A Fuzzy Inference Approach to Control Robot Speed in Human-robot

Shared Workspaces

Angelo Campomaggiore, Marco Costanzo, Gaetano Lettera and Ciro Natale

Dipartimento di Ingegneria, Universit

`

a degli Studi della Campania ”Luigi Vanvitelli”, Via Roma 29, Aversa, Italy

Keywords:

Human-robot Collaboration, Workspace Monitoring, Fuzzy Logic.

Abstract:

Nowadays, human-robot collaboration (HRC) is an important topic in the industrial sector. According to the

current regulations, the robot no longer needs to be isolated in a work cell, but a collaborative workspace in

which human operators and robots coexist can be acceptable. Human-robot interaction (HRI) is made possible

by proper design of the robot and by using advanced sensors with high accuracy, which are adopted to monitor

collaborative operations to ensure the human safety. Goal of this article is to implement a fuzzy inference

system, based on the ISO/TS 15066, to correctly compute the minimum protective separation distance and

adjust the robot speed by considering different possible situations, with the aim to avoid any collisions between

operators and robots trying to minimize cycle time as well.

1 INTRODUCTION

The research paper tackles the human-robot collab-

oration problem by following the line of the current

regulations and introducing a new approach to be used

in manufacturing industry. The novel method assures

human operators safety, without modifying the robot

predefined path and defining a safety metric to scale

robot trajectory only when indispensable, thus trying

to maximize the production time.

The research work is carried out in the framework

of a European project (The LABOR project, 2019),

which has the objective to propose novel robotized

assembly paradigms of aircraft fuselage panels. Un-

til recently, the aerospace industry was still conserva-

tive and companies tended to use successful assem-

bly methods that had already been proven to work in

the past. Nowadays, many assembly sub-operations

try to exploit robotics, e.g., drilling, fastening and

sealing tasks. These operations are no longer man-

ually performed by human operators but by industrial

robots equipped with dedicated tools or by large au-

tomated machines dedicated to assembly of specific

parts. However, there are some detailed operations

which require human capabilities and that must be

still executed by operators. This is the case of hy-

brid metal and composite structures, where, after the

drilling operation, some parts have to be manually re-

moved for further manual operations, like deburring,

and then re-installed on the skin panel before the seal-

ing and riveting operations, as shown in Figure 1.

This requires to setup a robotic cell that has to

foresee the presence of a human operator, hence the

necessity to monitor the shared workspace. Real-time

workspace monitoring for human-robot coexistence is

not an easy problem to solve. Even more, implement-

ing strategies to maximize the production time and

preserve human safety at the same time is a research

challenge. The approach proposed here is to adopt

a fuzzy inference logic that can update the planned

robot velocity in real-time according to robust per-

ception data and a set of rules formulated based on

a risk analysis. This can lead to a novel, acceptable

solution.

Ensuring the safety of a human operator is the

main purpose of the current research of industrial col-

laborative robotics. The safety standards for appli-

cations of industrial robots are laid out by the Inter-

national Organization for Standardization (ISO) (ISO

10218-1, 2011), (ISO 10218-2, 2011), and by the up-

coming ISO proposed draft Technical Specification

(TS) (ISO/TS 15066, 2016), which addresses four

collaborative scenarios:

1. Safety-rated Monitored Stop (SMS), which re-

quires that the robot stops when a human is in the

collaborative workspace;

2. Hand Guiding (HG), which allows the operator

to hand-guide the robot through an hand guiding

equipment (e.g., an analog button cell attached to

78

Campomaggiore, A., Costanzo, M., Lettera, G. and Natale, C.

A Fuzzy Inference Approach to Control Robot Speed in Human-robot Shared Workspaces.

DOI: 10.5220/0007838700780087

In Proceedings of the 16th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2019), pages 78-87

ISBN: 978-989-758-380-3

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

the robot) and an emergency stop conforming to

International Electrical Commission (IEC) (IEC

60204-1, 2009);

3. Speed and Separation Monitoring (SSM), which

monitors the robot speed according to the separa-

tion distance from the operator;

4. Power and Force Limiting (PFL), which limits the

momentum of the robot such that the potential

for operator injury upon impact is minimized, ac-

cording to the established injury standards (Bicchi

et al., 2008).

In this paper, a strategy to handle the operators

safety in industrial SSM scenarios is investigated.

The main goal is to reasonably scale down the size

of the protective zone around the robot and improve

productivity, taking into account safety regulations.

The robot behavior is modified, in terms of trajec-

tory scaling, only if there is a real and imminent

risk of collision. The operator approach into the col-

laborative workspace is deeply analyzed to general-

ize the computing method of the safety index and

face the extreme variability and unpredictability of

human behaviours. The devised solution computes

the points at minimum distance between the robot

and the closest human and presents several desir-

able features with respect to other solutions, e.g.,

(Zhang et al., 2016),(Bascetta et al., 2011),(Lippi and

Marino, 2018),(Bjerkeng et al., 2014); many of these

approaches rely on evasive actions to increase safety.

