Design of a Self-tuning Predictive PI Controller for Delay Systems based

on the Augmented Output

Yoichiro Ashida

1 a

, Shin Wakitani

2 b

and Toru Yamamoto

2 c

1

Department of Electrical Engineering and Computer Science, National Institute of Technology,

Matsue College, 14-4 Nishiikumacho, Matsue, Japan

2

Graduate School of Engineering, Hiroshima University, 1-4-1 Kagamiyama, Higashi-hiroshima, Japan

Keywords:

Predictive PI Controller, Predictive Control, Delay System, Data-driven, Self-tuning.

Abstract:

This paper proposes an online type control parameter tuning method for a predictive PI controller. Predictive

PI controller is based on a PI controller with a Smith predictor, and it is effective for a controlled object with

large dead-time. Control performance of the predictive PI controller strongly depends on control parameters.

Recently, some data-driven controller tuning methods have been proposed. The methods directly calculate

suitable parameters from one or some sets of operating data. In addition, almost controlled processes are

time-variant. In this paper, a data-driven self-tuning predictive PI controller is proposed. The effectiveness of

the proposed scheme is evaluated by a simulation example.

1 INTRODUCTION

PID controllers(Astrom and Hagglund, 2005; Berner

et al., 2018) are often applied in industries. Espe-

cially in chemical process systems, 90% or more of

controllers are PID controllers. However, according

to some surveys, most of the employed PID form

controllers are PI controllers(Bialkowski, 1993; Sun

et al., 2016). One of the reasons is the difficulty of

tuning of derivative gains. To obtain good control

performance for a controlled object with a long dead-

time, the derivative gain should be large. However,

the larger the derivative gain is, the stronger the influ-

ence of noise is. This is because a derivative element

amplifies high-frequency signals. Therefore, it is dif-

ficult to tune derivative gain suitably than the other

gains.

Lots of controllers which can obtain good con-

trol performance for a dead-time system are pro-

posed. Representative examples are Smith pre-

dictors(Ingimundarson and Hagglund, 2001; Sanz

et al., 2018) and model predictive controllers

(MPC)(Rawlings and Mayne, 2009; Gallego et al.,

2019). The Smith predictor constructs positive feed-

back for a conventional controller like a PI controller.

a

https://orcid.org/0000-0001-7751-5270

b

https://orcid.org/0000-0002-3850-3864

c

https://orcid.org/0000-0001-6500-8394

By the Smith predictor, dead-time of a controlled sys-

tem is removed from a closed-loop. Therefore, the

conventional controller can be designed for a system

without a dead-time. A MPC needs a mathematical

model of the process. The input value is calculated

based on an output of the mathematical model. These

MPCs are sometimes employed in industries. How-

ever, both controllers predict future output, and accu-

racy of a mathematical model strongly affects con-

trol performance. Separately, a predictive PI con-

troller(Hagglund, 1992; Airikka, 2014; Hassan et al.,

2016) has been proposed. Although the predictive PI

controller is a combination of a PI controller and a

Smith predictor, a mathematical model is not required

overtly and has only four parameters. Authors also

propose a tuning scheme of the predictive PI con-

troller(Ashida et al., 2019), and effectiveness for a

noisy system is shown by comparing a PID controller.

Recently, data-driven controller tuning methods

are proposed. According to the conventional con-

troller parameters tuning methods, the parameters are

determined based on a mathematical model of a con-

trolled system. In contrast, data-driven methods di-

rectly compute the control parameters without any

system model. Therefore, the methods can reduce

the cost of the modeling and attract attention. Rep-

resentative examples are Iterative Feedback Tuning

(IFT)(Hjalmarsson et al., 1998; Wang and Ma, 2015),

Virtual Reference Feedback Tuning (VRFT)(Campi

672

Ashida, Y., Wakitani, S. and Yamamoto, T.

Design of a Self-tuning Predictive PI Controller for Delay Systems based on the Augmented Output.

DOI: 10.5220/0007919306720679

In Proceedings of the 16th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2019), pages 672-679

ISBN: 978-989-758-380-3

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

et al., 2002; Campestrini et al., 2016) and Fictitious

Reference Iterative Tuning (FRIT)(Soma et al., 2004;

Kaneko, 2015). Among the data-driven methods,

FRIT method requires only one set of input/output

data, and some examples of actual systems are re-

ported. However, these methods determine one set

of controller parameters, and it is difficult to main-

tain control performance for a time-variant system.

To tackle this problem, data-driven tuning methods

are extended to some self-tuning controllers. Au-

thors also propose a data-driven PID controller tuning

method(Ashida et al., 2016), and the method is ex-

tended to the self-tuning PID controller(Ashida et al.,

2017).

In this paper, a self-tuning predictive PI controller

is proposed. The proposed controller is an extent

of a self-tuning PID controller proposed by the au-

thors(Ashida et al., 2017). A recursive least squares

method(Goodwin and Sin, 1984) is employed as an

adaptive algorithm. In the second section, a predic-

tive PI controller is derived from a PI controller with

a Smith predictor. In addition, it is proved that the

predictive PI controller can realize complete model

matching for a first-order system with a dead-time.

