definitions do exist as well.

In Broy`s definition different aspects regarding the

functions and components of CPS are included. He

explains that the objective of CPS is the connection

of embedded systems with help of world-wide

networks. This enables a direct connection and back

coupling between the digital and the physical world.

This interaction of embedded systems, based on

software systems and interfaces, creates new system-

functionalities (Broy, 2010).

Beyond the connection between the physical and

digital world as well as the enabling of new system

functionalities, the following characteristics are

essential for a CPS. Access through networks needs

to be transportable and transregional; additionally,

time requirements exist. More characteristics are the

existence of sensors and actuators and the connection

within the systems and between different systems.

CPS should be applicable within difficult physical

environments and for long-time operations as well

(Broy, 2010).

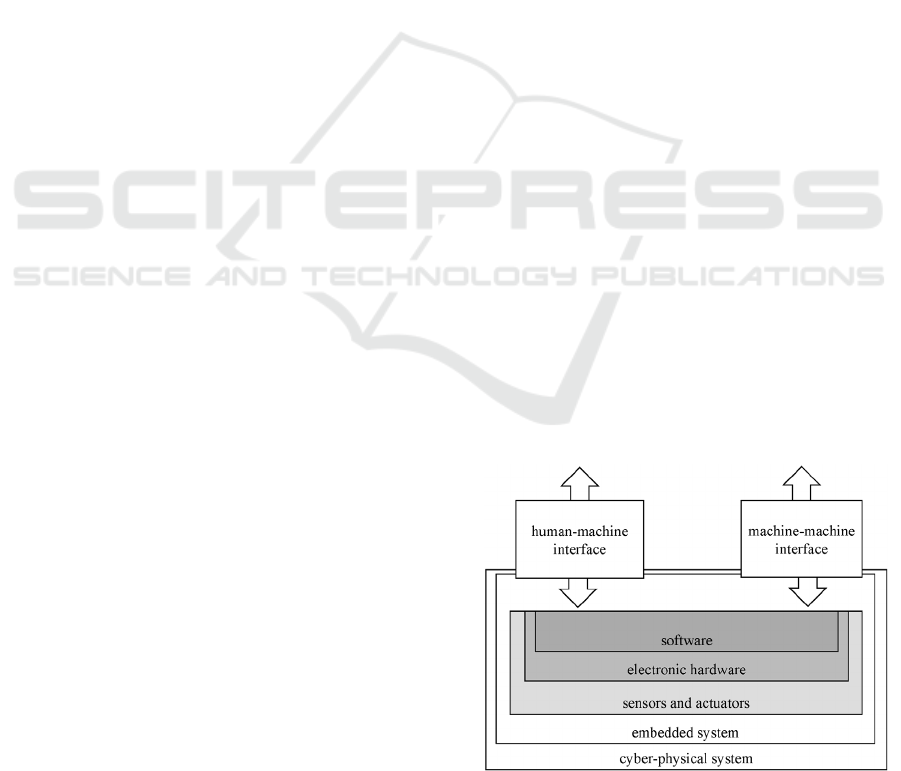

A possible visualization of the structure of CPS is

presented below.

Figure 1: Structure of a CPS (based on Broy, 2010,

Siepmann, 2016).

Life Cycle-Oriented Evaluation of Cyber-Physical Systems

333

The general structure of the CPS shows that

different elements encounter each other. This leads to

technical, but also economic challenges (Broy, 2010).

2.3 Life Cycle-Oriented Analysis of

Cyber-Physical Systems

As shown in chapter 2.2, CPS consist of various

elements, e. g. the physical system and the included

software. While a machine can be used over some

years, software life cycles are much shorter,

sometimes only last some weeks (Drossel, et al,

2018).

To show the life cycles of the elements, life cycle

concepts provide support options. The aim of life

cycle concepts is to identify specific phases of a life

cycle and to visualize the time references of processes

(Herrmann, 2010). The considered objects of life

cycle models vary, e. g. organisations, technologies

or products can be in focus (e. g. Höft, 1992). A lot of

models that describe life cycles do exist.

One possibility to outline a life cycle is the system

life cycle referring to complex systems (Wildemann,

1982). In general terms, a system is a number of

elements which coact with each other to serve a

special purpose (e. g. Schenk, Wirth, 2004). The life

cycle phases of the system life cycle model are the

initiation phase, the planning phase, the realisation

phase, the use phase and the decommissioning phase

(more details about the phases: e. g. in Wildemann,

1982). Normally the phases are not strictly separated,

often they are characterized by an iterative and

parallel sequence (Wildemann, 1982).

