Dynamic Modeling and Simulation of a Slurry Mixing and Pumping

Process: An Industrial Case

Ridouane Oulhiq

1,2

, Khalid Benjelloun

1

, Maarouf Saad

3

, Yassine Kali

3

and Laurent Deshayes

2

1

AII Laboratory, Ecole Mohammadia d’Ing

´

enieurs, Mohammed V University, Rabat, Morocco

2

Innovation Lab for Operations, Mohammed VI Polytechnic University, Benguerir, Morocco

3

Electrical Engineering Department,

´

Ecole de Technologie Sup

´

erieure, Montreal, QC H3C 1K3, Canada

laurent.deshayes@um6p.ma

Keywords:

Mixing Tank, Centrifugal Pump, Slurry, Modeling, Simulation, Density Variation, Level Variation.

Abstract:

In this paper, a dynamic model of a slurry mixing and pumping process is proposed. The centrifugal pump

is modeled based on the hydraulic application, the hydraulic part and the induction motor models, taking into

account the pumped slurry density. This paper also proposes a new approach to estimate the parameters of the

pump’s hydraulic part model based on the pump characteristic curves. Additionally, a dynamic simulation of

the system is realized under MATLAB/Simulink environment and the variation effect of the process inputs on

the outputs is studied.

1 INTRODUCTION

In many process industries, the mixing and pumping

process is a decisive step. It is common to blend dif-

ferent products together to form a mixed slurry for

downstream processes. Eventually, the quality of the

final product will be derived by how good the mix

is and the precision of the inlet flows (Nienow et al.,

1997). Considering the widespread of such a pro-

cess, understanding its dynamics is of great impor-

tance. A steady state approach is often used to de-

scribe the system. However, a steady state process

requires constant properties. For slurry processes,

solids’ properties such as the granulometry change

as a function of time and place as does the solids’

density (Miedema, 1996). Since inlet density impacts

how easily the slurry is pumped (Blevins and Nixon,

2010), this change in density impacts the flow rate of

the slurry. Therefore, a dynamic model is needed, for

a better understanding, simulation and control of the

system.

A mathematical model, based on first order non-

linear differential equations, is used to describe the

mixing process (Deng, 2002). For the slurry pumping

process, the centrifugal pump is used. In (Kallesøe

et al., 2006), the dynamic model of the centrifugal

pump is divided into three sub parts: the pump mo-

tor, the hydraulic part and the hydraulic application.

The parameters of hydraulic part are calculated based

on the physical properties of the pump. The hydraulic

application is not detailed and the variation of flow is

not discussed. In (Valtr, 2017), the centrifugal pump

is modeled based on the hydraulic system without

considering the pump’s motor. In (Miedema, 1996) a

dynamic model for the system pump/pipeline is pro-

posed and simulated. However, the model assumes

that the pump drive behaves like a constant torque

system. Concerning the pump’s motor, the induction

motor is used. The model of the induction motor is

extensively described in literature. The most popular

representation is the so-called qd model based on a

series of mathematical transformations (Manekar and

Bodkhe, 2013). The idea of a revolving reference

frame, dq, is introduced to transform the ac compo-

nents of the vectors in the stator frame into dc sig-

nals in order to simplify calculations (Trzynadlowski,

2000).

In this work, a graphical method is used to es-

timate the pump’s hydraulic part, the head and the

load torque parameters. In literature, a numerical

method is used to calculate these parameters based on

the physical properties of the pump (Isermann, 2007;

Kallesøe et al., 2006), which is time consuming and

hard to apply in an industrial environment. For the

hydraulic application, it depends on the studied sys-

tem. A generalized method is presented in this work,

taking into account the friction factor variation along

with the slurry flow rate variation.

Oulhiq, R., Benjelloun, K., Saad, M., Kali, Y. and Deshayes, L.

Dynamic Modeling and Simulation of a Slurry Mixing and Pumping Process: An Industrial Case.

DOI: 10.5220/0007774000270035

In Proceedings of the 9th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH 2019), pages 27-35

ISBN: 978-989-758-381-0

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

27

The outline of this paper is as follows. Section 2

exposes the process description and dynamic analysis

of the mixing tank and the centrifugal pump. Section

3 presents the simulation and the performance results.

Section 4 concludes the paper.