In the third section, the proposed design method of a

self-tuning predictive PI controller is described. Data-

driven controller parameters tuning method is firstly

explained. Next, an extension of the self-tuning con-

troller is described. At last, the proposed control

scheme is evaluated by some simulation and experi-

mental results.

2 DISCRETE-TIME PREDICTIVE

PI CONTROLLER

In this section, a discrete-time predictive PI control

law is derived. The predictive PI controller is based

on a PI controller with a Smith predictor. At first, a

controlled object G(z

−1

) is assumed to be the follow-

ing first-order system:

G(z

−1

) = G

p

(z

−1

)z

−d

, (1)

where G

p

(z

−1

) denotes a delay element of the sys-

tem, and d denotes a dead-time which is known. A

PI controller with Smith predictor can be expressed

as follows:

u(t) =

K

P

+

K

I

∆

n

e(t) − G

p

(z

−1

)

z

−d

− 1

u(t)

o

,

(2)

where K

P

, K

I

and u(t) denote a proportional gain, an

integral gain and an input signal. ∆ denotes the differ-

encing operator defined by ∆ := 1 −z

−1

, where z

−1

is

the shift operator which means z

−1

y(k) = y(k −1). In

addition, u(t) also denotes a controlled input, and e(t)

denotes a controlled error defined as follows:

e(t) := r(t) − y(t), (3)

where r(t) and y(t) denote a reference signal and an

output signal respectively. G

p

(z

−1

) is assumed to be

the following first-order system:

G

p

(z

−1

) =

z

−1

b

0

1 + a

1

z

−1

. (4)

By substituting (4), (2) can be rewritten as follows:

u(t) =

K

P

+

K

I

∆

e(t)

+

z

−1

b

0

(K

P

∆ + K

I

)

∆(1 + a

1

z

−1

)

(z

−d

− 1)u(t). (5)

Next, PI gains K

P

and K

I

are set as follows:

K

P

= −

a

1

b

0

K

pred

K

I

=

1

b

0

K

pred

, (6)

where K

pred

is a prediction gain. By substituting (6)

to (5), the following predictive PI control law is ob-

tained:

u(t) =

K

P

+

K

I

∆

e(t) +

z

−1

K

pred

∆

(z

−d

− 1)u(t).

(7)

To control a first-order system with delay shown

in (1) and (4) by the predictive PI controller, a closed-

loop transfer function is as follows:

W (z

−1

) =

K

pred

(1 + a

1

z

−1

)z

−(d+1)

1 + (K

pred

− 1 +a

1

)z

−1

+ a

1

(K

pred

− 1)z

−2

. (8)

The transfer function is simplified using (6). A pre-

diction gain K

pred

is set as follows:

K

pred

= 1 + p

1

, (9)

where p

1

is a value included in a following first-order

reference model with a dead-time:

G

m

(z

−1

) :=

1 + p

1

1 + p

1

z

−1

z

−(d+1)

. (10)

p

1

is an user-specified parameter and determines a

rise-time. By substituting (9) to (8), the closed-loop

transfer function is rewritten as follows:

W (z

−1

) =

(1 + p

1

)(1 + a

1

z

−1

)

1 + (p

1

+ a

1

)z

−1

+ p

1

a

1

z

−2

z

−(d+1)

=

1 + p

1

1 + p

1

z

−1

z

−(d+1)

. (11)

Design of a Self-tuning Predictive PI Controller for Delay Systems based on the Augmented Output

673

Therefore, the predictive PI controller can control a

first-order system with a dead-time as a first-order

reference model. When a controlled object has high-

order characteristics strongly, control performance of

the predictive PI controller deteriorates. Therefore,

the controller should be applied for a system like a

first-order system.

3 DESIGN OF A DATA-DRIVEN

SELF-TUNING PREDICTIVE PI

CONTROLLER

According to (6) and (9), a predictive PI controller

can be designed if system parameters are known. To

obtain the system parameters, system modeling is

required. However, it takes considerable burden to

make a mathematical model. In this paper, a data-

driven controller design method is employed to deter-

mine controller parameters. The method calculates

the controller parameters directly from a set of in-

put/output data. In addition, the controller parameter

tuning method is extended to a self-tuning controller

by employing a recursive least squares method.

