Intelligent Manufacturing System of LGS Profiles for Green Metallic

Constructions

Mihaiela Iliescu

1

a

, Marius Pandelea

1

b

, Maria-Magdalena Rosu

2

c

, Luige Vladareanu

1

d

,

Dragos Capatina

1

e

and Adrian Margean

3

1

Institute of Solid Mechanics, Romanian Academy, Constantin Mille 15, Bucharest, Romania

2

Department of Manufacturing Technologies, POLITEHNICA University of Bucharest,

Splaiul Independentei 313, Bucharest, Romania

3

SC Casa Metalica SA, Erou Iancu Nicolae 8, Voluntari, Romania

capatina.dragos@gmail.com, adrianmargean75@yahoo.com

Keywords: Manufacturing System, Light Gauge Steel (LGS), Induction Hardening, Metallic Construction, Green,

Intelligent.

Abstract: The paper evidences research results on an innovative intelligent manufacturing process and its

manufacturing system. The metallic construction, based on steel framing and, consequently, on Light Gauge

Steel profiles, has got an increasing attention lately, due to their specific features that involve environmental

friendly building technologies, process efficiency and, last but not the least, relatively low costs. A metallic

construction has a steel framing structure, similar to that of wood, but is lighter and easier to build, not to

mention that it is recyclable waste. It is based on LGS profiles, that are manufactured by cold plastic

deformation process of relatively low carbon steel. In order to improve the profile’s material mechanical

characteristics, induction hardening process is introduced, distinctly, during the whole manufacturing

process stages. Thus, it is estimated a reduction of material consumption, about 10 % and, consequently, a

reduction of construction costs by 7%.

a

https://orcid.org/0000-0002-3280-5933

b

https://orcid.org/0000-0002-4670-0956

c

https://orcid.org/0000-0002-9243-7060

d

https://orcid.org/0000-0003-1745-2997

e

https://orcid.org/0000- 0001-9285-0093

1 INTRODUCTION TO LIGHT

GAUGE STEEL FRAMING

High industrialization and intensive use of natural

resources have caused severe climatic changes that

impact, not for the best usually, so many people’s

lives. Against this backdrop, there comes the need of

building constructions in a wise way, to be able to

have as much affordable space as possible in a given

perimeter, to be safe and sustainable, not to mention

to have as many recyclable materials as possible. First

in the USA, rather than in Europe, steel framed

construction has been and extended, so that, an

interesting and promising market is available.

Characteristics, benefits and limitation of this type

of buildings are presented further in this paper. Still,

the focus is on the research developed in order to

improve the mechanical characteristics of the steel in

profiles called Light Gauge Steel (LGS) profiles.

As mentioned in (www.designingbuildings.

co.uk), light gauge steel framing systems consist of

structural frames made of cold formed steel sections.

They can be used throughout a structure, including

load-bearing exterior walls, non-load bearing interior

walls, floor joists, curtain walls and roof trusses.

Factors that led to the use of LGS frames in

buildings (Yandzio, et al., 2015) are these:

environmental necessity to preserve use land; efficient

and sustainable construction process; adaptability to

provide more adaptable use of space.

Some methods of building light gauge steel

framed constructions are as follows: stick-build

construction, when discrete elements are assembled

234

Iliescu, M., Pandelea, M., Rosu, M., Vladareanu, L., Capatina, D. and Margean, A.

Intelligent Manufacturing System of LGS Profiles for Green Metallic Constructions.

DOI: 10.5220/0007832902340241

In Proceedings of the 8th International Conference on Smart Cities and Green ICT Systems (SMARTGREENS 2019), pages 234-241

ISBN: 978-989-758-373-5

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

on-site; panel construction, when wall panels, floor

cassettes, roof trusses etc. are manufactured in a

factory and assembled on site; modular construction,

when units are completely manufactured in a factory

and, further, delivered to site.

Lightweight steel framing (LSF) constructions do

present many specifics advantages, as many

specialists mention.

For example, Claudio Martins (Martins et. al,

2013) emphasizes the thermal performance of LSF

elements (made of Light Gauge Steel profiles)

focusing on available strategies for the mitigation of

thermal bridges, such as: keep the facade geometry as

simple as possible; avoid the interruption of the

insulated layer; the insulation layers to be joined at

full length, etc.

