Application of the Statistical Analysis Methods for Improving the

Managing the Dealer-service Network Efficiency

Irina Makarova

1a

, Larisa Gabsalikhova

1b

, Eduard Mukhametdinov

1c

, Ksenia Shubenkova

1d

and Aleksandr Kapitonov

2

1

Kazan Federal University, Syuyumbike prosp., 10a, 423822, Naberezhnye Chelny, Russian Federation

2

Public Corporation KAMAZ, Transportny pr-d, 70, Naberezhnye Chelny, Russian Federation

Keywords: Dealer-service Network, Effectiveness, Data Envelopment Analysis, Performance Evaluation.

Abstract: The article proposes a method to increase the efficiency of dealership service centres (DSC) based on the

system analysis use. The method is based on clustering the DSC into groups according to formats, a

differentiated approach to the assessment of their activities and the relative useful efficiency calculation. The

analysing purpose effectiveness of the dealer-service network (DSN) is to obtain an objective efficiency

assessment of each DSC, identify the causes of inefficient operations and develop a strategy for improvement.

As a formalization tool, it is proposed to use the software product Konsi-DEA ANALYSIS, which allows to

evaluate the parameters of the objects functioning, as well as calculate the coefficients of efficiency and

superefficiency for each of them.

1 INTRODUCTION

The main trend in the development of the economy

and society, with which intelligent and rational

management and development of all activity fields,

including the automotive industry, is currently

associated is digitalization. In all activity areas, the

methods for finding optimal sustainable solutions is

associated with the fourth industrial revolution, which

is the main trend in the development of the

automotive industry. The high motorization level and

markets globalization are forcing automakers to

search for new solutions, constantly improving both

the vehicles design and production technology, as

well as new ways to attract customers.

The automotive industry development and

growing competition in world markets are leading to

the new trends' emergence, such as expanding the

assembly plants network in different countries,

updating the automotive vehicles’ model line,

including the emergence of more environmentally

friendly and energy-efficient models. Today, the

economy's linear model, based on the principle of

a

https://orcid.org/0000-0002-6184-9900

b

https://orcid.org/0000-0003-3325-3285

c

https://orcid.org/0000-0003-0824-0001

d

https://orcid.org/0000-0002-9246-6232

“take - make - waste”, has been replaced by the so-

called “circular economy”, which has a reducing and

closed nature and is based on minimizing the

consumption of primary raw materials and reducing

waste disposal. All this is completely correlated with

such a key direction of the Fourth Industrial

Revolution, as the formation of environmentally

friendly technical and technological systems.

According to research by the international company

Persistence Market Research (2015), their

introduction to the automotive industry will create an

opportunity to reduce raw material consumption by

98%; to save 83% of energy; reduce the finished

products cost to 40% and carbon dioxide emissions to

87%. This can be realized in the event that the

manufacturer is responsible for his product over the

course of its life cycle.

Under these conditions, the task of creating a

corporate service system and increasing the processes

efficiency in it becomes urgent. In order to ensure

customer loyalty, their trust in the brand, the producer

company should improve the quality of not only the

vehicles produced, but also their subsequent service

638

Makarova, I., Gabsalikhova, L., Mukhametdinov, E., Shubenkova, K. and Kapitonov, A.

Application of the Statistical Analysis Methods for Improving the Managing the Dealer-service Network Efficiency.

DOI: 10.5220/0007878506380648

In Proceedings of the 5th International Conference on Vehicle Technology and Intelligent Transport Systems (VEHITS 2019), pages 638-648

ISBN: 978-989-758-374-2

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

support. The customer focus principle can be

implemented by intellectualizing the management

and scientific methods using. Modern enterprises

operate in conditions of tough competition, which

dictates the need to improve their activities' every

aspect efficiency. Evaluation of the enterprise

functioning effectiveness is based on identifying and

systematizing the functions performed by the

enterprise and in the selection of indicators that allow

you to perform a information qualitative analysis and

make decisions based on the results obtained. In this

case, the selected methods should provide an increase

in the analysis accuracy and prediction in evaluating

the effectiveness.

There are three main methods groups for

measuring performance: use of economic factors as

variables reflecting the enterprise efficiency;

mpirical (expert) performance evaluation methods;

methods based on creating effectiveness' confines.

Considering the corporate service's system of as

one of the subsystems of a vehicles manufacturer,

functioning in close cooperation with production and

logistics systems, the connection between which is

carried out using information and material flows, we

can affect the efficiency and sustainability of the

entire system, which increases vehicles

competitiveness and consumer confidence in the

brand.

