Smoothing and Time Parametrization of Motion Trajectories

for Industrial Machining and Motion Control

Kv

ˇ

etoslav Belda

a

Department of Adaptive Systems, The Czech Academy of Sciences, Institute of Information Theory and Automation,

Pod Vodarenskou vezı 4, 182 08 Prague 8, Czech Republic

Keywords:

Path Model, G-Code, Path Smoothing, Time Parametrization, B

´

ezier Curves, Industrial Robotics.

Abstract:

The paper deals with path smoothing and time parametrization procedures intended for motion control of in-

dustrial machine tools and robots. Path smoothing, considered in this paper, is based on the application

of B

´

ezier curves. A possible straightforward solution ensuring compliance with given admissible positional

tolerances is introduced. Consequent time parametrization considered here employs arc length and specific

construction of acceleration polynomials. It describes the motion along the obtained smoothed curve geome-

try. It is given by timing the arc length, thus the construction of the feed rate profile. The key parts of the time

parametrization comprise: computation of path length; time parametrization with respect to arc length; and de-

composition to the individual Cartesian components describing individual curve coordinates. The theoretical

results are presented by representative examples in 2D and 3D spaces.

1 INTRODUCTION

Nowadays, a lot of Computer-Aided Design (CAD)

tools offer a simple way of construction of various

paths and shapes with complicated geometry. This ge-

ometry is usually stored as sets of points and modeled

by a combination of specific parametric curves. One

example of the advanced CAD tools is NX PLM

software (Siemens, 2019), which, with the applica-

tion of industry-oriented modules, offers the option

to store path’s description in specific G-Code used

in Computer Numeric Control (CNC) machine tools

(Xavier et al., 2010). This G-Code can be uploaded

directly to the real control system of a machine tool

or robot to ensure required motion along reference

trajectory.

In G-Code, the geometry data are typically re-

stricted to low level segments such as points (dwell,

fixed positions), straight lines (abscissas, linear seg-

ments) and arcs (circular segments). These restric-

tions lead to huge numbers of linear segments due

to complicated initial curve geometry and several cir-

cular segments for pure circular arcs. Transition be-

tween such segments are contiguous, but not smooth.

In order to satisfy the given kinematic constrains

without having to stop at each point of higher or-

a

https://orcid.org/0000-0002-1299-7704

der discontinuity, the path needs to be smoothed

in a preprocessing procedure before the actual time

parametrization, from which full-featured motion tra-

jectories arise (Zhang et al., 2018). Note that every

stop means increase of working time and increasing

of energy demands on braking and repeated starting

(Othman et al., 2015).

A recent trend in industrial production is to em-

ploy increasingly complicated motion trajectories es-

pecially in the case of industrial robots, see e.g. Fig. 1.

Thus, real-world testing on machine tools becomes

increasingly expensive. Therefore, newly generated

trajectories are first verified using software simula-

tions so that collisions and unreachable G-code parts

can be detected and optimized.

9

www.rcmt.cvut.cz

CAD/CAM systém

3D model CL-data

NC program

Výkresová

dokumentace

Seřizovací listy,

listy nástrojů a

přípravků, polotovar

SW pro roboty

- verifikace pohybů

- postprocessing

NC úloha

CAM

Příprava NC programů pro roboty

CAD

Robot

Figure 1: Machining with an industrial robot.

The focus of this paper is to introduce straight-

forward smoothing path algorithm and its incorpora-

Belda, K.

Smoothing and Time Parametrization of Motion Trajectories for Industrial Machining and Motion Control.

DOI: 10.5220/0007831402290236

In Proceedings of the 16th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2019), pages 229-236

ISBN: 978-989-758-380-3

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

229

Surface finish

Accuracy Speed

Figure 2: Qualitative triangle: Speed-Accuracy-Surface fin.

tion to a specific one-shot off-line time parametriza-

tion of the motion trajectories given by individ-

ual lines of G-Code. For smoothing of the trajecto-

ries, a specific analytical algorithm employing B

´

ezier

curves of fifth-degree (quintic B

´

ezier curve) is pro-

posed. The degree of B

´

ezier curve was selected

to achieve smooth connection to other trajectory seg-

ments (Sencer et al., 2015). The problem can be

looked at from a more general point of view, repre-

sented by the qualitative triangle: Speed-Accuracy-

Surface finish, shown in Fig. 2. It depicts relations

among specific qualitative features taken in to account

in motion control. All three features cannot naturally

be achieved simultaneously in full. Instead, a suitable

compromise is sought, which respects the given tech-

nological and economic requirements.

Recently, the requirement is to have very short

production cycle with reasonable accuracy and qual-

ity. Therefore, to solve such antagonistic requirement

(dual problem), the technology takes into account def-

inite tolerances i.e. engineering fits, since no element

or part can be manufactured completely accurately.

The range of permissible dimensions or tolerances is

determined with respect to the element or part func-

tion. This feature determine useful admissible range

in which the motion trajectory should be maintained.

The size of the admissible range (tolerance) forms in-

terval for the motion smoothing. This idea of admis-

sible tolerances is considered in the intended solution

of smoothing problem, proposed here in our paper.

