Integration of Open Source Arduino with LabVIEW-based

SCADA through OPC for Application in Industry 4.0

and Smart Grid Scenarios

Isaías González Pérez

a

, A. José Calderón Godoy

b

and Manuel Calderón Godoy

c

Industrial Engineering School,University of Extremadura, Avenida de Elvas, Badajoz, Spain

Keywords: SCADA, LabVIEW, Arduino, Open Source, OPC, Ethernet, Industry 4.0, IoT, Smart Micro-grid.

Abstract: Modern innovative concepts around Digital Information and Communication Technologies (DICTs), like

Industry 4.0, the Internet of Things or Smart Grids, are impacting the scientific and technological worlds and,

hence, in control and automation arenas. These trends involve networked interconnection and continuous data

flow between a number of hardware and software actors. In parallel, open source technology has gained

increasing attention from last years, especially due to the widespread presence of the open source hardware

Arduino microcontroller. Focusing on industrial advanced frameworks, Supervisory Control and Data

Acquisition (SCADA) systems are required to exchange data with new smart devices, sensors and/or

actuators. Arduino boards are commonly used as development platforms for such smart devices. Therefore,

communication solutions must be designed towards the convergence of open source hardware and widely

used traditional SCADA-devoted software. This paper presents a system that seamlessly integrates Arduino

boards into a LabVIEW-based SCADA system through Ethernet connection. The open connectivity provided

by the Open Platform Communications (OPC) protocol enables such integration. The proposed framework is

a novelty in scientific literature. The development of the system is reported and initial results are provided to

demonstrate the feasibility of the proposal.

1 INTRODUCTION

The ever-growing expansion of Digital Information

and Communication Technologies (DICTs) has

created a set of modern and innovative paradigms like

the Internet of Things (IoT), Cyber-Physical Systems

(CPSs), Big Data, and Cloud computing. Regarding

control and automation-related arenas, two intimately

linked concepts have arisen as a consequence of their

application to industrial environments, namely

Industry 4.0 and Industrial IoT (IIoT).

In industrial facilities, Supervisory Control and

Data Acquisition (SCADA) systems carry out the

paramount tasks of data gathering and display to the

operator, enabling a continuous surveillance/tracking

of the process behaviour and status of the involved

components. A network of data acquisition and

control/automation devices exchanges data with a

software application that processes them. This way,

a

https://orcid.org/0000-0001-5645-3832

b

https://orcid.org/0000-0003-2094-209X

c

https://orcid.org/0000-0001-8380-8547

the operator is capable of monitoring the automated

system behaviour by means of real-time information

through numerical and/or graphical visualizations.

The introduction of DICTs in these facilities has

enhanced the functions afforded by SCADA systems

as well as the amount of interconnected devices and

data flows.

In parallel, open source technology has gained

increasing attention from last years (González et al.,

2017), even contributing to the progressive real

implementation of such modern trends. For instance,

as asserted by Martínez et al. (Martínez et al., 2017),

open source hardware and software projects are key

accelerators for the industry adoption of IoT.

Focusing on open source hardware equipment, a

small, cheap and easy-to-configure microcontroller

has reached a widespread presence: Arduino

(Arduino Online). It acts as core or as auxiliary device

in a great number of applications in the fields of data

174

Pérez, I., Calderón Godoy, A. and Godoy, M.

Integration of Open Source Arduino with LabVIEW-based SCADA through OPC for Application in Industry 4.0 and Smart Grid Scenarios.

DOI: 10.5220/0007795301740180

In Proceedings of the 16th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2019), pages 174-180

ISBN: 978-989-758-380-3

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

acquisition, automation and engineering in general

(Calderón et al., 2016). Some recent examples are

devoted to educational remote laboratories (Mejías et

al., 2017; Chacón et al., 2017), ZigBee-based wireless

networks (Pereira et al., 2015), CPSs (García et al.,

2016), greenhouse control (Robles et al., 2017), or

monitoring of fuel cells (Calderón et al., 2016; Segura

et al., 2017).

Nonetheless, despite the versatility of Arduino

boards, for industrial locations they present several

weaknesses like signals levels non-compliant with

industrial ranges, not suitability for rail-mounting,

low robustness, etc. (Puigt, 2015).

Within the context of the abovementioned new

paradigms, SCADA systems are required to exchange

data with new smart devices, sensors and/or actuators.