2 PROCESS DESCRIPTION AND

DYNAMICS ANALYSIS

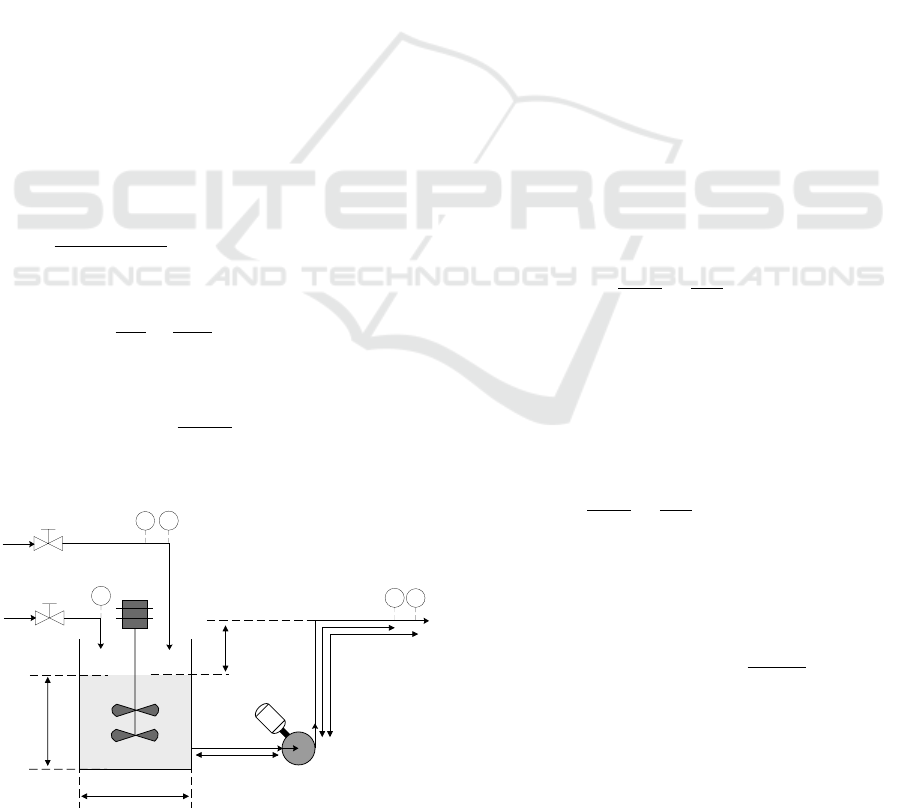

The process studied is a part of an industrial thick-

ening unit as shown in Fig. 1. The slurry arriving to

the unit is delivered to a cylindrical mixing tank in

which it is kept in agitation in order to avoid the de-

cantation of the solid. The process water is used to

adjust the solid rate of the slurry. The mixed slurry is

then pumped, using a centrifugal pump driven by an

induction motor, to downstream processes.

2.1 Dynamic Analysis of the Mixing

Tank

The dynamic behavior of the mixing tank is described

by the following equations (Skogestad, 2008; Hougen

et al., 1954):

• Conservation of the total mass in the mixing tank

d(M

pm

+ M

wm

)

dt

= d

w

F

w

+d

ps1

F

ps1

− d

ps2

F

ps2

(1)

• Level of the mixing tank:

dL

m

dt

=

4

π.D

2

m

(F

ps1

+ F

w

− F

ps2

) (2)

• Density of the slurry at the outlet of the mixing

tank:

d

ps2

=

4

πD

2

m

L

m

(M

pm

+ M

wm

) (3)

Slurry

Process water

Centrifugal pump

Mixing tank

p1

p2

Lmp

LpF

Kpt

Kmp

z2

z1

Hs

Mixed Slurry

Lm

Dm

DIT FIT

{ Fps1, dps1 }

Fw

{ Fps2, dps2 }

LpD

FIT

DITFIT

Figure 1: Pump hydraulic application parameters.

Where M

pm

is the total mass of dry product in the

mixing tank (Kg), d

ps1

is the density of slurry at the

inlet of the mixing tank (Kg/m

3

), F

ps1

is the volumet-

ric flow rate of slurry at the inlet of the mixing tank

(m

3

/s), d

ps2

is the density of slurry at the outlet of the

mixing tank (Kg/m

3

), F

ps2

is the volumetric flow rate

of slurry at the outlet of the mixing tank (m

3

/s), M

wm

is the total mass of water in the mixing tank (Kg), d

w

is the density of water (Kg/m

3

), F

w

is volumetric flow

rate of water at the inlet of the mixing tank (m

3

/s), L

m

is the level of slurry in the mixing tank (m) and D

m

is the diameter of the mixing tank (m). In what fol-

lows, it is assumed that the mixing tank is perfectly

mixed. The perfect mixing assumption is valid for

low-viscosity liquids that receive an adequate degree

of agitation (Seborg et al., 2010).

2.2 Dynamic Analysis of the Centrifugal

Pump

The flow of a centrifugal pump is related to two pa-

rameters, namely, the pump head and the system head.

The intersection of the two head curves is the flow

operating point of the system (Bachus and Custodio,

2003). The equation describing this fact is given by

the different parts of the pump.

First of all, applying Newton’s second law of mo-

tion to the fluid in the pipe (Matko et al., 2001; Valtr,

2017) yields to:

dF

ps2

dt

=

gA

p

L

mt

∆H (4)

where ∆H is the head variation (m), A

p

is the pipe

section (m

2

), L

mt

is the length of the pipe between the

mixing tank and the downstream process (m) and g is

the gravity (m/s

2

).

Then, based on (4), the equation describing the

variation of flow in function of the pump head H

p

and

the system head H

sys

is obtained:

dF

ps2

dt

=

gA

p

L

mt

(H

p

− H

sys

) (5)

2.2.1 The Hydraulic Application

The system head between p1 and p2 (Fig. 1) (Menon,

2004) is:

H

sys

= H

s

+ H

l

+ H

v

+

P

2

− P

1

d

ps2

g

(6)

where H

sys

is the system head between p1 and p2 (m),

H

s

is the static head of the system (m), H

l

is the to-

tal head losses in the system (m), H

v

is the velocity

head (m), P

1

and P

2

represent the pressure at p1 and

p2 respectively (Pa) and d

ps2

is the density of slurry

(kg/m3) (Fig. 1) with:

SIMULTECH 2019 - 9th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

28

• P

1

= P

2

= P

atm

(Atmospheric pressure);

• H

v

=

v

2

2

−v

2

1

2g

;

• H

s

= z

2

− z

1

.

v

1

and v

2

are respectively the velocity at p1 and p2

(m/s) where:

• v

1

≈ 0;

• v

2

=

4F

ps2

πD

2

p

;

For the total head losses:

H

l

= H

l f riction

+ H

llocal

(7)

where H

l f riction

is the friction losses (Pa) and H

llocal

is the local losses (Pa).