This paper is organized as follows. Section 2 de-

scribes the tested path model and its G-Code. Sec-

tion 3 contains the description of the proposed

smoothing algorithm based on a specific construction

of quintic B

´

ezier curves. Section 4 deals with arc-

length time parametrization procedure including the

computation of arc-length using Simpson’s rule, time

parametrization with respect to adaptive arc length

and backward decomposition to the individual Carte-

sian components, i.e. individual curve coordinates.

Section 5 demonstrates representative examples of

smoothed curves constructed by the proposed algo-

rithm implemented in MATLAB environment.

2 PATH MODEL AND G-CODE

Path model reflects the target application and its

technological parameters. In the case of machining,

the parameters include maximum feed rate, accelera-

tion and jerk. These parameters are given by the spe-

cific construction of the machine tool or robot. Limits

on mentioned parameters are accompanied by addi-

tional technological limits such as maximum cutting

velocity and required accuracy (admissible or pre-

scribed tolerances and character of nominal dimen-

sions).

All these parameters determine resultant motion,

the parameters of machine tools determine start-up

time (acceleration, time to reach the desired feed

rate from zero) and stopping time (deceleration, time

to stop from feed rate to zero) whereas inherent run-

ning phase depends on prescribed feed rate (given

by specific technology and the used cutting tool)

and the geometry of the motion path (Msaddek et al.,

2014; Luo et al., 2007).

Thus, the path model consists of the above men-

tioned constraints on the tool motion together

with the description of the path geometry. The sim-

plest (and still most common) way of describing

the geometry of the path is to use a combination of lin-

ear and circular arc segments. Other, more advanced

methods for the path description and representation

exist, such as B-spline, Akima spline and NURBS,

but these elements are not universally supported.

A lot of research has been done in the recent years

on the topic of construction of and motion planning

on these curves (Erkorkmaz et al., 2017; Heng and

Erkorkmaz, 2010; Sencer et al., 2015). However,

the research is still ongoing and the commercial im-

plementation is not yet common and standardized.

The used G-code in this paper is presented in this

section. Its parametric interpretation by linear seg-

ments and B

´

ezier curves will be used for the proposed

smoothing algorithm. The algorithm outputs will be

involved in the method of time parametrization.

Now, let us introduce the G-Code used for test-

ing. The elements in the G-Code are the fol-

lowing: Rapid positioning G00; Linear interpo-

lation G01; (for completeness: Circular interpola-

tions, clockwise/counterclockwise G02/G03; Dwell

ICINCO 2019 - 16th International Conference on Informatics in Control, Automation and Robotics

230

G04;) End of program M30; Feed rate F [mm min

−1

].

The used G-Code example is in the Table 1.

Table 1: G-Code of testing trajectory (mm).

N010 ADIS = 0.005 % smth. tol.

N020 G01 X100 Y0 Z0 F18000

N030 G01 X100 Y0 Z100

N040 G01 X100 Y0 Z100

N050 G01 X100 Y100 Z0

N060 G01 X0 Y100 Z0

N070 G01 X0 Y100 Z100

N080 G01 X0 Y0 Z100

N090 G00 X0 Y0 Z0

N100 M30

(considered starting point: X0 Y0 Z0)

3 SMOOTHING ALGORITHM

This section deals with the algorithm using quintic

B

´

ezier curves (curves described using 5

th

order Bern-

stein’s basis polynomials) (Piegl and Tiller, 1997).

The algorithm copes with the smoothing of sharp cor-

ners while satisfying the specified tolerance limits.

The proposed algorithm relies only on analytic for-

mulas. Two types of parameters u and p are consid-

ered here. The parameter u is the parameter given

by B

´

ezier curve parametrization. Its relation to arc

length cannot be analytically described. Whereas,

the parameter p is the parameter corresponding to arc-

length. It is directly applicable in abscissa and arc

segments, where is in linear proportion to distance

and angle respectively.

3.1 Definition of Used B

´

ezier Curve

As was mentioned, used B

´

ezier curve is general, quin-

tic curve. It is described by the following set of equa-

tions for its geometric points B(u) (1) and appropriate

derivatives (2) - (5):

B(u) = (1 − u)

5

P

1

+ 5u(1 − u)

4

P

2

+10u

2

(1 − u)

3

P

3

+ 10u

3

(1 − u)

2

P

4

+5u

4

(1 − u)P

5

+ u

5

P

6

(1)

dB(u)

du

= 5(1 − u)

4

(P

2

− P

1

)

+20u(1 − u)

3

(P

3

− P

2

) + 30u

2

(1 − p)

2

(P

4

− P

3

)

+20u

3

(1 − u)(P

5

− P

4

) + 5u

4

(P

6

− P

5

) (2)

d

2

B(u)

du

2

= 20(1 − u)

3

(P

3

− 2P

2

+ P

1

)

+60u(1 − u)

2

(P

4

− 2P

3

+ P

2

)

+60u

2

(1 − u)(P

5

− 2P

4

+ P

3

)