However, in industrial setting, it is generally recom-

mended to follow the robot predefined path without

deviating from it, especially in complex work cells,

where clashes are likely to occur. The main charac-

teristics of the proposed approach are:

• it considers the whole surface of human opera-

tors, without using skeleton-based techniques and

without approximating the body to a single point;

• it considers the whole robot kinematic chain, the

entire volume and possible tools, without factor-

ing only a singular representative element of the

robot (e.g., the end effector);

• it explicitly takes into account the regulations;

• it predicts the human velocity v

H

, by estimating

it from perception data without assuming it con-

stant;

• it is based on a risk analysis that considers the rel-

ative directions of velocities, which are not taken

into account in the equation proposed by the cur-

rent regulations;

• it does not modify the robot programmed path and

it does not require the task to be aborted.

Figure 1: Example of a manual assembly operation where

the operator shares the workspace with a robot.

2 ISO ANALYSIS: SSM

SSM allows the robot system and the operator to

move concurrently in the collaborative workspace.

Risk reduction is achieved by maintaining at least the

minimum protective separation distance, S, between

the human operator and the robot all the time. Dur-

ing robot motion, the robot system never gets closer

to the operator than S. When the Euclidean separation

distance, d, is equal to or less than S, the robot system

stops, before it can impact the operator. When the op-

erator moves away from the robot system, the robot

system can resume the motion automatically while

maintaining at least the protective separation distance.

(ISO 13855, 2010) is the first document which in-

vestigates the issue of safeguards positioning for hu-

man safety in stationary, active machinery. The docu-

ment suggests to compute S as

S = vT +C, (1)

where v is the approach speed of human body parts

and its value is assumed to be as the maximum opera-

tor speed of 2.0m/s, unless d is greater than 0.5 m, in

which case may be set at 1.6 m/s. T is the total sys-

tem stopping performance time, in seconds, and it is

a combination of the time required by the machine to

respond to the operator’s presence (i.e., T

R

) and the

response time of the machine which brings the robot

to a safe, controlled stop (i.e., T

S

). C is the intrusion

distance safety margin, which represents an additional

distance, based on the expected intrusion toward the

critical zone prior to the actuation of the protective

equipment.

From eq. (1), ISO/TS 15066 updates the S mean-

ing by including robot dynamic properties. When

the robot system reduces its speed, the protective

separation distance decreases correspondingly, i.e.,

A Fuzzy Inference Approach to Control Robot Speed in Human-robot Shared Workspaces

79

S(t

0

) ≥

Z

τ=t

0

+T

R

+T

S

τ=t

0

v

H

(τ)dτ +

Z

τ=t

0

+T

R

τ=t

0

v

R

(τ)dτ

+

Z

τ=t

0

+T

R

+T

S

τ=t

0

+T

R

v

S

(τ)dτ + (C + Z

S

+ Z

R

)

(2)

In (2), v

H

is the “directed speed” of the closest op-

erator which travels toward the robot, v

R

is the speed

of the robot in the direction of the operator, v

S

is the

directed speed of the robot in course of stopping. The

remaining terms represents uncertainties: the intru-

sion distance C is based on the operator reach, Z

R

is

the robot position uncertainty, and Z

S

is the operator

position uncertainty (i.e., the sensor uncertainty). Fi-

nally, t

0

is considered the current time.

The main issue of (ISO 13855, 2010) is that

the separation distance was initially intended for

static machinery, not for dynamic and reconfigurable

robotic systems. Therefore, extending what is con-

tained in the standard to the case of industrial robotics

is not trivial. Nevertheless, ISO/TS 15066 tries to

make a contribution to the HRC problem and de-

scribes S using the linear function

S = (v

H

T

R

+ v

H

T

S

) + (v

R

T

R

) + (B) + (C + Z

S

+ Z

R

)

(3)

where B is the Euclidean distance travelled by the

robot while braking. Note the one-to-one correlation

between eq. (2) and the linear relationship (3). The

first term in parentheses describes the contribution at-

tributable to the operator’s change in location in the

time necessary to bring the robot to a full stop from its

current speed. The second term describes the contri-

bution attributable to the robot system reaction time,

before it initiates the braking sequence. The third

term describes the distance travelled by the robot dur-

ing its braking. Finally, the fourth term describes the

possible distance of intrusion into the robot work vol-

ume as a function of the operator reach and the un-

certainty of the sensory system and robot kinematics.

The values of v

H

, T

S

, B and C can be found in the

safety standards: the values of v

H

and C are given in

ISO 13855, while guidelines for evaluating T

S

and B

are given in Annex B of ISO 10218-1 and they result

from measurements that directly depend on the robot

system under test.

This paper decomposes and assesses the perfor-

mance of ISO/TS 15066 SSM minimum protective

distance metric and adds a contribution to improve

some aspects to allow its applicability in industrial

scenarios. The following sections widely discuss

four main areas that are directly pertinent to SSM:

human detection and tracking, prediction of human

and robot motions, safety separation maintenance and

robot speed monitoring.

3 HUMAN-ROBOT

INTERACTION

The robot control system must be able to adapt the

robot trajectory to the current observed scene and to

perform its task efficiently and safely. This means

that the control system must be able to detect the

presence of human operators inside the collaborative

workspace, to track the human closest to the machine

and, finally, to modulate the robot speed according to

the minimum protective distance S.

The HRC has been addressed dividing it into

two distinct problems: human detection and tracking

(HDT) and intention estimation (IE).

3.1 Perception System

The experimental set-up of this work is composed by

two depth cameras, which have been used to monitor

the collaborative workspace: a Microsoft Kinect v1

and an Intel RealSense D435 (see Figure 2a). At least

two views become necessary to minimize the occlu-

sions of the observed area, as shown in Figure 2b and

Figure 2c.