The friction losses are described by the Darcy

equation (Green and Perry, 1997):

H

l f riction

=

f v

2

2

L

mt

2gD

p

(8)

Then:

H

l f riction

=

f L

mt

2gD

p

4F

ps2

πD

2

p

!

2

(9)

where D

p

is the pipe diameter (m) and f is the Darcy

friction factor.

The Darcy friction factor depends on the pipe

properties and on the nature of the pumped fluid

(Menon, 2004; El-Emam et al., 2003).

Moreover, for the local losses :

H

llocal

=

1

g

v

2

2

n

∑

i

K

i

(10)

where K

i

are are the local loss coefficients.

Then:

H

llocal

=

1

g

(K

mp

+ K

pt

)

4F

ps2

πD

2

p

!

2

(11)

where K

mp

is the local loss coefficient caused by the

sudden contraction between the mixing tank and the

pipe and K

pt

is the local loss coefficient caused by the

change in pipe geometry between the pump and the

thickener.

After simplifying (6), the relation of the system

head is obtained:

H

sys

= α + βF

2

ps2

+ γ f F

2

ps2

(12)

where :

α = z

2

− L

m

β =

1

2g

4

π.D

2

p

2

[1 + 2(K

mp

+ K

pt

)]

γ =

1

2g

4

π.D

2

p

2

L

mt

D

p

In classic pumping systems design, the friction

factor f is fixed at the beginning according to the flow

operating point (Wright and Gerhart, 2009; Chiasson,

2016). However, the friction factor depends on the

fluid velocity and properties. Thus, the friction factor

changes as the flow changes and it must be updated in

each iteration of the dynamic model simulation.

2.2.2 The Hydraulic Part

The pump head H

p

(m) is a function of flow F

ps2

and

shaft speed w

p

(rad/s). The equation describing this

fact is (Kallesøe et al., 2006; Kallesøe et al., 2004):

H

p

= a

h

F

2

ps2

+ b

h

F

ps2

.ω

p

+ c

h

ω

2

p

(13)

where a

h

, b

h

and c

h

are constant parameters fixed

from the physical properties of the pump.

However, obtaining these physical properties of

the pump is time consuming and maybe impossible

in an industrial environment. In this work, these pa-

rameters are determined using the H-Q curves of the

used pump.

The pump torque (or the load torque) T

p

(N.m)

is described by the equation (Kallesøe et al., 2006;

Kallesøe et al., 2004):

T

p

= −d

ps2

a

t

F

2

ps2

+ d

ps2

b

t

F

ps2

ω

p

+ c

t

ω

2

p

(14)

where a

t

, b

t

and c

t

are constants found from the phys-

ical properties of the pump.

In this work, these parameters are determined us-

ing the H-Q curves of the used pump.

2.2.3 The Induction Motor

The equation describing the mechanical part of the

pump is (Chan and Shi, 2011; Trzynadlowski, 2000):

dω

p

dt

=

1

J

m

+ J

p

(T

e

− T

p

) −

C

f

J

m

+ J

p

ω

p

(15)

where J

m

is the moment of inertia of the pump me-

chanical parts (Kg m

2

), J

p

is the moment of inertia

of the fluid inside the pump impeller (Kg m

2

), C

f

is

the friction losses coefficient of pump induction mo-

tor (Kg m

2

/s) and T

e

is the torque produced by the

pump induction motor (Nm).

The torque T

e

is calculated based on the electro-

mechanical and the electrical parts of the induction

motor (Chan and Shi, 2011; Trzynadlowski, 2000).