Precisely, Arduino boards are commonly used as

development platforms for such smart devices.

Therefore, communication solutions must be

designed towards the convergence of open source

hardware and widely used traditional SCADA-

devoted software. A widely used SCADA software

environments is Laboratory Virtual Instrumentation

Engineering Workbench (LabVIEW) of National

Instruments (LabVIEW Online). This package is

considered as representative due to the fact that it has

a worldwide presence and support for thousands of

technologies and instruments (Arpaia et al., 2015).

In this case, the integration of Arduino with

LabVIEW can be approached by means of the

LabVIEW Interface for Arduino (LIFA) toolkit.

Examples of the first approach have been reported in

(Calderón et al., 2016), (Segura et al., 2017) and

(Vivas et al., 2019), where an Arduino

microcontroller is used as data acquisition board for

measuring hydrogen fuel cells voltage and

temperature, whereas a LabVIEW-based interface

feeds information to the user.

Nevertheless, this toolkit does not provide

Ethernet connection. An option consists on

developing a TCP or UDP linkage between the

LabVIEW and the Arduino, but this solution involves

deep expertise about such kind of communication.

This paper presents a system that seamlessly

integrates Arduino boards into a LabVIEW-based

SCADA system through Ethernet connection and a

standardized protocol widely used for industrial

facilities, the Open Platform Communications (OPC)

interface.

In order to solve Ethernet communication, a

suitable option consists on using the open source

software package Arduino OPC Server, developed by

I. Martínez Marchena (Arduino OPC Server Online).

It enables the communication between Arduino

boards and software applications that support OPC

connectivity, like LabVIEW.

It must be noted that OPC interface was created in

1996 to handle interoperability in industrial control

and automation applications (OPC Foundation

Online). Currently, it is considered as one of the main

contenders to lead the standardization and systems

integration in advanced frameworks (González et al.,

2017b; González et al., 2019). According to the

literature survey conducted by the authors, there is no

paper reporting an OPC communication between

LabVIEW and Arduino.

This proposal is framed in a research project to

develop and implement a Smart Micro-Grid based on

renewable energy sources and its digital replica. To

this aim, an automation and supervision system is

crucial to manage and operate such challenging

facility. Arduino chips need to be connected to a

LabVIEW-based SCADA for a proper measurement

and monitoring of several of the involved variables.

The goal of this work is to promote the joint

utilization of open source tools with industrial

supervisory software. Therefore, with the aim of

demonstrating the feasibility and validity of the

proposed approach, an experimental system has been

implemented using an Arduino Mega and a

LabVIEW-based SCADA.

In the authors’ humble opinion, the integration of

the de facto standard software for supervision and

instrumentation, LabVIEW, and the versatility of the

open source Arduino microcontroller provides a

powerful benchmark for R&D activities in the fields

of Industry 4.0, IIoT and Smart Grids.

The remainder of the paper is as follows. Section

2 deals with the description of the developed system,

both hardware and software subsystems. In Section 3,

the development of the system and initial outcomes

are reported. Finally, main conclusions and further

works are outlined in Section 4.

2 MATERIALS AND METHODS

The developed system comprises hardware and

software components therefore; in this section the

involved entities are separately described.

2.1 Hardware Subsystem

Among the available Arduino boards (Uno, Yun,

Mini, Nano, Mega, Duemilanove, Lilypad, etc.) the

model Mega 2560 R3 has been selected. It

incorporates an ATmega2560 microcontroller, 16

analog inputs, 54 digital input/output ports, 4 UARTs,

Integration of Open Source Arduino with LabVIEW-based SCADA through OPC for Application in Industry 4.0 and Smart Grid Scenarios

175

a 16 MHz crystal oscillator, a power jack, and a reset

button. A USB port enables powering the board and

establishing communication with the configuration

computer.

The so called shields are expansion cards that

provide additional features to the main board and can

be directly coupled to it. In this application, an

Ethernet shield delivers Ethernet communication by

means of a RJ45 port. Concretely, the Hanrun

HR911105A Ethernet shield has been chosen. It uses

the Serial Peripheral Interface (SPI) protocol to

exchange data with the Arduino board.

Also, some ancillary devices are required, such as

an Ethernet switch, the corresponding Ethernet wires,

and power supplies.

Finally, a PC executes the software applications

that are commented in the next subsection. To

summarize, this PC is used for configuration tasks of

both the hardware and software entities, and also as

supervisory station since the SCADA system runs in

it.