The steel producer, ArcelorMittal (https://

constructalia. arcelormittal.com) states that the light

weight steel frame house is very efficient, from the

sustainability point of view. That is due to the fact

that steel is 100% recyclable and almost 80% of the

steel in construction comes from recycling.

Moreover, the structure is light and can be built on

less foundation on regular, or even, poor soils.

In the project Waste Reduction Potential of Light

Steel Frame Construction (WAS 003-003) there are

mentioned the principles of the lean process and their

impact on the waste minimisation potential of the

offsite manufacture, which are focused on the

manufacturing processes of the LSF elements for

walls and floors, as shown in Table 1.

A lightweight steel framed construction is safe in

case of earthquakes, usually in higher degree than a

common (wood) construction, due to specific features

as the ones that follow next (http://

www.steelframing.org/earthquake).

-Steel is a stable material with consistent chemical

attributes and once the steel stud has been formed, it

will remain straight with virtually no change to the

thickness, width or other dimensional properties.

- Steel frame is typically one-third the weight of a

wood frame and, consequently, damage through

"inertia" will be significantly reduced.

- Steel framing is impervious to rot, termites and

other pests that can slowly degrade the structural

integrity of the framing members, lessening the ability

of a house to withstand seismic forces

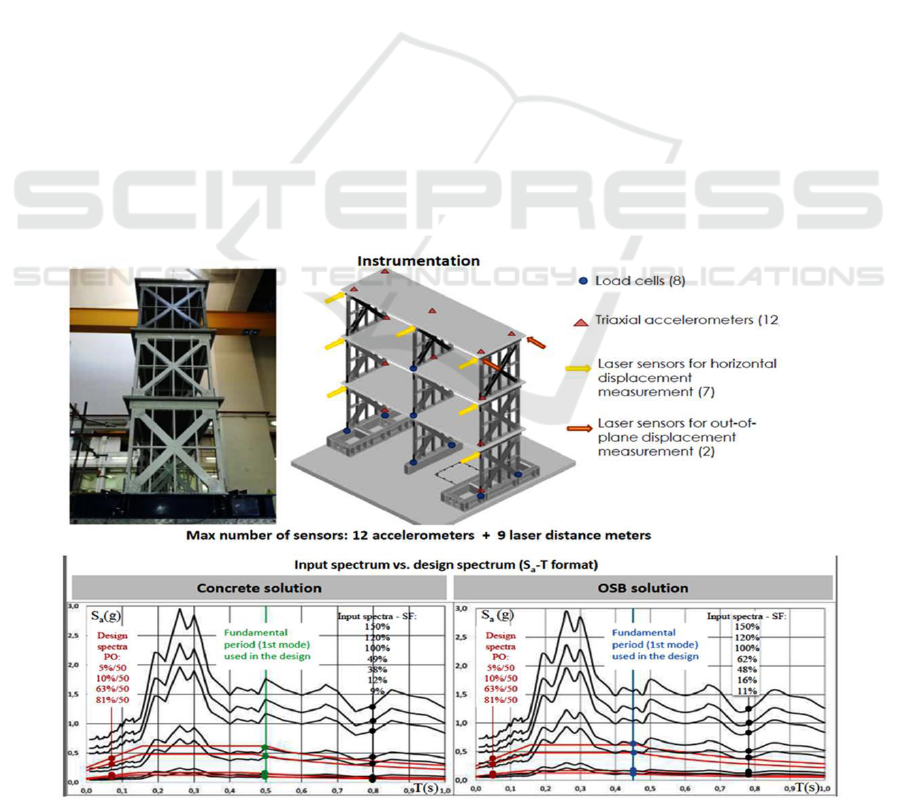

A study on the seismic behavior of the steel

lightweight structures, has been developed in the

ELISSA project (Landolfo R, 2018) . It is mentioned

that all the steel structures could be designed

according a DCL (low dissipative approach for low

seismicity zones) by assuming the behavior factor

equal to 1.5. Still, this approach may be restrictive,

since the lightness of lightweight systems also makes

them a good solution for high seismicity zones. Some

relevant results of this research are shown in Figure 1.

Figure 1: Seismic behavior of lightweight structures. (Landolfo R, 2018).

Intelligent Manufacturing System of LGS Profiles for Green Metallic Constructions

235

Table 1: Summary of saved materials and waste generated. (WAS 003-003).