2 EXISTING METHODS FOR

ASSESSING THE AUTO

SERVICE EFFECTIVENESS

Customer focus and processes optimization by

reducing losses are the main goals of the transition to

Industry 4.0. The need for production systems'

constant adjustment to customer variable

requirements stimulates the development of new

methods in the framework of process organization or

production control (Trojanowska et al., 2011).

The automotive industry development is the

country's industrial standard, according to which the

vehicles number in a country can be considered as an

indicator of the living standard. That is why

industrialized countries will seek to develop the

automotive industry. The authors of the article

(Maritz, Alex et al., 2013) as a basis for research in

the automotive industry in 2007-2009 integrated data

coverage analysis (DEA) and Malmquist

performance analysis to measure total efficiency

(TE), pure technical efficiency (PTE) and scale

efficiency (SE) of nine automotive enterprises in

Taiwan to further improve the manufacturers

operational efficiency.

The research (Kumar, 2017) aims to measure and

evaluate the performance of vehicles manufacturers

in India using the DEA, which provides management

with information on the most efficient vehicles

manufacturing companies in the observations set and

identifies relatively inefficient companies compared

to the most effective. The authors believe that the

main factor leading to their poor performance is

excessive employee costs. Therefore, enterprises

must dismiss some employees, or reduce the costs of

employee benefits.

To optimize the processes using various methods

or combinations thereof. As a rule, this is an

effectiveness assessment and identification of

"limited" places for the subsequent processes

modernization. The document (Lee et al., 2010)

DEA-based analyses the performance of twenty

retailers of two Taiwanese car dealers, combined with

practical automotive industry experience. The authors

select important input and output variables for

evaluating effectiveness to identify the causes of

inefficiency, and also suggest ways to improve

project management. The DEA is introduced to

evaluate the performance of each automotive

company retailer. The result makes it possible to

develop operations management strategies for car

dealers in the future in accordance with an important

goal for all car retailers - maximizing revenue and

permanent job. In addition, it is important to

strengthen the ability of vendors in the field of

archiving in customer services and increase customer

loyalty and stability.

The article authors (Hladík, 2019) propose a new

DEA method for calculating efficiency indicators.

The method is based on reliable optimization: higher

estimates for those decision-making units (DMU),

which remain effective even for large simultaneous

and independent changes of all data and vice versa.

The approach novelty is that it preserves the ranking

order in comparison with the classical approach and

is a single invariant. It is naturally normalized, so it

can be used to calculate unrelated models' universal

DMU indices, which makes it possible to evaluate

both inefficient and effective decision-making units.

The method can be extended to generalized or

alternative models, for example, for processing

interval data. The new approach can be adapted to

reliability and to other used measurement methods,

such as super-efficiency models or cross-

effectiveness. Particularly promising are recent

results in assessing cross-performance, two-step and

network

DEA, probabilistic approaches, and DEA

Application of the Statistical Analysis Methods for Improving the Managing the Dealer-service Network Efficiency

639

models with uncertainties.

Currently, the decision-making process is

confronted with various problems that need to be

taken into account and planned, since, for example,

programs in the automotive industry related to vital

human factors are not structured (Baghery et al.,

2018). One way to evaluate potential failures of a

product or process and their consequences is the

process failure mode and effects analysis (PFMEA),

which identifies actions to eliminate failure or reduce

their effects throughout the product life cycle. A well-

known method for prioritizing failures is the risk

priority number (RPN). The authors have proposed a

new approach to setting priorities in the uncertainty

condition. In addition, a new score was used to

calculate the risk of each production process. In fact,

the assessment obtained from the combination of the

DEA interval methods and the Gray relational

analysis (GRA) reduced the traditional method

problems, since the production processes were

prioritized on their criticality basis. At this stage, the

SOD factors (severity, occurrence, and detection)

were considered as input to the DEA interval model.

Then, the first stage results were used as input data in

the GRA method for determining the priority of parts

manufacturing processes. Finally, some suggestions

were made to avoid potential disruptions in auto parts

production processes, and some measures were taken

in this regard.

Given the fierce competition between large

companies, in recent years, a sustainable supply chain

has been recognized as a key component of corporate

responsibility. The supplier’s classification can

facilitate the selection of a suitable supplier for

management, which saves the company time and cost.

DEA has become one of the most commonly used

tools for measuring the supplier’s relative

performance. The article authors (Tavassoli et al.,

2019) proposed a new super-efficient stochastic

model DEA for measuring the supplier’s relative

effectiveness in the presence of zero data. The

proposed method has many advantages for

practitioners in the sustainability field and supply

chain management: first, the proposed model can

rank all providers in sustainability terms. Secondly,

the recently developed stochastic model DEA with

high efficiency provides an optimal solution using

cost savings and output surplus for efficient suppliers.