As the characteristics of CPS in chapter 2.2 show,

CPS are systems that consist of different elements.

The system life cycle is an option to model, analyse,

evaluate and design the life cycle of a CPS and its

elements. The elements have own life cycles, too.

These heterogeneous life cycles enhance the

complexity of analysing CPS. Hence, a structured

analysis of CPS including the life cycles of the

different elements and their costs and benefits is

necessary.

3 MODEL REQUIREMENTS FOR

A LIFE CYCLE-ORIENTED

EVALUATION OF CYBER-

PHYSICAL SYSTEMS

For the implementation of evaluations in general as

well as for the realisation of life cycle-oriented

evaluations various requirements have to be met. The

requirements consist of diverse criteria which should

be adhered to enable a problem adequate evaluation

and assessment (Meynerts, 2017).

Models in general have to meet formal

requirements, e g. applicability/profitability,

rationality, acceptance, and closeness to reality (e. g.

Meynerts, 2017; Schmidt, 2014). To meet the demand

of applicability/profitability, the level of complexity

needs to be as low as possible. Thus, support in form

of IT-systems can be used to reach an appropriate

level between benefits and costs of model building

and usage (Faßbender-Wynands, 2001). The

rationality is a very important requirement, as the

model needs to have the capability to enable the

decision maker to select the best and rational solution.

To examine the rationality, the guidance of the

normative decision theory is advisable (Schmidt,

2014). Additionally, the model has to be structured as

simple as possible, so that it can be applied without a

lot of background knowledge. Thus, the acceptance

of the users can be enhanced (Meynerts, 2017).

Nevertheless, the contents of the model have to show

closeness to reality to support a well-founded and

rational decision-making (Schmidt, 2015).

Beside the general model requirements the

specialities of a life cycle-oriented evaluation have to

be noted. The key task of a life cycle-oriented

evaluation is to model the life cycle with its phases,

activities and the resulting monetary consequences.

Therefore, life cycle models (as mentioned in chapter

2.3) have to be considered as a basis for identifying

and analysing decision interdependences and

problem formulations (Kemminer, 1999), because

not only the acquisition costs, but also the follow-up

costs as well as the arising benefit should be included

for decision-making. In this context, the considered

objects and their costs have to be broken down into

their components (Meynerts, 2017, Kemminer,

1999). Furthermore, forecast models should be

included to estimate the costs and benefits over the

complete life cycle and to involve uncertainties (e. g.

Dhillon, 1989). Finally, appropriate calculation

methods for a determination of the life cycle-oriented

success have to be chosen (e. g. Riezler, 1996).

Beside the formal and the life cycle-specific

requirements, the characteristics of CPS have to be

considered within the evaluation model. Especially

the different kinds of elements a CPS consists of

should be investigated separately, as mentioned

regarding the life cycle-oriented evaluation, too. This

comes along with heterogeneous life cycles, which

implicate different lifetimes of the elements.

For the analysis of the life cycle of a CPS and its

elements, a structured approach is necessary.

IoTBDS 2019 - 4th International Conference on Internet of Things, Big Data and Security

334

Therefore, a procedure model is recommended to

enable a transparent and significant evaluation of CPS

(e. g. Faßbender-Wynands, 2001).

4 PROCEDURE MODEL FOR A

LIFE CYCLE-ORIENTED

EVALUATION OF

CYBER-PHYSICAL SYSTEMS

Procedure models are models that describe

procedures of special projects or processes in an

idealising and abstracting way (e. g. Hesse, et al,

1992).

The procedure model should take into account the

requirements mentioned in chapter 3. Therefore, the

theory of decision-making can be used as a basis. The

basic model of decision theory consists of different

elements: objectives and preferential relations,

alternatives like actions, states of environment and

result functions (for more details about decision

theory see Sieben and Schildbach, 1994).

The procedure model suggested in the following

is appropriate for the structuring of decision problems

and the various activities and instruments for the

evaluation of CPS. It is based on preliminary studies

(e. g. Götze, et al, 2010; Weber, 2013) as well as

engineering approaches. The model enables the

evaluation of product- and process-based action

alternatives and consists of several linked levels. To

handle the variety of possible configurations and

influencing variables in a structured way, the

evaluation task can be divided into different parts.