3 INTELLIGENT INNOVATIVE

MANUFACTURING SYSTEM

FOR LGS PROFILE

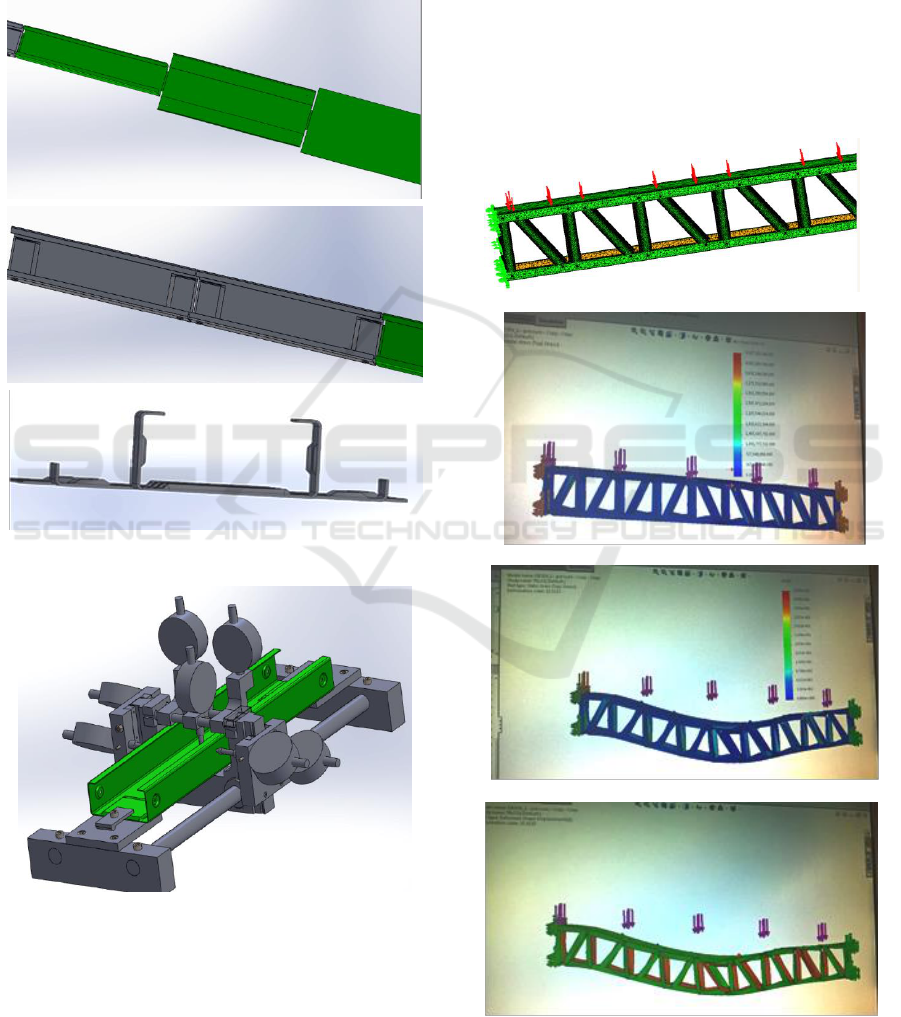

Lightweight steel framed constructions have as basic

element the light gauge steel (LGS) profile, usually

of C, or U type cross section. Depending on their

position within the structure and, consequently, on

its loading, the shape and dimensions of the LGS

profile varies – see Figure 2. For this research, it has

been considered of interest to study the C shape

profile, with 420 mm length – due to the high

loading stress when used in trusses and studs.

U / C type

LGS profile

300 mm

length

C type LGS

profile

420 mm

length

Figure 2: LGS profile type.

LGS profiles are made of steel with relatively

low carbon percentage, delivered as tape coil,

previously galvanized. Images of LGS profiles are

presented in Figure 3.

LGS

profiles

LGS profiles assembled

Figure 3: LGS profile.

MoMa-GreenSys 2019 - Special Session on Modelling Practical Paradigms of Green Manufacturing Systems

236

The basic manufacturing process for LGS profiles

is that of cold plastic deformation. Mainly, from strip

coil, in successive stages, starting from flat shape (coil

material) final profile cuts, wholes and side bending

are obtained. For the studied C type LGS profile, of

420 mm length, conventionally called C420, the

technological scheme is shown in Figure 4.