The predictive PI control law shown in (7) can be

rewritten as follows:

r(t) =

1

K

P

∆ + K

I

∆u(t) + y(t)

+

K

pred

K

P

∆ + K

I

{u(t − 1) − u(t −d − 1)}. (12)

Augmented output φ(t) is defined as

φ(t) =

1

K

P

∆ + K

I

∆u(t) + y(t)

+

K

pred

K

P

∆ + K

I

{u(t − 1) − u(t −d − 1)}. (13)

From the definition, the following relationship is ob-

tained;

φ(t) = r(t). (14)

In the proposed method, it is desired to make the

system output y(t) tracks the reference model output

y

m

(t) which is defined as

y

m

(t) = G

m

(z

−1

)r(t), (15)

where G

m

(z

−1

) has been already defined by (10), and

p

1

is determined using the following formulation:

p

1

= −exp

−

T

s

T

m

. (16)

T

m

denotes a time-constant of the reference model

G

m

(z

−1

). The evaluation function J is defined as fol-

lows:

J =

N

∑

j=0

ε( j)

2

, (17)

where N denotes the number of data and ε(t) is de-

fined as follows:

ε(t) = y(t) −G

m

(z

−1

)φ(t), (18)

where optimized parameters are K

P

and K

I

. It is not

required to search K

pred

because K

pred

depends only

on p

1

of reference model G

m

(z

−1

). By minimizing

the evaluation function J, G

m

(z

−1

)φ(t) becomes iden-

tical to y(t). When the minimization has been finished

enough, the following relationship can be obtained:

G

m

(z

−1

)φ(t) = y(t). (19)

By using a relationship as (14), the following relation

can be obtained:

y(t) = G

m

(z

−1

)r(t). (20)

Therefore, the controlled output becomes identical to

the reference model output using optimized controller

parameters.

The above discussions are based on deterministic

systems. However, actual systems are stochastic sys-

tems. To reduce the influence of noise, the filtered

input/output signals u

f

(t) and y

f

(t) are used. A de-

lay part of the reference model is used as a filter, thus

u

f

(t) and y

f

(t) are defined as follows.

y

f

(t) :=G

mp

(z

−1

)y(t), (21)

u

f

(t) :=G

mp

(z

−1

)u(t). (22)

G

mp

(z

−1

) denotes a delay part of the reference model

as follows:

G

m

p(z

−1

) =

1 + p

1

1 + p

1

z

−1

z

−1

. (23)

From a view of the frequency domain, φ(t) is band-

limited by the reference model and ε(t) is composed

with band-limited φ(t) in the proposed tuning scheme.

Therefore, the reference model filter not only reduces

the influence of noise but also emphasizes the impor-

tant band of the signal. Hereinafter u

f

(t) and y

f

(t)

are used instead of u(t) and y(t).

In this paper, a self-tuning predictive PI controller

is designed by employing recursive least squares

(RLS) method(Goodwin and Sin, 1984). However,

the evaluation function J cannot be minimized by

RLS method because ε(t) is not linear to optimized

ICINCO 2019 - 16th International Conference on Informatics in Control, Automation and Robotics

674

parameters K

P

and K

I

. By multiplying K

P

∆ + K

I

to

(18), the following relation is obtained:

(K

P

∆ + K

I

)ε(t) =(K

P

∆ + K

I

)y

f

(t)

+ G

m

(z

−1

)(K

P

∆ + K

I

)φ(t). (24)

Based on (24),

˜

ε(t) is defined as

˜

ε(t) = (K

P

∆ +

K

I

)ε(t), and it can be rewritten as follows:

˜

ε(t) =G

m

(z

−1

)[∆u

f

(t)

+ K

pred

{u

f

(t − 1) − u

f

(t − d − 1)}]

− a

1

{y

f

(t) − G

m

(z

−1

)y

f

(t)}

− a

2

{G

m

(z

−1

)y

f

(t − 1) − y

f

(t − 1)}, (25)

where a

1

and a

2

are optimized parameters and defined

as follows:

a

1

:= K

P

+ K

I

a

2

:= K

P

. (26)

As a result, a new evaluation function is defined as

follows:

˜

J =

1

N

N

∑

j=0

˜

ε( j)

2

. (27)

˜

ε(t) is linear to a

1

and a

2

, then a minimization of

˜

J

is a least squares problem. a

1

and a

2

are calculated

recursively using the following recursive least squares

algorithm, and a

1

and a

2

are converted to K

P

and K

I

by (26).

ˆ

θ(t) =

ˆ

θ(t − 1) + K(t)

˜

ε(t), (28)

K(t) =

P(t − 1)ϕ(t)

ω + ϕ

T

(t)P(t − 1)ϕ(t)

, (29)

P(t) =

1

ω

P(t − 1) −

P(t − 1)ϕ(t)ϕ

T

(t)P(t − 1)

ω + ϕ

T

(t)P(t − 1)ϕ(t)

,

(30)

where ω is a forgetting factor, and

˜

ε(t), θ(t) and ϕ(t)

are calculated as follows:

˜

ε(t) :=G

m

(z

−1

)[∆u

f

(t)

+ K

pred

{u

f

(t − 1) − u

f

(t − d − 1)}]

−

ˆ

θ

T

(t − 1)ϕ(t) (31)

ˆ

θ(t) :=[ ˆa

1

(t), ˆa

2

(t)]

T

, (32)

ϕ(t) :=[y

f

(t) − G

m

(z

−1

)y

f

(t),

G

m

(z

−1

)y

f

(t − 1) − y

f

(t − 1)]

T

. (33)

An initial value of covariance matrix P(t) and

ˆ

θ(t)

which is estimated vector of a

i

(t) are determined by

the following equations:

P(0) =αI (34)

ˆ

θ(0) =[ ˆa

1

(0), ˆa

2

(0)]

T

, (35)

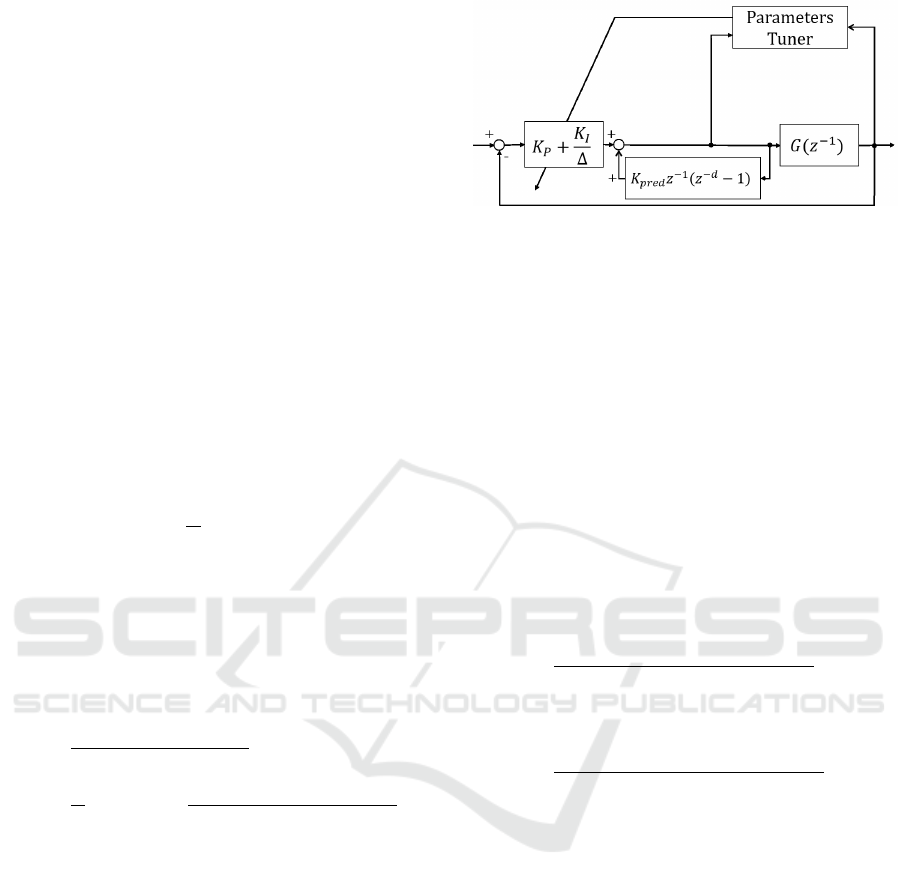

Figure 1: Block diagram of the proposed self-tuning con-

troller.

where α is determined under a condition of α > 0, and

I is a 2 × 2 matrix.

A block diagram of the proposed scheme is shown

in Fig. 1. A predictive PI controller can be divided

into a PI controller and a predictor. K

P

and K

I

are the

optimized parameters, thus only PI controller is tuned

recursively and the predictor is fixed.

4 SIMULATION RESULT

In this section, the proposed controller is evaluated by

the following time-variant system.

(i) t ≤ 3500

G(s) =

390s + 260

35s

4

+ 209s

3

+ 418s

2

+ 316s +7

e

−100s

,

(36)

(ii) t > 3500

G(s) =

312s + 208

70s

4

+ 418s

3

+ 836s

2

+ 632s +14

e

−100s

.

(37)

The system is discretized by T

s

= 1 s and the follow-

ing discrete system can be obtained:

(i) t ≤ 3500

y(t) =1.33y(t − 1) −0.41y(t − 2) + 0.07y(t −3)

− 0.003y(t − 4) +0.55u(t − 101)

+ 0.36u(t − 102) −0.29u(t − 103)

− 0.02u(t − 104) +ξ(t), (38)

(ii) t > 3500

y(t) =1.33y(t − 1) −0.41y(t − 2) + 0.07y(t −3)

− 0.003y(t − 4) +0.28u(t − 101)

+ 0.18u(t − 102) −0.15u(t − 103)

− 0.01u(t − 104) +ξ(t), (39)

where ξ(t) denotes the Gaussian white noise sequence

with zero mean and variance 0.1

2

. A reference model

Design of a Self-tuning Predictive PI Controller for Delay Systems based on the Augmented Output

675

0 1000 2000 3000 4000 5000 6000 7000 8000 9000 10000

-50

0

50

100

150

y

Reference signal

Output

Reference trajectory

0 1000 2000 3000 4000 5000 6000 7000 8000 9000 10000

Time [step]

-5

0

5

10

15

u

Figure 2: Control result using the proposed method.