An intrinsic calibration is necessary to update

the rough intrinsic default parameters, as well as, a

sphere-tracking procedure has been developed for ex-

trinsic calibration. The obtained homogeneous trans-

formation matrices, T

robot

camera1

and T

robot

camera2

, express the

poses of the camera frames with respect to the robot

base frame.

The goal of the extrinsic calibration is to obtain

an accurate identification of the camera pose, which

guarantees the minimum relative positioning error

when the two camera views are merged.

Therefore, a 3D tracking technique has been de-

veloped by using a polystyrene sphere of 0.12 m di-

ameter. The red sphere has been mounted at the

robot end effector, so as to match the center of the

sphere with the origin of the end-effector frame, as

shown in Figure 2. The calibration procedure uses

the M-estimator SAmple Consensus (MSAC) algo-

rithm (Torr and Murray, 1997) (which is an exten-

sion of the best known RANdom SAmple Consensus

(RANSAC) algorithm (Fischler and Bolles, 1981)), to

find a sphere within a radius constraint, and to provide

its geometric model. The robot has been positioned

at specific configurations, which allow to correctly

distinguish the target within the two camera views.

From the robot joint states, the forward kinematics

computes the pose of the center of the red sphere. At

the same time, the developed procedure acquires the

depth images, converts them into point clouds (Rusu

and Cousins, 2011) and estimates the target model.

ICINCO 2019 - 16th International Conference on Informatics in Control, Automation and Robotics

80

(a) Perception system.

(b) Kinect RGB view. (c) RealSense RGB view.

Figure 2: Experimental set-up.

The method is iterated to cover the entire collabora-

tive workspace and to minimize the positioning error.

Finally, the transformation matrices have been eval-

uated through an optimization algorithm with a cost

function that combines the data of both cameras.

3.2 Human Detection and Tracking

Realizing a safe HRC application requires a very fast

HDT algorithm, which detects human operators in

real time. In this study, a novel point cloud-based

methodology is presented to compute the minimum

distance between the whole body of the detected op-

erators and a robot. Since this operation is computa-

tionally heavy, a Background Segmentation (BS) al-

gorithm is developed to subtract the static environ-

ment from the observed scene and to process exclu-

sively the information related to the dynamic objects.

The developed pipeline is shown in Figure 3.

The perception system described in Section 3.1

observes the surroundings of the manipulator and the

robot kinematic chain is fully visible. While the

workspace is monitored, the robot executes its task,

thus it becomes a dynamic entity. Therefore, the Re-

altime URDF Filter (Blodow, 2012) is used to remove

the robot from the scene.

The implementation of the BS step consists of an

efficient algorithm that performs the subtraction of a

stored background, at pixel level: 50 frames of a static

scene in the absence of human workers are initially

captured and the mean value of each pixel is stored in

a memory area. Therefore, the stored frame is sub-

tracted from the current frame at every acquisition.

Figure 3: Implemented HDT pipeline.

The algorithm makes use of PCL: the depth in-

formation is converted into Point Cloud Data (PCD)

and a uniform sampling filter can be applied to make

the algorithm more reactive, by decreasing the PCDs

density.

Subsequently, a reference camera has been se-

lected to express the entire output of the perception

system relative to a single camera frame, in this case,

the Kinect camera. The point clouds have been com-

bined through the merging step (MS). The accuracy

reached during the extrinsic calibration procedure, de-

scribed in Section 3.1, allowed to obtain a satisfying

correspondence.

Finally, the clustering process (CP) provides as

many clusters as single dynamic areas are detected

in the foreground. The Euclidean cluster extraction

method is performed to highlight all the human clus-

ters of the collaborative workspace. The bottom right

image of Figure 3 shows three detected human op-

erators, whose shapes are distinguishable by different

colors. To compensate the sensors measurement noise

that could sometimes provide false clusters, the areas

in the foreground should be large enough to represent

a human body. Therefore, a valid cluster should have

A Fuzzy Inference Approach to Control Robot Speed in Human-robot Shared Workspaces

81

a minimum PCD cardinality, empirically determined.

3.3 Human-robot Separation Distance

The goal of the proposed HRC strategy is to identify

the nearest pair of points, one belonging to the robot

(P

R

) and the other one belonging to the operator (P

H

),

that minimize the distance, i.e.,

P

H

∈ H , P

R

∈ R | d(P

H

, P

R

) ≤ d(P

0

H

, P

0

R

)

∀P

0

H

∈ H , P

0

R

∈ R

(4)

where d(·, ·) is the Euclidean distance between two

points, H and R represent the set of all points that

belong to the operator and to the robot, respectively.

Therefore, alongside the HDT strategy, a robot

modeling method has been also implemented. To the

best of authors knowledge, the typical SoA assump-

tion is to consider only a representative elements of

the robot (e.g., the end effector), introducing only an

approximate estimation of the distance between the

operators and the robot kinematic chain. Other so-

lutions report the pose of the robot only in terms of

either joint configurations or in terms of the Carte-

sian pose of the robot link frames, without taking

into account the link shapes but considering only spe-

cific points. On the contrary, the proposed solution

models the entire robot kinematic chain with its vol-

ume. A computationally efficient way to represent

the whole robot is to use primitive shapes, e.g., el-

lipses and spheres (Choi and Kim, 1999). A simi-

lar convention was proposed in (Bosscher and Hed-

man, 2009) . This work is inspired by the same idea,

but pays attention to some aspects: since the robot

links can have different lengths, its kinematic chain

has been padded through dummy frames to protect

the robot homogeneously, and a 0.10m diameter se-

curity sphere has been created around each frame, tak-

ing into account the last frame that can incorporate an

end-effector tool.

