Automated Draping of Wide Textiles on Double Curved Surfaces

Patrick Kaufmann

a

, Georg Braun

b

, Andreas Buchheim

c

and Marcin Malecha

d

German Aerospace Center, Institute of Structures and Design, Center for Lightweight Production Technology (ZLP),

86159 Augsburg, Germany

Keywords: Automation, Layup, Draping, Textile, Double Curved Surface, Automated Preforming.

Abstract: In many different industries like aviation, shipbuilding or the production of wind turbines, the draping of

textiles is a common issue. Especially large components in long- and medium-haul aircraft have a high po-

tential of weight reduction by using composites. In many cases increasing material and manufacturing costs

are caused compared to metal design. Therefore automation is one approach to achieve profitability. A robot

end effector for the automated deposition of 50 inch wide fibre fabrics was tested. The experiments were

performed in full scale, with plies of an aircraft pressure bulkhead. When depositing these fabrics on curved

surfaces, defects such as waves or wrinkles appear. In order to solve this issue, the end effector was extended

by adding an adaptable material buffer. The development regarding mechanical design, calculation for deter-

mining the axis movement as well as the axes control is presented. Compared to previous attempts without an

adaptable material buffer, an improved deposition quality was achieved. The results of the experimental in-

vestigation are shown.

1 INTRODUCTION

In the field of aviation, wind turbines and ships, large

components made of fibre composites are used, as

these have a very good strength to weight ratio. Dur-

ing the production of these components in the process

step referred to as preforming large textiles have to be

deposited on shape-giving moulds. This can be done

via precut plies or by direct deposition from the sup-

ply roll in a rolling motion. In order to reduce produc-

tion costs, a high deposition rate (kg/h) is targeted. In

this context, the influencing factors for a specific au-

tomated process are the process speed and the type of

fabric used. One approach to increase the deposition

rate is the use of wide textiles with a material width

of up to approximately 1270 mm (50 inch).

During preforming, the textiles have to be manip-

ulated to conform to the mould surface. In case of

double curved geometries draping is necessary.

(Elkington et al., 2017) In this process the textile is

distorted in a defined way, meaning that the angle be-

tween weft and warp roving (shear angle) is modified

a

https://orcid.org/0000-0003-1181-7211

b

https://orcid.org/0000-0002-8181-5513

c

https://orcid.org/0000-0003-3333-7227

d

https://orcid.org/0000-0003-2824-0914

locally. The maximum achievable change of the shear

angle (locking angle) depends on the geometry of the

mould and the type of textile. (Manson et al., 2000)

The use of wide textiles in terms of preforming poses

special challenges, as larger areas have to be manipu-

lated at the same time. If draping is insufficient, fabric

imperfections will appear. Thus, out-of-plane defor-

mation in form of wrinkles can occur at the inner ra-

dius of curved plies (Olsen and Craig, 1993). Since

the components mechanical properties depend to a

large extent on the quality of the preforming,

measures must be taken to prevent fabric imperfec-

tions. Therefore the main challenge is the develop-

ment of a process that allows the draping of textiles

to be controlled in a defined way. In this respect, the

main influencing factors in the automated rolling dep-

osition of textiles must be considered, such as syn-

chronization of the rotary movement of the supply

roll and end effector movement, contact pressure on

the mould surface and length differences between in-

ner and outer radius of curved plies. The compensa-

tion of these length differences was investigated in

the present work by developing an adaptable material

50

Kaufmann, P., Braun, G., Buchheim, A. and Malecha, M.

Automated Draping of Wide Textiles on Double Curved Surfaces.

DOI: 10.5220/0007833200500058

In Proceedings of the 16th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2019), pages 50-58

ISBN: 978-989-758-380-3

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

buffer for a robot end effector used for the rolling dep-

osition of carbon fibre fabrics.

2 STATE OF THE ART

In the manufacturing process of fibre composite

structures, the layup and draping of textiles is often

still carried out manually, such as for the rear pressure

bulkhead of particular aircraft types (Schnitzer,

2013), wind turbine blades (Zhu, 2015) or shipbuild-

ing. For this purpose, precut textiles are used. The fi-

nal draping is done by manually applying pressure on

the fabric. The worker's level of skill and experience

is decisive here in order to avoid inducing fabric im-

perfections and achieve the desired positioning toler-

ance.

The most well-established automated processes in

the industrial production of composite components

are the rolling deposition of textiles with Automated

Tape Laying (ATL) and Automated Fibre Placement

(AFP). These processes can be carried out completely

automated with systems from various manufacturers,

such as Fives (France) or MTorres (Spain). (Sloan,

2008, Marsh, 2011) Here a respective placement head

end effector is guided by an industrial robot or a gan-

try system. In most cases an active system to prevent

wrinkles during depositing is not integrated. These

are avoided by adhering to the process constraints en-

suring that the process-specific minimum depositing

radii are not exceeded.