0 1000 2000 3000 4000 5000 6000 7000 8000 9000 10000

-0.05

0

0.05

0.1

0.15

K

P

0 1000 2000 3000 4000 5000 6000 7000 8000 9000 10000

Time [step]

-2

0

2

4

6

K

I

10

-3

Figure 3: Trajectories of the control parameters correspond-

ing to Fig. 2.

was determined as the following system:

G

m

(z

−1

) =

0.05z

−1

1 − 0.95z

−1

z

−100

, (40)

where time-constant was set as T

m

= 20 s and dead-

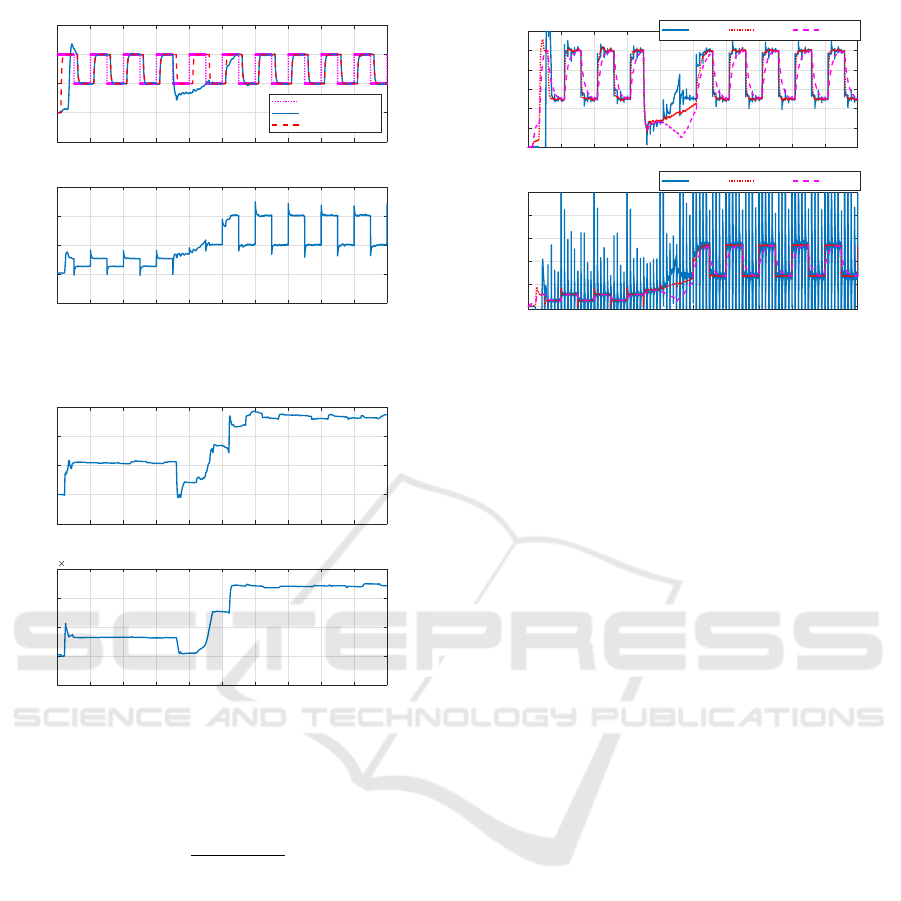

time was set as known. The control result using the

proposed method is shown in Fig. 2, and trajectories

of the controller parameters are also shown in Fig. 3.

Parameters of RLS method was as follows:

α = 1, ω = 0.995. (41)

Before and after the characteristics of the system

were changed, a good control performance was ob-

tained. From Fig. 3, the PI gains were tuned adap-

tively after the varying of the controlled object. How-

ever, just after the varying of the system, the PI pa-

rameters did not converge quickly, and the control

performance was strongly deteriorated. It is future

work to solve the problem.

At last, influence of the time-constant of the refer-

ence model is discussed. Figure 4 shows the control

0 1000 2000 3000 4000 5000 6000 7000 8000 9000 10000

0

20

40

60

80

100

120

y

T

m

= 0.1 T

m

= 20 T

m

= 100

0 1000 2000 3000 4000 5000 6000 7000 8000 9000 10000

Time [step]

0

5

10

15

20

25

u

T

m

= 0.1 T

m

= 20 T

m

= 100

Figure 4: Controlled outputs corresponding to the time-

constant of the reference model.

outputs when T

m

were set as 0.1, 20, and 100. The

reference signal and designed parameters except the

reference model were the same as Figure 2. When

T

m

= 20, the result is likely the same as 2, and when

T

m

= 100, there were no overshoots. However, the

output sometimes became spike-like when T

m

= 0.1.

In this simulation, there is a mismatch. The reason

of the mismatch is that the controlled object is high-

order although the predictive PI controller is designed

for a first-order system. From Figure 4, the influence

of the mismatch tends to be larger as T

m

becomes

smaller. Therefore, it is recommended that a refer-

ence model with the slow response should be applied

firstly, and T

m

should become smaller gradually in an

actual usage.