+20u

3

(P

6

− 2P

5

+ P

4

) (3)

d

3

B(u)

du

3

= 60(1 − u)

2

(P

4

− 3P

3

+ 3P

2

− P

1

)

+120u(1 − u)(P

5

− 3P

4

+ 3P

3

− P

2

)

+60u

2

(P

6

− 3P

5

+ 3P

4

− P

3

) (4)

d

4

B(u)

du

4

= 120(1 − u)(P

5

− 4P

4

+ 6P

3

− 4P

2

+ P

1

)

+120u(P

6

− 4P

5

+ 6P

4

− 4P

3

+ P

2

) (5)

where u ∈ h0, 1i is a parameter of B

´

ezier curve;

P

i

, i = 1, ··· , 6 are control points of the curve;

B(u) = [x(u), y(u), z(u)]

T

are the Cartesian coordi-

nates of curve points;

dB(u)

du

= [v

x

(u), v

y

(u), v

z

(u)]

T

,

d

2

B(u)

du

2

= ··· represent the appropriate derivatives

with respect to the parameter u.

Note that the equations (1) - (5) are expressed

as polynomials in the parameter u with coefficients

explicitly given by the combination of the control

points.

3.2 Algorithm Principle

The principle of the algorithm is to use B

´

ezier curve

segment that smoothens the sharp connection be-

tween two intersecting lines. To construct the suit-

able B

´

ezier segment, all control points can be ex-

pressed using only one parameter d, which corre-

sponds to the admissible tolerance ε.

Hence, for prescribed tolerance, a unique analyt-

ical solution, depending just only on the tolerance ε

and the initial, transition and end points P

s

, P

t

and P

e

(see Fig. 3), can be obtained.

The proposed algorithm procedure includes the

following parts:

i) evaluation of B

´

ezier points and derivatives

for u = 0, u = 0.5 and u = 1

ii) points and derivatives for intersecting lines

iii) comparison of corresponding derivatives

iv) determining point B(u)|

u=0.5

v) expressing control points via parameter d

vi) computation of the parameter d

These parts represent a sequence of steps for the de-

termination of the parameter d as it is shown in Fig. 3.

Smoothing and Time Parametrization of Motion Trajectories for Industrial Machining and Motion Control