The ATL process consists of applying one or more

tapes from supply rolls to the mould surface simulta-

neously. The tapes have a width of approximately 75

- 300 mm (3 - 12 inch). A maximum material width

of approximately 600 mm (24 inch) can be achieved

in a multitape configuration. Since steering is only

possible to a limited extent due to the material width,

the process is mainly used for large flat or simply

curved components, such as wing skins, fuselage pan-

els (Gardiner, 2011) or wind turbine blades (Black,

2009).

One approach for applying tapes to more complex

geometries is the advanced ply placement process

(APP). (Szcesny et al., 2017) Here, precut plies are

gripped and guided by two robots to the correct posi-

tion. Simultaneously, a third robot drapes the textiles

onto the mould surface with a roll end effector.

The AFP process is comparable to ATL. Here, up

to 32 narrow textile strips (tows) with a width be-

tween 3.175 and 12.7 mm (1/8 - 1/2 inch) are deposi-

tioned at once. An overview of the process can be

found in (Kozaczuk, 2016). Compared to ATL,

smaller steering radii can be achieved due to the use

of smaller textiles. Depending on the degree of cur-

vature, gaps or overlaps between the tows can occur,

which can only be tolerated to a certain degree, since

they have a negative influence on the mechanical per-

formance (Croft et al., 2011). A summary of the ca-

pabilities and limitations of the ATL and AFP process

is given in (Lukaszewicz et al., 2012).

Another approach of depositing textiles on double

curved surfaces shows (Zhu et al., 2017). The auto-

mated layup of 280 mm wide dry glass-fibre non-

crimp fabric (NCF) was tested with a method called

shifting. Hereby the fabric is manipulated in such way

that no out-of-plane waviness occurs.

Few publications regarding rolling deposition of

textiles with widths over 600 mm can be found. As

part of the research project "mapretec" (Ohlendorf et

al., 2014) an end effector was developed which can

be used to wind up precutted plies with a maximum

width of approximately up to 1270 mm (50 inches)

and apply them to the layup position by rolling. How-

ever, only deposition on flat surfaces without contact

to the mould surface is possible, since the rigid struc-

ture of the end effector does not allow adaptation to

the mould geometry. Draping is carried out separately

by means of a form variable tooling. Likewise, end

effectors with comparable properties were developed

in the research projects "preblade" (Weigel and

Müller, 2007) (material width: 300 - 1300 mm, max.

ply length: 10 m) and "PRO-CFK" (Müller, 2007)

(max. material width: 1400 mm). In the latter, the di-

rect deposition of the textiles from the supply roll into

the contoured mould was additionally tested. Here no

precutted textiles are used. The ply length is only lim-

ited by the material quantity on the supply roll. The

draping takes place without active control via the de-

positing movement of the textile.

The layup process of the Precision Feed End Ef-

fector (PFE) developed by Automated Dynamics

(Groppe, 2007, Black, 2003) is comparable to the pro-

cess of the end effector used in this study. The PFE

features a flexible compaction roller design and can

accommodate curved panels with a 40-ft minimum

radius. It is possible to process textiles with an ap-

proximately width of 150 - 1500 mm (6 - 60 inch).

The end effector developed in the context of the re-

search project "BladeMaker" (Richrath et al., 2017) is

also capable for layup on double curved moulds. The

precut plies can have a material width of up to 1270

mm (50 inch).

A general overview of existing roller gripping and

draping systems is given in (Ehinger, 2013).

Automated Draping of Wide Textiles on Double Curved Surfaces

51

3 RESEARCH ISSUE

One big issue according the automated handling of

textiles is: how to apply a two-dimensional fabric

onto a three-dimensional mould without creating

waves, wrinkles or other critical defects. In this con-

text waves are out of plane defects characterized

through their width and height while wrinkles are de-

fects in which the fabric doubles over itself (Wade,

2012). The compensation of different lengths be-

tween the two textile edges is one approach to an au-

tomated draping of textiles.

