A Multi-Agent based Decision Framework for Sustainable Supplier

Selection, Order Allocation and Routing Problem

Maria Drakaki

1

, Hacer Güner Gören

2

and Panagiotis Tzionas

1

1

Department of Automation Engineering, Alexander Technological Educational Institute of Thessaloniki,

P.O. Box 141, GR-574 00, Thessaloniki, Hellas, Greece

2

Department of Industrial Engineering, Pamukkale University, Kinikli Campus, Denizli, Turkey

Keywords: Supplier Selection, Order Allocation, Vehicle Routing, Sustainability, Multi-Agent System, Web Services.

Abstract: Supply chain decisions should aim for sustainability, in order to meet the global market needs, as well as the

Industry 4.0 requirements, therefore they should consider beyond economic and environmental, societal

dimensions as well. The complexity in decision making increases, moreover, supply network relationships

become important, including inter-relationships and those developed with the suppliers. Agent technology is

compatible with Industry 4.0, whereas multi-agent systems (MAS) can provide decision support for supply

chain management and model the relatationships and interactions between entities in the supply chain

environment. Therefore, in this paper, a MAS-based framework is proposed to address sustainability focused

decision making in supplier selection, order allocation and routing. Fuzzy Multi Criteria Decision Making

(MCDM) approaches and multi-objective programming are used by the agents in the MAS in order to adress

sustainability requirements. Futrhermore, developed agent services for the supply chain business processes

are integrated with web services, in order to facilitate business process execution as web services.

1 INTRODUCTION

From the perspective of a network, supply chain

entities must collaborate in order to supply, produce,

deliver and recover products, therefore, relationships

including coordination and collaboration, between

supply chain partners, as well as with suppliers and

customers affect the network performance.

Furthermore, globalisation has shifted the focus of

supply chain performance from pure economic

profitability or even economic and environmental

aspects to sustainability. The performance of supply

chains with respect to sustainability is measured in

terms of operations that meet the needs of current

population which do not compromise future needs

(Krysiak, 2009). Sustainability dimensions, labelled

as Triple Bottom Line (TBL) dimensions (Elkington,

1997), include economic, environmental and social

ones. Economic sustainability refers to fiscal

performance, whereas environmental sustainability

relates to green supply chain management and the

management of scarce environmental resources.

Social sustainability refers to fair practices at work,

occupational health and safety, as well as social

welfare (Aktin and Gergin, 2016). Globalisation is a

key driver for integration of sustainability in supply

chain management. Global supply chains face

increased risks, whereas sustainability integration

could address these risks (Giannakis and

Papadopoulos, 2016).

Global supply chains consist of distributed and

autonomous business entities which collaborate with

each other, whereas they communicate with the

Internet. Agent technology is increasingly being used

in supply chain business processes, due to its

distributed artificial intelligence origin and the

capability of enabling interactions between the

different autonomous, distributed software agents

(Woolridge and Jennings, 1995), connected in a

network. Agents can represent various supply chain

entities, business processes, machines, vehicles, as

well as information and material elements. Business

entities in global supply chains use negotiation,

coordination and cooperation mechanisms in order to

jointly deliver supply chain services and products,

whereas these interaction features are inherent in

agent technology (Swaminathan, 1998; Long, 2011).

In the context of the supply chain, multi-agent

systems (MAS) enable decision support by using

individual agents, each one with local knowledge,

Drakaki, M., GÃ˝uren, H. and Tzionas, P.

A Multi-Agent based Decision Framework for Sustainable Supplier Selection, Order Allocation and Routing Problem.

DOI: 10.5220/0007833306210628

In Proceedings of the 5th International Conference on Vehicle Technology and Intelligent Transport Systems (VEHITS 2019), pages 621-628

ISBN: 978-989-758-374-2

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

621

capable of interacting to achieve the global supply

system goal. Collaborative manufacturing decision

support including supplier selection (such as Jiao et

al., 2006, Trappey et al., 2007; Yu et and Wong, 2015;

Ghadimi et al., 2018), and vehicle routing as well as

intelligent transportation has been provided by MAS

and agent technology (such as Davidsson et al, 2005;

Martin et al., 2016). Collaboration in sustainable

supply chain management aims to meet the

sustainability goals. However, the impact of logistics

in sustainability has not been well explored.