231

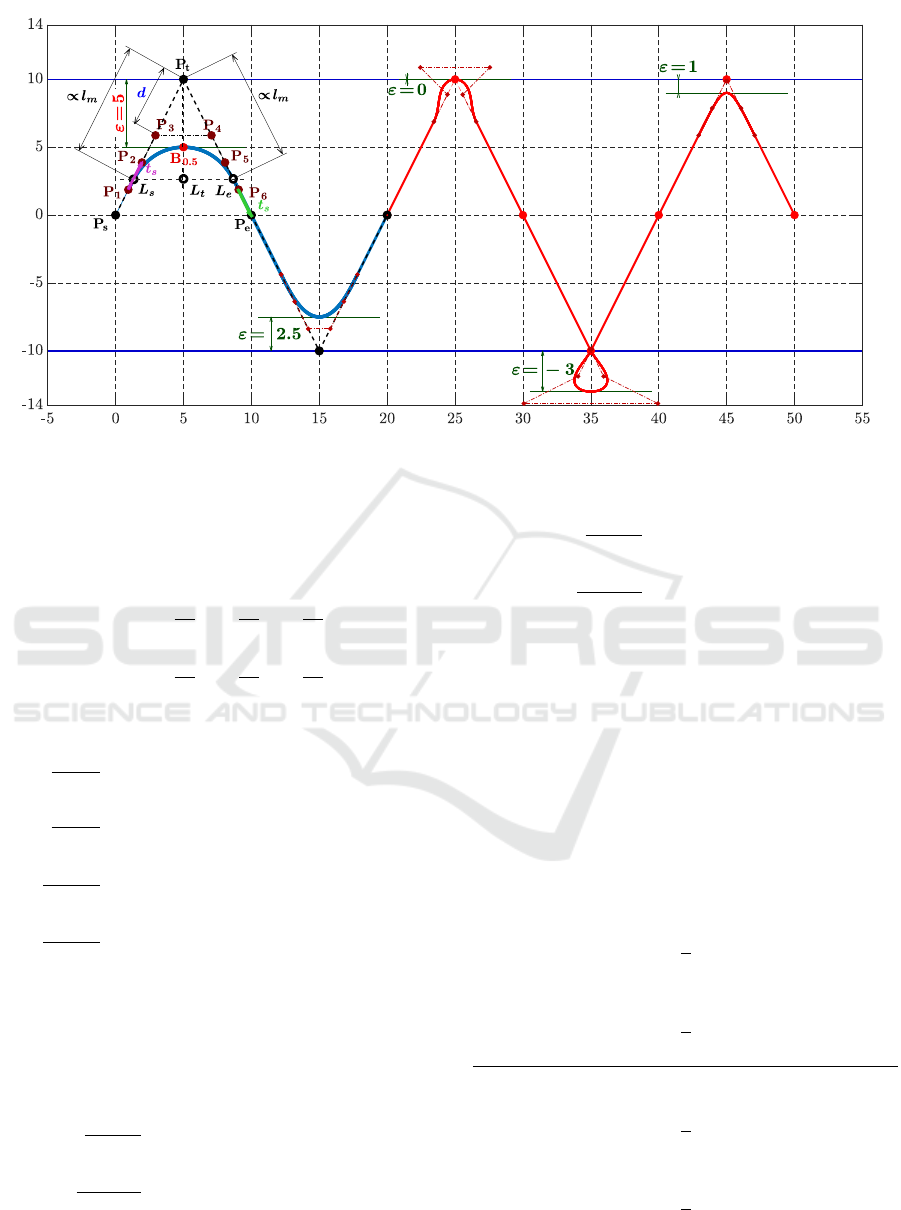

Figure 3: B

´

ezier parameters and examples of the smoothing for different required offsets (tolerances).

The explanation of individual parts is as follows:

i) evaluation of B

´

ezier points and derivatives

for u = 0, u = 0.5 and u = 1:

B(u)|

u=0

= P

1

(6)

B(u)|

u=0.5

=

1

32

P

1

+

5

32

P

2

+

10

32

P

3

+

10

32

P

4

+

5

32

P

5

+

1

32

P

6

(7)

B(u)|

u=1

= P

6

(8)

dB(u)

du

u=0

= 5(P

2

− P

1

) (9)

dB(u)

du

u=1

= 5(P

6

− P

5

) (10)

d

2

B(u)

du

2

u=0

= 20(P

3

− 2P

2

+ P

1

) (11)

d

2

B(u)

du

2

u=1

= 20(P

6

− 2P

5

+ P

4

) (12)

ii) points and derivatives for intersecting lines:

The initial description, used in this part, follows

from parametric equations of lines, see (13) and (16)

and Fig. 3:

L

s

(p) = P

s

+ p(P

t

− P

s

) (13)

dL

s

(p)

d p

= P

t

− P

s

(14)

d

2

L

s

(p)

d p

2

= 0 (15)

L

e

(p) = P

t

+ p(P

e

− P

t

) (16)

dL

e

(p)

d p

= P

e

− P

t

(17)

d

2

L

e

(p)

d p

2

= 0 (18)

Note that the parameter p, appearing in (13)

and (16), is a natural geometric parameter corre-

sponding to arc length of the segment. This parameter

will be used as the reference parameter in time param-

eterisations. Since the parameter of B

´

ezier curve u is

not linearly related to the arc-length, it will be also

transformed to the mentioned parameter p. However,

both parameters are considered as uniform parame-

ters, i.e. p ∈ h0, 1i as well as u ∈ h0, 1i by definition;

iii) comparison of corresponding derivatives

(for smooth joining of abscissas and B

´

ezier curve):

1

st

derivative: 5(P

2

− P

1

) = P

t

− P

s

(19)

⇒ P

2

=

1

5

(P

t

− P

s

) + P

1

(20)

2

nd

derivative: P

3

− 2P

2

+ P

1

= 0 (21)

⇒ P

3

=

2

5

(P

t

− P

s

) + P

1

(22)

1

st

derivative: 5(P

6

− P

5

) = P

e

− P

t

(23)

⇒ P

5

=

1

5

(P

t

− P

e

) + P

6

(24)

2

nd

derivative: P

6

− 2P

5

+ P

4

= 0 (25)

⇒ P

3

=

2

5

(P

t

− P

e

) + P

6

(26)

ICINCO 2019 - 16th International Conference on Informatics in Control, Automation and Robotics

232

iv) determining point B(u)|

u=0.5

:

l

s

=

p

(x

t

− x

s

)

2

+ (y

t

− y

s

)

2

+ (z

t

− z

s

)

2

l

e

=

p

(x

t

− x

e

)

2

+ (y

t

− y

e

)

2

+ (z

t

− z

e

)

2

l

m

= min(l

s

, l

e

) (27)

L

s

= P

t

+ (P

s

− P

t

)

(0.5l

m

)

l

s

L

e

= P

t

+ (P

e

− P

t

)

(0.5l

m

)

l

e

L

t

=

1

2

(L

s

+ L

e

) (28)

l

t

=

q

(x

L

t

− x

P

t

)

2

+ (y

L

t

− y

P

t

)

2

+ (z

L

t

− z

P

t

)

2

(29)

B(0.5) = P

t

+ ε

L

t

− P

t

l

t

(30)

v) expressing control points via parameter d:

Unknown control points of B

´

ezier curve can be ex-

pressed straightforwardly by specific distance d from

transition point (intersection point of two contiguous

lines). Specifically, d is the distance from transition

point P

t

to control points P

3

and P

4

.

t

s

=

P

t

− P

s

l

s

, (l

s

= kt

s

k) (31)

t

e

=

P

t

− P

e

l

e

, (l

e

= kt

e

k) (32)

P

1

= P

t

−

2

5

l

m

t

s

− d t

s

(33)

P

2

= P

t

−

1

5

l

m

t

s

− d t

s

(34)

P

3

= P

t

− d t

s

(35)

P

4

= P

t

− d t

e

(36)

P

5

= P

t

−

1

5

l

m

t

e

− d t

e

(37)

P

6

= P

t

−

2

5

l

m

t

e

− d t

e

(38)

vi) computation of the parameter d:

The computation of the searched parameter d is deter-

mined by eqs. (30) and (7) with eqs. (33) – (38).