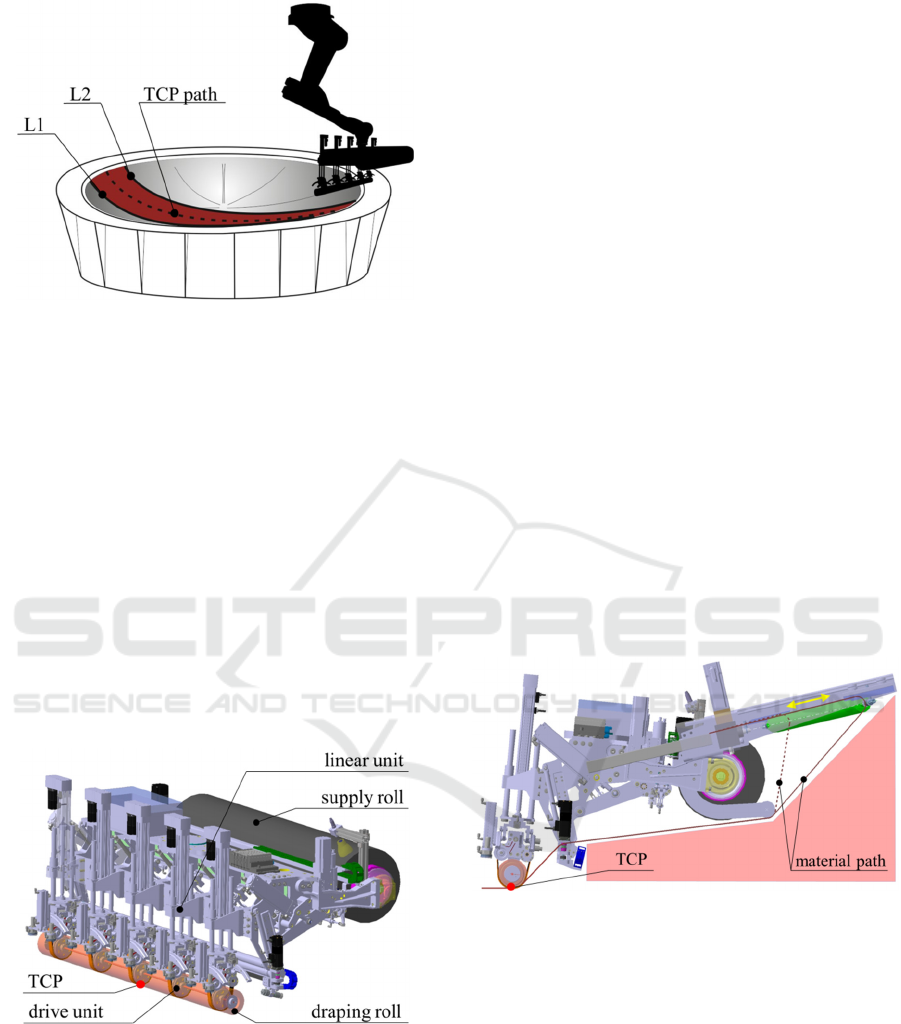

Figure 1: Generic sketch of a textile ply on an aircraft fuse-

lage with the path of Tool Centre Point (TCP).

Looking at the geometry of a generic aircraft fu-

selage and the ply placed on it, one can see that L2 in

Figure 1 is shorter than L1. Depositing the ply with-

out further measure would cause waves due to the sur-

plus material on L2. A compensation of the difference

in lengths of L1 and L2 is necessary.

Dependent on the process conditions one solution

could be to perform an optimized path generation to

overcome this issue (Schmidt-Eisenlohr et al., 2019).

In the considered scenario, the fibre angles are critical

to the mechanical properties of the component.

Therefore it is not possible to modify the ply orienta-

tion. A different approach for a defect free draping

process had to be found.

4 APPROACH

One approach to buffer the different length of the ply

in the robot end effector is a mechanical solution.

Therefore an adaptable material buffer was devel-

oped.

The concept was to create a mechanical buffer that

could independently add or absorb material from both

sides of the fabric as needed. Assuming that the cur-

vatures on large aircraft components are not subject

to strong fluctuations, a system was conceived that

contains an additional deflection roller between two

independently movable and electrically driven linear

guides. With this setup it should be possible to influ-

ence the lengths of the two edges of the fabric without

affecting the layup position. Figure 2 shows a sketch

of this concept.

Figure 2: Material buffer concept.

4.1 Process Description

The use case considered in the work for draping tex-

tiles is the automated preforming of a rear pressure

bulkhead of an airplane. This component is located at

the end of the aircraft cabin. It is highlighted in Figure

3.

Figure 3: Rear pressure bulkhead in an aircraft.

In Figure 4 the used end effector guided by an in-

dustrial robot together with the mould and one ply is

shown. There are three curves highlighted: L1 as the

length of the left edge and L2 as the length of the right

edge of the ply and the path of the Tool Centre Point

(TCP). The TCP is located in the middle of the drap-

ing roll (see Figure 5 and Figure 6) and has contact to

the mould during the deposition process. The draping

roll can be adapted by five linear units to ensure a

compliant contact over the whole width of the draping

roll. Further it is driven by five stepper motors at the

bearing points of the linear units. The stepper motors

are synchronised to the robot movement.