Under such assumptions, the pair of human-robot

points that are closest to each other can be immedi-

ately identified. This step strongly justifies the choice

of a point cloud-based pipeline. In fact, the point

cloud provides much more detailed information, ac-

curacy and precision if compared to the major HDT

techniques present in the SoA literature cited in Sec-

tion 1. Unlike common skeleton-based techniques,

the proposed approach allows tracking humans also

when they are carrying objects. Moreover, it is not

necessary that human operators are in front of the

camera view: the point cloud will recognize them

anyway. Furthermore, detecting the pair of human-

robot points at minimum distance (4) is particularly

immediate. The algorithm calculates the distance be-

tween all points of a cluster point cloud and the origin

Figure 4: Identification of the minimum distance points: the

yellow sphere is the robot point closest to the human and the

purple one is the human point closest to the robot.

Figure 5: Multi-humans tracking.

of every robot frame. Eventually, the robot point P

R

will be the one on the surface of the virtual sphere,

around the identified frame, which lies on the line

connecting the origin of this frame and the closest

point in the cluster. From these results, the closest

human cluster is indirectly selected if more than one

human have been detected.

Figure 4 shows the results. Note that the proposed

approach is able to identify more detailed body parts,

e.g., a elbow, the head, an hand, the chin or the chest,

and also that P

R

can be detected along the whole robot

kinematic chain. Figure 5 demonstrates the effective-

ness of the proposed approach in multi-humans sce-

narios. The results of the experimental tests described

in Section 6 will be used to evaluate the performances

ICINCO 2019 - 16th International Conference on Informatics in Control, Automation and Robotics

82

of the algorithm.

3.4 Estimation of Operator and Robot

Velocities

Another fundamental function of the HRC problem is

represented by IE, i.e., the prediction of human move-

ment. From such information, the robot control sys-

tem will select the most appropriate value of its joint

speeds to avoid a potentially dangerous situation, as

explained in Section 5.

IE consists in estimating the next position and ve-

locity of the trajectory performed by the operator on

the basis of a series of positions previously acquired.

The sensor fusion strategy that has been integrated

into this work is based on a Linear Kalman Filter

(LKF), which tries to solve the problem of estimat-

ing the state of a discrete-time process governed by

the equations

x

k+1

=

I

3

∆tI

3

O

3

I

3

x

k

+ w

k

, (5)

y

k

=

I

3

O

3

x

k

+ n

k

(6)

where ∆t is the sampling time, I

3

and O

3

are the iden-

tity and zero matrices of size 3 × 3, respectively; w

and n are the process and measurement noises with

covariance matrices W and N , respectively. Finally,

x is the state vector of the system, i.e., the posi-

tion and the velocity of the operator x =

p

T

H

˙p

T

H

T

,

and the measured output y is a vector containing

the coordinates of the point P

H

described in Sec-

tion 3.3. The covariance matrix N is experimentally

estimated, while the covariance matrix Q has been

chosen as

Q =

I

3

∆t

2

O

3

O

3

Q

2

(7)

where Q

2

quantifies the uncertainty on the velocity

dynamics (assumed constant) of the state equations.

Based on the vector nature of the velocity, it is

possible to make some considerations about the di-

rection (trend) of the operator, that is to say, to predict

in which direction he/she is travelling to. Section 4

describes how to take advantage from these consid-

erations for industrial collaborative applications with

the aim to maximize productivity.

The LKF equations implemented in this work are

the standard ones and thus are not reported for brevity,

while the tuned parameters are fully described in Sec-

tion 6.

Figure 6 shows sample movements of the operator

and the three components of his/her estimated speed.

The linear velocity ˙p

R

of the point on the robot

closest to the operator can be computed according to

Figure 6: Estimation of operator velocity.

the differential kinematics equation

˙p

R

= J

p

(q) ˙q, (8)

where q [rad] and ˙q [rad/s] are the robot joint posi-

tion and velocity vectors, respectively; while, J

p

is

the position part of the Jacobian matrix calculated till

the closest point.

The (ISO/TS 15066, 2016) states that the “di-

rected speeds” of the robot and the human should be

used to compute S. This means that, in eq. (3), v

h

is

the operator speed in the direction of the moving part

of the robot and v

R

is the robot speed in the direction

of the selected operator. Note also that these speeds

are vector magnitudes, hence they are always grater

or equal to 0. Therefore, the velocity terms of (3) can

be computed as

v

H

=

˙

ˆp

T

H

p

R

− ˆp

H

k

p

R

− ˆp

H

k

(9)

v

R

=

˙p

T

R

ˆp

H

− p

R

k

ˆp

H

− p

R

k

, (10)

where ˆp

H

and

˙

ˆp

H

are the operator position and ve-

locity estimated by the LKF, respectively, and p

R

is a

vector containing the coordinates of the point P

R

de-

fined in Section 3.3.