2.2 Software Subsystem

The Integrated Development Environment (IDE), a

free software package, is used to configure the

Arduino chip by means of a programming language

based on a simplified version of the C++ language.

The IDE runs in a PC to which the microcontroller is

connected via serial communication.

In order to enable OPC communication, the

Arduino OPC Server version 2.0 is used. This

freeware and open source package provides OPC

Data Access (DA) –compliant communication with

various Arduino boards, namely Uno, Yun and Mega.

Both serial and Ethernet connections are supported to

link the Arduino board and the PC where the server

runs.

LabVIEW is proprietary software that supports a

large number of technologies and protocols, and

includes powerful in-built functions. The programs

built with LabVIEW are called Virtual Instruments

(VIs) and are programmed via a high-level graphical

language. Hence, this environment has been chosen

to implement the SCADA system that retrieves data

from the Arduino. Besides, an additional module is

required to establish OPC linkage, the Datalogging

and Supervisory Control (DSC) module.

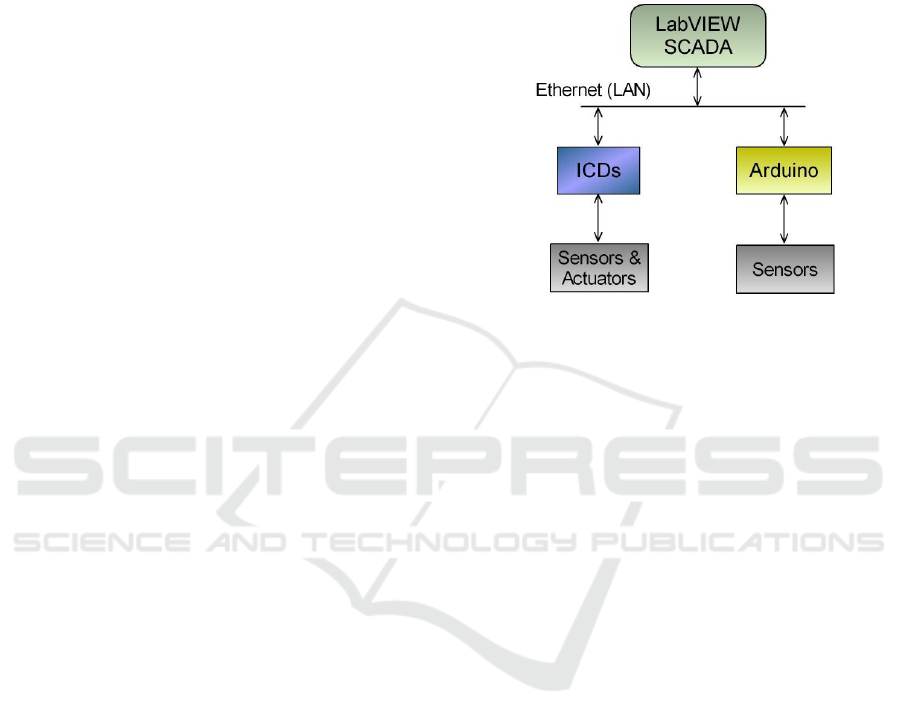

Figure 1 depicts the schematic block diagram of

the system. To the open source board, different

compatible sensors can be connected for sensing and

data acquisition purposes. The OPC server for

Arduino and the LabVIEW-based SCADA (OPC

client) run in the same PC. Such a PC and the Arduino

board are integrated through Ethernet into a Local

Area Network (LAN), establishing a continuous data

flow between them. In addition, Industrial Control

Devices (ICDs), like Programmable Logic

Controllers (PLCs), can also be communicated to the

supervisory system through the network.

Figure 1: Block diagram of the developed system.

3 DEVELOPED APPROACH AND

INITIAL OUTCOMES

This section is devoted to describe the development

of the system paying special attention to the

configuration of the OPC link between the Arduino

and the SCADA. Moreover, achieved initial

outcomes in an experimental facility are reported in

order to validate the proposal.

3.1 Communication Configuration

The communication established between the

microcontroller and the SCADA system must be

configured at hardware and software levels.

Regarding the first one, as previously commented, an

Ethernet network is used to interconnect the Arduino

(by means of its shield) and the PC where the

supervisory application runs.

At the software level, in the Arduino chip is

necessary to incorporate three libraries in the sketch.