The deposition process starts with a robot move-

ment into the start positon. Then the contour of the

draping unit is adapted to the mould surface by mov-

ing the linear units. After that the robot moves per-

pendicularly into the mould and presses the draping

roller onto the surface. The torque control of the lin-

ear units is switched on and the deposition process

starts.

ICINCO 2019 - 16th International Conference on Informatics in Control, Automation and Robotics

52

Figure 4: Experimental setup.

The trajectories for the depostion process have to

be perpendicular to the mould surface. Thus the paths

generation is quite complex and would be to impre-

cise and time consuming by hand. Therefore the robot

movement is generated by Offline Programming

(OLP). The OLP is based on a CAD model of the ro-

botic cell, the mould and the end effector. It can gen-

erate the programs for the robot motion.

4.2 Mechanical Design

As mentioned, the motivation for adding a material

buffer was the occurrence of waves during previous

layup test. The end effector used was designed by

Premium Aerotec as part of the project AZIMUT

(Niefenecker, 2014) and is shown in Figure 5

Figure 5: End effector without material buffer.

With the scope of the design of the material buffer

various requirements had to be observed. The main

technical requirements are:

The added weight to the end effector must not lead

to an overload of the robot.

The maximum moment of inertia of the entire end

effector, including the buffer, is decisive for the

movement processes of the robot. It has to be

taken into account when designing the storage ca-

pacity.

The end effector together with the material buffer

must not collide with outer or inner interfering

contours during the deposition process. Therefore

an OLP path planning should be carried out be-

forehand by means of a simulation tool.

An accessibility analysis was carried out to deter-

mine the installation space for the material buffer and

to prevent collisions with the mould. According to

this offline simulation there is no interfering end ef-

fector contour allowed in between the red-marked

area shown in Figure 6. Therefore the arrangement of

the material buffer took place as an extension in the

longitudinal direction of the end effector. The solid

line in Figure 6 represents the edge length of the ma-

terial at the maximum deflection of the material

buffer. The dotted line represents the edge length of

the material at its minimum deflection. A yellow dou-

ble arrow indicates the direction of movement. Since

both sides of the material buffer work according to

the same principle, only one side is described in the

further example. The buffer system consists of the

parts shown in Figure 7.

Figure 6: Side view of the end effector with material buffer.

The fabric coming from the supply roll is guided

over the angle adjustable roll to the fixed guiding rolls

where it is passes through. After that the fabric is

guided to the draping roll and is finally applied on the

mould surface. For controlling the length of the ma-

terial edges the angle adjustable roll has a linear guid-

ing system. During the deposition process the car-

riage of the guiding system is moved by a gear screw

jack which is driven by a servo motor. The control of

the buffer system is described in chapter 4.4.

Automated Draping of Wide Textiles on Double Curved Surfaces

53

Figure 7: Material buffer in detail.

Figure 8: Material guiding.

In previous test there were two additional issues

according to the material guiding and buffering. De-

pending on the robot position, single textile layers on

the supply roll can lose position by sliding to one side.

By shifting the material layers the occurring offset

also effects the fabric position on the mould. There-

fore a mechanical end stop was added to the supply

roll. Further it has to be considered, that as a result of

moving the angle adjustable roll differently on both

sides, a material guiding is created were one axis is

not parallel to all the other guiding rolls. This can

cause a material drift whose strength and direction de-

pends on the inclination of the angel adjustable roll.

Therefore fixed guiding rolls were added to the end

effector. Design details are shown in Figure 8. One

guiding roll was designed with support edges which

should prevent the material from drifting. The other

roll can press onto the material to prevent wrinkling.

The pressure can be adjusted by a mechanical mech-

anism.

For the control of the material buffer it is im-

portant to know the exact geometrical conditions

within the buffer system. By moving the linear guide

of the material buffer the length of the material edge

changes nonlinear in relation to the axis movement.

Therefore the target position of the two linear guides

of the angle adjustable roll must constantly be calcu-

lated during the applying processes. The exact geo-

metrical calculation is shown in chapter 4.3.

4.3 Capacity Calculation

For simplifying the calculation of the storage capac-

ity, only the two material edge lengths are calculated.

The difference between the edge lengths is the theo-

retical storage capacity. The maximum deflected end

of the roll is, decisive for the maximum length of the

unrolled material. The edge length of the minimally

deflected roll end provides a base value for the calcu-

lation of the edge length change.

Regarding the formulas shown in chapter 4.3, it

was assumed that the minimal radius of the supply

roll r

ma

is greater than the radius of the angle-adjusta-

ble roll r

1

(see Figure 10). The planes of the material

edges intersect the longitudinal axis of the deflected

angle-adjustable roll (see Figure 9). In the following

formulas, a simple circle contour is assumed as a sim-

plification. With the construction, the maximum error

is less than 1 mm.