Third, the newly developed DEA-DA can predict new

supplier group membership with high accuracy in a

stochastic context.

The article (Rashidi, 2019) presents a results

comparative analysis achieved in identifying the most

preferred steady suppliers, using two widely used

methods - methods for Technique for Order

Preference by Similarity to Ideal solution (TOPSIS)

and DEA. Fuzzy DEA and fuzzy TOPSIS apply to a

common set of logistics service providers in Sweden.

Sources of initial materials and the associated

supplier selection process are important strategic

decisions and actions in any organization. Research is

important for interested parties because it indicates

future research directions: comparison of suppliers'

sustainability assessment methods; sensitivity results

analysis to the number and nature of the criteria

included in the analysis; solution to the problem of

data collection. The results show that the suppliers

rating depends on the method. Recognizing the

assessment methodology, suppliers should be

motivated to respond quickly to the sustainability

requirements of the procuring customer.

Choosing a sustainable supplier is the process of

identifying the right partners for the supply

organization with the best value for money while

reducing the various effects of its activities on society

and the environment. Therefore, it plays an important

role in promoting the organization towards

sustainable development. This article (Moheb-

Alizadeh et al., 2019) aims to develop an inclusive

multi-purpose model of mixed integer linear

programming that takes into account several periods,

several products and multimodal transportation to

evaluate suppliers and distribute order volumes.

Among all the Pareto-optimal solutions to the original

multi-purpose programming problem, a preferable

solution is reasonably chosen based on the DEA

super-efficiency indicator of all procuring firms as a

decision support tool. The applicability of the

proposed approach is illustrated by the example of

practical use in the automotive industry.

Since the beginning of the 90s, many world

countries began to pay great attention to the

environment and raw materials resources. This

interest has led to the emergence of a number of new

concepts in the industry, including reverse logistics

(RL). To solve these problems, scientists use an

effective class of methods called metaheuristics. The

article authors (Rachih et al., 2019) classify

previously published articles on RL on the basis of

metaheuristic approaches and the problematic context

of the reverse supply chain.

Article (Wang et al. 2019) explores seven

enterprises from the Shanghai Professional

Committee for the vehicles disposal. The authors

believe that the proposed decision analysis using

several attributes in the ELV industry will facilitate

the ELV processing industry's management.

Empirical studies in this article indicate the

LogiTrans 4.0 2019 - Special Session on Logistics and Transport in the Industry 4.0

640

following. (1) The projection value of relatively

inefficient DMU can be calculated by combining

triple exponential smoothing and DEA, which

provide the increasing efficiency goal, while a slight

improvement in inefficient DMU can be used to build

a decision matrix for efficiency. (2) The preferred

solution can be selected from the decision matrix by

combining the entropy weight method with TOPSIS.

In addition, comparison of decision making

alternatives on additive weighting, weighted product

and ELECTRE (Elimination et Choice Translating

Reality) and TOPSIS alternatives can be performed to

test the stability of the decision process with several

attributes. (3) Finally, a combination of the above

methods is an effective decision-making method with

several attributes to increase the efficiency of the

ELV industry with several input and output

indicators.

Recycling is aimed at preventing rapid depletion

of natural resources when converting received waste

into value for the economy. However, this process is

becoming a serious problem in the automotive

industry, which requires the joint participation of

several players in a complex supply chain. The study

(Kusakcı, 2019) aims to develop a fuzzy mixed

integer positioning model for the ELV RL network in

accordance with the directives in force in Turkey.

Accordingly, this study uses a new approach and

assumes that the ELV supply on the network is

uncertain. The proposed mathematical model's merits

are proved in a real scenario, which solves the

problem of designing RL for ELVs generated in the

Istanbul metropolitan area.

The article goal (Hao Hao, 2018) was to improve

the reverse supply chain's management in the

automotive industry in the context of environmentally

friendly, circular and sustainable development by

predicting the number of vehicles with an expired

service life to be processed, by creating a multi-factor

model. To solve the problems associated with

nonlinear characteristics and the uncertainty of the

recyclable end-of-life vehicles' number, as well as

taking into account the many factors affecting the

recirculation’s number, this article presents a

combined forecasting model consisting of a grey

model, exponential smoothing and an artificial neural

network, optimized by the particle swarm

optimization (PSO) algorithm.