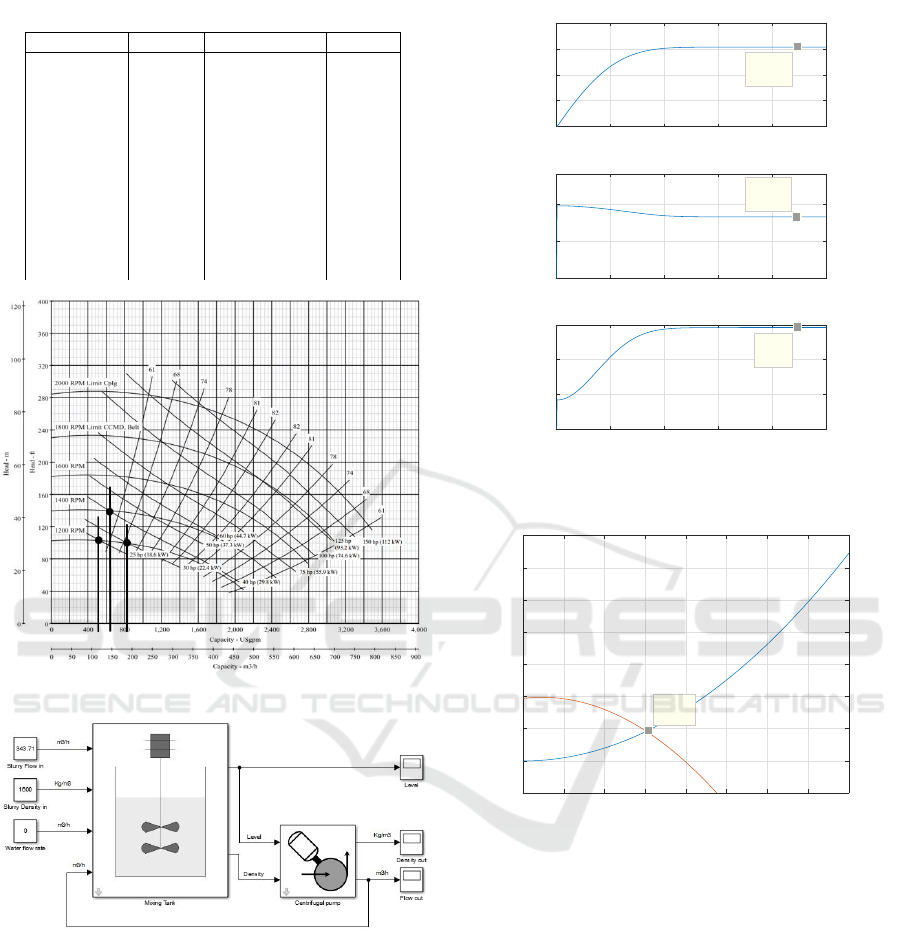

2.3 Mixing and Pumping Unit Global

Model

From the process parts dynamic analysis, the overall

model of the system is described by Fig. 2 and the

Dynamic Modeling and Simulation of a Slurry Mixing and Pumping Process: An Industrial Case

29

equations:

dL

m

dt

=

4

πD

2

m

(F

ps1

+ F

w

− F

ps2

) (16)

d(d

ps2

)

dt

=

4

πD

2

m

L

m

(d

w

− d

ps2

)F

w

+ (d

ps1

− d

ps2

)F

ps1

(17)

dF

ps2

dt

=

gA

p

L

mt

(a

h

− β − γ f )F

2

ps2

+ b

h

ω

p

F

ps2

+ c

h

ω

2

p

− α

(18)

dω

p

dt

=

1

J

m

+ J

p

(T

e

+ d

ps2

a

t

F

2

ps2

− d

ps2

b

t

F

ps2

ω

p

− c

t

ω

2

p

)

−

C

f

J

m

+ J

p

ω

p

(19)

Mixing tank

+

Centrifugal Pump

(18), (19), (20), (21)

Slurry flow rate

Fps1

Water flow rate

Fw

Slurry flow rate

Fps2

Mixing tank level

Lm

Slurry density

dps1

Slurry density

dps2

Induction motor speed

wp

Figure 2: The mixing unit bloc diagram.

The model takes into consideration the density

and the friction factor variations and assume that the

mixing tank is perfectly mixed.

The model inputs and outputs shown in Fig. 2

are as follows: The model manipulated inputs are

the slurry flow rate (F

ps1

) and the water flow rate

(F

w

); The model disturbance input is the slurry den-

sity (d

ps1

); The model outputs are the mixing tank

level (L

m

), the slurry density (d

ps2

), the slurry flow

rate (F

ps2

) and the induction motor speed (w

p

).

3 SIMULATION

3.1 Simulation Parameters

The simulation parameters are given in Table 1.

Where p is the pole number of the pump induction

motor, L

mn

is the mutual inductance of the pump in-

duction motor (H), L

s

and L

r

are the stator and the

rotor inductances (H), R

s

and R

r

are the stator and

the rotor resistances (Ω), E is The voltage of the

power supply (V), θ is the Initial phase angle of the

power supply (rad), ω is the supply angular frequency

(rad/s) and R

i

is the internal resistance of the power

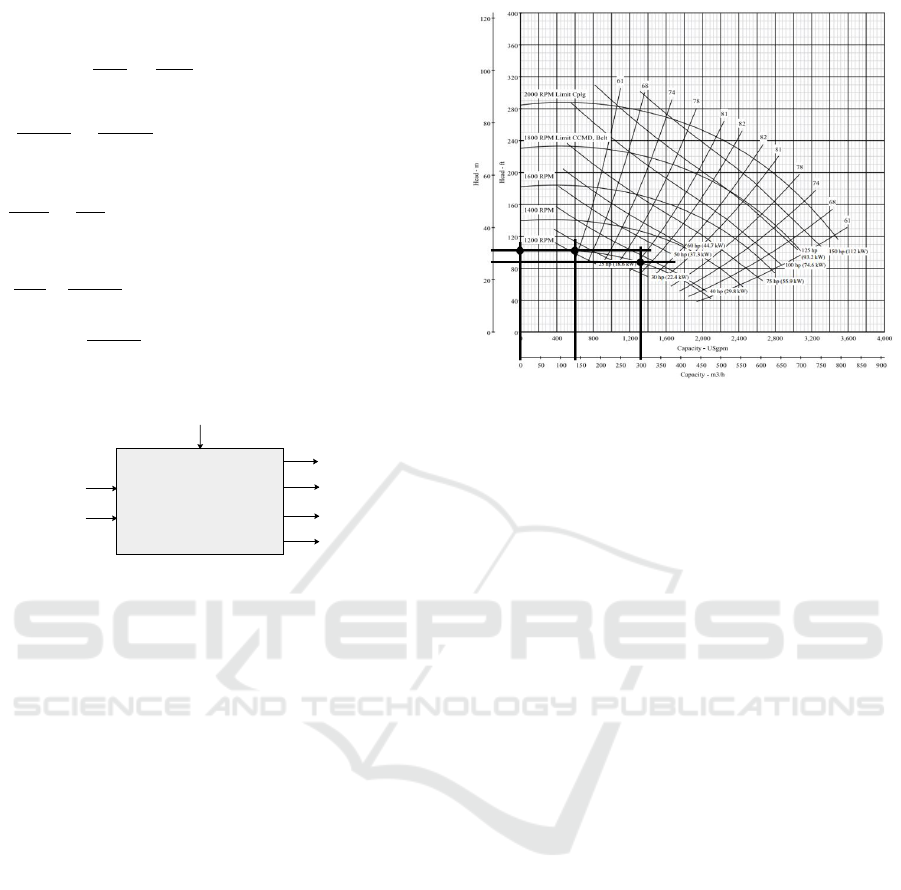

supply (Ω). To determine the parameters a

h

, b

h

and c

h

in (13), the pump characteristic curve is used. Three

different operating points are chosen (Fig. 3) in order

Figure 3: The method used to determine a

p

, b

p

and c

p

.

to get three equations with the three variables. The

solution of the system gives :

a

h

= −1.04 × 10

−4

b

h

= 1.21 × 10

−6

c

h

= 2.15 × 10

−5

(20)

To fix the parameters a

t

, b

t

and c

t

in (14), equation

(21) is used (Isermann, 2007) :

P

p

= ω

p

T

p

(21)

where P

p

is the power required by the pump.