4 FUZZY INFERENCE SYSTEM

The protective separation distance S in (3), computed

by using the speeds of (9)–(10), does not take into ac-

count the relative travel direction of the robot and the

operator. This means that, if the robot and the opera-

tor are going away from each other, the value of S un-

necessarily increases (proportionally to the computed

speed). To improve the production time considering

also this situation, the protective separation distance

has been redefined as follows

S = α[(v

H

T

R

+v

H

T

S

)+(v

R

T

R

)]+(B)+(C +Z

S

+Z

R

),

(11)

where α is a coefficient in the interval [0, 1] that is

1 when the operator and the robot are actually ap-

proaching to each other and is smaller than 1 other-

wise.

A Fuzzy Inference Approach to Control Robot Speed in Human-robot Shared Workspaces

83

To chose the value of α, a fuzzy inference ap-

proach has been implemented. The fuzzy logic, also

called faded logic, is a methodology in which each

proposition possesses a degree of truth into the inter-

val [0, 1] (Ross, 2010). The variable α must be clas-

sified taking into account some qualitative attributes

and it may have varying levels of validity between a

maximum (1) and a minimum (0). Hence, it is neces-

sary to generate linguistic rules of fuzzy inference to

realize a mapping of the inputs to the desired output.

The fuzzy inference process has been developed

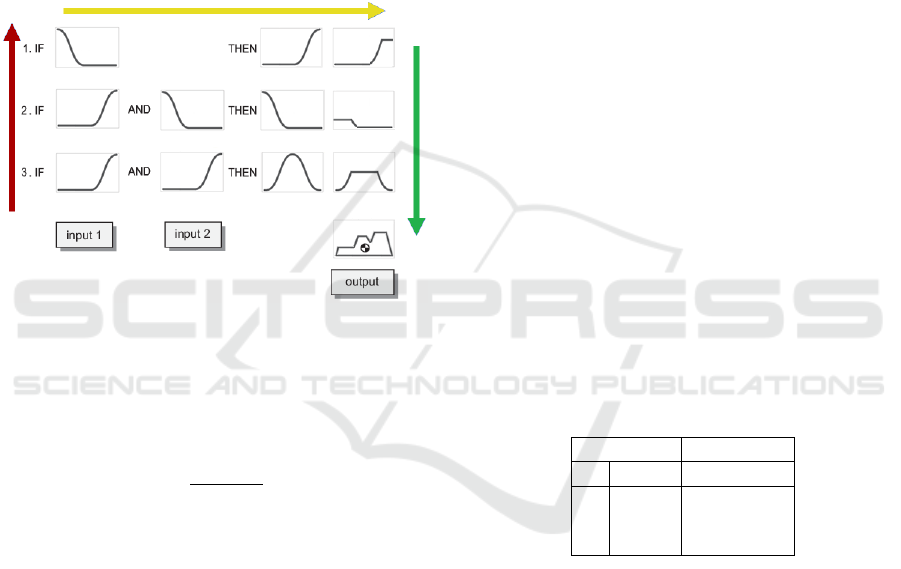

as a two-input, one-output, three-rule problem, as

shown in Figure 7.

Figure 7: Fuzzy inference system: the fuzzification step

(red arrow), the implication step (yellow arrow) and the ag-

gregation step (green arrow).

The first step is to select the inputs. Two data in-

puts have been selected:

1. the time derivative of the distance between human

and robot, i.e.,

˙

d =

d

k

ˆp

H

−p

R

k

dt

;

2. the scalar product between the robot and the hu-

man velocity vectors, i.e., ˙p

T

R

˙

ˆp

H

.

The first input is useful to distinguish cases when the

operator and the robot are getting closer and cases

when they are moving away from each other. The

scalar product specifies the relative direction of travel

of the operator and the robot.

The next step is the fuzzification step (red arrow

of Figure 7). The ranges of variability of each input

have been defined, and the appropriate membership

function of each interval has been selected. This step

requires attention to correctly determine the degree

to which the input belongs to each of the appropriate

fuzzy set, by assigning a fuzzy degree of membership

in the interval from 0 to 1. Two membership functions

have been selected to represent positive (P) and nega-

tive (N) values, a Z-shape and a S-shape, respectively.

These functions, with different parameters, have been

chosen to describe both ˙p

T

R

˙

ˆp

H

and

˙

d.

After the inputs are fuzzified, the implication step

(yellow arrow of Figure 7) determines the degree to

which each part of the antecedent is satisfied for each

rule. The antecedent of the developed fuzzy infer-

ence rules has three parts, combined through an AND

method (min) to obtain an implicated number that rep-

resents the result of the rule antecedent. Each rule is

designed to consider one possible risk scenario.

Since the final decision is based on the result of

all the tested rules, the outputs of the rules must be

combined in some way. The aggregation step (green

arrow of Figure 7) is the process by which the fuzzy

sets representing the outputs of each rule are com-

bined into a single fuzzy set, before the last defuzzifi-

cation step. For each interval of the consequent, the

maximum value of the fuzzy set is chosen and the de-

fuzzification method is the centroid, as shown at the

end of Figure 7.

The output value, α, has been generated by an-

alyzing different possible risk situations, with the

twofold aim of avoiding any collisions between hu-

man and robot, and being in line with the current

ISO/TS 15066. With reference to the second rule: if

the human-robot distance is increasing and they are

moving further from each other, than the safety dis-

tance can be decreased. The three rules are summa-

rized in Table 1.