Faced with the contradiction between the rapid

growth in the vehicle owners' number and the low

return rate of end-of-life vehicles, RL services carried

out by third-party companies for the processing and

ELV dismantling in China are experiencing major

problems in a low carbon economy. This document

builds a four-level model of a RL network, which

includes ELV sources, collection centers, recovery

centers, and dismantling. The article authors (Xiao et

al., 2019) have developed a mathematical model of

mixed integer linear programming (MILP) for

solving a problem using the Lingo global

optimization software. The MILP model is designed

to minimize overall costs (location, transportation,

and environment) arising from improper management

of the ELV. The model successfully takes into

account the location, number and power level of key

objects at the same time, which increases the RL

network model's complexity and fills the existing gap

in research. This provides important management

implications for the ELV reverse logistics system at

two levels: the macro environment and the micro-

industry. For the micro-industry, logistics managers

must rationally distribute the number and key

facilities' capacity level in the network, including the

collection and dismantling center, based on actual

demand, and reduce resources waste and

environmental pollution. Further research may

develop stochastic or fuzzy MILP models that take

into account unspecified ELV quantities. In addition,

it is possible to design a closed supply chain network,

which direct consists and RL for the simultaneous

processing of the ELV, in order to analyse the

environmental impact on different network

participants.

As can be seen from the above review, the method

choice depends on the problem being solved.

Nevertheless, the DEA is a good optimization tool in

management tasks at different stages of the life cycle

in the automotive industry.

3 RESULTS AND DISCUSSION

3.1 The Indicators System for

Evaluating the Auto Service

Effectiveness

The dealer-service network (DSN) is a complex

system consisting of dealer service centers (DSC)

with three subsystems that operate in close

cooperation, i.e. implemented on the principle of "3S"

(Sales, Spare Parts, Service). The DSN development

has two directions - the construction of new and the

reconstruction of existing service centers. The

development strategy includes the effectiveness

evaluating stage of the existing network to identify

leaders and outsiders, determine the using possibility

existing development potential, taking into account

the regional development strategy and the vehicle

Application of the Statistical Analysis Methods for Improving the Managing the Dealer-service Network Efficiency

641

fleet structure. The direction of DSN development

depends on the analysis results and the effectiveness

of the existing DSN.

For an adequate comparison effectiveness of the

existing DSC, we must bring their indicators to a

comparable form. Each such DSC has potential

capabilities that can be numerically designated by a

parameters set. The activity of any of these DSC is to

strive to maximize apply their capabilities, what can

be represented as a desire for an ideal system. The

ideal system, in this case, is such a system that reaches

the possibilities limit in its activity. Thus, we must

understand that there are enterprises that are similar

in their capabilities and activities. These enterprises

can be ranked according to the achievement

indicators degree of an ideal system. Since any DSN

is comprised of DSC with different potential, before

comparing their effectiveness, it is necessary to

cluster them into comparable groups.

If the service needs are not met in a separate

region, then it is necessary to consider options for

adjusting the development strategy:

1) if the existing DSN is inefficient, and DSC have

reached the limits of their capabilities, then the

DSN needs to be expanded (either upgrading

existing enterprises or building new ones);

2) if the existing DSN works inefficiently, but the

DSC has not reached the possibilities limit, then it

is necessary to identify the inefficiency causes and

stimulate the efficiency's growth;

3) if the existing DSN is working effectively, but

there is a significant gap between the leaders and

the outsiders, then the strategy should be revised

and the resources should be adjusted.

For these purposes, i.e. to evaluate the DSN

effectiveness and to choose the development strategy,

the authors developed an algorithm (Buyvol et al.,

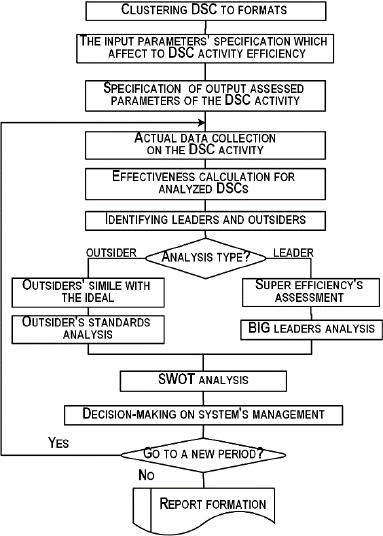

2017), which consists of several stages (Figure 1).

At the first stage, it is necessary to evaluate the

effectiveness of the existing region DSN, including in

terms of its expansion possibility:

clustering of the DSC into single-format groups

by characteristics (parameters characterizing

enterprises in terms of types of activities, volumes

of services, etc.) and services provided types for

comparability of performance estimates;

identifying leaders and outsiders within single-

format groups, for which it is necessary to

determine the input parameters characterizing the

potential of the DSC under study and their

capabilities, which are defined as the resources

used in the work; and the conditions in which the

DSC

operates, as well as the output parameters

that reflect the its results activities.

