Design of a Circular-type Pod Silencer

for a High-pressure Axial Flow Fan

Hyun Gwon Kil

1

, Chan Lee

1

, Jong Jin Park

1

and Sang Moon Yang

2

1

Department of Mechanical Engineering, University of Suwon, Hwaseong-si, Gyeonggi-do, Republic of Korea

2

Samwon E&B, Siheung-si, Gyeongg-doi, Republic of Korea

Keywords: Circular-type Pod Silencer, Axial Flow Fan, Transmission Loss.

Abstract: A circular-type pod silencer has been designed to reduce a high noise level generated from an axial flow

fan. The noise consists of two components such as discrete frequency noise component at blade passing

frequency due to rotating impellers and broadband noise component due to turbulence produced in the axial

fan. Main contribution into the high noise level is due to the discrete frequency noise component. In order to

effectively reduce the noise level of the axial flow fan, the circular-type pod silencer has been modelled in

this paper. In order to identify critical design parameters, finite element analysis (FEA) with commercial

ANSYS acoustic code was implemented. The results of the design parametric study have been used to

design the circular-type pod silencer that effectively reduces the high noise level of the axial flow fan in

subway ventilation system.

1 INTRODUCTION

Axial flow fans are widely used in low pressure air

handling systems such as cooling, air-conditioning,

or ventilating equipment (Dixon, 2014). But subway

ventilation systems require axial flow fans with

relatively high pressure at high flow capacity. Those

generate high noise level. The noise consists of two

components such as discrete frequency noise

component at blade passing frequency (BPF) due to

rotating impellers and broadband noise component

due to turbulence in inflow and exhaust jet mixing

(Lee and Kil, 2018). Main contribution into the high

noise level is due to the discrete frequency noise

component. It is needed to attach silencers to reduce

the high noise level. Rectangular silencers in subway

ventilation systems have been widely used. But

those silencers generate relatively high pressure loss.

Therefore, there have been industrial needs for

reducing high noise level with circular-type pod

silencers effective to axial flow fan performance

with lower pressure loss.

The circular-type pod silencer was analyzed by

using transfer matrix method with plane wave

approximation (Munjal, 2003). Multimode sound

propagation was used to analyze the circular-type

pod silencer (Kirby, 2006). FEA approach was

implemented to analyze dissipative silencers (Peat

and Rathi, 1995; Mehdizadeh and Paraschivoiu,

2005; Cui et al., 2014). The design curves for

performance evaluation of passive pod silencers

were provided by simulating the acoustic

performance of the silencers with commercial FEA

software (Ramarkrishnan, 2015). Practical design of

the circular-type pod silencer have been widely

performed experimentally or based on existing

experimental results and design curves in reference

(Ver and Beranek, 2006). In this paper, in order to

reduce the high noise level of an axial flow fan in a

subway ventilation system, design of the circular-

type pod silencer has been performed with FEA

simulation using commercial ANSYS acoustic code

(ANSYS, 2019). The transmission loss of the

silencer was evaluated by solving the three-

dimensional sound wave equation inside the silencer.

The design parametric study has been performed to

identify critical design parameters. It has been

implemented to design the circular-type pod

silencer that

effectively reduces the high noise level

of the axial flow fan in the subway ventilation

system.

Kil, H., Lee, C., Park, J. and Yang, S.

Design of a Circular-type Pod Silencer for a High-pressure Axial Flow Fan.

DOI: 10.5220/0007838402630268

In Proceedings of the 9th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH 2019), pages 263-268

ISBN: 978-989-758-381-0

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

263

2 THEORY

2.1 Sound Transmission Loss and

Insertion Loss

In order to reduce the noise generated from the axial

flow fan, a silencer is attached to the fan. The noise

attenuation performance of the silencer is evaluated

in terms of transmission loss (TL) and insertion loss

(IL).

TL is defined as the logarithmic ratio between

the incident sound power

at the inlet of the

muffler and the transmitted sound power

at the

outlet of the silencer in Figure 1 as

(1)

Figure 1: Layout for evaluation of transmission loss.

If the area of the inlet is the same as the area of the

outlet, TL can be experessed with complex

amplitude of the incident pressure

and complex

amplitude of transmitted pressue

as

(2)

Figure 2: Layout for evaluation of insertion loss.