Namely, the corresponding to the SPI bus (SPI.h), to

the Ethernet link (Ethernet.h) and the one devoted to

share data through OPC (OPC.h).

By means of the Ethernet library, the IP address,

gateway and the subnet are specified so the VI and the

Arduino can establish an Ethernet connection. The

port for the connection is 80, the default one used for

web linkages. Figure 2 illustrates the configured

parameters for such a communication.

ICINCO 2019 - 16th International Conference on Informatics in Control, Automation and Robotics

176

Figure 2: Ethernet library configuration.

Concerning the OPC library, its configuration

consists on declaring the variables to be shared via

OPC so the OPC server makes them available for the

client program.

As indicated in Section 2, the Arduino OPC

Server allows both serial and Ethernet connections.

The first type was used during the starting stage of the

development to test the configuration of the libraries

and the OPC link. However, the Ethernet connection

is the most powerful since it enables the Arduino and

the PC to be physically distant but communicated

through the network.

The configuration of the Ethernet connection of

Arduino in the OPC server is very intuitive; simply

the IP address and the port must be introduced as can

be seen in Figure 3. It is evident that this IP address

must be coincident with the one configured in the

Ethernet library.

Figure 3: Ethernet communication parameters in the OPC

server.

3.2 SCADA Configuration

Once the Arduino has been configured for both

Ethernet and OPC communications, the SCADA has

to be parameterized to exchange data with it. The VI

is created within a LabVIEW project in order to use

the capabilities provided by the DSC module. Thanks

to the OPC channel, this stage can be performed

through three main steps:

1. Addition of the OPC-shared variables to the

LabVIEW project. The Arduino OPC server must be

added like a new I/O Server, by selecting it among the

available servers registered in the operative system

(Figure 4). Once the server is selected, the variables

shared via OPC can be chosen, in the present case, the

item has been named in the Arduino sketch as AI8, as

shown in Figure 5.

Figure 4: Selection of the Arduino OPC server among the

available servers.

Figure 5: Addition of the OPC-shared variables to the

LabVIEW project.

During this phase, the Info tab of the OPC server

shows details about the connection of the OPC client,

the VI, as can be seen in Figure 6.

Integration of Open Source Arduino with LabVIEW-based SCADA through OPC for Application in Industry 4.0 and Smart Grid Scenarios

177

Figure 6: OPC client connection information provided by

the Arduino OPC Server.

2. Selection of the shared items via OPC. The

items are available via the project library so can be

directly chosen within the VI, as can be appreciated

in Figure 7. The DSC module provides the shared

variable element in order to choose a variable among

those that have been defined in the project. In this

case, the analogue input of the Arduino is selected.

Figure 7: Selection of OPC-shared items in the VI.

3. Design of the interface. This last step

consists on carrying out the design and organization

of the interface that will provide continuous

information to the user. In this sense, some

considerations regarding easy-to-use and intuitive

distribution of the elements have been taken into

account. The design includes the incorporation of

every type of element required to visualize the data

retrieved from the Arduino like trend graphics,

analogue and Boolean indicators. In the present case,

as a proof of concept, a graphical chart and numerical

indicators have been considered In order to improve

the information afforded to the user, a Boolean signal

is used to inform about the successful connection of

the OPC server. To this aim, the own OPC server

provides a bit named Connected?, so its true value

indicates that the connection has been established.