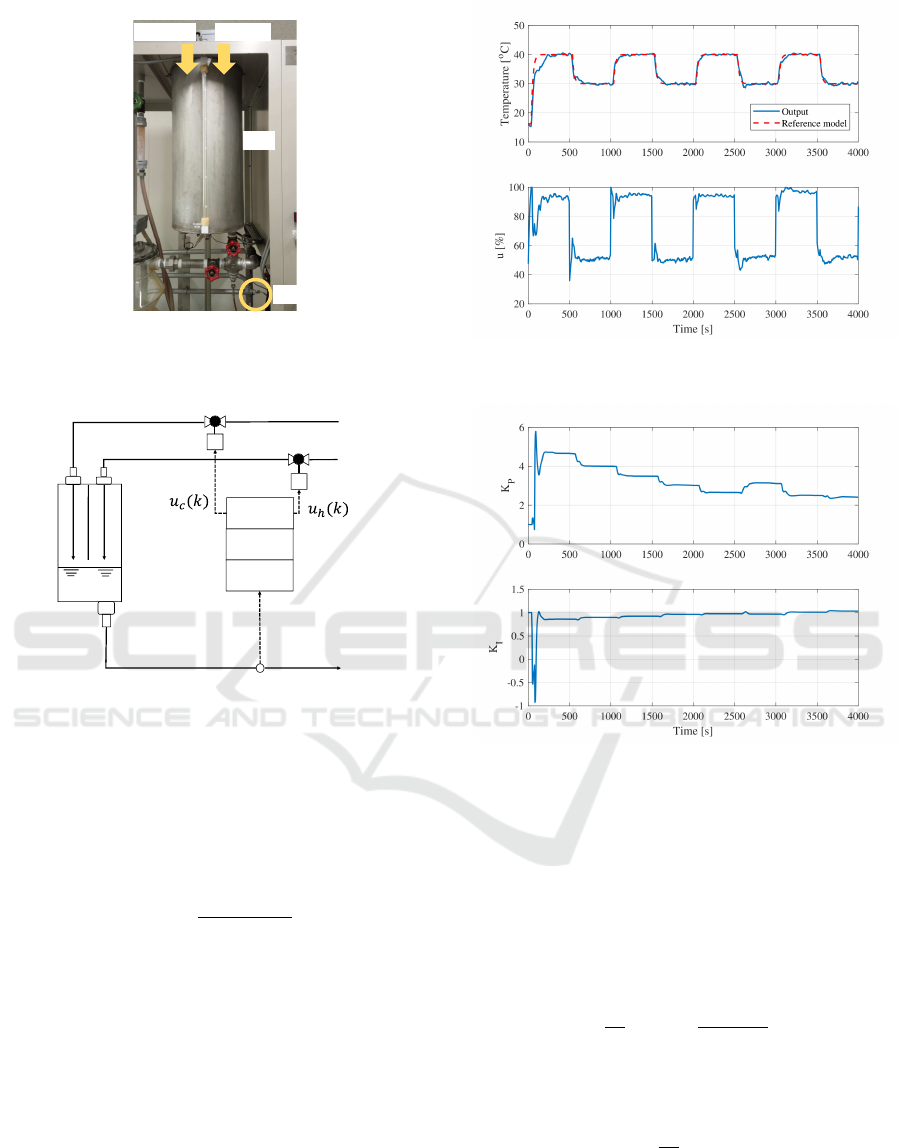

5 EXPERIMENTAL RESULT

In this section, a pilot-scale tank system is used to

evaluate the proposed method under the condition

more realistic than the simulation example. Fig. 5

shows an appearance of the system, and the corre-

sponding schematic figure is illustrated in Fig. 6. The

controlled object is to regulate the temperature of the

mixed water. There are two valves which regulate the

flow of the cold and hot water respectively. In this re-

sult, the opening ratio of the cold water’s valve u

c

(t)

was constant as 40%. A predictive PI controller deter-

mined the opening ratio of the hot water’s valve u

h

(t)

to regulate the temperature. In this section, a sam-

pling time T

s

is 5 s. The experimental system has a

transfer delay as a dead-time. The delay is about 30

seconds. In addition, a time-constant is about 30 sec-

onds. Therefore, ratio of dead-time and time-constant

is about 1. A control result by using the proposed

method is shown in Fig. 7, and the trajectories of the

ICINCO 2019 - 16th International Conference on Informatics in Control, Automation and Robotics

676

Cold water Hot water

Tank

Thermometer

Figure 5: Appearance of the experimental temperature con-

trol system.

M

D/A

Computer

A/D

M

Cold Water

Hot water

Resistance thermometer

Tank

Figure 6: Schematic figure of the experimental temperature

control system.

PI gains are also shown in Fig. 8. In this result, pa-

rameters of the proposed method were set as follows:

α = 100, ω = 0.995. A reference model was deter-

mined as the following system:

G

m

(z

−1

) =

0.22z

−1

1 − 0.78z

−1

z

−7

, (42)

where time-constant was set as 20 s and dead-time

was set as d = 7. It is difficult to realize a trajectory of

the reference model without dead-time compensation

because the dead-time is longer than the time-constant

in the reference model. The initial value of

ˆ

θ(t) was

determined as follows:

ˆ

θ(0) = [2, 1]

T

. (43)

This led the following initial PID gains:

K

P

(0) = 1, K

I

(0) = 1. (44)

From the control results, likely desired response was

obtained as time went on. However, control perfor-

mance sometimes deteriorated in the transient state.