B(0.5) = P

t

+ ε

L

t

− P

t

l

t

32B(0.5) = P

1

+ 5P

2

+ 10P

3

+ 10P

4

+ 5P

5

+ P

6

= 32P

t

− 16 d(t

s

+t

e

) −

7

5

l

m

(t

s

+t

e

)

⇒ d = 2

(P

t

− B(0.5))

.(t

s

+t

e

)

−

7

80

l

m

(39)

4 TIME PARAMETRIZATION

The time parametrization with respect to arc length

includes just computation of path length, time

parametrization with respect to arc length (timing

of geometric parameter p(t)) and decomposition

to the individual curve coordinates. The following in-

dividual sections will show related theoretical back-

ground.

4.1 Computation of the Path Length

Computation of the path length is defined as:

` = s(u)|

u=1

=

u=1

Z

0

ds =

u=1

Z

0

p

˙x

2

+ ˙y

2

+ ˙z

2

du (40)

The integral (40) can be evaluated analytically

only for simple segments such as lines or arcs. How-

ever, for B

´

ezier curve it is necessary to use some ap-

proximative numerical method. Here, it is suitable

to consider Simpson’s rule: The given interval of pa-

rameter u is divided into an even number of subin-

tervals by equidistant points, similarly as in the case

of the trapezoidal rule, and in any interval [u

2i

,u

2i+2

],

i = 0, 1,·· · ,

m

2

− 1, of the length 2h and the Newton-

Cotes formula is used, then the resulting formula is

b

Z

a

f (u)du =

1

3

h[ f (u

0

) + 4 f (u

1

) + 2 f (u

2

)

+ 4 f (u

3

) + ··· + 4 f (u

m−3

)

+ 2 f (u

m−2

) + 4 f (u

m−1

) + f (u

m

)] + E( f (u)) (41)

where f (u) =

p

˙x(u)

2

+ ˙y(u)

2

+ ˙z(u)

2

, h =

b−a

m

,

a = 0 and b = 1; and E( f (u)) = −

1

180

h

4

d

4

f

du

4

(o)

is a numerical error (Rektorys, 1994).

4.2 Timing of Geometric Parameter

Time parametrization based on arc length can be re-

alized according to selection of acceleration polyno-

mial a of 1

st

, 3

rd

or 5

th

order. For purpose of this

paper, let us consider acceleration polynomial a of 1

st

order. Other possibilities are described e.g. in (Heng

and Erkorkmaz, 2010; Huang and Zhu, 2016).