4.3.1 Track Calculation of the Carriage

The length l

gr

is defined as the length between the gear

screw jack and the center of the first roll (see Figure

10). For this purpose, the gear screw jack was pro-

jected into the material edge plane. The length differ-

ence ∆l

gr

of the lengths l

gr2

of the right side and l

gr1

of

the left side (see Figure 9) can be calculated according

to formula (1).

∆l

l

1

l

2

(1)

The calculation of the material edge length is de-

scribed in chapter 4.3.2. All geometrical quantities on

the opposite sides are indicated with the indices 1 or

2 (see Figure 9).

The roll width l

ma

as well as the lengths between

the axis of the gear screw jack and the rolls of material

l

am1

and l

am2

are known. The difference ∆l

gr

must be

calculated beforehand (see chapter 4.3.2). Thus the

stroke change ∆s of the carriage can now be calcu-

lated with formula (2).

ICINCO 2019 - 16th International Conference on Informatics in Control, Automation and Robotics

54

∆

Δl

∙

l

(2)

Figure 9: Geometric quantities for calculating the differ-

ence ∆l

gr

of the lengths l

gr1

and l

gr2

.

Figure 10: Geometric quantities for calculating the lengths

l

1

to l

4

.

With the stroke change ∆s the new stroke s

1

can

be calculated.

∆

(3)

4.3.2 Edge Length Calculation

The illustrated geometric quantities are differentiated

into the types of constructively determined quantities,

measurable quantities and variables. These quantities

are described below.

All geometrical quantities with the index “h” are

auxiliary quantities. These are determined construc-

tively, as well as the radii r

1

and r

4

. The radius of the

supply roll r

ma

can be measured by a sensor or calcu-

lated based on historical values. The length l

gr

is the

length in the material edge plane between an edge of

the projection of the gear screw jack and the centre of

the angle-adjustable roll. The total material edge

length L is calculated with formula (4).

(4)

The equations (5) to (8) describe the calculation of the

lengths shown on Figure 10.

1

cos

arcsin

∙

(5)

2

2∙

1

∙

360

∙ arctan

14

15

arcsin

1

15

14

90arctan

34

31

(6)

3

31

cosarctan

34

31

(7)

4

2∙

4

∙

360

∙180

41

arctan

34

31

(8)

The length l

5

is also a constructive determined

length. All rolls in contact are stationary with respect

to the end effector. According to the geometry of the

mould, the length difference ∆l

gr

per time unit or dis-

tance unit is determined. Due to this length differ-

ence, it is possible to calculate the stroke change ∆s,

necessary in this unit, according to equation (2).

With the given quantity L of the length of the ma-

terial edge of the roll, the implicitly contained quan-

tity l

gr

can be calculated with equation (9).

0

(9)

This can be done, for example, with the help of

the zero approximation method named “false position

method” or “Regular Falsi”. This method is described

in (Bronstein et al., 2008) and (Kiusalaas, 2013).

These calculations can be done by the robot control-

ler.

Automated Draping of Wide Textiles on Double Curved Surfaces

55

4.4 Control Architecture

The control architecture for the experimental investi-

gation is as follows. The industrial robot with its lin-

ear axis is controlled by the KUKA Robot Control

(KRC). All other actors and axis of the end effector

as well as the axis for the material buffer are con-

trolled by a PLC. The communication between the

KRC and the PLC goes via EtherCAT. Since both

systems act as masters, there is a master/master bridge

between them. For controlling the material buffer

there are three points that need to be considered:

Robot Speed. For buffering the correct amount of

material it is important that the axis movement of the

material buffer is synchronised to the velocity of the

TCP. The synchronisation is done via the submit in-

terpreter of the KUKA robot by transmitting the cur-

rent robot speed (speed of the TCP).

Geometric Characteristics of the Mould. Further, it

is important to consider the geometric characteristics

of the mould for the deflection of the material buffer.

For calculating the axis movement in context of the

length difference between the material edges one has

to consider the ratio of the side lengths and the length

of the TCP path for calculating the axes speeds.

Therefore a CAD based plybook contains the target

positions of all plies. Out of this plybook a CSV file

was created with the 3D length information of the two

material edges and the TCP path. With this infor-

mation it is possible to calculate the target position of

each material buffer axis. In order to achieve an exact

material buffering not only the target position but also

the buffering speed is decisive. For this purpose the

three paths were divided into equal pieces with a de-

fined length and imported into the CSV. During the

deposition process a position counter detects the cur-

rent sequence and transfers the length information

into the geometrical calculation part of the software.

There a geometrical induced offset is calculated for

controlling the two axes speeds of the material buffer.

This approach provides some inaccuracies related to

the number of pieces in which the path is divided, but

it is a good approximation of reality. The calculations

become more accurate by an increasing number of de-

nominations.