The characteristic curve of P

p

is given in the H-

Q curve of the pump. Using this characteristic, three

different points are chosen (Fig. 4). Each point is as-

sociated with a shaft speed, flow and power. Then,

using (21), the torque T

p

is determined for each cou-

ple (shaft speed, flow). Based on (14), three equations

with the variables a

t

, b

t

and c

t

, are obtained. The so-

lution of the system gives :

a

t

= −20.23

b

t

= −1.56 × 10

−4

c

t

= 7.98 × 10

−3

(22)

3.2 Simulation Results

The simulation is done using the Matlab/Simulink

software. The simulation blocks are created based

on Level-2 Matlab s-functions. After the simulation

of the different blocks of the process, the simulation

of the whole process is done as depicted in Fig. 5.

The chosen initial parameters are: Mixing tank slurry

density : 1600 Kg/m

3

; Mixing tank level : 6 m; In-

let slurry flow rate : 300 m

3

/h; Inlet slurry density :

1600 Kg/m

3

; Inlet water flow rate : 0 m

3

/h

SIMULTECH 2019 - 9th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

30

Table 1: Simulation parameters.

Parameter Value Parameter Value

D

m

(m) 13 D

p

(m) 0.4

L

mt

(m) 21 K

mp

0.5

K

pt

0.3 g (m/s

2

) 9.81

ν (m

2

/s) 0.015 ε (m) 0.07

z

2

(m) 11 J

m

(Kgm

2

) 0.4

J

p

(Kgm

2

) 0.4 C

f

(Kgm

2

/s) 0.062

p 6 L

mn

(m) 0.041

L

s

(H) 0.0425 L

r

(H) 0.0418

R

s

(Ω) 0.288 R

r

(Ω) 0.158

E (V) 220 θ (rad) 0

ω (rad/s) 2π×50 R

i

(Ω) 0.05

Figure 4: The method used to determine a

t

, b

t

and c

t

.

Figure 5: The mixing and pumping unit simulation using

Matlab/Simulink.

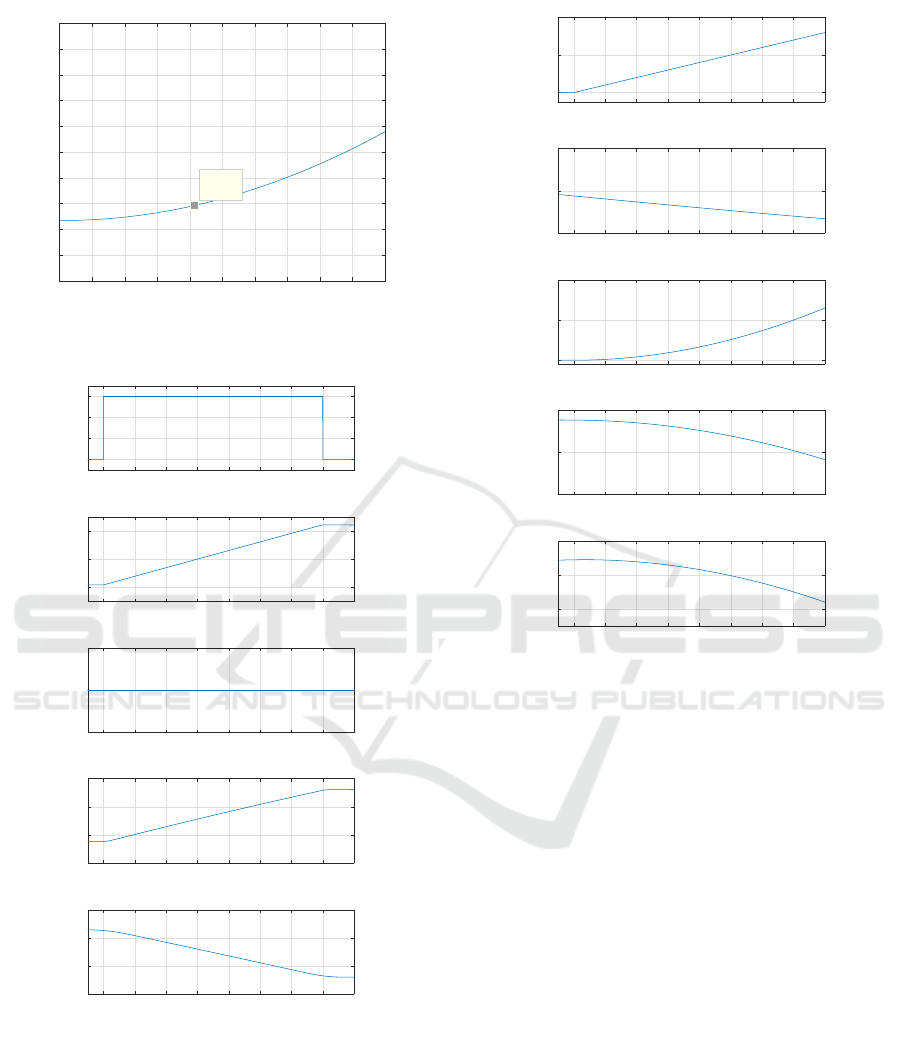

3.2.1 The System Operating Point

After the simulation is launched, the outlet flow of

the pump stabilizes at 306 m

3

/h, the induction motor

speed stabilizes at 826 rpm and the load torque at 293

Nm (6). In order to validate the operating point of

the system, the pump and the system head curves are

plotted (Fig. 7). The intersection of the two curves

gives the same flow operating point 285 m

3

/h. Then

the pump load torque is plotted in function of the in-

duction motor speed for a flow of 306 m

3

/h (Fig. 8) .