Figure 7: Experimental result by using the proposed

method.

Figure 8: Trajectories of the PI gains corresponding to Fig.

7.

A mismatch between the controller and the controlled

object is considered to cause deterioration. Although

the experimental system is a high-order system, the

controller is designed for a first-order controlled ob-

ject.

At last, the role of the predictive term is consid-

ered. the predictive PI control low is as follows:

u(t) =

K

P

+

K

I

∆

e(t) +

z

−1

K

pred

∆

(z

−d

− 1)u(t).

(45)

PID control low is also shown in follows:

u

PID

(t) =

K

P

+

K

I

∆

e(t) + K

D

∆e(t), (46)

where the third term is a derivative term and K

D

de-

notes a derivative gain. It is well-known that the

derivative term works like a brake. When PI gains

are large, sometimes large input is calculated by PI

Design of a Self-tuning Predictive PI Controller for Delay Systems based on the Augmented Output

677

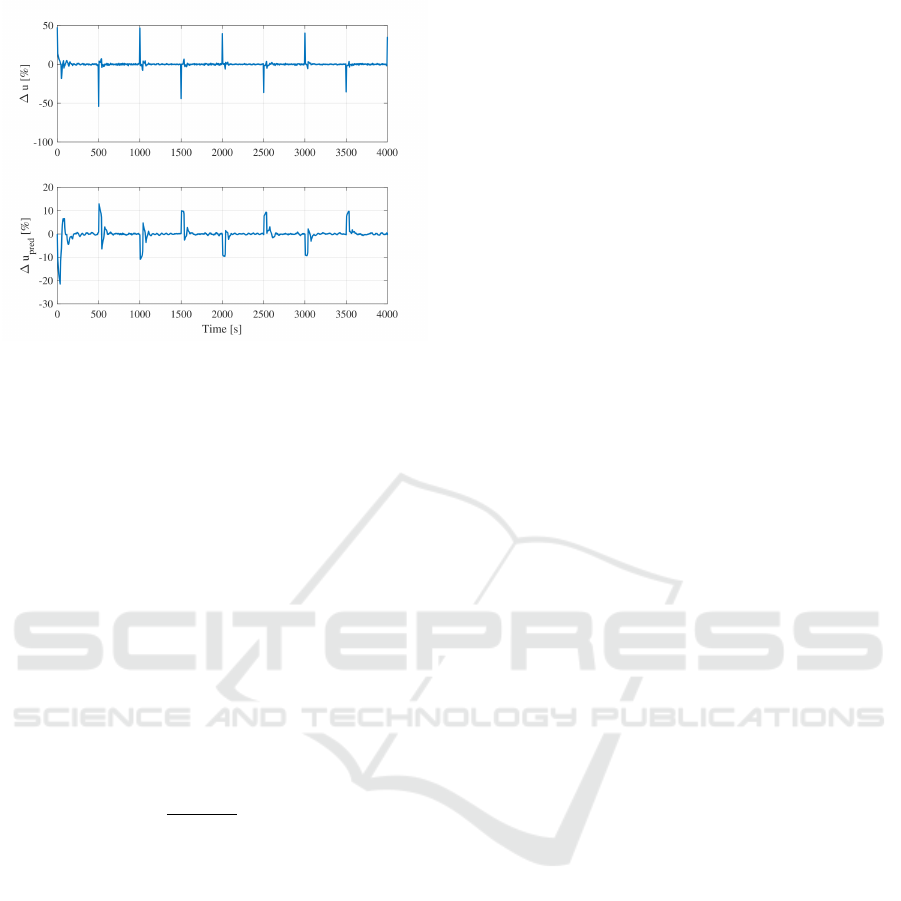

Figure 9: Comparison between ∆u(t) and ∆u

pred

(t).

terms and an overshoot is occurred. In contrast, the

derivative term predicts a future error and calculate

an input which reduces the overshoot based on the es-

timated error. The derivative term predicts a future

error under the assumption that the error is a propor-

tional function. However, the assumption is unrealis-

tic, and a large derivative gain sometimes causes prob-

lems. In contrast, the predictive term of the predictive

PI controller is based on a Smith predictor when a

controlled object is first order. Therefore, the predic-

tive PI controller employs more advanced prediction

than the PID controller although the predictive and

derivative terms have the same role.

Next, the consideration above is checked using the

experimental result. The input signal calculated by

the predictive term is defined as:

u

pred

(t) =

z

−1

K

pred

∆

(z

−d

− 1)u(t). (47)

Fig. 9 shows a comparison between ∆u(t) and

∆u

pred

(t). According to Fig. 9, the prediction term

worked like a brake. For example, ∆u(t) was about

−50 at 1505 second to lower the temperature. In con-

trast, ∆u

pred

(t) was about 10 between 1505 and 1535

seconds. The 30 seconds between 1505 and 1535

mean the estimated dead-time, and the predictive term

tried to suppress a large input signal in the period.