This facilitates the detailed analysis of evaluation

tasks on subordinated levels (e. g. the evaluation of

software components within the CPS). The obtained

values can be merged within the top level to enable

the evaluation of the different alternatives. The

determination of the steps of the procedure model

follows the differentiation of the elements of decision

models according to the basic model of decision

theory. The majority of the steps refers to one of the

elements of this basic model (Götze, et al, 2014).

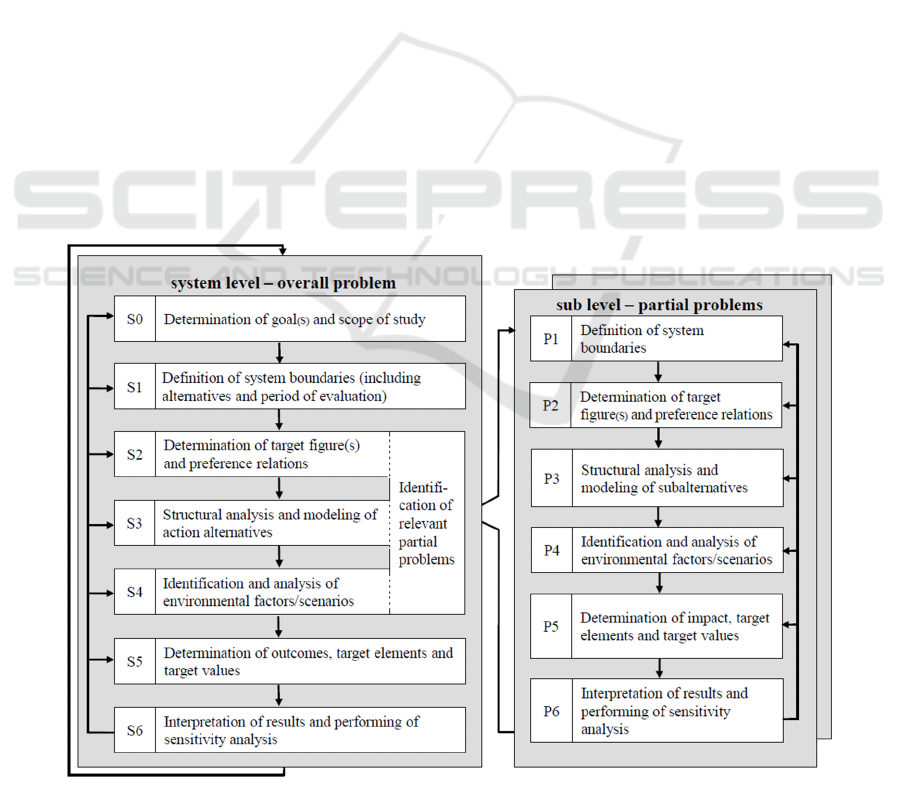

Figure 2 shows the top level of the procedure

model. Additionally, it is shown, how the evaluation

task can be divided into sub tasks. Within the step S0:

Determination of goal(s) and scope of study the

concern and conditions of the study are determined

closer (Ferry, Flanagan, 1991). Thus, the objective of

the analysis has to be defined. In the light of CPS, it

can be the development and choice of I4.0-solutions

which have the lowest negative monetary impact or

the highest economic success along their life cycle.

Beside the economic ones, also other objectives, e. g.

ecological ones, are possible, too. The superior

Figure 2: Procedure model for evaluation of CPS (based on Weber, T., 2013, Meynerts, L., 2017).

Life Cycle-Oriented Evaluation of Cyber-Physical Systems

335

objective needs further specification regarding the

results to decide why the analysis is necessary. In this

regard, a reason for an analysis can be to identify

relevant solution approaches, to choose a suitable

supplier and, as the most important cause, to find the

most advantageous alternative. Depending on the

goals of the study, the scope has to be defined as well

to enable a well-founded decision-making including

the relevant influences (Meynerts, 2017).

Step S1: Definition of system boundaries

(including alternatives and period of evaluation) is

necessary to determine the relevant system

boundaries. First, the system under study and the

different alternatives have to be distinguished. This

can be a CPS or a combination of different CPS – so

within the production area it can be one or more

machines right up to a whole factory. Furthermore, it

has to be determined, which environmental statuses

(e. g. legal background like existing data privacy acts)

have to be integrated in the evaluation. Additionally,

the evaluation period as well as the life cycle phases

which are considered have to be defined (Götze, et al,

2014). Therefore, a system- and project-analysis

should be conducted.