Under efficiency on this case is understood as the

ratio of output parameters to input. The DSN subject

will be effectiveness if, at the current value of the

input parameters, it is impossible to achieve large

output values. For the outsiders identified as a result

of this phase, a SWOT analysis is carried out, which

allows to determine the strategic planning directions,

identifying the strengths and weaknesses of the

enterprise, as well as identifying threats and

opportunities for development.

Figure 1: Algorithm for evaluating the effectiveness of the

DSN functioning.

The second stage consists in a comprehensive

assessment of the regional needs for vehicles-care

services under region’s development different

scenarios. To perform the analysis, you need:

assess the current state of the park and fulfil the

forecast of changes in its structure under different

development scenarios;

calculate the need for services under different

development scenarios;

assess the capabilities of the existing DSN to meet

the needs for corporate service operations at

various development scenarios;

determine the most appropriate scenario for the

DSN development, taking into account

investment risks.

LogiTrans 4.0 2019 - Special Session on Logistics and Transport in the Industry 4.0

642

At the third stage, the chosen strategy adequacy is

assessed: determination of the current performance

DSC indicators and the complex indicator values of

the DSC effectiveness at the period beginning;

monitoring system status and comparing performance

indicators with baseline ones; indicators analysis,

problem situations identification and strategy

adjustment.

To assess the DSC effectiveness, various analysis

methods are used, one of which is the DEA method,

that allows to evaluate the objects functioning

parameters, which implemented in the Konsi-DEA

ANALYSIS software package (Makarova et al.,

2012). The DEA method is based on creating

effectiveness' confines and finding the relative

performance of each object studied. This method is

used to assess the effectiveness of homogeneous

objects systems that are engaged in the same

activities, while using the same resources. With this

approach, the DSC efficiency is assessed by

comparing it with the “ideal” enterprise, which works

“at the limit” and at the same time uses the resources

at its disposal in an optimal way.

DEA-analysis allows you to highlight the leaders

and outsiders in their format groups, compare them

with the standards and develop objective strategic

solutions for taking the enterprise to the leaders. The

outsider indicators analysis suggests a changes

assessment to which the DSC parameters should be

subjected in order to increase the its activities

effectiveness. To make changes in the outsider's

work, it is necessary to compare it with the standard

(enterprises involved in the formation of the ideal).

Customer satisfaction and loyalty are described in

a non-linear function, according to which it is

beneficial for an enterprise to achieve a high degree

of client loyalty, and not to be content with an average

level, because the regular customers circle can be

formed only at the funds expense spent on increasing

their loyalty (Buyvol et al., 2012).

Potential financial benefits manifest themselves in

the long term, while the consequences of consumer

dissatisfaction manifest themselves much faster and

can be significant, since the secondary effect can

negatively affect to future services provided volumes.

For service companies (b2c), customer satisfaction

score should be above 80%. In case it exceeds 90%,

it can be argued that the company has become one of

the leaders. To achieve customer loyalty in a highly

competitive environment, it is necessary to achieve a

high degree of satisfaction with the services provided.

This means that the company needs to raise the level

of quality of service to a value that is impossible (or

extremely difficult) to copy.

Therefore, it is no coincidence that the ISO 9004-

2000 standard for enterprises certification of

prescribes the mandatory monitoring of the own

consumer’s satisfaction (clients, customers, buyers)

as one of the indicators of the quality management

system efficiency (ISO, 2000). Based on the selected

performance indicators, a comprehensive system for

assessing the DSN subject was developed.

Since the DSC differ in the work performed types,

the results assessment of their activities should also

be carried out differentially, highlighting for each

homogeneous group its own factors list affecting the

efficiency of the results and, consequently, the

enterprise competitiveness. In this sense, the

distinction should be made both of the indicators

themselves and of their values for different DSC

types and also the subjects themselves should be

separated into one-format groups. To classify DSC,

you can use a complex indicator characterizing the its

project potential. As a rule, when creating DSN in the

regions, the following scheme is used: in the “bush's”

center there is a large DSC of format A, and on the

“bush's” periphery, depending on the specific

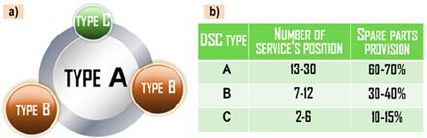

location, there are DSC of format B or C (Figure 2a).

In this case, standard DSC formats are used (Figure

2b).

Figure 2: a) disposition scheme DSC in region; b) DSC

parameters of different formats.