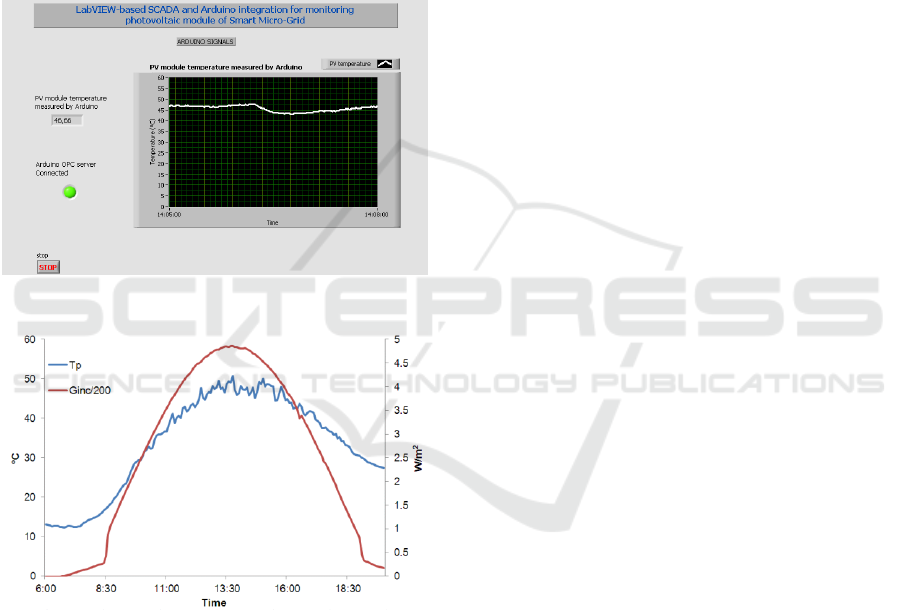

3.3 Initial Outcomes

Aiming to demonstrate the validity of the proposal,

the temperature of a photovoltaic module has been

measured and monitored. This approach constitutes a

preliminary stage for the application to a Smart

Micro-Grid, as it was commented in the Introduction.

A photograph of the experimental setup is

provided in Figure 8. The Ethernet shield and the

Arduino board can be observed placed on the left of

the module.

The achieved initial outcomes are shown in Figure

9, where the SCADA can be observed working under

real conditions. In the presented case, only reading

operations have been implemented, i.e., the Arduino

acts as a data acquisition system and sends the

information to the SCADA.

To this aim, one temperature sensor Lm35 has

been connected to one of the analogue input ports of

the Arduino board. A numerical field shows the value

of the measured temperature. Moreover, a graphical

chart illustrates the evolution of such signal over time.

Figure 8: Experimental setup of the Arduino and the

photovoltaic module.

In order to reflect the effective data exchange

between the nodes (Arduino and LabVIEW SCADA

system), Figure 10 shows sthe evolution of the solar

irradiance and the temperature of the module during

a day of operation. The solar irradiance in the inclined

plane is represented in red colour and divided by 200

(Ginc/200) in order to be represented in the same

graphic. To depict the temperature of the panel, the

measurement carried out by the Lm35 sensor and the

Arduino board has been chosen. This magnitude is

named as Tp and corresponds to the blue- coloured

curve.

These outcomes prove that the Arduino measures

the variations of the module temperature and

ICINCO 2019 - 16th International Conference on Informatics in Control, Automation and Robotics

178

successfully sends in real time the information to the

SCADA system.

It should be remarked that the presented system is

expandable and adaptable to accommodate new

developments in automation, control, measurement

and communications. On the open source view, future

enhancements of Arduino libraries and devices are

expected to empower the system.

Moreover, Arduino boards can also execute

control orders from the SCADA system or even

implement control algorithms.

Nevertheless, more evaluations of the proposal as

well as long-term operation must be studied.

Figure 9: Developed SCADA working.

Figure 10: Irradiance and temperature of the photovoltaic

module measured by Arduino during a sunny day.

4 CONCLUSIONS AND

FURTHER WORKS

This article has presented a successful

communication based on Ethernet and OPC to

integrate Arduino microcontrollers with LabVIEW-

based supervisory systems.

The open source feature of Arduino offers

important benefits like low cost, vast amount of

information available in the Internet and easy

configuration, just to name a few. On the other hand,

LabVIEW is a well-known software environment to

implement monitoring and supervisory systems

widely used by both Academia and industry. Indeed,

the presented integrative framework is a novelty in

scientific literature.

In fact, two open source tools have been

successfully used, at hardware level the Arduino

board, and at software level, the OPC server for

Arduino. Achieved outcomes about sensing a

photovoltaic module temperature have shown a

proper operation of the system, demonstrating the

feasibility of the proposal.

The presented approach is envisioned to facilitate

the integration of open source tools within industrial

infrastructures under the frameworks of innovative

trends like the Industry 4.0, the IoT and Smart Grids.

Further works are focused on applying the

proposal to measure different magnitudes of a Smart

Micro-Grid. This way, Arduino will belong to the

Advanced Metering Infrastructure (AMI) operating

in an integrated manner with the SCADA system.

ACKNOWLEDGEMENTS

This research has been funded by the project IB18041

supported by the Junta de Extremadura in the VI Plan

Regional de I+D+i (2017-2020), co-financed by the

European Regional Development Funds FEDER

(Programa Operativo FEDER de Extremadura 2014–

2020).