Logistics, including transportation, contribute to the

total carbon footprint, therefore, efficient planning

and execution of logistics and transportation network

can positively affect the carbon footprint of supply

chains as well the long-term sustainability goals

(Reefke and Sundaram, 2017). Hofmann and Rusch

(2017) explore the potential of Industry 4.0 in

logistics management. They argue that Industry 4.0

will result in the deployment of autonomous

knowledge-based, self-regulating production

systems, as well as the emergence of new services and

business models. They suggest a physical supply

chain model which includes autonomous, self-

controlled logistics sub systems, such as transport

units, or order processing units, interacting with each

other. The digital supply chain model includes

different types of data, transferred via a connectivity

layer, such as in the cloud, in order to be processed,

delivering value-added business services. Just-in-

Time systems, which focus on buyer-supplier

relationships, will benefit, since suppliers will receive

real-time production order information at buyer sites

via cloud-based ERP systems, thereby, triggering

their production.

Digital integration as well as servitisation add

value in smart supply chains. Supplier selection is a

critical component of supply chain performance

(Ghadimi and Heavy, 2014). Ho et al. (2009)

emphasize that supply chain management goals

include long term partnerships with suppliers,

therefore a few but reliable suppliers are prefered.

Govindan et al. (2015) further consider suppliers as

the fifth echelon in the sustainable order allocation

and supply chain network design. Sustainable

supplier selection and subsequent order allocation is

crucial in supply chain management, therefore

organisations must cooperate with suppliers on

sustainable practices. Besides, in the sustainable

supplier selection process, long-term relationship-

continuity has been identified as a sustainability

criterion (Gören, 2018). The critical decisions in

supplier selection include the types of products,

identification of suitable suppliers, order quantities

and time periods for order allocation (Songhori et al.,

2010). Order allocation refers to the decisions

regarding the order quantities to order from each

selected supplier. Traditional supplier selection has

focused on economic criteria, such as cost, quality,

delivery times and has been summarised in reports

(such as Ho, 2009). Sustainable supplier selection

considers the tripple-bottom line dimensions (Gören,

2018). Research on sustainable supplier selection

considering economic, environmental, as well as the

social dimension (such as Kuo et al., 2010; Govindan

et al., 2013) is growing. However, sustainable

supplier selection with order allocation has been the

focus of a limited number of studies (such as Αktin

and Gergin, 2016; Gören, 2018; Govindan et al.,

2015; Ghadimi, 2018). Transportation and

distribution decisions affect logistics performance.

Vehicle Routing Problem (VRP) optimises routes for

vehicles from a set of depots to a set of destinations

(Laporte, 1995). VRP is a supply chain optimisation

method including optimisation of routes between

suppliers and customers (Wang et al., 2018).

Songhori (2010) consider supplier selection with

order allocation and optimal selection of

transportation alternatives. Supplier selection with

order allocation and vehicle routing has been studied

in the literature only recently (Govindan et al., 2017;

Nasiri et al., 2018). Nasiri et al. (2018) address

supplier selection and order allocation and vehicle

routing for the multi-cross-dock problem with mixed

integer linear programming. Govindan et al. (2017)

present a closed loop supply chain network design

which integrates decisions on supplier selection,

order allocation, vehicle selection and routing.

However, the authors have not addressed

sustainability in their method. Ghadimi et al. (2018)

develop a MAS method for sustainable supplier

selection and order allocation. The authors argue that

the proposed MAS enhanced structured

communication and information exchange in the

partnership, and therefore, enhanced the long-term

relationships between buyer and suppliers as well as

their partnership.

In this paper, an intelligent MAS is presented to

assist in the integrated decision making in sustainable

supplier selection with order allocation and routing.

MAS agents represent supply chain entities such as

project managers, information elements such as

knowledge manager, business processes, such as

supplier selection, order allocation and vehicle

routing suppliers, as well as vehicles. Agent types are

categorized to execution, information, outsourcing

partner and mobile agents. Individual agents use

different methods for local decision making include

LogiTrans 4.0 2019 - Special Session on Logistics and Transport in the Industry 4.0

622

fuzzy MCDM and optimization. The MAS global

goal is to make decisions in supplier selection, order

allocation and vehicle routing taking into account

logistics oriented Industry 4.0 concepts including

sustainability. The proposed approach facilitates

cooperation and communication between different

supply chain members and enhances supply chain IT

performance, since it can integrate with web services.

In the following, the proposed method is

presented next, followed by a description of the

proposed method. Finally, conclusions are drawn.