Figure 4: LGS profile cold plastic deformation.

Figure 5: Control device for LGS profile.

Even if it is assumed that the geometric precision

of the LGS profile stands within the prescribed

tolerance, there has been designed a device checking

the resulting dimensions, shape and position of the

relative surfaces (after the cold deformation process)

of the profile (Figure 5).

This device is basic, either portable, or fixed, for

profiles not longer than 700 mm (420 mm being the

length of the C420) and fit for further automation

and computer assisted command.

As mentioned before, while being components of

modular structures in lightweight framed

constructions, the LGS profiles are submitted to

various loads (snow, wind, vibration, shearing /

compression / bending forces) and, consequently the

state of stress and strain is induced within its

material. Example of loads, stress and strains for a

truss made of C420 profiles is presented in Figure 6.

a. loading

b. von Mises stress

c. strain

d. deformed truss

Figure 6: Modelling and simulation of stress and strain.

Intelligent Manufacturing System of LGS Profiles for Green Metallic Constructions

237

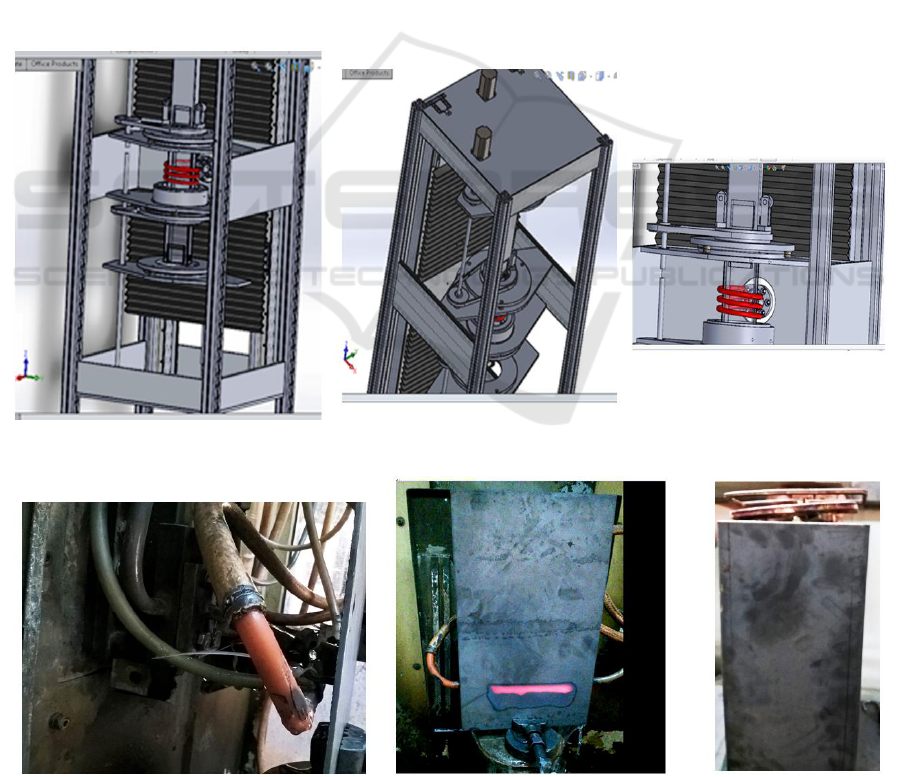

Improving the LGS profile’s material mechanic

characteristics, so as to have higher tensile strength

and, when necessary, higher hardness, has been

considered of benefit for the complex process of

building metallic steel framed constructions. As

profile thickness is of low vaules (usually, about 1.0

3.0 mm) and, moreover, the material’s ductility

should be maintained whithin reasonable values (to

avoid fragile failure) the induction hardening, process

has been considered and studied in this research. In a

real situation when the steel framing structure is build

for the metallic costruction, it is not necessary to

have higher hardness or / and tensile strength values

on all the profile’s length, just only on individualized

parts of it, where stress and strain values are estimated

to be significantly high (see the modeling and

simulation in Figure 6).

The device to be used for induction hardening of

the LGS C420 profile, has been designed so that to

enable (Iliescu, 2018) the following:

- adequate fixture of profile (without fixturing

deformation and minimising thermal deformation);

- motion of the induction coil along the profile’s

longitudinal axis – with variable speed;

- rotation of the profile around its longitudinal axis,

IF necessary for the thermal process optimisation;

- real time command and control of motions and

process parameters values.