IL is defined as the difference between sound

power level Lp

2

at the termination without the

silencer and sound power level Lp

1

at the

termination with the silencer installed as shown in

Figure 2. In the case of IL, it is not necessary to

install an anti-reflection terminal as shown in Figure

2. Thus it is closer to an actual value of noise

attenuation because all actually installed connectors

related to the fan and the silencer are considered.

If the cross-sectional area of the inlet is equal to

the cross-sectional area of the outlet and the outlet is

anti-reflected, TL and IL become equal. Assuming

this condition, TL has been considered to design the

silencer in this paper.

2.2 Finite Element Analysis

Numerical simulation methods play an increasingly

important role in the design of silencers as well as

other noise and vibration applications. FEA offers an

advantageous combination of modelling flexibility,

computational efficiency and result accuracy.

Comparing to the boundary element analysis (BEA),

FEA allows modelling more complex physics of

acoustics considering multiple fluid domains, sound

propagation in a mean flow and effects of

temperature gradients in a fluid medium. FEA can

be especially used to design of the silencers to

reduce relatively high frequency noise considering

the higher modes above the cut-off frequency for the

plane wave approximation as well as to design the

silencers with relatively complex shapes.

(a) (b)

Figure 3: (a) Structural shape and (b) finite element model

of an circular-type pod silencer.

The linear wave equation for perfect gas with no

damping is expressed in terms of pressure and

speed of sound as

(3)

At each frequency in the interested frequency range

that equation (3) becomes Helmholz’s equation as

(4)

where P, mean complex pressure amplitude and

the acoustic wavenumber at the given frequency,

respectively. The three dimensional acoustic domain

of the silencer in Figure 3(a) is divided into elements

in Figure 3(b). The variational formulation of the

silencer problem allows to formulate the discretized

equation of linear systems of algebraic equations as

(5)

SIMULTECH 2019 - 9th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

264

where

and are the coefficient matrix,

sound pressure amplitude vector of nodal values and

forcing function vector of nodal values, respectively.

In the present silencer problem, is only a non-

zero value at the inlet pipe according to Dirichlet

boundary condition with unit pressure.

In this study, FEA is performed with a

commercial FEA program ANSYS. For more

efficient way to model perforation of the silencer,

meshes on the perforated tube are replaced by the

two inner and outer concentric surfaces with

acoustic transfer admittance. For the acoustic

transfer admittance, the transfer admittance of the

perforated plate (Mechel, 2008) with the same

perforation pattern of the perforation tube is used.

Another effective method is to use equivalent fluid

model to model sound absorbing materials in the

silencer. In this work Miki equivalent fluid model

(Miki, 1990) has been implemented, that uses the

following expressions for the complex

characteristics impedance

and complex

wavenumber of the sound absorbing material at

frequency as

(6)

(7)

Here

and correspond to air density, speed of

sound and fluid resistivity of the sound absorbing

material, respectively. It is known that Miki

equivalent fluid model is regarded valid in the

frequency range of < 0.01. .