2 THE PROPOSED METHOD

2.1 The MAS

The MAS is developed in order to achieve the

following tasks:

a) to evaluate and select appropriate supplier(s)

taking into account sustainability dimensions,

b) to allocate orders to the selected suppliers, and

c) to configure product pickup vehicle routing

starting from the depot and visiting suppliers in

order to collect purchased products.

The MAS has been developed with Java Agent

Development Framework (JADE) (Bellifemine et al.,

2007). Agents interact with the FIPA-ACL

Interaction Protocol (IP). The MAS agents are

classified as execution, information, outsourcing

partner and mobile agents. Agents located in different

sites and JADE platforms communicate with the

HTTP Message Transport Protocol. Lim and Zhang

(2004) have classified agents such as information and

execution. Wang and Lin (2009) classified agents as

soft agents, namely information and execution ones

as well as mobile ones. In this paper, execution agents

are responsible for carrying out procedures and

making decisions. Information agents are responsible

for giving information including data to other agents

upon request. Ousourcing partner agents represent

suppliers, whereas mobile agents represent vehicles,

Outsourcing partner agents represent outsourcing

partners, they can make decisions as well as provide

data upon request and include the supplier agents.

Mobile agents can move according to a scheduling

and routing plan, provide information upon request

and include vehicle agents. However, mobile agents

could represent different mobile elements such as

data or products. The MAS consists of a project

manager agent (PMA), a coordinator agent (CA), a

supplier selection agent (SSA), a knowledge manager

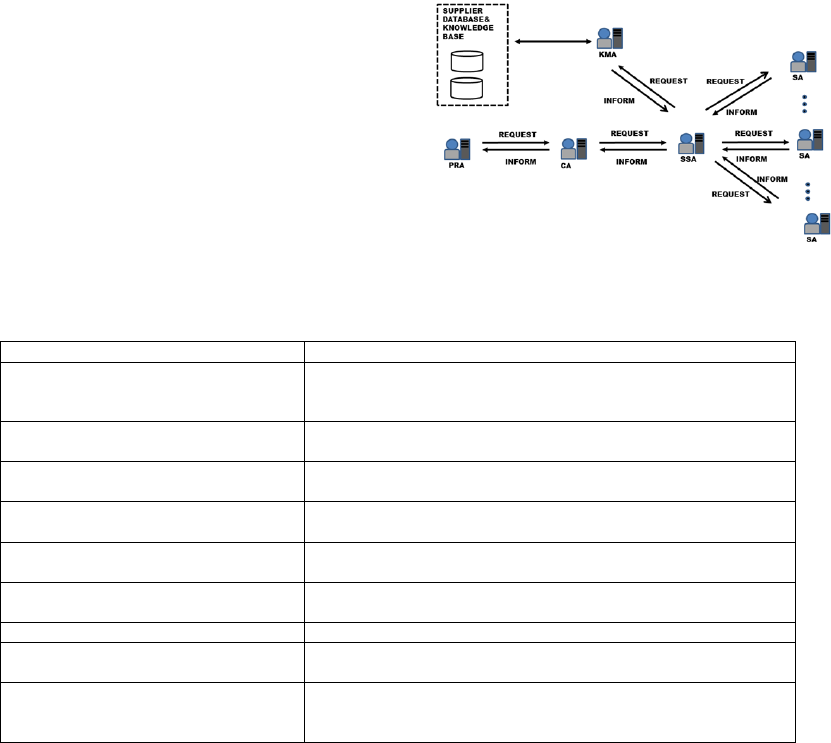

Figure 1: The MAS agent interaction diagram for the

supplier selection process.

Table 1: MAS agents and their respective goals.

Agent Goal

Project Release Agent (PRA) Releases sequentially the supplier selection, order allocation and

vehicle routing tasks to be executed by the MAS. Communicates with

the CA.

Coordinator Agent (CA) Coordinates task executions. Communicates with the SSA, OAA and

VRA.

Knowledge Agent (KMA) Retrieves and stores data and knowledge to the databases.

Communicates with the SSA, OAA and VRA.

Supplier Selection Agent (SSA) Executes the supplier selection task, evaluates and ranks potential

suppliers. Communicates with the SAs, KMA and CA.

Supplier Agent (SA) Represents potential suppliers. Each SA provides supplier data

necessary for the supplier selection task. Communicates with the SSA.

Order Allocator Agent (OAA) Executes the order allocation task. Communicates with the CA, KMA

and OA.