To find the relative effectiveness of each studied

DSC, it is need to determine the input and output

parameters, and the ratio of these parameters will

determine the effectiveness. Due to territorial

dissociation, as well as differences in the functioning

parameters, for the effective DSC work, there should

be a single managing centre, which should receive

timely and operatively information about the

productivity indicators of each DSC. Adjustment of

the development strategy of the DSN, as well as, in

the short term, a change in the managing actions and

the resources redistribution, should take into account

the analysis results of the incoming operational

information.

Analysing the information received, at the first

stage, the DSC productivity indicators are

determined, and then the ineffective activity causes

are identified. If the current efficiency is so low that

Application of the Statistical Analysis Methods for Improving the Managing the Dealer-service Network Efficiency

643

it casts doubt on the enterprise existence, then the

strategy should become short-term and focus

primarily on preventing the funds outflow. Even if the

DSC works effectively, it does not follow from this

that it is necessary to adhere to the chosen strategy.

The market is constantly changing, and the strategy

role is to help the company quickly adapt to changes

in the market. Significant reserves for improving the

competitiveness and corporate service system's

stability are rooted in the management improvement.

One of the methods widely used nowadays involves

monitoring the system efficiency indicators and

comparing their values in the previous and present

periods. Decision making is carried out depending on

how the indicators values have changed.

3.2 Methodology for Evaluating DSC

Effectiveness

In order to assess the performance of each DSC

indicators were comparable, it is necessary to

calculate the relative indicators for each activity.

When DSN analysing, we proceeded from the fact

that the services rendered volume, relative to the

number of work station (K

WST

), is an output

parameter. The following parameters were chosen as

input parameters: using of the production premises

area (K

PPA

), warehouse space (K

WS

), work station

operating time (K

op.t

).

K

WST

- work station use rate - is the ratio of the

services rendered volume to the number of work

station. This indicator allows to evaluate the work

organization, personnel qualification and work

mechanization. The better the work organization

indicators, staff qualifications and mechanization of

work, the higher the efficiency of the work station

use:

(1)

where V - the volume of services rendered, mln. rub;

x - the number of work station, units.

К

PPA

- coefficient of technical workroom area use

- the ratio of the maintenance and repair (M&R) area

to the number of vehicles' maintenance work station:

&

(2)

K

WS

- coefficient of warehouse space use - is the

ratio of the warehouse space area to the work station

number:

(3)

K

op.t

- the coefficient of operating time use is the

ratio of services rendered volume to the product of the

number of work station and hourly productivity:

.

(4)

.

(5)

where T

wsh

is the work shift duration, an hour; N is

the number of work shifts; D

op.y

– the number of

operation days in a year, days.

In order for the calculated efficiency absolute

indicators to be combined into one general aggregate

efficiency indicator, their conversion to the

benchmarkable indicator, reflecting the possibilities

maximum, is need. Evaluation of the DSS

effectiveness involves the use of a complex indicator

q, which is defined as the product of indicators:

∏

.

.

(6)

where k is the number of indicators.

The complex indicator for assessing the DSN

competitiveness is defined as the arithmetic mean of

the complex rating DSC indicators and serves as an

evaluative measure of the whole network:

∑

(7)

For DSC different format groups, the minimum

requirements for the general indicators are different.

They are used to evaluate the DSC (number of

personnel, minimum technical workroom's area,

warehouse space placement, administrative and

household rooms, parking lots, the minimum

equipment set, special tools and accessories, M&R

documentation). These indicators are divided into two

groups: design parameters ("etalon"), affecting to

DSC efficiency, and output calculated parameters.

The design parameters characterize the potential

of the DSC under study and their capabilities, they are

defined as the resources that are used in the work, and

the conditions in which the DSC operates. The

estimated parameters for DSCs of different formats

should also vary and reflect the activities results both

in vehicles sales and spare parts (turnover of spare

parts and sold cars) and in service (services volume

rendered by activity type, customer satisfaction with

the services quality, percentage loading work station).

To evaluate the performance of both individual

DSCs and DSNs in general, it is necessary to have the

initial design parameters of them each, as well as

statistical information about the parameters of their

functioning in different periods. Therefore, for each

typical service center, the optimal its operational

indicators are determined, corresponding to the

projected design capacities (profitability,

profitableness, costs level per client, etc.).

Since the effectiveness of DSC each, regardless of

its format, is characterized by the achievement degree

LogiTrans 4.0 2019 - Special Session on Logistics and Transport in the Industry 4.0

644

of each limiting values of the input design parameters,

it is more logical to use relative unit performance

indicators to compare the integral indicators of the

DSC functioning in each group. Therefore, at the first

stage, relative indicators are calculated,

characterizing the achievement degree of the

maximum values of these parameters, who will be

taken as single performance indicators.