0 50 100 150 200 250

Time (s)

0

100

200

300

400

Flow (m3/h)

Outlet slurry flow rate

0 50 100 150 200 250

Time (s)

0

500

1000

Speed (rpm)

Motor speed

0 50 100 150 200 250

Time (s)

0

100

200

300

Torque (N.m)

Pump load torque

X: 223

Y: 306.8

X: 223

Y: 826.4

X: 223

Y: 293

Figure 6: The operation point of the system.

0 100 200 300 400 500 600 700 800

Flow (m3/h)

0

5

10

15

20

25

30

35

40

Head (m)

H-Q curve of the system

X: 306

Y: 9.705

Figure 7: The H-Q curve of the system.

For a speed of 826 rpm the curve gives the same load

torque 293 Nm.

3.2.2 The System Response to Large Variations

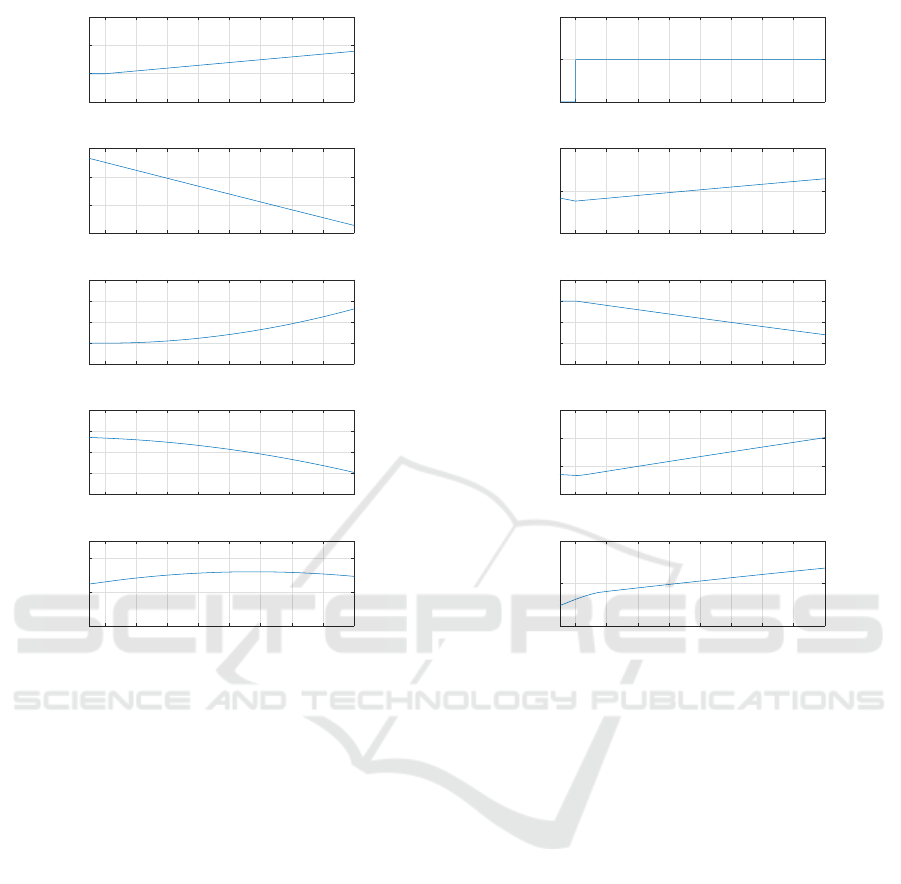

Effect of Inlet Slurry Flow Rate Large Variation.

Keeping the inlet slurry density and the water flow

rate constants, the inlet slurry flow rate is varied. Fig.

9 shows the effect of the inlet slurry flow rate large

variation on the outputs. An increase in the inlet

slurry flow rate results in an increase in the mixing

tank level. Which results in an increase in the out-

let slurry flow rate and a decrease in the motor speed.

This is explained by a change in the static head of the

system along with a change in the load torque of the

pump.

Dynamic Modeling and Simulation of a Slurry Mixing and Pumping Process: An Industrial Case

31

0 200 400 600 800 1000 1200 1400 1600 1800 2000

Speed (rpm)

0

100

200

300

400

500

600

700

800

900

1000

Torque (N.m)

The load torque in fuction of motor speed

X: 826.8

Y: 292.5

Figure 8: The Load torque in function of motor speed.

300 400 500 600 700 800 900 1000 1100

Time (s)

300

400

500

600

Flow (m3/h)

Inlet slurry flow rate (Fps1)

300 400 500 600 700 800 900 1000 1100

Time (s)

6

6.2

6.4

Level (m)

Mixing tank level (Lm)

300 400 500 600 700 800 900 1000 1100

Time (s)

1590

1600

1610

Density (Kg/m3)

Outlet slurry density (dps2)

300 400 500 600 700 800 900 1000 1100

Time (s)

306

307

308

309

Flow (m3/h)

Outlet slurry flow rate (Fps2)

300 400 500 600 700 800 900 1000 1100

Time (s)

815

820

825

830

Speed (rpm)

Motor speed (wp)

Figure 9: The effect of inlet slurry flow rate large variation.