All the above features of the device enable the

optimisation of the induction hardening process and,

consequently, required values of the thermal process

output variables (tensile strength, R

m

, and hardness,

HV) to be obtained.

Images of this customized device design for LGS

profile induction hardening are shown in Figure 7.

The induction hardening process, experiments carried

out in order to determine, by statistical methods

(design of experiments and multivariable regression),

the optimal process parameters values, are presented

in Figure 8.

Figure 7: Device for induction hardening of the LGS profiles.

Figure 8: Experiments on induction hardening of the LGS profile’s material.

MoMa-GreenSys 2019 - Special Session on Modelling Practical Paradigms of Green Manufacturing Systems

238

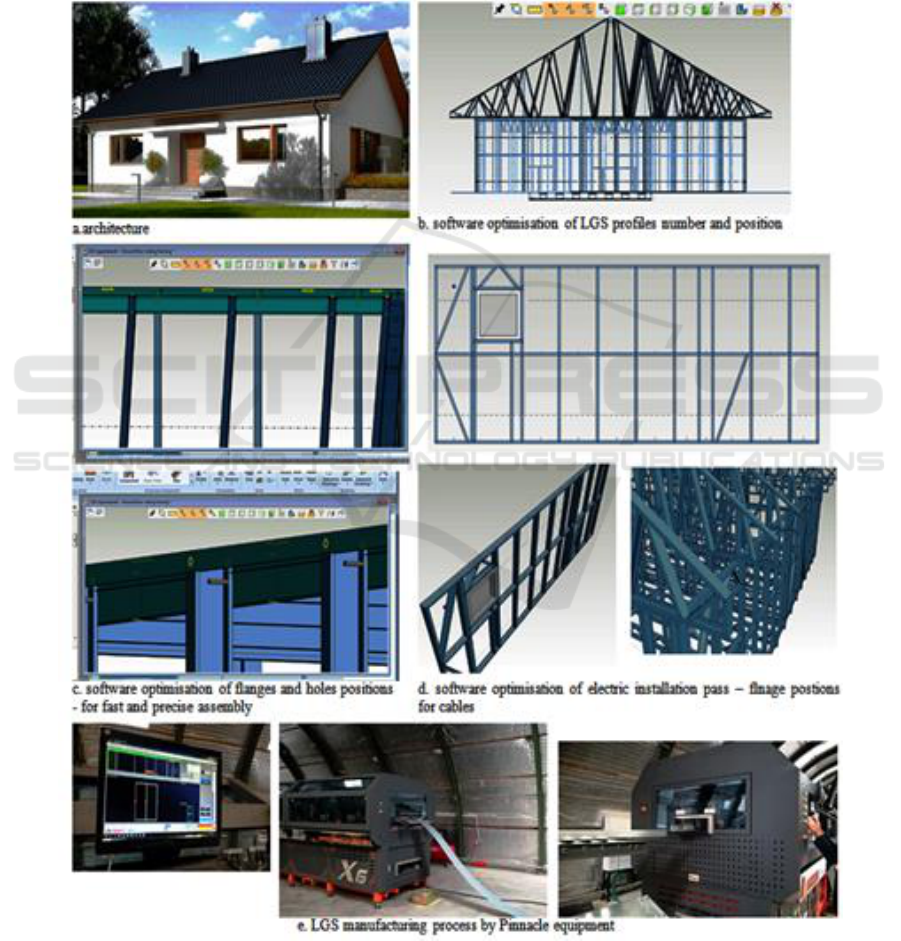

The complete manufacturing process of LGS

profiles, as previously mentioned involves the cold

plastic deformation process and the induction

hardening process. An intelligent equipment, that

enables integrated and customized building of the

metallic construction is Pinnacle LGS.

Assisted by the Vertex software, the complete

design and, further on, the manufacturing of LGS

profiles are done, as shown in Figure 9:

- architecture;

- resistance of the steel framed construction;

- optimisation of utilities’ (electricity, sanitary,

thermal) paths;

- roll forming manufacturing of LGS profiles,

according to all the optimisations previously set;

- estimation of all the material and components

consumptions;

- estimation of time for erection of construction;

- estimation of costs: overall and categories.