In step S2: Determination of target figure(s) and

preference relations the relevant technical, economic,

social and/or ecological target figures have to be

defined while analysing the determined requirements

(see S0). An example for an economic target figure is

the net present value; a possible ecological target

figure is the global warming potential. Afterwards,

these figures have to be weighted to define their

priorities. For this purpose, preference relations, e. g.

preferences regarding the type of target, risk or time,

can be used (Meynerts, 2017, Götze, et al, 2014). The

choice of suitable evaluation methods to determine

the target figures is necessary within this step, too. As

I4.0-solutions in form of CPS are normally causing

long-term effects, for economic targets reference can

be made to established methods such as the net

present value method (Götze, Northcott, Schuster,

2015).

Then step S3: Structural analysis and modeling of

action alternatives follows. It means that the objects

(e. g. one CPS, a system of different CPS) and related

decision alternatives have to be selected, analysed

and modeled. Therefore, product- and process-related

modelling approaches like the I-T-O-model can be

used (Götze, Hache, Schmidt, Weber, 2011). If partial

alternatives exist, it can be useful to explore them

detailed within a sub level (Götze, et al, 2014).

The next step is S4: Identification and analysis of

environmental factors/scenarios. The effects

resulting from the different alternatives are affected

by a lot of environmental factors, which arise from

within or from outside of the company.

Environmental factors can influence the payments

and costs directly, like market prices of technical

assets. Additionally, they might also determine the

way of usage of the CPS and its sub systems in an

indirect way. Examples therefore are the customer

demand or legal guidelines. The determination of

environmental factors depends on subjective

assessment (Meynerts, 2017). Additionally, the

interdependencies between the factors should be

analysed, e. g. with causal diagrams (e. g. Coyle,

1996). As a result, environmental scenarios can be

built. In terms of decision theory, this is the step of

developing the states of environment (Götze, et al,

2014). Therefore, forecast models should be used as

well (e. g. von Reibnitz, 1992).

Step S5: Determination of outcomes, target

elements and target values is characterized by the

forecast of costs or payments within the different life

cycle phases or the forecast of benefits (monetary and

non-monetary). Regarding the estimation of costs,

revenues or payments, methods of the development-

and development-concurrent cost calculation are

suggested (Ehrlenspiel, et al., 2007). Additionally,

instruments such as check lists or expert reports for

technical figures are applicable. In case of economic

figures, instruments like traditional cost accounting,

budgeting or activity based costing are recommended.

If ecological target figures are included, instruments

like Life Cycle Assessment can be utilized. The

Social Life Cycle Assessment or other instruments of

the Human Resource Management are suitable, if

social target figures exist. As a result, the values of

target figures are determined. If more than one target

figure exists, the decision value has to be ascertained

with help of methods of multicriteria decision-

making (Götze, et al, 2014). For applying the various

instruments, basic approaches of knowledge

management are recommended to facilitate a valid

database (Köhler, 2012).

Within the last step S6: Interpretation of results

and performing of sensitivity analysis the final

decision-making follows, e. g. in form of choice of

the CPS that will be realized. Therefore, the

determined target figures are compared (Meynerts,

2017). However, the results should be interpreted

carefully because of the high complexity, the limited

availability of data and the uncertainties involved.

Thus, it is advisable to conduct sensitivity analyses to

IoTBDS 2019 - 4th International Conference on Internet of Things, Big Data and Security

336

show the consequences of deviations of the

influencing variables on the target values.

Alternatively, critical values of the influencing

variables can be identified (Götze, et al, 2014; Götze,

et al, 2015).

The different steps within all levels of the process

model are connected among each other in form of

information flows and feedback loops and the results

of one step can be input of another one (Götze, et al,

2014).

A special challenge within the model is posed by

the division of the evaluation tasks and the related

formation of sub levels. It depends on the structure of

the evaluation object and different approaches for the

division are possible (for more information about the

possibilities see Götze, et al, 2014).

5 CONCLUSION

The presented procedure model enables a structured

analysis and evaluation of CPS and supports the

decision-making regarding the use of CPS. The

decomposition into sub levels fosters the

transparency of the evaluation. This is important,

especially because of the typical complexity of the

evaluation object. CPS consist of different elements

and various challenges for their evaluation exist. This

especially refers to the handling of the heterogeneous

life cycles of the elements and the data acquisition.