Table 1: Fuzzy rules: [S] Small, [M] Medium, [H] High,

[N] Negative, [P] Positive, [∼] any.

antecedent consequent

˙

d ˙p

T

R

˙

ˆp

H

α

N ∼ H

P N S

P P M

Note that the scalar product between the opera-

tor velocity and the robot velocity (second input) is

a complementary information to the time derivative

of the distance between human and robot (third in-

put). Since ˙p

T

R

˙

ˆp

H

= k ˙p

R

kk

˙

ˆp

H

kcos θ, when θ = 180

◦

,

a critical situation is possible. The result of the scalar

product is negative, ˙p

T

R

˙

ˆp

H

< 0, but it is not possible

to distinguish the cases shown in Figure 8, in which

the directions are opposite but it is not known if the

human and the robot are getting closer or are moving

away from each other. This is the reason why it is

necessary to combine the scalar product information

with the time derivative of the distance between the

human operator and the robot.

ICINCO 2019 - 16th International Conference on Informatics in Control, Automation and Robotics

84

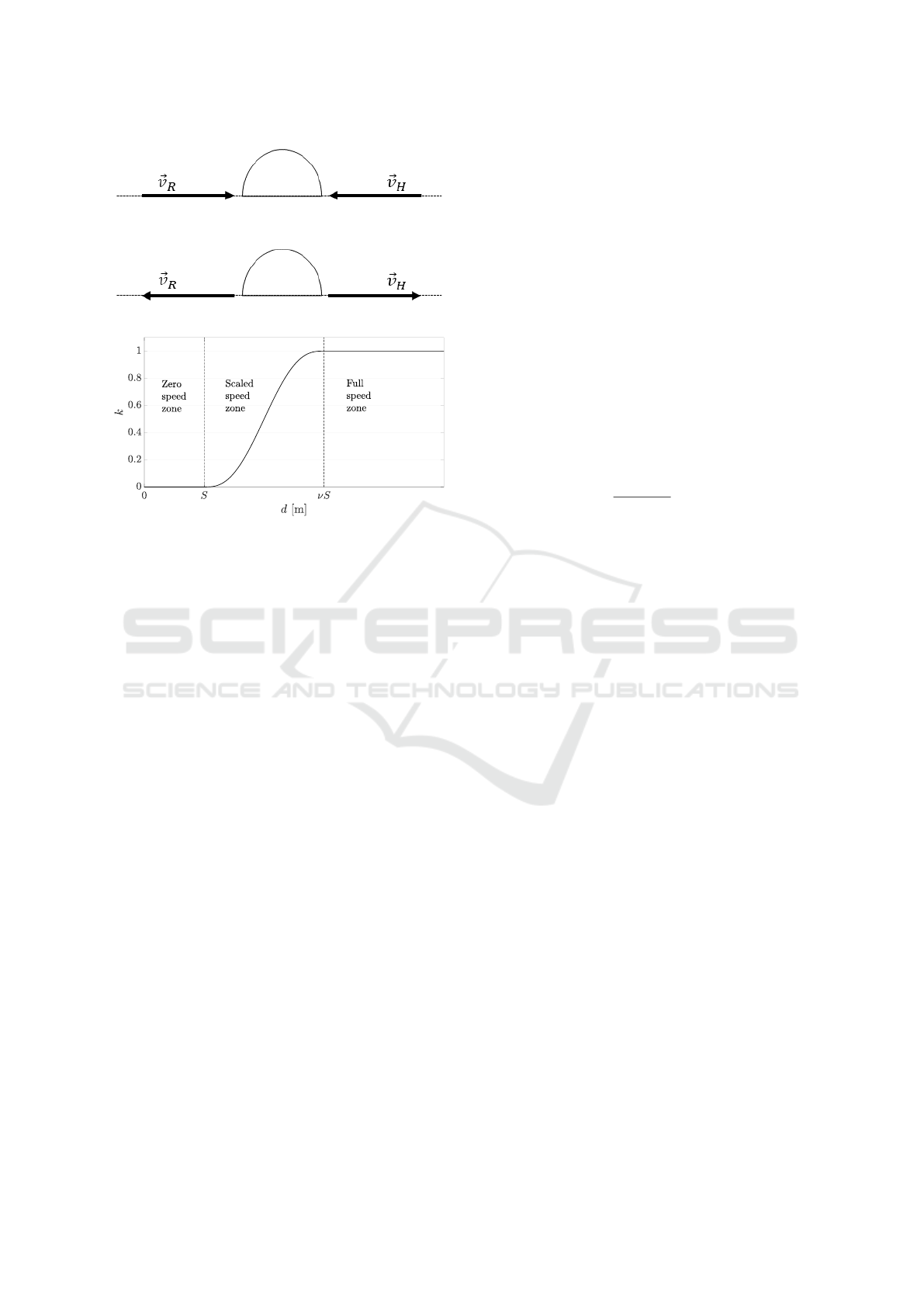

Figure 8: Problem of the scalar product.

Figure 9: Relation between d and k.

5 TRAJECTORY SCALING

SSM scenarios usually sacrifice the production time

because a lot of time is spent in low speed mode

when a human operator is inside the collaborative

workspace. On the contrary, the proposed strategy en-

sures human-robot coexistence according to the stan-

dard regulations, and also guarantees the task effi-

ciency by using a time-scaling approach to change

robot operating speed without introducing accelera-

tion discontinuities.