3 ANALYSIS

3.1 Noise Characteristics Analysis

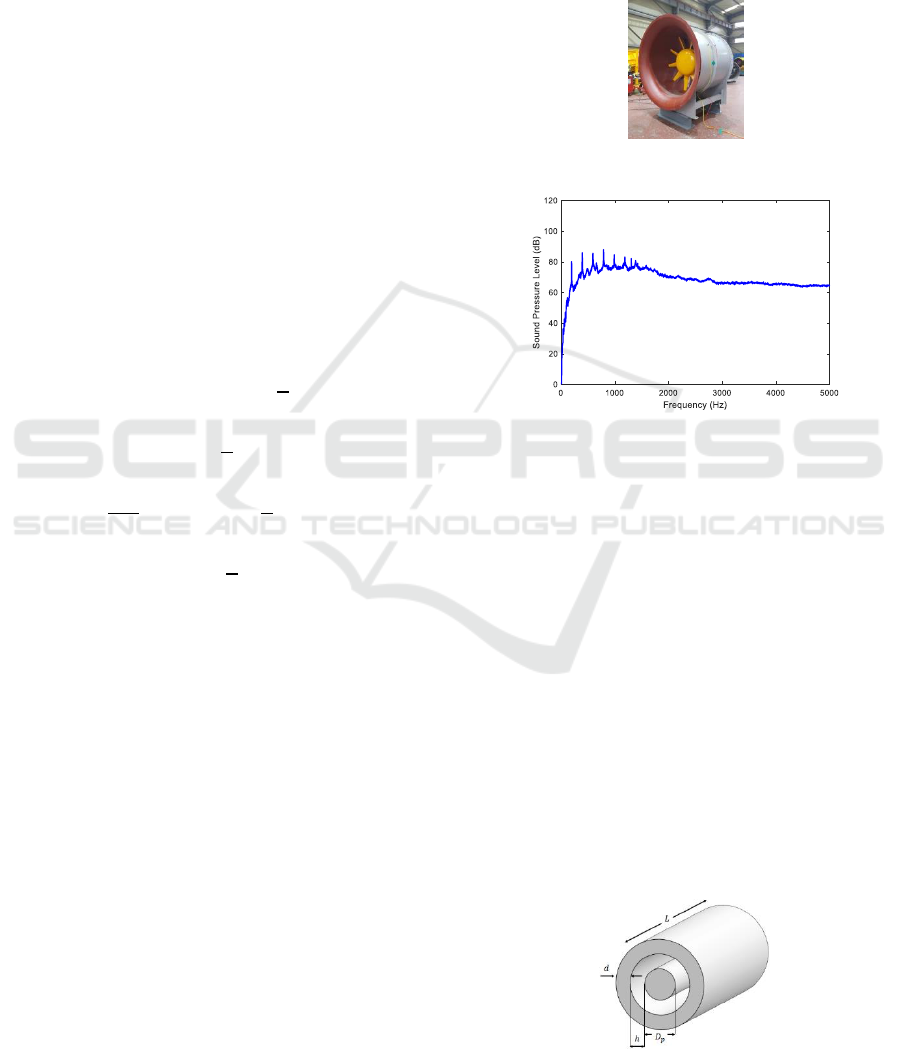

The noise source considered in this research is an

axial flow fan (Figure 4) operating with high

pressure rise at high flow capacity in the subway

ventilation system. It generates high noise level. The

noise consists two kinds of noise components such

as discrete frequency noise at BPF and the

broadband noise distributed over wide frequency

range. BPF noise is produced mainly due to rotating

steady fan blade thrust and blade interaction.

Broadband noise is produced over entire frequency

range due to turbulent boundary layer on blade

surface, inflow turbulence and blade wake. Figure 5

shows the typical pattern of noise spectrum

measured from the regenerative blower. Here BPF

corresponds to 198 Hz.

Figure 4: Axial flow fan.

Figure 5: Measured noise spectrum of axail flow fan.

3.2 Verification of Analysis

In order to verify the FEA simulation approach, FEA

has been applied to evaluate TL of silencer models

in reference (Beranek, 2006). The silencer models

are circular-type silencer without a pod, circular-

type silencer with a rigid pod and circular-type

silencer with sound absorbing pod (

. Those have dimensions as

and as

shown in Figure 6.

The predicted numerical results for TL have been

compared with the corresponding results in the

reference (Beranek, 2006) as shown in Figure 7. It

showed that FEA approach can be used to evaluate

TL of the circular-type pod silencers in good

agreement with the experiment results in the

reference.

Figure 6: Silencer models for analysis verification.

Design of a Circular-type Pod Silencer for a High-pressure Axial Flow Fan

265

Figure 7: Comparison of the predicted TL of silencers

(without a pod [model A], with a rigid pod [model B] and

with an sound absorbing pod [model C], respectively) with

results in the reference.

3.3 Tl Characteristics

The design model is the circular-type pod silencer as

shown in Figure 8. The outer surface of the sound

absorbing pod and the inner surface of the outer

sound absorbing layer are formed of perforated tubes.

The design variables are outer diameter

, inner

diameter

, sound absorbing pod diameter

, air

flow gap thickness , sound absorbing outer layer

thickness , type of sound absorbing material,

density of sound absorbing material and porosity

of perforated tubes. Considering a flame retarding

material, glass wool is selected as the type of the

sound absorbing material.

Figure 8: Design model of the circular-type pod silencer.