Thus, a division into partial problems seems to be

unavoidable.

As shown in chapter 4, various instruments can be

used within the different steps and partial problems.

Following studies should focalize on the

concretisation of the model and its steps. Therefore,

existing studies (e. g. Götze, et al, 2014), which focus

on other evaluation objects, can be used as a basis.

Additionally, a refinement of the instruments applied

to the model, like the net present value method, is

necessary. Such refinements, for instance, should

refer to the precise determination of CPS-related

benefits as well as the integration of replacement

decisions.

REFERENCES

Broy, M., 2010. Cyber-Physical Systems –

Wissenschaftliche Herausforderungen bei der

Entwicklung. In: Broy, M., Cyber-Physical Systems –

Innovation durch softwareintensive eingebettete

Systeme.

Braccini, A. M., Margherita, E. G., 2019. Exploring

Organizational Sustainability of Industry 4.0 under the

Triple Bottom Line: The Case of a Manufacturing

Company. In: Sustainability, Volume 11, Issue 1, pp. 36

ff.

Coyle, R.G., 1996. System Dynamics Modeling: A

Practical Approach. London.

Dhillon, B.S., 1989. Life Cycle Costing: Techniques,

Models and Applications. New York.

Drossel, G., Ihlenfeldt, S., Langer, T., Dumitresco, R.,

2018. Cyber-Physische Systeme – Forschen für die

digitale Fabrik. In: Neugebauer, R., Digitalisierung –

Schlüsseltechnologien für Wirtschaft & Gesellschaft.

Berlin Heidelberg, pp. 197–222).

Ehrlenspiel, K., Kiewert, A., Lindemann, U., 2007.

Kostengünstig Entwickeln und Konstruieren:

Kostenmanagement bei der integrierten

Produktentwicklung. Berlin, 6

th

edition.

Faßbender-Wynands, E., 2001. Umweltorientierte

Lebenszyklusrechnung: Instrument zur Unterstützung

des Umweltkostenmanagements. Wiesbaden.

Ferry, D. J. O., Flanagan, R., 1991. Life Cycle Costing: A

radical approach. Report 122 Construction Industry

Research and Information Association (CIRIA).

London.

Götze, U., Schmidt, A., Weber, T., 2010. Vorgehensmodell

zur Abbildung und Analyse des Lebenszykluserfolgs

von Werkstoffen – Konzeption und beispielhafte

Veranschaulichung. In: Materialwissenschaft und

Werkstofftechnik, Volume 41, Issue 6, pp. 464–475.

Götze, U., Hache, B., Schmidt, A., Weber, T., 2011.

Methodik zur kostenorientierten Bewertung von

Prozessketten der Werkstoffverarbeitung. In:

Materialwissenschaft und Werkstofftechnik, Volume

42, Issue 7, pp. 647–657.

Götze, U., Schmidt, A., Symmank, C., Kräusel, V.,

Rautenstrauch, A., 2014. Zur Analyse und Bewertung

von Produkt-Prozessketten-Kombinationen der

hybriden Produktion. In: Neugebauer, R.; Götze, U.;

Drossel, W.-G. (Hrsg.): Energetisch-wirtschaftliche

Bilanzierung – Diskussion der Ergebnisse des

Spitzentechnologieclusters eniPROD: 3.

Methodenband der Querschnittsarbeitsgruppe

"Energetisch-wirtschaftliche Bilanzierung" des

Spitzentechnologieclusters eniPROD, pp. 21–32.

Auerbach.

Götze, U. Northcott, D., Schuster, P., 2015. Investment

Appraisal – Methods and Models. Berlin, Heidelberg.

Herrmann, C., 2010. Ganzheitliches Life Cycle

Management. Berlin Heidelberg.

Hesse, W., Merbeth, G., Frölich, R., 1992. Software-

Entwicklung: Vorgehensmodelle, Projektführung,

Projektverwaltung. München.

Höft, U., 1992. Lebenszykluskonzepte – Grundlage für das

strategische Marketing- und Technologiemanagement.

Berlin.

International Performance Research Institute (IPRI), 2017.

IPRI-Pressemitteilung vom 02.02.2017 – IPRI-

Forschungsprojekt „Industrie 4.0 profitabel“ startet.