Figure 9: Intelligent manufacturing system.

Intelligent Manufacturing System of LGS Profiles for Green Metallic Constructions

239

4 MANAGEMENT

In the current market economy, the products and

services will develop in accordance with the client’s

ordering, therefore these will be individualized. In

this context, the approaches of open innovation and

product intelligence, as well as product memory, are

of outstanding importance (Roblek et all, 2016).

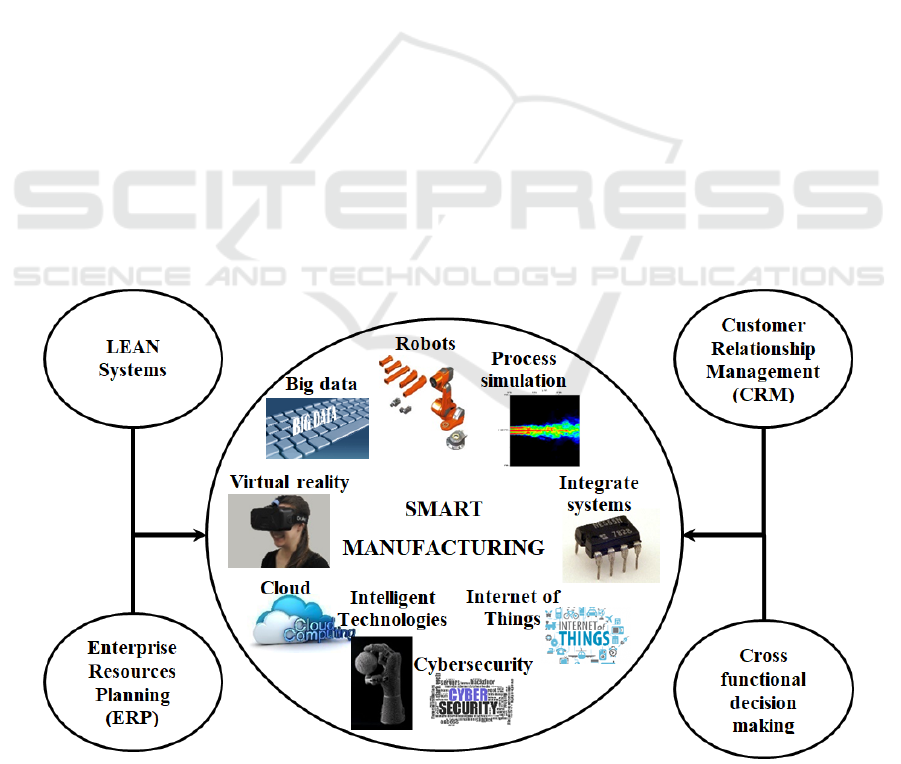

In the LGS production processes, we are talking

about smart manufacturing and smart factories.

Production processes will be intelligent, flexible and

dynamic and machines as well as the equipment will

have the ability to improve productions processes

through self-optimization and autonomous decision

making (Roblek et all, 2016).

Thus, production processes are optimized in the

framework of the Lean systems, resource planning is

optimized in framework of ERP systems, and

decisions are taken in accordance with the

customer’s requirements anticipation (Customer

Relationship Management CRM) (Nahmias, 2009).

The Lean system is a concept which is developed

on the basis on the total system approach for the

efficient optimization of all production processes.

EPR is a software system that is quite

sophisticated and difficult to use for identifying and

planning all the necessary resources of an enterprise.

The main purpose of this system is to coordinate all

the production and product delivery activities.

Cross-functional decision making is a software

solution that allows businesses to collect data about

specific customers and all the decisions are taken at

each level within the organization.

The four systems integration in any production

process is called smart manufacturing (see Figure

10). The smart manufacturing system includes

cyber-physical systems, the Internet of things, cloud

computing, and cognitive computing. The smart

manufacturing system will create what is called a

smart factory. Within the modular structure of a

smart factory, cybernetic systems monitor the

physical processes, create virtual copies in a

physical world, and decentralized decisions are

made. The Internet of Things (IoT) and cybernetic

systems communicate and cooperate with people in

real time through the Internet services, providing

added value.

Smart manufacturing combines various

intelligent technologies: nanotechnology, 3D

printers, mobile networks and brain research,

making possible things that in the past seemed

incredible. Now everyone has access to technology,

and if anyone has ideas, can create inexpensive and

fast products, in this mode the business model of

each industry will be changed.