In addition, authors are grateful to the

community that supports Arduino-based

developments under open source philosophy. Special

thanks are given to I. Martínez Marchena, developer

of the open source Arduino OPC Server.

REFERENCES

Arduino Online. Available: www.arduino.cc (accessed on

30 January 2018)

Arduino OPC Server Online. Available: https://www.

st4makers.com/opc-server-for-arduino (accessed on 30

January 2018)

Arpaia, P., De Matteis, E., Inglese, V., 2015. Software for

measurement automation: A review of the state of the

art. Measurement, vol. 66, pp. 10–25.

Calderón, A. J., González, I., Calderón, M., Segura, F.,

Andújar, J. M., 2016. A New, Scalable and Low Cost

Multi-Channel Monitoring System for Polymer

Electrolyte Fuel Cells. Sensors, vol. 16(3), pp. 349.

Integration of Open Source Arduino with LabVIEW-based SCADA through OPC for Application in Industry 4.0 and Smart Grid Scenarios

179

Chacón, J., Saenz, J., de la Torre, L., Diaz, J. M.,

Esquembre, F., 2017. Design of a Low-Cost Air

Levitation System for Teaching Control Engineering.

Sensors, vol. 17, pp. 2321.

García, M. V., Irisarri, E., Pérez, F., Estévez, E., Marcos,

M., 2016. OPC-UA Communications Integration using

a CPPS architecture. IEEE Ecuador Technical

Chapters Meeting, Guayaquil, Ecuador.

González, I., Calderón, A. J., Barragán, A. J., Andújar, J.

M., 2017. Integration of Sensors, Controllers and

Instruments Using a Novel OPC Architecture. Sensors,

vol. 17(7), pp. 1512.

González, I., Calderón, A. J., Andújar, J. M., 2017. Novel

Remote Monitoring Platform for RES-Hydrogen based

Smart Microgrid. Energy Conversion and

Management, vol. 148, pp. 489-505.

González, I., Calderón, A. J., Figueiredo, J., Sousa, J. M.

C., 2019. A Literature Survey on Open Platform

Communications (OPC) Applied to Advanced

Industrial Environments. Electronics, vol. 8, pp. 510.

LabVIEW Online. Available: http://www.ni.com/en-

gb/shop/labview.html (accessed on 30 January 2018)

Martinez, B., Vilajosana, X., Kim, I. H., Zhou, J., Tuset-

Peiró, P., Xhafa, A., Poissonnier, D., Lu, X., 2017.

I3Mote: An Open Development Platform for the

Intelligent Industrial Internet. Sensors, vol. 17, pp. 986.

Mejías, A., Reyes, M., Márquez, M. A., Calderón, A. J.,

González, I., Andújar, J. M. 2017. Easy handling of

sensors and actuators over TCP/IP Networks by Open

Source Hardware/Software. Sensors, vol. 17, 94, 2017.

OPC Foundation Online. Available: https://

opcfoundation.org/ (accessed on 20 January 2018)

Pereira, R., Figueiredo, J., Melicio, R., Mendes, V. M. F.,

Martins, J., Quadrado, J. C., 2015. Consumer energy

management system with integration of smart meters,”

Energy Reports, vol. 1, pp. 22-29.

Puigt, M., 2015. How Arduino is Open-sourcing Industry.

Presentation at Arduino Day 2015, Fablab Côte

d'Opale, Calais, France. Available online: http://www-

lisic.univ-littoral.fr/~puigt/LectureNotes/Arduino/

ArduinoDay2015_vfinal.pdf.

Robles, C., Callejas, J., Polo, A., 2017. Low-Cost Fuzzy

Logic Control for Greenhouse Environments with Web

Monitoring. Electronics, vol. 6, pp. 71.

Segura, F., Bartolucci, V., Andújar, J. M., 2017.

Hardware/Software Data Acquisition System for Real

Time Cell Temperature Monitoring in Air-Cooled

Polymer Electrolyte Fuel Cells. Sensors, vol. 17(7), pp.

1600.

Vivas, F. J., Heras, A., Segura, F., Andújar, J. M., 2019.

Cell voltage monitoring All-in-One. A new low cost

solution to perform degradation analysis on air-cooled

polymer electrolyte fuel cells. International Journal of

Hydrogen Energy, in press.

ICINCO 2019 - 16th International Conference on Informatics in Control, Automation and Robotics

180