A typical industrial pre-programmed task, T , is

composed by N positions ˜q

i

, associated to veloci-

ties

˙

˜q

i

, accelerations

¨

˜q

i

and time instants

˜

t

i

with i =

1, . . . , N. Typically, the pre-programmed joint posi-

tions have to be interpolated according to the sam-

pling time T

c

required by the robot control interface.

In this work a quintic interpolation is used, i.e., the

planned interpolated trajectory is

˜q

h

= p

5

(t

h

; T ) (12)

˙

˜q

h

= p

4

(t

h

; T ) (13)

t

h+1

= t

h

+ T

c

, (14)

where t

h

is the h-th discrete time instant, p

4

is the

derivative of the polynomial p

5

, ˜q

h

and

˙

˜q

h

are the

planned joint position and velocity at time t

h

, respec-

tively.

The proposed method modulates the robot speed

by scaling the time with a safety scale factor k, which

can assume values in the interval [0, 1]. The scale fac-

tor is related to d (Section 3.3) as shown in Figure 9.

When d is below the minimum protective distance S,

k is 0 and the robot stops. When the distance d is far

from S, i.e. d > νS (ν > 1), the robot can move at full

speed to improve the production time. Between S and

νS the function in Figure 9 smoothly varies to avoid

acceleration discontinuities. Obviously, ν is another

design parameter that changes the size of the scaled

speed mode zone.

Practically, the trajectory is scaled computing (12)

using a scaled time τ

h

, i.e.,

q

h

= p

5

(τ

h

; T ) τ

h+1

= τ

h

+ kT

c

, (15)

where q

h

is the actual joint command at time t

h

. Ob-

viously, the joint command q

h

, as well as the scaled

time τ

h

, are generated with sampling time T

c

.

This approach effectively scales the joints veloci-

ties. In fact, using (15), it is

˙

τ ≈

τ

h+1

− τ

h

T

s

= k. (16)

By time differentiating (15), (17) demonstrates

that the velocity is scaled by the safety factor k,

˙q

h

= p

4

(τ

h

; T )k.. (17)

This approach guarantees that the task T remains

the same in position, but, simultaneously, the result-

ing velocity is scaled according to k.

When the operator is going to be into a dangerous

situation, the robot operates at diminished capacity

with limits on velocity that respect human-robot col-

laboration norms, until restoration of the safety con-

ditions. Note that the side effect of the velocity re-

duction is the reduction of the minimum protective

distance S, since this value is proportional to the robot

velocity. Experimental results are shown in Section 6.

6 EXPERIMENTAL RESULTS

AND VALIDATION

This section shows an example of experimental re-

sults obtained by simulating an SSM human-robot

collaboration task inside the collaborative workspace

of Figure 2. A manufacturing industrial sealing oper-

ation has been virtually realized: the robot executes

a pre-planned path at a given nominal speed, while,

suddenly, a human operator enters the collaborative

workspace to perform some manual operation close

to the robot, at different distances.

The main goal of this experiment is to prove the

efficiency of the fuzzy inference approach into in-

dustrial applications to better handle the production

time and, at the same time, to guarantee the safety of

A Fuzzy Inference Approach to Control Robot Speed in Human-robot Shared Workspaces

85

the operators when they are inside the collaborative

workspace.

Table 2 summarizes the used hardware and the ex-

perimental case study.

Table 2: Case study and available hardware.

Robot Yaskawa SIA5F

Collaborative workspace 4x2 m

Depth camera (1) Microsoft Kinect v1

Depth camera (2) Intel RealSense D435

Robot simulated task Sealing operation

Operator simulated task Manual piece change

The covariance matrix Q

2

in (7) has been chosen

as

Q

2

= diag(0.02, 0.05, 0.05)m

2

/s

2

, (18)

while the noise covariance has been estimated by ac-

quiring a constant human position as

N = diag(0.0009, 0.0008, 0.001)m

2

. (19)

The parameters to compute the protective separa-

tion distance S of (3) and (11) are reported in Table 3.

The value of C has been chosen to better appreciate

the zero speed zone.

Table 3: Constant parameters of S.

T

R

0.10s

T

S

0.08s

B 0.563mm

Z

R

0.001m

Z

S

0.1067m

C 0.20m

Figure 10 shows the results of the experiment. The

graph at the top of the figure shows the distance be-

tween the human operator and the robot and it can

be compared with the minimum protective distance

computed as in 3 (S

ISO

in the legend) and the two

thresholds proposed in this paper: S in the legend is

the protective distance computed as in (11) and νS

is the threshold used in the trajectory scaling algo-

rithm (Section 5). The bottom plot of Figure 10 shows

the two inputs of the fuzzy inference system (

˙

d and

˙p

T

R

˙

ˆp

H

) and the trajectory scale factor k. In this exper-

iment S

ISO

is not used and it is showed in the plot for

comparison purposes. A video of the experiment is

available at https://youtu.be/RzLZ6RQBPCY.

The robot executes a planned task, suddenly (at

about 16s) an operator enters into the workspace sim-

ulating a manual task. This is visible in the top plot of

Figure 10, where the human-robot distance decreases.

Note that for almost the whole task duration the sep-

aration distance robot-operator is below the S

ISO

sig-

nal, this would have caused frequent starts and stops

of the robot. Instead, through the proposed trajectory

scaling algorithm, the robot reduces its velocity ac-

cording to the observed separation distance. This is

visible in the k signal of the bottom plot that varies

according to d. Notice that k goes to 0 only when

the distance d goes below the protective distance S.