Optimisation Agent (OA) Communicates with the OAA and KMA.

Vehicle Routing Agent (VRA) Executes the vehicle routing task. Communicates with the CA, KMA,

VAs and OA

Vehicle Agent (VA) Represents vehicles to be used for routing. Each VA provides vehicle

data necessary for the vehicle routing task. Communicates with the

VRA.

A Multi-Agent based Decision Framework for Sustainable Supplier Selection, Order Allocation and Routing Problem

623

agent (KMA), supplier agent(s) (SA), vehicle

agent(s) (VA), an order allocation agent (OAA), an

optimisation agent (OA) and a vehicle routing agent

(VRA). Execution agents include the project manager

agent (PMA), the coordinator agent (CA), the

supplier selection agent, the order allocation agent,

the optimisation agent and the vehicle routing agent.

Information agents include the knowledge manager

agent, supplier agent and product agents. Table 1

shows the agents of the MAS. Figure 1 shows the

MAS agent interaction diagram for the supplier

selection process and Figure 2 shows the agent IP for

the presented MAS focusing on supplier selection and

order allocation processes.

Figure 2: The agent interaction protocol for the presented

MAS for the supplier selection and order allocation

processes.

2.2 Elements of the MAS

Project Release Agent (PRA)

PRA decides on outsourcing tasks based on

information received from project managers and

releases project tasks to the coordinator agent. Tasks

include supplier selection, order allocation and

vehicle routing, taking into account sustainability

(TBL) dimensions. PRA requests from CA to initiate

supplier selection process. Upon receiving

notification from CA that the task has been

completed, he requests from CA order allocation

execution. Upon receiving notification from CA that

the task has been completed, he requests from CA

vehicle routing execution. PRA communicates with

the FIPA-Request IP.

Coordinator Agent (CA)

CA

coordinates

the

execution

of

the

tasks

issued

by

PRA. He receives requests for task execution from

PRA. When he receives request from PRA for

supplier selection, the agent requests from SSA to

evaluate and rank suppliers, taking into account

sustainability. After SSA informs CA that he finishes

the task, CA informs PRA of the results. When he

receives request from PRA for order allocation, he

requests from OAA to allocate orders to the suppliers.

After CA receives results from OAA, he informs PRA

of the results. When CA receives request from PRA

for vehicle routing execution, he requests VRA to do

the vehicle routing. After he receives the vehicle

routing results from VRA, the agent informs PRA of

the results. CA communicates with the FIPA-Request

IP.

Knowledge Manager Agent (KMA)

KMA receives requests for information regarding the

list of potential suppliers and sustainability criteria

from the SSA and informs SSA on the requested

information based on information, he retrieves from

the databases. The agent has access to supplier

database. KMA receives requests for information

regarding ranking of suppliers from OAA and

informs OAA about the results. He receives order

allocation results from OAA and informs the supplier

and manufacturer databases. KMA receives requests

for order allocation information from VRA and

informs VRA about the results. He receives vehicle

routing results from VRA and informs the supplier

and manufacturer databases. KMA communicates

with the FIPA-Request IP.

Supplier Selection Agent (SSA)

SSA receives request for sustainable supplier

selection from CA. SSA communicates with KMA to

receive list of suppliers and list of sustainability

criteria for supplier evaluation. Next, he

communicates with the potential supplier agents

(SAs) in order to obtain the necessary data for

supplier evaluation. He may use Contract Net

Protocol (CNP) for communicating with the

suppliers. A supplier agent (SA) may refuse to enter

into negotiation with SSA. Alternatively, he may

communicate with potential suppliers with FIPA

Request IP. He applies different fuzzy MCDM

approaches such as AHP, TOPSIS etc. to evaluate and

rank suppliers. SSA sends evaluation results to CA

and KMA. SSA communicates with the FIPA-

Request IP and FIPA-CNP.

Order Allocation Agent (OAA)

OAA receives request for order allocation from CA.

OAA requests from KMA supplier supplier ranking

results and product data. OAA executes a bi-objective

LogiTrans 4.0 2019 - Special Session on Logistics and Transport in the Industry 4.0

624

model to allocate orders to potential suppliers. When

the agent receives optimisation results from OA, he

informs both CA and KMA about the vehicle routing

results. OAA informs order allocation results to the

CA and KMA. OAA communicates with the FIPA-

Request IP or FIPA-CNP.