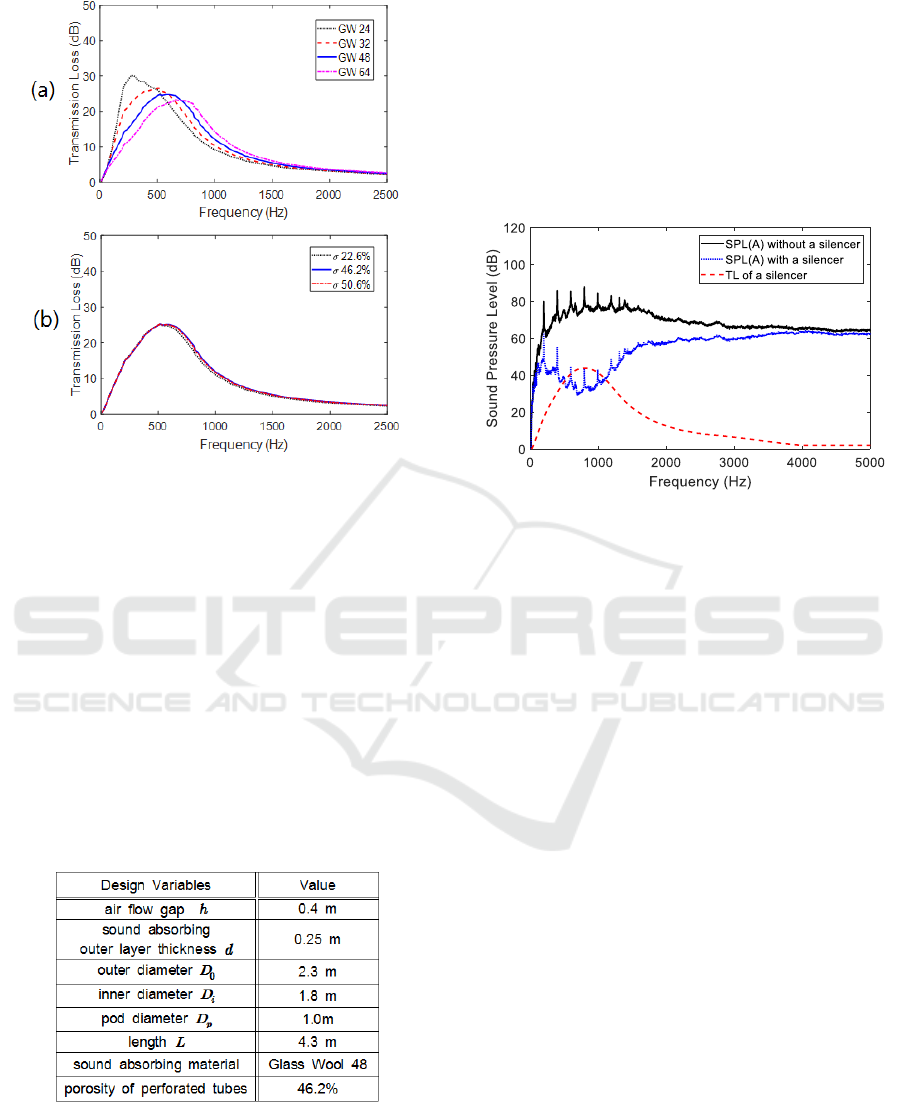

The design parametric study was performed by

evaluating TL. Figures 9-11 show the influence of

changing corresponding design variable on TL of the

silencer. Figure 9(a) shows little influence of

changing the thickness of the absorbing outer layer

on TL if it is more than about 0.2 m. Figure 9(b)

shows that the air flow gap thickness decreases, TL

increases in all frequency region and the frequency

at which the maximum TL value occurs also

increases.

Figure 10(a) shows that the length of the silencer

increases, the TL value increases in the main noise

reduction frequency band. Figure 10(b) shows that

the pod diameter increases, TL also increases in the

main noise reduction frequency band.

Figure 9: Influence of corresponding design variable

change on TL of the silencer as (a) outer sound absorbing

layer thickness, (b) air flow gap thickness.

Figure 10: Influence of corresponding design variable

change on TL of the silencer as (a) silencer length and (b)

sound absorbing pod diameter.