Geometric Characteristics of the Material Buffer.

Locking at the mechanical design of the material

buffer (chapter 4.2) it is clear, that the axis movement

of the buffer is neither equal nor linear to the buffered

material length. Therefore it is necessary to calculate

the axis movement in consideration of the geomet-

rical behaviour of the material buffer. A more detailed

description of the calculations is described in (chapter

4.3). Figure 11 shows the control architecture for the

material buffer.

Figure 11: Schematic sketch of the control structure for the

adaptable material buffer.

5 VA L I D AT I O N

The adaptable material buffer was validated in an ex-

perimental investigation

5.1 Setup and Implementation

For validating the material buffer an exemplary ply

(P0011) was chosen. Table 1 shows the basic geomet-

rical characteristics of ply P0011.

Table 1: Geometrical characteristics of the ply P0011.

Pl

y

No. P0011

L1 3599 m

m

L2 4060 m

m

Len

g

th difference 461 m

m

For increasing the adhesion, a thin film of epoxy

resin was sprayed onto the mould surface. The ply

was at first laid up without using the buffer system.

After that the mould was cleaned and the resin film

was renewed. Then the same ply was laid up by using

the material buffer. The process parameters are

shown in Table 2. Apart from the buffering, all other

settings remained the same, including the Parameters

of the geometrical velocity offset for the draping rolls

as well as the robot speed and the amount of resin.

The general setup for the experimental investigation

is shown in Figure 4.

Table 2: Process parameters of the experimental investiga-

tion.

Fabric type Satin wave

Material width 50 inch

Wei

g

ht

p

er unit area 370

g

/m²

Process spee

d

0,1 m/s

Layer fixation Yes (epoxy resin)

Velocity offset for the drives of

the dra

p

in

g

roll

Yes

ICINCO 2019 - 16th International Conference on Informatics in Control, Automation and Robotics