The Bi-objective Model for Order Allocation

Multiple products and multiple periods are assumed

in the model which is adapted from Gören (2018).

Indices:

i: index of a supplier

j: index of a product

t: index of a period

Parameters:

S: number of suppliers

P: number of products

T: number of periods

C

i

: capacity of supplier i

P

ij

: Purchasing price of product j from supplier i

W

i

: Supplier rating value

O

ij

: Ordering cost of product j from supplier i

H

j

: holding cost for product j

q

ij

: Average defect percent of supplier i for product j

Q

j

: Maximum acceptable defect ratio for product j

p

ij

: production time of supplier j for product j

Decision Variables:

X

ijt

: Quantity of product j delivered by supplier i in

period t.

Y

ijt

: Binary variable equal to 1 if an order is placed to

supplier i for product j in period, else 0.

I

jt

: Available inventory of product j at the end of

period t.

Objective Functions and Constraints

The first objective function aims to minimise the total

cost of purchasing (TCP) from the suppliers.

∗

∗

∗

(1)

The second objective function aims to maximise the

total sustainability value (TSV) of the suppliers.

∗

(2)

Constraints:

Demand constraint:

∀

,

(3)

Quality constraint:

∗

∀

,

(4)

Supplier capacity constraint:

∗

∀,

(5)

Non-negativity constraint:

0 ∀,

,

(6)

Each objective function subject to the constraints is

solved separately. Results of each objective function

are sent to the optimisation agent (OA). The bi-

objective model is finally optimised and solved by

OA.

Optimisation Agent (OA)

OA receives requests for optimisation from OAA and

VRA. He informs the results of optimisation to OAA

and VRA. The objective of OA is to find a set of

optimal solutions that satisfy multiple objectives

which could be conflicting, subject to a set of

constraints.

OA follows the procedure adopted in (Hamdan

and Cheaitou, 2017). OA receives from either OAA

or VRA the solution to each objective function solved

separately. A weighted approach is followed by OA

in order to merge the two objective functions in a

single objective function, f, which is shown below in

response to OAA requests

(7)

(8)

(9)

where α

1

and α

2

are relative weights. Their sum is

equal to 1. Equation (9) gives the optimized solution

for the order allocation. OA informs OAA with the

results.

Vehicle Routing Agent (VRA)

VRA receives request for vehicle routing from CA.

VRA requests from KMA order allocation results as

well as product data and from vehicle agents data

regarding vehicle parameters. VRA executes a bi-

objective model for vehicle routing. Each objective

A Multi-Agent based Decision Framework for Sustainable Supplier Selection, Order Allocation and Routing Problem

625

function subject to the constraints is solved

separately. Results of each objective function are sent

to the optimisation agent (OA). The bi-objective

model is finally optimised and solved by OA. When

the agent receives optimisation results from OA, he

informs both CA and KMA about the vehicle routing

results. VRA communicates with the FIPA-Request

IP or FIPA-CNP. Heterogeneous vehicles with

different capacities, costs and carbon emission rates

are represented by the vehicle agents.

The Bi-objective Model for Vehicle Routing

The problem is formulated such that each route starts

and ends at the depot. The load of each vehicle should

not exceed its capacity. Each supplier is visited once

by one vehicle during each period.

Indices:

i: index of a supplier

j: index of a product

t: index of a period

v: index of a vehicle

Parameters:

S: number of suppliers

P: number of products

T: number of periods

V: number of vehicles

W

j

: weight of product j

CP

v

: capacity of vehicle v

FC

v

: Fixed cost for vehicle v

VC

v

: Variable cost for vehicle v

CE

v

: Carbon emission of vehicle v per km

dn

i

n

j

: Distance between suppliers (nodes) i and j

Decision Variables:

X

ijvt

: Quantity of product j of supplier i in period t

delivered by vehicle v.

y

ninjtv

: : Binary variable equal to 1 if arc (n

i

, nj) is part

of the route of vehicle v in period t.

c

0ijtv

: Binary variable equal to 1 if vehicle v starts from

depot and visits immediately after supplier i in period

t.

Objective Functions and Constraints

The first objective function aims to minimise the total

cost of transportation activities (TCT).

The second objective function aims to minimise

total carbon emissions from the vehicles used to

pickup and deliver the purchased products (TCE).