For the selection of the acceleration polynomial

of a of 1

st

order, there exist two main acceleration

shapes: triangular and trapezoidal, both with three

special cases: limit case without involved central zero

acceleration determining constant feed rate; start-up

and stop phases. The mentioned two main shapes are

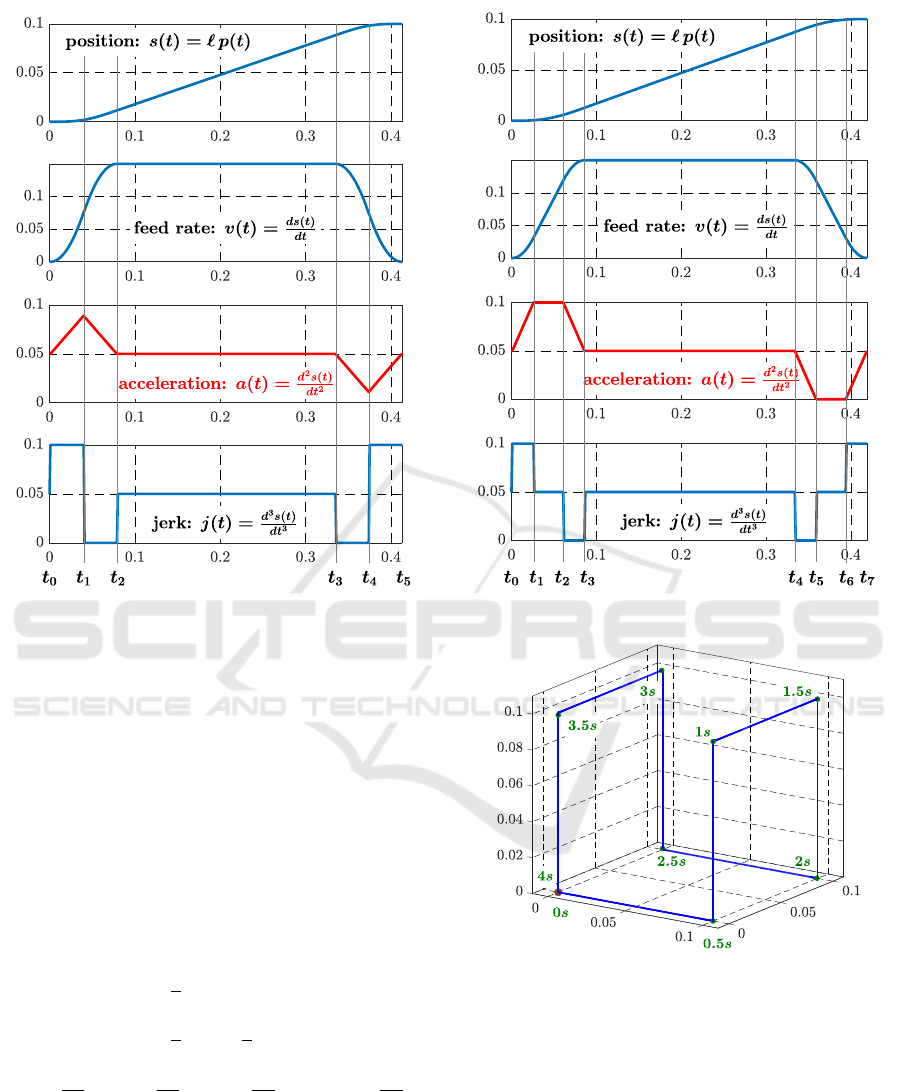

illustrated in Fig. 4 (Belda and Novotn

´

y, 2012).

Smoothing and Time Parametrization of Motion Trajectories for Industrial Machining and Motion Control

233

Figure 4: Kinematic quantities considering acceleration a(t) of 1

st

order with triangular (left) or trapezoidal (right) profile.

Time parametrization follows from the profiles

(Fig. 4) and it is determined for all indicated time in-

tervals, in which all related limiting kinematic quan-

tities ( j

max

, a

max

, v

max

) are considered. The intervals

for triangular acceleration profile are:

(t

0

, t

1

i, (t

1

, t

2

i, (t

2

, t

3

i, (t

3

, t

4

i and (t

4

, t

5

i;

and for trapezoidal acceleration profile are:

(t

0

, t

1

i, (t

1

, t

2

i, (t

2

, t

3

i, (t

3

, t

4

i, (t

4

, t

5

i, (t

5

, t

6

i and (t

6

, t

7

i.

In general, the following consecutive integration

is solved just within defined time intervals:

j(t) = a

0

, a

0

= k j

max

, k ∈ {−1, 0, 1} (42)

a(t) =

Z

j(t)dt = a

0

t + a

1

(43)

v(t) =

Z

a(t)dt =

1

2

a

0

t

2

+ a

1

t + a

2

(44)

s(t) =

Z

v(t)dt =

1

6

a

0

t

3

+

1

2

a

1

t

2

+ a

2

t + a

3

(45)

p(t) =

s(t)

`

, ˙p(t) =

v(t)

`

, ¨p(t) =

a(t)

`

and

...

p

(t) =

j(t)

`

.

The result of the integration are coefficients in indi-

vidual resulting equations. Then, the geometric pa-

rameter including its appropriate derivatives can be

applied in the decomposition of the motion trajectory

to individual coordinate components (axes) (Belda

et al., 2007).