Effect of Inlet Slurry Density Large Variation. In

this case, the inlet density is varied, keeping the other

inputs constants. Fig. 10 shows the effect of the

inlet slurry density variation on the system outputs.

It is clear that an increase in the inlet slurry density

increases the outlet density. Since the higher is the

density, the greater is the resistance to flow (Blevins

300 400 500 600 700 800 900 1000 1100

Time (s)

1600

1800

2000

Density (Kg/m3)

inlet slurry density (dps1)

300 400 500 600 700 800 900 1000 1100

Time (s)

6

6.02

6.04

Level (m)

Mixing tank level (Lm)

300 400 500 600 700 800 900 1000 1100

Time (s)

1600

1610

1620

Density (Kg/m3)

Outlet slurry density (dps2)

300 400 500 600 700 800 900 1000 1100

Time (s)

305

306

307

Flow (m3/h)

Outlet slurry flow rate (Fps2)

300 400 500 600 700 800 900 1000 1100

Time (s)

825

826

827

Speed (rpm)

Motor speed (wp)

Figure 10: The effect of inlet slurry density large variation.

and Nixon, 2010), this increase in the outlet slurry

density increases the pump load torque. The rise in

load torque decreases the motor speed then the outlet

slurry flow rate decreases. Thus, a change in slurry

density impacts inversely the outlet slurry flow rate.

Effect of Inlet Water Flow Large Variation. In or-

der to study the effect of the inlet water flow varia-

tion, water flow rate is varied while the other inputs

remain constant. The Fig. 11 shows the effect of

varying the inlet water flow rate on the system out-

puts. By adding water, the level starts to increase, the

density decreases as d

w

< d

ps1

and the outlet slurry

flow rate starts to increase as a result of level and den-

sity changes (cf. 3.2.2 and 3.2.2).

3.2.3 The System Response to Small Variations

Effect of Inlet Slurry Flow Rate Small Variation.

In order to study the response of the system to in-

puts’ small variations, the inlet slurry flow rate (F

ps1

)

is increased by 3% of the initial value (Fig. 12). By

increasing F

ps1

, the mixing tank level and the outlet

slurry flow rate increase but with a slight evolution,

SIMULTECH 2019 - 9th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

32

300 400 500 600 700 800 900 1000 1100

Time (s)

0

100

200

300

Flow (m3/h)

Inlet water flow rate (Fw)

300 400 500 600 700 800 900 1000 1100

Time (s)

6

6.2

6.4

6.6

Level (m)

Mixing tank level (Lm)

300 400 500 600 700 800 900 1000 1100

Time (s)

1560

1580

1600

1620

Density (Kg/m3)

Outlet slurry density (dps2)

300 400 500 600 700 800 900 1000 1100

Time (s)

306

308

310

312

314

Flow (m3/h)

Outlet slurry flow rate (Fps2)

300 400 500 600 700 800 900 1000 1100

Time (s)

820

825

830

Speed (rpm)

Motor speed (wp)

Figure 11: The effect of water flow rate large variation.

without impacting the other outputs. However, this in-

crease of level will surely have an impact on the static

head of the system in a long-term and subsequently

an important impact on the outputs (3.2.2).

Effect of Inlet Slurry Density Small Variation.

Increasing the inlet slurry density by 3% of the initial

value, the outlet slurry density, the outlet slurry flow

rate and the mixing tank level vary slightly (Fig. 13).

However, this confirms the indirect impact of the inlet

density on the level and on the outlet slurry flow rate

even for small variations.

Effect of Inlet Water Flow Small Variation. Fig.

14 shows the effect of the inlet water flow rate small

variation on the system outputs. By adding water, the

level starts to increase, the density decreases as d

w

<

d

ps1

and the outlet slurry flow rate starts to increase

as a result of level and density changes. Thus, even a

slight variation impacts the outputs.

300 400 500 600 700 800 900 1000 1100

Time (s)

290

300

310

320

Flow (m3/h)

Inlet slurry flow rate (Fps1)

300 400 500 600 700 800 900 1000 1100

Time (s)

6.01

6.015

6.02

6.025

Level (m)

Mixing tank level (Lm)

300 400 500 600 700 800 900 1000 1100

Time (s)

1590

1600

1610

Density (Kg/m3)

Outlet slurry density (dps2)

300 400 500 600 700 800 900 1000 1100

Time (s)

306.76

306.78

306.8

Flow (m3/h)

Outlet slurry flow rate (Fps2)

300 400 500 600 700 800 900 1000 1100

Time (s)

826.35

826.4

826.45

826.5

Speed (rpm)

Motor speed (wp)

Figure 12: The effect of inlet slurry flow rate small varia-

tion.

4 CONCLUSION

The study puts forward a dynamic model and a simu-

lation for a slurry mixing and pumping process. The

dynamic model of the centrifugal pump takes into ac-

count its different parts: the hydraulic application, the

hydraulic part and the induction motor. In addition

to that, the proposed model takes the slurry density

into consideration. Therefore, the applicability of the

model is extended to other slurry types.

In order to determine the parameters of the pump

head and load torque equations, a practical method

is used based on the pump’s graphical experiments

schemes. Regarding the simulation of the process,

it is conducted using level 2 Matlab s-fucntions and

simulink environment.