56

5.2 Results

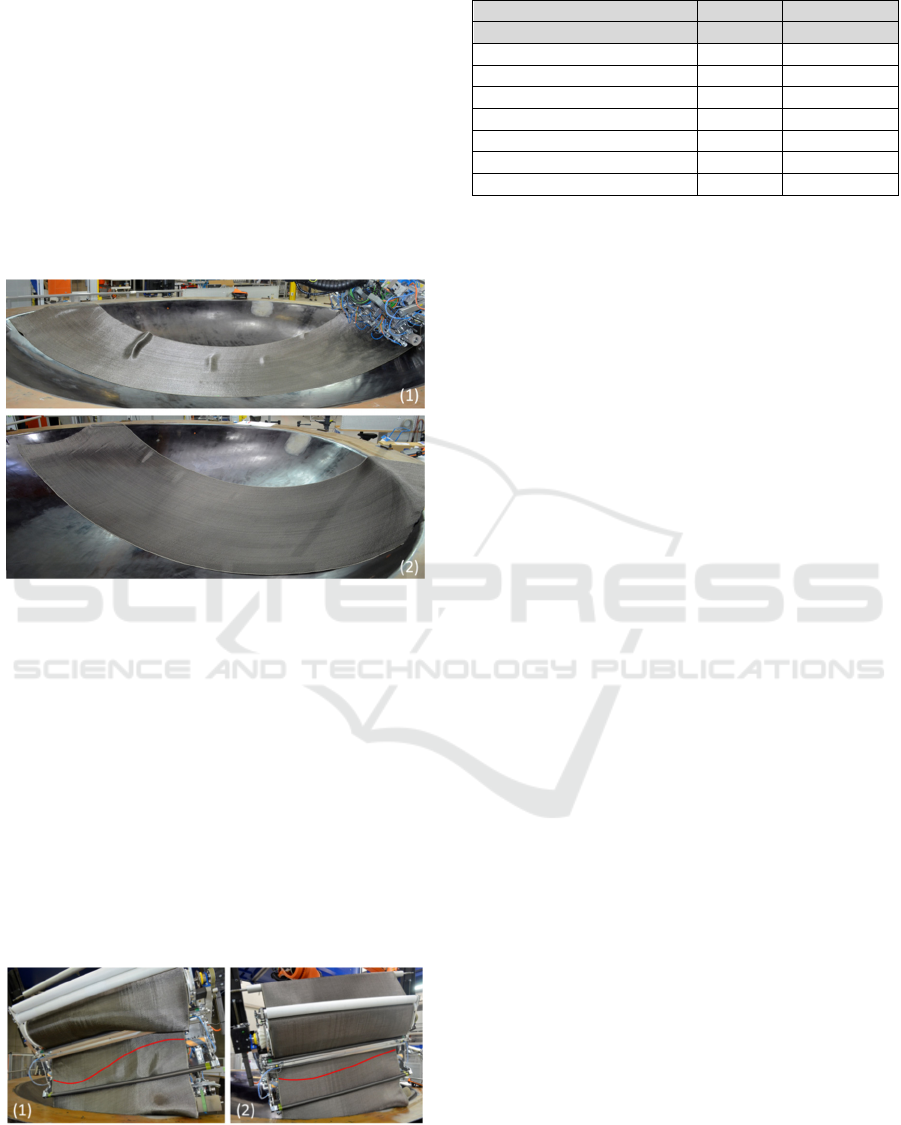

The results of the experimental investigation are

shown in Figure 12. Picture (1) shows the ply deposi-

tioned without using the material buffer. There are

four out of plane defects (waves). The first wave is a

large one on the left side in picture (1). The second

one is a midrange wave in the middle of the ply and

the last two waves located in the rear section are quite

small. Picture (2) shows the ply depositioned by using

the material buffer. One can see a small wave at the

beginning of the ply. The rest of the ply is without any

defects.

Figure 12: Results without buffer (1), with buffer (2).

Figure 13 shows the condition of the material in

the end effector after finishing the layup. Picture (1)

shows the end effector after applying the fabric with-

out using the material buffer. One can see the loosley

material tension in between the guiding rolls by the

accumulation of the surplus material on the right. Fur-

ther one can see the strongly distorted fibre angel

roughly indicated by the red line. Picture (2) shows

the end effector after applying the fabric by using the

material buffer. One can see the material with more

tension and less surplus material. Also the distortion

of the fibre angle is less, indicated by the red line. A

summary of the experimental results is shown in Ta-

ble 3.

Figure 13: Material tension and fibre angle without buffer

(1) and with buffer (2).

Table 3: Results of the experimental investigation.

Pl

y

No. P0011 P0011

Material Buffe

r

y

es no

Material tension ti

g

ht loosel

y

Fibre distortion small high

Out of plane defects:

Numbe

r

1 4

T

yp

e / Classification wave wave

Size small

b

i

g

- small

Location start continuous

6 DISCUSSION

The implementation of the adaptable material buffer

improved the results of depositioning wide textiles

onto double curved surfaces. It could be shown, that

the material guiding in between the end effector im-

proved. The material tension was higher and less sur-

plus material was left in the end effector Figure 13.

Also undesired shearing of fibre angles within the end

effector has been reduced.

But there are also disadvantages that have to be

mentioned. As described in chapter 4.2, inserting an

inclined axis causes a material drift. The strength and

direction of this drift strongly depends on the angle

between the buffer axis and the other guiding rolls.

Also the implemented support edge could not com-

pletely prevent the material drift. By using the buffer

system in its rear workspace this undesired material

movement can be reduced, but not completely

avoided. This would require an online position cor-

rection of the robot movement.

Additionally there are still small waves on the ply

were at least the bigger one would be critical in the

industrial production. One reason that could be deter-

mined was an influence of the buffer system on the

supply roll. For providing a constant tension the sup-

ply roll is controlled by a torque limitation. By mov-

ing the angle adjustable guiding roll of the buffer sys-

tem an additional force acts on the supply roll. This

force can lead to an increasing output of material

which causes waviness. Therefore an improvement of

the control settings for both systems (material buffer

and supply roll) is necessary.

Further it has to be mentioned that the experi-

mental results shown in Figure 12 were both reached

with the use of a geometrical velocity offset on the

drives of the draping roll. It has to be pointed out, that

the use of just one of these two methods would not be

enough to reach proper results. The geometrical ve-

locity offset for the draping roll will be presented in a

further work.

Automated Draping of Wide Textiles on Double Curved Surfaces

57

7 CONCLUSION

In this paper a buffer system is introduced that acts as

an assisting system for the automated draping of tex-

tiles. The issue of length differences when deposition-

ing textiles on double curved surfaces is addressed.

As a solution, an adaptable material buffer which can

independently control the two edge lengths of the fab-

ric during the application process is proposed. For this

solution the mechanical design, the control architec-

ture and the mathematical background for controlling

the buffer system are presented. The suggested ap-

proach was implemented and evaluated by an experi-

mental investigation. The results were emphasized

and improvements like layup quality, material guid-

ance as well as the occurring disadvantages are dis-

cussed. Future works have as goal the improvement

of the interaction between the supply roll and the

buffer system, as well as the correction of the material

drift by deflecting the adjustable roll of the material

buffer. The geometrical velocity offset, passed onto

the drives of the draping roll, must also be fully inte-

grated. Nevertheless the present approach is a prom-

ising solution which can contribute to the automated

draping of textiles.

REFERENCES

Black, S. 2003. Precision Feed End-Effektor composites

fabric tape-laying apparatus and method. High

Performance Composites Magazine.