Moreover, another property of the proposed solution

is that S increases only when the distance decreases

(i.e., when

˙

d < 0) and not when the distance increases.

This is due to the computation of the directed speed

and the fuzzy rules. The shown experiment and the

related video demonstrate how the proposed approach

guarantees a safe human-robot coexistence in the col-

laborative workspace. This is achieved both in ac-

cordance with the ISO/TS regulations and minimizing

dead times in the production process.

7 CONCLUSIONS

The human-robot interaction and their intentions to

compete or cooperate in collaborative workspaces are

challenging research fields. The purpose of this work

is to improve the current regulations both to maxi-

mize the production time and guarantee the safety of

human operators inside the shared workspace. The

expected human movements relative to the robot are

classified to identify all possible industrial SSM sce-

narios from which fuzzy rules for the robot reactions

are derived. Collisions between robot and human op-

erators are avoided by identifying human-robot in-

tersections through a detection algorithm which pro-

cesses data obtained by merging two depth camera

images. Results obtained from experimental data

show the applicability of the presented methods to

many common manufacturing industry applications.

ACKNOWLEDGEMENTS

This work has received funding from the Clean Sky

Horizon 2020 Programme under the LABOR project,

grant agreement n. 785419.

REFERENCES

Bascetta, L., Ferretti, G., Rocco, P., Ardo, H., Bruyninckx,

H., Demeester, E., and Lello, E. D. (2011). Towards

safe human-robot interaction in robotic cells: An ap-

proach based on visual tracking and intention estima-

tion. In 2011 IEEE/RSJ International Conference on

Intelligent Robots and Systems. IEEE.

ICINCO 2019 - 16th International Conference on Informatics in Control, Automation and Robotics

86

0 10 20 30 40 50 60 70

0

0.5

1

1.5

2

2.5

0 10 20 30 40 50 60 70

-1

-0.5

0

0.5

1

-0.15

-0.1

-0.05

0

0.05

Figure 10: Experiment: an operator enters the shared workspace while the robot is moving. The top plot shows the estimated

distance robot-operator (d), the protective distances proposed by the regulation without sensing (S

ISO

) and the protective

distances proposed by the paper (S and νS). The bottom plot shows the trajectory scaling factor k, the time derivative of the

distance

˙

d and the scalar product of velocities.

Bicchi, A., Peshkin, M. A., and Colgate, J. E. (2008). Safety

for physical human–robot interaction. In Springer

Handbook of Robotics, pages 1335–1348. Springer

Berlin Heidelberg.

Bjerkeng, M., Falco, P., Natale, C., and Pettersen, K. Y.

(2014). Stability analysis of a hierarchical architec-

ture for discrete-time sensor-based control of robotic

systems. IEEE Transactions on Robotics, 30(3):745–

753.

Blodow, N. (2012). Realtime urdf filter.

Bosscher, P. and Hedman, D. (2009). Real-time collision

avoidance algorithm for robotic manipulators. In 2009

IEEE International Conference on Technologies for

Practical Robot Applications. IEEE.

Choi, S. I. and Kim, B. K. (1999). Obstacle avoid-

ance control for redundant manipulators using coll-

idability measure. In Proceedings 1999 IEEE/RSJ

International Conference on Intelligent Robots and

Systems. Human and Environment Friendly Robots

with High Intelligence and Emotional Quotients (Cat.

No.99CH36289). IEEE.

Fischler, M. A. and Bolles, R. C. (1981). Random sample

consensus: a paradigm for model fitting with appli-

cations to image analysis and automated cartography.

Communications of the ACM, 24(6):381–395.

IEC 60204-1 (2009). Safety of machinery - Electrical

equipment of machines - Part 1: General require-

ments. Technical report, International Electrotechni-

cal Commission.

ISO 10218-1 (2011). Robots and robotic devices - Safety re-

quirements for industrial robots. Part 1: Robots. Tech-

nical report, International Organization for Standard-

ization.

ISO 10218-2 (2011). Robots and robotic devices - Safety

requirements for industrial robots. Part 2: Robot sys-

tem and integration. Technical report, International

Organization for Standardization.

ISO 13855 (2010). Safety of machinery - Positioning of

safeguards with respect to the approach speeds of

parts of the human body. Technical report, Interna-

tional Organization for Standardization.

ISO/TS 15066 (2016). Robots and robotic devices - collab-

orative robots. Technical report, International Organi-

zation for Standardization.

Lippi, M. and Marino, A. (2018). Safety in human-multi

robot collaborative scenarios: a trajectory scaling ap-

proach. IFAC-PapersOnLine, 51(22):190–196.

Ross, T. J. (2010). Fuzzy Logic with Engineering Applica-

tions. John Wiley & Sons, Ltd.

Rusu, R. B. and Cousins, S. (2011). 3d is here: Point cloud

library (PCL). In IEEE International Conference on

Robotics and Automation. IEEE.

The LABOR project (2019). https://www.labor-project.eu/.

Torr, P. and Murray, D. (1997). The development and com-

parison of robust methods for estimating the funda-

mental matrix. International Journal of Computer Vi-

sion, 24(3):271–300.

Zhang, P., Jin, P., Du, G., and Liu, X. (2016). Ensuring

safety in human-robot coexisting environment based

on two-level protection. Industrial Robot: An Inter-

national Journal, 43(3):264–273.

A Fuzzy Inference Approach to Control Robot Speed in Human-robot Shared Workspaces

87