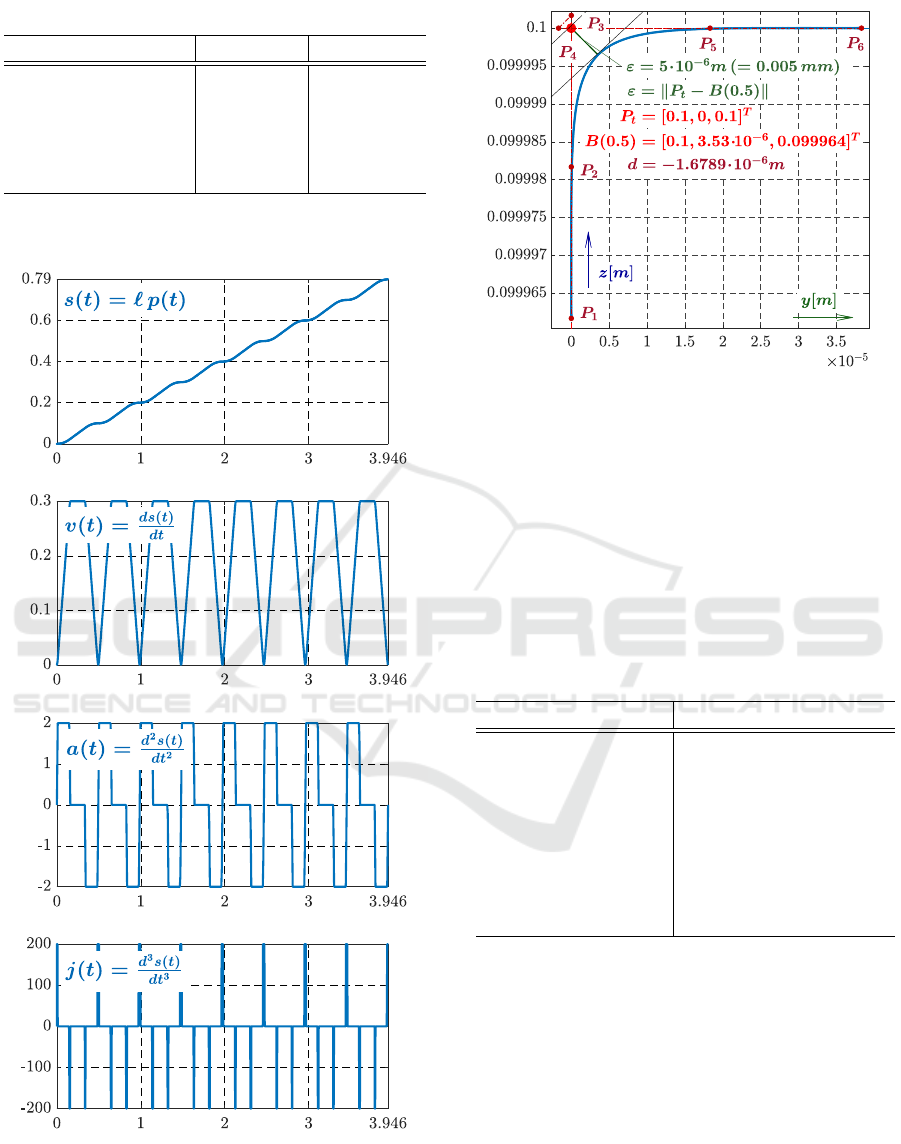

Figure 5: Testing trajectory (axes in [m]).

5 REPRESENTATIVE EXAMPLES

5.1 Runs with Tolerances ≈ 10

−6

m

As was mentioned, the G-Code, used for comparative

runs, is already introduced in the Table 1. Its graph-

ical representation is in Fig. 5. The time labels show

approximative time and direction of the motion.

The used parameters of the runs is in the Table 2.

ICINCO 2019 - 16th International Conference on Informatics in Control, Automation and Robotics

234

Table 2: Testing parameters.

parameter symbol value

admissible tolerance ε 5 · 10

−6

m

max. feed rate v

max

0.3ms

−1

max. acceleration a

max

2ms

−2

max. jerk j

max

200ms

−3

sampling period T

s

10

−3

s

The runs are shown in the following Fig. 6 -Fig. 7.

Figure 6: Time behaviours [s]: s(t), v(t), a(t), j(t).

Fig. 6 shows results of proposed smoothing algo-

rithm with time parametrization. Since the tolerance

ε = 0.005mm is too small, it is necessary to explore

Figure 7: Detail of smoothing with proposed algorithm.

the details in Fig. 7, which shows one B

´

ezier segment

of the testing geometric path (segment at front upper-

right vertex P

t

= [0.1, 0, 0.1]

T

). Total length saving is

0.04mm per 7 corners only. However, in sum in in-

dustrial machining, the saving is noticeable.

5.2 Example with Tolerances ≈ 10

−3

m

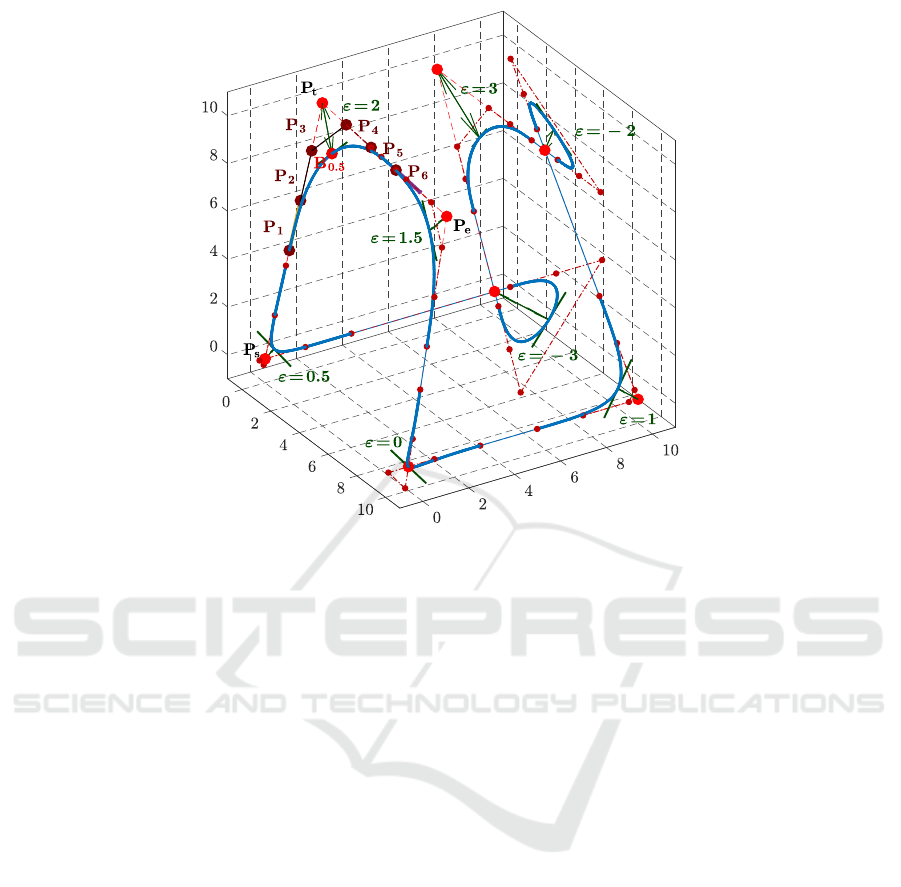

Values of d-parameter for set of B

´

ezier curves in gen-

eral 3D position (Fig. 8) are in the Table 3.