∑∑∑∑∑

∗

∑∑∑∑

∗

(10)

∗

(11)

Constraints:

Vehicle load capacity constraint:

∗

∀,

(12)

Equation (13) states that each vehicle visits at most

one node at the beginning of the pickup:

1∀,

(13)

Equations (14)-(16) state the degree constraints and

route continuity:

1 ∀,

1,2….,

(14)

1 ∀,

1,2….,

(15)

∀,

(16)

The bi-objective model is solved following with the

procedure adopted in (Hamdan and Cheaitou, 2017)

by OA. VRA requests from OA optimisation,

providing to the agent TCT, TCT

min

, TCE and TCE

min

results.

The Java API of CPLEX is used by the MAS for

the multi-objective programming development.

2.3 Integration of MAS with Web

Services

Agent services can be published as web services by

using the Web Service Integration Gateway (WSIG)

in JADE (

Bellifemine et al., 2007). Figure 3 shows the

integrated MAS with WSIG architecture. WSIG

consists of two basic components, namely the WSIG

Servlet and the WSIG Agent. The WSIG Servlet is

the front-end to the internet. Its tasks include serving

incoming HTTP/SOAP (Simple Object Access

Protocol) requests, determining the requested agent

action and informing the WSIG agent, as well as

sending the HTTP/SOAP response to the client. The

WSIG Agent is the gateway between the internet and

LogiTrans 4.0 2019 - Special Session on Logistics and Transport in the Industry 4.0

626

the agent worlds. The tasks include forwarding

requested agent actions to the agents in order to

perform them and receiving the responses from the

agents, as well as creating the Web Service

Description Language (WSDL) corresponding to

each agent registered service and publish it in a

Universal Description, Discovery and Integration

(UDDI) repository.

Figure 3: The integrated MAS with WSIG architecture.

3 CONCLUSIONS

Digital servitisation in smart supply chains requires

synchronisation of business processes and real time

information exchange between supply chain

members. Challenges created by sustainability

requirements lead to the emergence of new methods

in order to address business processes. Therefore, in

this paper, a MAS-based framework is proposed to

address sustainability requirements and integrated

decision making in supplier selection, order

allocation and vehicle routing. Fuzzy MCDM

approaches and multi-objective programming are

used by the agents in the MAS. Agents represent

different supply chain entities, business processes,

information elements as well as vehicles. They are

categorized as execution, information, outsourcing

partner and mobile agents. Furthermore, developed

agent services for the supply chain business processes

are integrated with web services, in order to facilitate

business process execution as web services. The

proposed method will be tested on a real case study in

the future studies.

REFERENCES

Bellifemine, F. L., Caire, G. & Greenwood, D. Developing

multi-agent systems with JADE (Vol. 7). John Wiley &

Sons (2007).

Wooldridge, M. & Jennings, N.R. (1995). Intelligent

agents: Theory and practice. The Knowledge

Engineering Review. 10, 115–152.

Gören Güner, H. (2018). A decision framework for

sustainable supplier selection and order allocation with

lost sales. Journal of Cleaner Production, 183, 1156-

1169.

Ho, W., Xu, X., Dey, P.K., (2009). Multi-criteria Decision

making approaches for supplier evaluation and

selection: a literature Review. European Journal of

Operational Research, 202, 16-24.

Swaminathan JM, Smith SF and Sadeh NM. (1998).

Modeling supply chain dynamics: a multi-agent

approach. Decision Sciences, 29 (3), 607–632.

Krysiak, F.C. (2009). Risk management as a tool for

sustainability. Journal of Business Ethics, 85 (3), 483-

492.

Long Q, Lin J, and Sun Z. (2011). Modeling and distributed

simulation of supply chain with a multi-agent platform.

International Journal of Advanced Manufacturing

Technology, 55, 1241–1252.

Elkington, J. (1998). Cannibals with forks: The triple

bottom line of the 21st century. Stoney Creek/CT: New

Society.

Aktin, Tülin, Gergin, Zeynep, (2016). Mathematical

modelling of sustainable procurement strategies: three

case studies. Journal of Cleaner Production, 113, 767-

780.

Giannakis, M., Papadopoulos, T. (2016). Supply chain

sustainability: a risk management approach.

International Journal Production Economics, 171, 455-

470.

Wooldridge, M. & Jennings, N.R. (1995) Intelligent agents:

Theory and practice. Knowledge Engineering Review,

10, 115–152.

Jiao J., You X. & Kumar A. (2006). An agent-based

framework for collaborative negotiation in the global

manufacturing supply chain network, Robotics

Computer-integrated Manufacturing, 22, 239–55.