According to the developed model and the simula-

tion results, it is clear that both the mixing tank level

and the slurry density impact the outlet slurry flow

rate. With regard to the slurry density effect, it di-

rectly impacts the pump torque, then the pump torque

Dynamic Modeling and Simulation of a Slurry Mixing and Pumping Process: An Industrial Case

33

300 400 500 600 700 800 900 1000 1100

Time (s)

1550

1600

1650

1700

Density (Kg/m3)

inlet slurry density (dps1)

300 400 500 600 700 800 900 1000 1100

Time (s)

6.005

6.01

6.015

6.02

Level (m)

Mixing tank level (Lm)

300 400 500 600 700 800 900 1000 1100

Time (s)

1599

1600

1601

1602

1603

Density (Kg/m3)

Outlet slurry density (dps2)

300 400 500 600 700 800 900 1000 1100

Time (s)

306.5

306.6

306.7

306.8

Flow (m3/h)

Outlet slurry flow rate (Fps2)

300 400 500 600 700 800 900 1000 1100

Time (s)

826.2

826.4

826.6

Speed (rpm)

Motor speed (wp)

Figure 13: The effect of inlet slurry density small variation.

affects the induction motor speed, then a change of the

induction motor speed changes the outlet flow rate.

That highlights the importance of these parameters in

the control strategy design.

Further research will be pursued to model the non

perfect mixture inside the mixing tank and to propose

new methods to control pumping slurry flow rate in

presence of slurry density variations.

REFERENCES

Bachus, L. and Custodio, A. (2003). Know and understand

centrifugal pumps. Elsevier.

Blevins, T. L. and Nixon, M. (2010). Control Loop Foun-

dation: Batch and Continuous Processes. ISA.

Chan, T. F. and Shi, K. (2011). Applied intelligent control

of induction motor drives. John Wiley & Sons.

Chiasson, A. D. (2016). Geothermal heat pump and heat

engine systems: Theory and practice. John Wiley &

Sons.

Deng, S. Y. (2002). Nonlinear & linear mimo control of

an industrial mixing process. Master’s thesis, McGill

University.

300 400 500 600 700 800 900 1000 1100

Time (s)

0

10

20

Flow (m3/h)

Inlet water flow rate (Fw)

300 400 500 600 700 800 900 1000 1100

Time (s)

6.01

6.02

6.03

Level (m)

Mixing tank level (Lm)

300 400 500 600 700 800 900 1000 1100

Time (s)

1597

1598

1599

1600

1601

Density (Kg/m3)

Outlet slurry density (dps2)

300 400 500 600 700 800 900 1000 1100

Time (s)

306.7

306.8

306.9

307

Flow (m3/h)

Outlet slurry flow rate (Fps2)

300 400 500 600 700 800 900 1000 1100

Time (s)

826.4

826.5

826.6

Speed (rpm)

Motor speed (wp)

Figure 14: The effect of water flow rate small variation.

El-Emam, N., Kamel, A., El-Shafei, M., and El-Batrawy, A.

(2003). New equation calculates friction factor for tur-

bulent flow on non-newtonian fluids. Oil & gas jour-

nal, 101(36):74–74.

Green, D. W. and Perry, R. H. (1997). Perry’s Chemical

Engineers’ Handbook/edici

´

on Don W. Green y Robert

H. Perry. Number C 660.28 P47 2008.

Hougen, O. A., Watson, K. M., and Ragatz, R. A. (1954).

Chemical Process Principles: Material and Energy

Balances, volume 1. John Wiley & Sons.

Isermann, R. (2007). Mechatronic systems: fundamentals.

Springer Science & Business Media.

Kallesøe, C. S., Cocquempot, V., and Izadi-Zamanabadi, R.

(2006). Model based fault detection in a centrifugal

pump application. IEEE Transactions on Control Sys-

tems Technology, 14(2):204–215.

Kallesøe, C. S., Izaili-Zamanabadi, R., Rasmussen, H., and

Cocquempot, V. (2004). Model based fault diagno-

sis in a centrifugal pump application using structural

analysis. In Proceedings of the 2004 IEEE Inter-

national Conference on Control Applications, 2004.,

volume 2, pages 1229–1235 Vol.2.

Manekar, G. and Bodkhe, S. B. (2013). Modeling Methods

of Three Phase Induction Motor. National Conference

on Innovative Paradigms in Engineering & Technol-

ogy, pages 16–20.

SIMULTECH 2019 - 9th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

34

Matko, D., Geiger, G., and Werner, T. (2001). Mod-

elling of the pipeline as a lumped parameter system.

AUTOMATIKA-ZAGREB-, 42(3):177–188.

Menon, S. (2004). Piping calculations manual. McGraw

Hill Professional.

Miedema, S. (1996). Modeling and simulation of the dy-

namic behavior of a pump/pipeline system. In 17th

Annual Meeting & Technical Conference of the West-

ern Dredging Association. New Orleans.

Nienow, A. W., Edwards, M. F., and Harnby, N. (1997).

Mixing in the process industries. Butterworth-

Heinemann.

Seborg, D. E., Mellichamp, D. A., Edgar, T. F., and

Doyle III, F. J. (2010). Process dynamics and control.

John Wiley & Sons.

Skogestad, S. (2008). Chemical and Energy Process Engi-

neering. CRC Press.

Trzynadlowski, A. M. (2000). Control of induction motors.

Elsevier.

Valtr, J. (2017). Mass Flow Estimation and Control in Pump

Driven Hydronic Systems. Master’s thesis, Czech

Technical University, Czech Republic.

Wright, T. and Gerhart, P. (2009). Fluid machinery: appli-

cation, selection, and design. CRC press.

Dynamic Modeling and Simulation of a Slurry Mixing and Pumping Process: An Industrial Case

35