In the framework of smart production processes,

each company can individualize its products

according to the needs of each customer in a

maximum efficiency context.

Figure 10: Smart manufacturing concept.

MoMa-GreenSys 2019 - Special Session on Modelling Practical Paradigms of Green Manufacturing Systems

240

5 CONCLUSIONS

As nowadays focus is on friendly environmental

constructions and technologies, steel framed

constructions have been and extended lately, so that,

an interesting and promising market is available.

Lightweight steel framed constructions have as basic

element the light gauge steel (LGS) profile, usually

of C, or U type cross section.

The basic manufacturing process for LGS

profiles is that of cold plastic deformation mainly

from strip coil, in successive stages. Improving the

LGS profile’s material mechanic characteristics, so

as to have higher tensile strength and, when

necessary, higher hardness, has been considered of

benefit for the complex process of building metallic

steel framed constructions. The induction hardening,

process has been considered and studied in this

research.

An intelligent equipment, that enables the

integrated and customized building of the metallic

construction is Pinnacle LGS. The presentation of

the manufacturing process of LGS profiles in the

context of using appropriate software and intelligent

equipment in conjunction with the smart

manufacturing concept, has highlighted the

efficiency of the production process, and pointed to

the customer’s satisfaction.

ACKNOWLEDGEMENTS

Constructii metalice ecologice si sustenabile prin

tehnologii eficiente de fabricare / Environmental

Friendly and Sustainable Metallic Constructions by

Efficient Manufacturing Technologies, TOP MetEco

AMBIENT, project no. 107/09.09.2016.

Casa Metalica – Romanian SME

http://www.casametalica.ro/constructii-case.html

REFERENCES

Martins C, Santos P, da Silva L.S., Lightweight Steel

Framed Construction System, Contribution of

Sustainable Building to Meet EU 20-20-20 targets,

Portugal SB13, 30 oct – 1 nov, 2013

Iliescu M, Vladareanu L, Pandelea M, Marin D, Testing

Mechanical Characteristics of Hardened LGS Profile

Material, The 2nd International Conference

“Experimental Mechanics in Engineering” – eMECH

2018, pp. 43 – 48, Brasov, 2018, ISSN 2457 – 8541,

ISSN-L 2457 - 8541

Yandzio E., Lawson R. M., Way A.G J, Light Steel

Framing in Residential Construction, SCI Publication

P402, ISBN 13:978-1-85942-215-1, 2015,

Nahmias S., Production and Operation Analysis, sixth

edition, McGraw Hill Education, 2009

Raffaele Landolfo, Seismic behavior of lightweight

structures in steel, October, 2018, Research funded by

European Commission within the Project named

"Energy Efficient LIghtweight-Sustainable-SAfe-Steel

Construction" (Project acronym: ELISSA)

Roblek V., Maja Meško M., and Alojz Krapež A., A

Complex View of Industry 4.0, Sage Open, April-June

I-II, 2016, DOI: 10.1177/2158244016653987

https://www.hilti.it/content/dam/documents/pdf/e4/engine

ering/seminari/atti_seismic_academy/Hilti_Seismic_A

cademy_2018_Pesentazione_Landolfo.pdf

https://constructalia.arcelormittal.com/files/european%20li

ghtweight%20steel-framed%20construction--

627c1249e5c97aecee4a7eb06658b457.pdf

European Lightweight Steel Framed Construction,

European Light Steel Construction Association

https://www.designingbuildings.co.uk/Light_gauge_steel_

framing_systems, accessed on February16, 2019

https://steel-sci.com/, accessed February16, 2019

http://www.steelframing.org/PDF/SFA_Framing_Guide_fi

nal%202.pdf, accessed on February 20, 2019

Performances of Steel Framed Houses During an

Earthquake, vol. 1, issue 2, 2003,

http://www.steelframing.org/PDF/issuepaper/earthqua

ke.pdf

http://www.wrap.org.uk/sites/files/wrap/Light%20Steel%2

0Frame%20-%20Full%20case%20study.pdf

WAS 003-003: Offsite Construction Case Study

Waste Reduction Potential of Light Steel Frame

Construction,

Intelligent Manufacturing System of LGS Profiles for Green Metallic Constructions

241