Table 3: List of d-parameters.

tolerance ε parameter d

ε

1

= 2.0 mm d

1

= 1.9223 mm

ε

2

= 1.5 mm d

2

= 1.2579 mm

ε

3

= 0.0 mm d

3

= −0.8750 mm

ε

4

= 1.0 mm d

4

= 0.3972 mm

ε

5

= −2.0 mm d

5

= −3.8915 mm

ε

6

= 3.0 mm d

6

= 3.5864 mm

ε

7

= −3.0 mm d

7

= −4.6811 mm

ε

8

= 0.5 mm d

8

= −0.2406 mm

6 CONCLUSION

This paper discusses the problem of smoothing con-

nection of linear segments by B

´

ezier curves. The re-

sults demonstrate achieving of prescribed tolerances

in the context of machine tools (≈ 10

−6

m) as well

as bigger motion (≈ 10

−3

m) for robotic case by de-

rived algorithm using MATLAB environment. Future

work will be focussed on on-line solution of smooth-

ing and time parametrization that will be able to con-

sider higher order polynomials.

Smoothing and Time Parametrization of Motion Trajectories for Industrial Machining and Motion Control

235

Figure 8: Example of general trajectory smoothing with tolerances ≈ 10

−3

m.

REFERENCES

Belda, K., B

¨

ohm, J., and P

´

ı

ˇ

sa, P. (2007). Concepts of

model-based control and trajectory planning for par-

allel robots. In Klaus, S., editor, Proc of 13th IASTED

Int. Conf. on Robotics and Applications, pages 15–20.

Acta Press.

Belda, K. and Novotn

´

y, P. (2012). Path simulator for ma-

chine tools and robots. In Proc. of the 17th Int. Conf.

on Methods and Models in Automation and Robotics,

pages 373–378. West Pomeranian University of Tech-

nology.

Erkorkmaz, K., Chen, Q.-G., Zhao, M.-Y., Beudaert, X.,

and Gao, X.-S. (2017). Linear programming and win-

dowing based feedrate optimization for spline tool-

paths. CIRP Annals, 66(1):393 – 396.

Heng, M. and Erkorkmaz, K. (2010). Design of a NURBS

interpolator with minimal feed fluctuation and contin-

uous feed modulation capability. Int. J. Machine Tools

& Manufacture, 50:281–293.

Huang, J. and Zhu, L. (2016). Feedrate scheduling for in-

terpolation of parametric tool path using the sine se-

ries representation of jerk profile. Proc. of the Inst.

of Mech. Engineers, Part B: J. Engineering Manufac-

ture, 231.

Luo, F.-Y., Zhou, Y.-F., and Yin, J. (2007). A universal

velocity profile generation approach for high-speed

machining of small line segments with look-ahead.

The Int. J. of Advanced Manufacturing Technology,

35(5):505–518.

Msaddek, E. B., Bouaziz, Z., Baili, M., and Dessein, G.

(2014). Influence of interpolation type in high-speed

machining (hsm). The Int. J. of Advanced Manufac-

turing Technology, 72(1):289–302.

Othman, A., Belda, K., and Burget, P. (2015). Physical

modelling of energy consumption of industrial articu-

lated robots. In Proc. 15th Int. Conf. on Control, Au-

tomation and Systems, ICCAS 2015, pages 784–789.

Institute of Control, Robotics and Systems, ICROS.

Piegl, L. and Tiller, W. (1997). The NURBS Book. Springer.

Rektorys, K. (1994). Survey of Applicable Mathematics.

Springer.

Sencer, B., Ishizaki, K., and Shamoto, E. (2015). A cur-

vature optimal sharp corner smoothing algorithm for

high-speed feed motion generation of NC systems

along linear tool paths. Int. J. Adv. Manuf. Technol.,

76:1977–1992.

Siemens (2019). NX docomentation. online.

Xavier, P., Yann, L., and Walter, R. (2010). Kinematic mod-

elling of a 3-axis NC machine tool in linear and circu-

lar interpolation. CoRR, pages 1004–2354.

Zhang, Y., , Zhao, M., Peiqing, Y., , Jiang, J., and Zhang,

H. (2018). Optimal curvature-smooth transition and

efficient feedrate optimization method with axis kine-

matic limitations for linear toolpath. The Int. J. of Ad-

vanced Manufacturing Technology, 99(1):169–179.

ICINCO 2019 - 16th International Conference on Informatics in Control, Automation and Robotics

236