Stuttgart.

Life Cycle-Oriented Evaluation of Cyber-Physical Systems

337

Kagermann, H., 2014. Chancen von Industrie 4.0 nutzen.

In: Bauernhansl, T. et al. Industrie 4.0 in Produktion,

Automatisierung und Logistik. Anwendung,

Technologien, Migration, pp. 603–614. Wiesbaden.

Kagermann, H., Wahlster, W., Helbig, J., 2013.

Deutschlands Zukunft als Produktionsstandort

sichern – Umsetzungsempfehlungen für das

Zukunftsprojekt Industrie 4.0 – Abschlussbericht des

Arbeitskreises Industrie 4.0.

Kemminer, J., 1999. Lebenszyklusorientiertes Kosten- und

Erlösmanagement, Wiesbaden.

Köhler, S., 2013. Kostenorientiertes Wissensmanagement

in den Konstruktionsprozessen des Maschinenbaus.

Chemnitz.

Lee, C.K.M., Lv, Y., Ng, K.K.H., Ho, W., Choy, K.L.,

2017. Design and application of Internet of things-

based warehouse management system for smart

logistics. In: International Journal of Production

Research, Volume 56, Issue 8, pp. 1–16.

Meynerts, L., 2017. Lebenszyklusorientierte

Wirtschaftlichkeitsanalysen und – bewertungen im

Rahmen der Fabrikplanung – Entwicklung eines

Analyse- und Bewertungsinstrumentariums unter

besonderer Berücksichtigung der Energieeffizienz.

Chemnitz.

Obermaier, R., Hofmann, J., Kirsch, V., 2015. Konzeption

einer Prozess- und Potenzialanalyse zur Ex-ante

Beurteilung von Industrie 4.0-Investitionen – Zur

Methodik einer Abschätzung von

Wirtschaftlichkeitspotenzialen. In: Controlling,

Volume 27, Issue 8/9, pp. 485–492.

Pahl, G. Feldhusen, J., Grote, K.-H., 2013. Pahl/Beitz

Konstruktionslehre. Berlin, 8

th

edition.

Riezler, S., 1996. Lebenszyklusrechnung: Instrument des

Controlling strategischer Projekte. Wiesbaden.

Roy, D.T., 2017. Industrie 4.0 – Gestaltung cyber-

physischer Logistiksysteme zur Unterstützung des

Logistikmanagements in der Smart Factory, Berlin.

Schenk, M., Wirth, S. 2004. Fabrikplanung und

Fabrikbetrieb. Berlin.

Schmidt, S., 2014. Investitionsentscheidungen unter

Unsicherheit – Eine vergleichende Gegenüberstellung

individueller und kapitalmarktorientierter

Konzeptionen zur Entscheidungsvorbereitung.

Chemnitz.

Sendler, U., 2013. Industrie 4.0 – Beherrschung der

industriellen Komplexität mit SysLM Systems

Lifecycle Management. In: Sendler et al., Industrie 4.0

– Beherrschung der industriellen Komplexität mit

SysLM, pp. 1–19.

Sieben, G., Schildbach, T., 1994. Betriebswirtschaftliche

Entscheidungstheorie. Düsseldorf.

Siepmann, D., 2016. Industrie 4.0 – Struktur und Historie.

In: Roth, A., Einführung und Umsetzung von Industrie

4.0 – Grundlagen, Vorgehensmodell und Use Cases aus

der Praxis, pp. 17–82.

Spath D., Ganschar, O., Gerlach, S., Hämmerle, M.,

Krause, T., Schlund, S., 2013. Produktionsarbeit der

Zukunft – Industrie 4.0. Stuttgart.

Thiede, S., 2018. Environmental Sustainability of Cyber

Physical Production Systems. In: Procedia CIRP, The

25

th

CIRP Conference on Life Cycle Engineering,

Volume 69, pp. 644–649.

Von Reibnitz, U., 1992. Szenario-Technik – Instrumente

für die unternehmerische und persönliche

Erfolgsplanung. Wiesbaden.

Weber, T., 2013. Lebenszyklusorientierte Analyse und

Steuerung des Werkstofferfolges, Chemnitz.

Wildemann, H., 1982. Kostenprognosen bei

Großprojekten. Stuttgart.

IoTBDS 2019 - 4th International Conference on Internet of Things, Big Data and Security

338