Thus, the control result shows that the predictive term

has the same role as the derivative term.

6 CONCLUSIONS

In this paper, a discrete-time predictive PI controller

has been discussed, and a data-driven self-tuning de-

sign method has also been proposed. Features of the

proposed controller are summarized as follows:

• The proposed controller can realize fast rise time

for a system with long dead-time.

• Any system model is not required to calculate PI

gains.

• Only PI gains are tuned in an on-line manner.

The proposed control scheme has been evaluated by

some numerical and experimental examples. In par-

ticular, the role of the predictive term included in the

proposed controller has been mentioned using the ex-

perimental example.

REFERENCES

Airikka, P. (2014). Robust predictive pi controller tuning.

IFAC Proceedings Volumes, 47(3):9301 – 9306. 19th

IFAC World Congress.

Ashida, Y., Hayashi, K., Wakitani, S., and Yamamoto, T.

(2016). A novel approach in designing pid controllers

using closed-loop data. In 2016 American Control

Conference (ACC), pages 5308–5313.

Ashida, Y., Wakitani, S., and Yamamoto, T. (2017). Design

of an implicit self-tuning pid controller based on the

generalized output. In Proc. of the 20th IFAC World

Congress, pages 14511 – 14516.

Ashida, Y., Wakitani, S., and Yamamoto, T. (2019). De-

sign of a data-driven pi controller. In Proc. of the

2020 International Conference on Artificial Life and

Robotics.

Astrom, K. and Hagglund, T. (2005). Advanced PID Con-

trol. International Society of Automation, North Car-

olina.

Berner, J., Soltesz, K., Hagglund, T., and Astrom, K.

(2018). An experimental comparison of pid auto-

tuners. Control Engineering Practice, 73:124–1133.

Bialkowski, W. (1993). Dreams versus reality: a view from

both sides of the gap: manufacturing excellence with

come only through engineering excellence. Pulp &

Paper Canada, 94:19–27.

Campestrini, L., Eckhard, D., Chia, L. A., and Boeira, E.

(2016). Unbiased mimo vrft with application to pro-

cess control. Journal of Process Control, 39:35 – 49.

Campi, M., Lecchini, A., and Savaresi, S. (2002). Virtual

reference feedback tuning: a direct method for the de-

sign of feedback controllers. Automatica, 38(8):1337

– 1346.

Gallego, A. J., Merello, G. M., Berenguel, M., and Cama-

choa, E. F. (2019). Gain-scheduling model predictive

control of a fresnel collector field. Control Engineer-

ing Practice, 82:1–13.

Goodwin, G. C. and Sin, K. S. (1984). Adaptive Filtering

Prediction and Control. Prentice-Hall, Upper Saddle

River.

Hagglund, T. (1992). A predictive pi controller for pro-

cesses with long dead times. IEEE Control Systems

Magazine, 12(1):57–60.

ICINCO 2019 - 16th International Conference on Informatics in Control, Automation and Robotics

678

Hassan, S. M., Ibrahim, R., Saad, N., Asirvadam, V. S., and

Chung, T. D. (2016). Predictive pi controller for wire-

less control system with variable network delay and

disturbance. In 2016 2nd IEEE International Sym-

posium on Robotics and Manufacturing Automation

(ROMA), pages 1–6.

Hjalmarsson, H., Gevers, M., Gunnarsson, S., and Lequin,

O. (1998). Iterative feedback tuning: theory and appli-

cations. IEEE Control Systems Magazine, 18(4):26–

41.

Ingimundarson, A. and Hagglund, T. (2001). Robust tuning

procedures of dead-time compensating controllers.

Control Engineering Practice, 9:1195–1208.

Kaneko, O. (2015). Fictitious reference iterative tuning of

internal model controllers for a class of nonlinear sys-

tems. In 2015 IEEE Conference on Control Applica-

tions (CCA), pages 88–94.

Rawlings, J. B. and Mayne, D. Q. (2009). Model Predic-

tive Control Theory and Design. Nob Hill Publishing,

Madison.

Sanz, R., Garcia, P., and Albertos, P. (2018). A generalized

smith predictor for unstable time-delay siso systems.

ISA Transactions, 72:197–204.

Soma, S., Kaneko, O., and Fujii, T. (2004). A new approach

to parameter tuning of controllers by using one-shot

experimental data (in japanese). Transactions of the

Institute of Systems, Control and Information Engi-

neers, 17(12):528–536.

Sun, L., Li, D., and Lee, K. Y. (2016). Optimal disturbance

rejection for pi controller with constraints on relative

delay margin. ISA Transactions, 63:103–111.

Wang, Y. and Ma, G. (2015). Fault-tolerant control of lin-

ear multivariable controllers using iterative feedback

tuning. International Journal of Adaptive Control and

Signal Processing, 29(4):457–472.

Design of a Self-tuning Predictive PI Controller for Delay Systems based on the Augmented Output

679