Trappey. J. C., T.-H. Lu & L.-D. Fu (2007). Development

of an intelligent agent system for collaborative mold

production with RFID technology, Journal of

Computer Integrated Manufacturing, 20, 5, 423–435.

Yu, C., & Wong, T.N. (2015). A multi-agent architecture

for multi-product supplier selection in consideration of

the synergy between products. International Journal of

Production Research, 53 (20), 6059-6082

Ghadimi, P., Toosi, F. G. & Heavey, C. (2018). A multi-

agent systems approach for sustainable supplier

selection and order allocation in a partnership supply

chain. European Journal of Operational Research, 269,

286–301.

Davidsson, P., Henesey, L., Ramstedt, L. (2005). Tornquist,

J., Fredrik Wernstedt, F., An analysis of agent-based

approaches to transport logistics. Transportation

Research Part C, 13, 255-271.

Martin, S., Ouelhadj, D., Beullens, P., Ozcan, E., Juan, A.

A., & Burke, E. K. (2016). A multi-agent based

cooperative approach to scheduling and routing.

A Multi-Agent based Decision Framework for Sustainable Supplier Selection, Order Allocation and Routing Problem

627

European Journal of Operational Research, 254(1),

169–178.

Reefke, H. & Sundaram, D. (2017). Key themes and

research opportunities in sustainable supply chain

management—Identification and evaluation. Omega,

66, 195–211.

Hofmann, E. & Rüsch, M. (2017). 4.0 and the current status

as well as future prospects on logistics. Computers in

Industry, 89, 23–34.

Govindan, K., Jafarian, A., & Nourbakhsh, V. (2015). Bi-

objective integrating sustainable order allocation and

sustainable supply chain network strategic design with

stochastic demand using a novel robust hybrid multi-

objective metaheuristic. Computers and Operations

Research, 62, 112-130.

Govindan, K, Darbari, J. D., Agarwal, V., Jha, P. C. (2017).

Fuzzy multi-objective approach for optimal selection of

suppliers and transportation decisions in an eco-

efficient closed loop supply chain network. Journal of

Cleaner Production, 165, 1598-1619.

Songhori, J.M., Tavana, M., Azadeh, A., & Khakbaz, M.H.

(2011). A supplier selection and order allocation model

with multiple transportation alternatives. International

Journal of Advanced Manufacturing Technology, 52,

365-376.

Kuo, R.J., Lee, L.Y., & Hu, T.-L. (2010). Developing a

supplier selection system through integrating fuzzy

AHP and fuzzy DEA: a case study on an auto lighting

system company in Taiwan. Production Planning and

Control, 21 (5), 468-484.

Govindan, K., Khodaverdi, R., & Jafarian, A. (2013). A

fuzzy multi criteria approach for measuring

sustainability performance of a supplier based on triple

bottom line approach. Journal of Cleaner Production,

47, 345e354

Laporte, G., & Osman, I. H. (1995). Routing problems: A

bibliography. Annals of Operations Research, 61, 227–

262.

Yong, W., Shuanglu, Z., Kevin, A., Jianxin, F., Maozeng,

X., & Yinhai, W. (2018). Economic and environmental

evaluations in the two-echelon collaborative multiple

centers vehicle routing optimization, Journal of

Cleaner Production, 197 (1), 443-461.

Nasiri, M. M., A. Rahbari, F. Werner, & R. Karimi. (2018).

Incorporating Supplier Selection and Order Allocation

into the Vehicle Routing and Multi-cross-dock

Scheduling Problem. International Journal of

Production Research, DOI: 10.1080/00207543.2018.

1471241

Lim, M. K., & Zhang, D. Z. (2004). An integrated agent-

based approach for responsive control of manufacturing

resources. Computers & Industrial Engineering, 46,

221–232.

L.C. Wang & S.K. Lin. (2009). A multi-agent based agile

manufacturing planning and control system. Computers

& Industrial Engineering, 57, 620-640.

Chen C., Lin C., Huang S. (2006). A fuzzy approach for

supplier evaluation and selection, International Journal

of Production Economics, 102, 289–301.

Hamdan, Sadeque & Cheaitou, A. (2017). Supplier

selection and order allocation with green criteria: an

MCDM and multi-objective optimization approach.

Computers and Operations Research, 81, 282-304.

LogiTrans 4.0 2019 - Special Session on Logistics and Transport in the Industry 4.0

628