Thus, each DSC will be characterized by

indicators set that comprehensively and adequately

reflect its competitive potential. At the same time,

given that the initial indicators set has a different

physical meaning and the impact nature on the final

DSC competitiveness assessment, they were divided

into groups: I

1

- indicators, the growth of which leads

to an increase in the overall DSC assessment (for

example, the growth of staff qualifications has a

positive effect on the productivity); I

2

- indicators, a

decrease in which leads to an increase in the overall

DSC rating (an increase in customer waiting time in

the queue adversely affects the image of the

enterprise and thereby reduces efficiency). To bring

their impact nature on the final assessment to a single

base, the indicators values of the second group should

be converted by the formula:

1

(8)

Then DSC are divided into homogeneous “single

format” groups, for which efficiency indicators and

use of production capabilities are analysed. DSCs are

compared with each other, the best use of production

capabilities is determined, and leading enterprises and

outsider enterprises are identified. DSC is effective if

at the current value of the design parameters it is

impossible to achieve large values of the output

parameters.

In order for the comparison to be correct, at the

first stage we divide the entire existing data array

about DSC into 3 groups, according to their format,

i.e. quantity of work station. Since DSC even into

one-format groups, have different potential for

development, it is expedient to evaluate their

production capabilities from this point of view. In

order for the comparison to be correct, the indicators

reduced to the number of work station are calculated.

Then ranking is carried out for each of the factors and

the total rank is calculated. The algorithm of DSC

classification by design parameters is shown in Figure

3. Thus, we obtain data on the potential, which can

later be used to build a DSN development strategy.

Figure 3: Algorithm for DSC classification.

3.3 An Example of the Developed

Methodology Implementation

In order to realize the developed methodology for

adjusting the development strategy for DSN, a

software implementation of the developed algorithm

was performed based on their activities analysis.

Ranging example of the DSC of format A is given in

the Figure 4.

Due to the availability of the upload and download

function of periodically generated files with data

coming into the managing center, the statistics of the

DSC activity results is accumulated, which can be

used to analyse data in comparison with the results of

previous periods and etalon values.

This program advantage is that its use minimizes

the subjective factors impact on the qualitative and

quantitative information assessment on the

enterprises activity and facilitates the adoption of

informed decisions based on its analysis without the

expert involvement. The information in the program

module window is divided into tabs in accordance

with the rating categories. Protection is provided

against the input of incorrect information

(information is entered strictly in accordance with the

data types), as well as the mandatory filling out of the

established list of fields is prescribed (with the

turning possibility off the reminder of field

completeness checking).

After entering the information into all the required

Application of the Statistical Analysis Methods for Improving the Managing the Dealer-service Network Efficiency

645

Figure 4: The calculation results of total ratings for DSC format A.

Figure 5: The program’s window for choosing the DSC development strategy based on the analysis results of their activities.

fields, the specialist responsible for collecting

information on all DSC sends the file with the data

that is loaded into a single database in the main

managing center. A DSN specialist of efficiency

evaluation uploads data from all DSCs to a single

database. The program allows calculating the relative

indicators for each DSC, comparing them with the

etalon values. After that, the change in indicators

comparing to previous periods is analyzed, the value

of efficiency is calculated as for each DSC, so for the

DSN in general. Based on this data, the correctness of

the chosen strategy is analyzed (Figure 5).

As a result of the DEA-analysis of the DSN

efficiency, it was established that five out of eleven

DSC are working with sufficient efficiency. DSC was

selected, which works with low efficiency. To

identify its strengths and weaknesses, a SWOT

analysis was conducted, and positive aspects were

identified, including a convenient operating mode and

a small number of competitors in the region. A

comparative analysis of the activities of this DSC for

past periods has shown that the deterioration of the

complex indicator is caused by a decrease in the work

station use rate and the coefficient of operating time

use, which requires identifying the causes of these

indicators deterioration and adjusting the

development strategy.

0.580.620.490.49

0.580.620.440.44

Comparative analysis of the integrated indicators of

the dealer-service network by years suggests that the

LogiTrans 4.0 2019 - Special Session on Logistics and Transport in the Industry 4.0

646

chosen strategy was effective, since there is a positive

trend.

1

∑

1.986

12

0.17

2

∑

2.174

12

0.18

In the DSC, where production capacity is fully

involved, the question of achieving the maximum

optimal managing is raised. For the DSC, which have

not exhausted their production capabilities, the

reasons for low efficiency are identified, the input

parameters are highlighted, the adjustment of which

will allow organizing processes more rationally, a

measures plan is developed for their optimization.

After this, the analyst assesses which improvements

will bring the planned activities to each DSC and the

system as a whole. Developed activities are brought

to the DSC attention for further implementation.