Figure 11(a) shows that the density of the sound

absorbing material increases, the main noise

reduction frequency band increases but the

maximum TL value decreases. Figure 11(b) shows

little influence of changing the porosity of the

perforated tube on TL, if it is more than about

46.2 %. The parametric study results show that the

most sensitive design parameter corresponds to the

air flow gap thickness.

SIMULTECH 2019 - 9th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

266

Figure 11: Influence of corresponding design variable

change on TL of the silencer as (a) sound absorbing

material density in unit of

and (b) porosity of the

perforated tubes.

4 RESULTS

In order to design the circular-type pod silencer, the

silencer installation space condition in subway

provides constraints as

and

Considering the fan casing inner diameter of

the axial flow fan, constraint as

is also

given.

Table 1: Specifications of the designed circular-type pod

silencer.

Considering the parametric study results and the

design constraints, the specifications of the circular-

type pod silencer have been determined as design

variables in Table 1. When the designed silencer is

attached to the axial flow fan, the reduced noise

reduction can be evaluated as follows. First, TL of

the designed silencer is evaluated over the frequency

range between 0 and 5 kHz as shown in Figure 12.

Second the reduced noise SPL spectrum is obtained

by subtracting TL from the measured noise spectrum

of the axial flow fan itself as shown in Figure 12.

The overall SPL of 106 dB(A) is expected to be

reduced to 94 dB(A) by attaching the circular-type

pod silencer.

Figure 12: Reduced noise spectrum of the axial fan with

the silencer, that is evaluated by subtracting TL from the

measured noise spectrum of the axial fan, itself.

5 CONCLUSIONS

A circular-type pod silencer has been designed to

reduce a high noise level that is generated from the

axial flow fan in subway. In order to effectively

reduce the noise, the design parametric study has

been performed using FEA. It has been implemented

to design the circular-type pod silencer that

effectively reduces the high noise level generated

from the axial flow fan. The overall SPL of

106dB(A) has been expected to be reduced to 94

dB(A). In order to get more noise reduction, a

circular-type pod silencer with annular two layers

can be considered. Further research is expected to

design the circular-type pod silencer with annular

two layers.

ACKNOWLEDGEMENTS

This work was supported by the Korea Institute of

Energy Technology Evaluation and Planning

(KETEP) and the Ministry of Trade, Industry &

Energy (MOTIE) of the Republic of Korea

(

20172010106010

).

Design of a Circular-type Pod Silencer for a High-pressure Axial Flow Fan

267

REFERENCES

Dixon, S.L., 2014. Fluid mechanics and thermodynamics

of Turbomachinery, Butterworth & Heinemann, 7

th

edition.

Lee, C., Kil, H.G., 2018. A new through-flow analysis

method of axial flow fan with noise models, Euronoise.

Munjal, M.L., 2003. Analysis and design of pod silencers,

Journal of Sound and Vibration, 262(3).

Kirby, R., 2006. Multi-mode sound propagation in pod

silencers, 13

th

International Congress on Sound and

Vibration.

Peat, K.S., Rathi, K.L., 1995. A finite element analysis of

the convected axcostic wave motion in dissipative

silencers, Journal of Sound and Vibration, 184(3).

Mehdizadeh, O.Z., Paraschivoiu, 2005. A three-

dimensional finite element approach for predicting the

transmission loss in mufflers and silencers with no

mean flow, Applied Acoustics, 66(8).

Cui, F., Wang Y., Cai R.C., 2014. Improving muffler

performance using simulation-based design, Inter-

noise 2014.

Ramarkrishnan, R., 2015. Performance analysis of annular

psssive silencers, Journal of Canadian Acoustical

Association, 43(3).

Ver., I.L., Beranek, L. L., 2006. Noise and vibration

control engineering-principles and applications, John

Wiley & Sons, INC., 2

nd

edition.

ANSYS, 2018. ANSYS user manual, ver. 18.0, ANSYS

Inc..

Mechel, F.P., 2008. Formulas of Acoustics, Springer, 2

nd

edition.

Miki, Y., 1990. Acoustical properties of porous materials-

modifications of Delany-Bazley models, Journal of

Acoustical Society of Japan, 11(1).

SIMULTECH 2019 - 9th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

268