Black, S. 2009. Automating wind blade manu-facture.

Composites World.

Bronstein, I. N., Semendjajew, K. A., Musiol, G. & Mühlig,

H. 2008. Taschenbuch der Mathematik. 7., vollstän-dig

überarbeitete und ergänzte Auflage. Frankfurt am

Main: Verlag Harri Deutsch.

Croft, K., Lessard, L., Pasini, D., Hojjati, M., Chen, J. H. &

Yousefpour, A. 2011. Experimental study of the effect

of automated fiber placement induced defects on

performance of composite laminates. Composites Part

a-Applied Science and Manufacturing, 42, 484-491.

Ehinger, C. A. 2013. Automatisierte Montage von Faser-

verbund-Vorformlingen. Dissertation, Technischen

Universität München.

Elkington, M., Ward, C. & Sarkytbayev, A. 2017.

Automated composite draping - A review. SAMPE

2017. SAMPE North America.

Gardiner, G. 2011. A350 XWB update: Smart manufacturing.

High-performance compos-tes, 19(5), 54-60.

Groppe, D. 2007. Precision Feed End-Effektor composites

fabric tape-laying apparatus and method. United States

patent applica-tion 10/661,383.

kiusalaas, J. 2013. Numerical methods in engineering with

Python 3, Cambridge university press.

Kozaczuk, K. 2016. Automated Fiber Placement Systems

Overview. Transactions of the Institute of Aviation,

245, 52-59.

Lukaszewicz, D. H. J. A., Ward, C. & Potter, K. D. 2012.

The engineering as-pects of automated prepreg layup:

History, present and future. Composites Part B:

Engineering, 43, 997-1009.

Manson, J.-A. E., Rozant, O. & Bourban, P.-E. 2000.

Drapability of dry textile fa-brics for stampable

thermoplastic preforms. Composites Part A: Applied

Science and Manufacturing(UK), 31, 1167-1177.

Marsh, G. 2011. Automating aerospace composi-tes

production with fibre placement. Rein forced Plastics,

55, 32-37.

Müller, D. H. 2007. Projekt PRO-CFK, Techni-scher

Abschlussbericht.

Niefenecker, D. 2014. Azimut - Automatisie-rung

zukunftsweisender industrieller Me-thoden und

Technologien für CFK-Rümpfe. Abschlussbericht.

Ohlendorf, J.-H., Rolbiecki, M., Schmohl, T., Franke, J. &

Ischtschuk, L. 2014. mapretec - ein Verfahren zur

preform-Herstellung durch ebene Ablage für ein

räumliches Bauteil als Basis einer automatisierten

Prozesskette zur Rotorblattfertigung.

Olsen, H. B. & Craig, J. J. Automated composi-te tape lay-

up using robotic devices. [1993] Proceedings IEEE

International Conference on Robotics and Automation,

1993. IEEE, 291-297.

Richrath, M., Franke, J., Ohlendorf, J.-H. & Thoben, K.-D.

2017. Effektor für die automatisierte Direktablage von

Textili-en in der Rotorblattfertigung. Lightweight

Design, 10, 48-53.

Schmidt-Eisenlohr, C., Kaufmann, P., Sonnenberg, M. &

Malecha, M. 2019. Optimised trajectory calculation for

the automated layup of wide lightning protection tapes

on double-curved fuselage sections. Composite

Structures, 210, 906-913.

Schnitzer, M. 2013. Anforderungen und Lösungsansätze

für einen höheren Automa-tisierungsgrad in der CFK-

Fertigung. 2. Augsburger Produktionstechnik-

Kolloqui-um. Augsburg.

Sloan, J. 2008. ATL and AFP: Defining the megatrends in

composite aerostructures. Composites World.

Szcesny, M., Heieck, F., Carosella, S., Middendorf, P.,

Sehrschön, H. & Schneiderbauer, M. 2017. The

advanced ply placement process – an inno-vative direct

3D placement technology for plies and tapes. Advanced

Manufacturing: Polymer & Composites Science, 3, 2-

9.

Wade, J. 2012. The effect of tow grouping resolu-tion on

shearing deformation of unidirec-tional non-crimp

fabric. Master of Science.

Weigel, L. & Müller, D. H. 2007. PREBLADE -

Gemeinsamer Technischer Abschlussbe-richt.

Zhu, S. 2015. An automated method for the layup of

fiberglass fabric. Dissertation, Iowa State University.

Zhu, S., Magnussen, C. J., Judd, E. L., Frank, M. C. &

Peters, F. E. 2017. Automated Composite Fabric Layup

for Wind Turbine Blades. Journal of Manufac-turing

Science and Engineering, 139.

ICINCO 2019 - 16th International Conference on Informatics in Control, Automation and Robotics

58