4 CONCLUSIONS

This research’s practical significance lies in the fact

that the developed algorithms use and techniques

contributes to improving the service vehicles quality,

and ensuring the effective implementation of their

resources and improving the service level in the DSC

by improving the quality of science-based

management decisions. A general method of

increasing the competitiveness of the DSC and DSN

as a whole is proposed. This method based by

highlighting the assessment factors and the

parameters affecting them, calculating the “etalon”

and actual values and adjusting the managing action

depending on the actual values degree of deviation

from the “etalon” values. Thus, consideration of the

DSN in the complex will allow identifying leaders

and outsiders among the DSC in format groups,

develop a plan for changes in the DSC operation and

implement a reasonable redistribution of resources

between the DSC within the DSN.

REFERENCES

Baghery Majid et al. Risk measurement and prioritization

of auto parts manufacturing processes based on process

failure analysis, interval data envelopment analysis and

grey relational analysis. J Intell Manuf (2018) 29:1803–

1825

Buyvol, P. at al. Improving the branded service network

efficiency based on its functioning evaluation. Astra

Salvensis. Vol. 2017, 2017, Pages 373-385

Buyvol, P.A. et al. Management of Automobile Plant

Dealer-Service Network Efficiency by Means of

Decision Support System. Third Forum of Young

Researchers: in the Framework of International Forum

Education Quality - 2012 Pages: 202-207 Published:

2012

Hao Hao et al. Forecasting the number of end-of-life

vehicles using a hybrid model based on grey model and

artificial neural network. Journal of Cleaner

Production 202 (2018) 684e696

Hladík Milan. Universal efficiency scores in data

envelopment analysis based on a robust approach.

Expert Systems With Applications 122 (2019) 242–252

ISO 9004:2000. Quality management systems -- Guidelines

for performance improvements. https://www.iso.org/

standard/28692.html

Kumar Nand et al. Evaluation of Efficiency of Automobile

Manufacturing Companies in India Using Data

Envelopment Analysis. International journal of

advanced production and industrial engineering.

IJAPIE-2017-01-111, Vol 2 (1), 01-06

Kusakcı Ali Osman et al. Optimization of reverse logistics

network of End of Life Vehicles under fuzzy supply: A

case study for Istanbul Metropolitan Area. Journal of

Cleaner Production 215 (2019) 1036-1051

Lee C.C., Chang F.T. A Performance Management on

Automobile Dealers with Applying Data Envelopment

Analysis. Proceedings of the 2010 IEEE IEEM. Pp.380-

384

Makarova, I. et al. Dealer-service center competitiveness

increase using modern management methods.

Transport Problems Vol: 7 Iss: 2 pp. 53-59 (2012)

Maritz, Alex, Shieh, Chich-Jen. Performance Analysis of

Automobile Industry in Taiwan with Data Envelopment

Analysis. International Journal of Applied

Mathematics and Statistics, Vol. 38; Issue No. 8; Year

2013, pp.84-95

Moheb-Alizadeh Hadi, Handfield Robert. Sustainable

supplier selection and order allocation: A novel multi-

objective programming model with a hybrid solution

approach. Computers & Industrial Engineering 129

(2019) 192–209

Rachih Hanane et.al. Meta-heuristics for reverse logistics:

A literature review and perspectives. Computers &

Industrial Engineering 127 (2019) 45–62

Rashidi Kamran, Cullinane Kevin. A comparison of fuzzy

DEA and fuzzy TOPSIS in sustainable supplier

selection: Implications for sourcing strategy. Expert

Systems With Applications 121 (2019) 266–281

Tavassoli Mohammad, Saen Reza Farzipoor. Predicting

group membership of sustainable suppliers via data

envelopment analysis and discriminant analysis.

Sustainable Production and Consumption 18 (2019)

41–52

Trojanowska, J. et al. Influence of selected methods of

production flow control on environment. In: Golinska,

P., Fertsch, M., MarxGomez, J. (eds.) Information

Technologies in Environmental Engineering, pp.

s.695–705. Springer, New York (2011). doi: 10.1007/

978-3-64219536-5_54

Application of the Statistical Analysis Methods for Improving the Managing the Dealer-service Network Efficiency

647

Wang Zhiguo et al. Multi-attribute decision making on

reverse logistics based on DEA-TOPSIS: A study of the

Shanghai End-of-life vehicles industry. Journal of

Cleaner Production 214 (2019) 730-737

Zhongdong Xiao et al. Location-allocation problem of

reverse logistics for end-of-life vehicles based on the

measurement of carbon emissions. Computers &

Industrial Engineering 127 (2019) 169–181

LogiTrans 4.0 2019 - Special Session on Logistics and Transport in the Industry 4.0

648