Towards Skills-based Easy Programming of Dual-arm Robot

Applications

Fan Dai

ABB Corporate Research, Ladenburg, Germany

Keywords: Dual-arm Manipulation, Robot Programming, Robot Skills.

Abstract: Programming dual-arm robotic applications requires good understanding of the tasks and the coordination

between both arms must be well specified. This article analyses the synchronization modes required in dual-

arm robot applications and describes a mechanism of programming these applications based on synchronizing

the execution phases of robot skill functions for the two arms. Combined with a graphical user interface, it

contributes to the ease of use of dual-arm robot systems.

1 INTRODUCTION

Dual-arm, or two-handed manipulation has been an

interesting topic in robotics since the very beginning

of robotics research related to tele-operation, and it is

again of high interest with new developments in

service and industrial robotics (Smith et al., 2012).

Many efforts and advances are known in control of

coordinated motion, but the programming of dual-

arm manipulation is still one of the main bottlenecks

of application development, because programming

dual-arm robot applications requires very good

understanding and specification of the coordination

between the two arms.

Zöllner et al., (2004) worked on programming by

demonstration for dual-arm manipulation tasks,

where task executions are modelled with Petri nets.

Having the arm states active or ready as conditions,

dual-arm task planning and execution can be learned

by mapping observed bimanual human

demonstrations. While this method is theoretically

quite promising, many problems still must be solved,

especially the interpretation of human intentions in

complex situations.

The concept of robot skills (e.g. Kröger et al.,

2010, Thomas et al., 2013, Dai et al., 2016) has been

introduced to allow task-level programming, which is

more intuitive for application engineers. Theoretical

concepts cover the coordination of parallel tasks as

well, but most approaches are still focused on single

arm application tasks, or tasks where two robot

manipulators must avoid collisions with each other.

An appropriate mechanism for two-arm robot

application tasks is needed.

Szynkiewicz (2012) worked on skill-based

bimanual manipulation planning, uses Rubik’s Cube

as an example to implement a two-handed

manipulation skill involving vision and force control.

However, the mechanism of specification and

realization of coordinated dual-arm tasks is not

clearly described.

Stenmark et al., (2017) worked on improving

intuitive dual-arm programming of collaborative

industrial robots, utilizing the concept of re-usable

robot skill functions, where the focus was on

synchronizing primitive dual-arm motion constructs.

They also combined it with an iconic graphical user

interface, allowing adding and modifying

synchronizations, but limited to primitive motion

synchronization.

Our approach goes further to a mechanism of

creating dual-arm robot skills by analysing and

specifying the synchronization of single arm robot

skills. It allows an easier way of programming

bimanual application tasks.

In this paper, we analyse two-handed

manipulation taking assembly applications as an

example (section 2). Based on this, we derive in

section 3 our concept of synchronizing two-arm tasks

by introducing phase-based synchronization. We

propose to implement robot skill functions with

clearly defined phases and synchronization points,

which can be parameterized, optionally via a

graphical user interface.

Dai, F.

Towards Skills-based Easy Programming of Dual-arm Robot Applications.

DOI: 10.5220/0007920203630370

In Proceedings of the 16th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2019), pages 363-370

ISBN: 978-989-758-380-3

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

363

2 TWO-HANDED ASSEMBLY

TASKS

In this section, we take an application-oriented view

on dual-arm manipulation, focusing on assembly

tasks. Applications in which two-handed operations

come into play can be grouped as follows:

Coordinated parallel tasks

In-hand manipulation using one hand as part

holder (fixture) for the other one

In-hand manipulation with simultaneous actions

of both hands

In the following, we analyse these three groups of

applications with some examples.

2.1 Coordinated Parallel Tasks

These types of applications may be further split into

two sub-groups. For most cases in the first sub-group

the overall task could be done by a single hand. Doing

it with two hands simply increases the efficiency or

shortens the cycle time.

For example, when piling up objects onto each

other, a single robot arm could take the parts one by

one and accomplish the task alone. But doing it with

two robot arms is much quicker. The same holds

when multiple different parts are to be mounted.

Similarly, in many applications, one arm is used to

take the raw part and place it at the location for

processing. The other arm then retrieves the finished

part.

Figure 1: Piling-up cubes with coordinated parallel tasks.

The second sub-group includes applications in

which two hands are needed to accomplish the task,

but they do not come into direct mechanical or spatial

interaction with each other, for example: One hand

opens the cover; the other one puts the part into the

container.

In these two-handed applications, compared to

single hand operation, the actions of both hands must

be synchronized with each other, but not the motion

details. Important are: 1) Temporal dependencies of

starting and ending the actions; 2) Spatial collision

avoidance.

The goal is to achieve the shortest cycle time. If

the constraints on cycle time allow, one can also try

to optimize energy consumption, minimize

mechanical stress etc.

2.2 One Hand as Part Holder for the

Other One

At manual workplaces, we can very often observe

two-handed operations in which one hand acts as a

part holder for the other hand. Here we can have the

following situations:

2.2.1 The One Hand Holds a Part, and the

Other Hand Mounts a Second Part

onto It

As shown in Figure 2, one of the robot hands holds

the base part, while the other hand mounts the other

part onto it. This is the most common case. In this

case, the first hand must maintain a fixed position for

the duration of the part assembly by the other hand.

a) Snap insert

b) Screwing

Figure 2: Examples of two-handed assembly with one hand

as part holder.

2.2.2 The One Hand Holds a Part, and the

Other Hand Mounts This Part onto

Other Part

The pictures below show a connector on a flexible flat

cable. One hand must place the part on top of the

socket, so that the other hand can then push on the

connector to mount it firmly.

a) Connector and

socket

b) Approaching

the target

c) At the target

position

Figure 3: One hand supports the other to fix the socket plug.

In this kind of applications, the first hand must be

compliant, following slightly the movement of the

part when the part is moved by the other hand while

mounting it.

ICINCO 2019 - 16th International Conference on Informatics in Control, Automation and Robotics

364

2.2.3 The One Hand Hands over a Part to

the Other Hand

When a part cannot be reached by the one hand that

should operate with the part, or it can be reached, but

cannot be picked at the right position, a commonly

used option is to take the part by another hand first,

and hand it over to the operating hand.

Figure 4: Handing over the cube.

In this case, there is a hand-over phase for a short

while, requiring synchronization as the second hand

takes the part.

2.2.4 Simultaneous Actions of Both Hands

The screw-mounting example can also be done by

simultaneously turning the two parts counter-wise.

This shortens the time for this task. In addition, if the

rotation of the last robot joint is used to screw the part,

like in this example, simultaneously turning both

parts avoids re-grasping, which may become

necessary due to joint limits in case of turning one

part only.

a) Screwing with both hands

b) Lifting with both hands

Snap insert Screwing

Figure 5: Examples of simultaneous actions.

Another example is using two hands to take a

relatively large part and perform placing or mounting.

Compared to a single-handed grasp, this can avoid

undesirable torques on the gripper tool.

In such applications, the motions of both hands

must be synchronized, or one of the hands must

follow the other hand for defined phases of motion.

3 SYNCHRONIZATION OF BOTH

HANDS

A two-handed robot task is composed of at least two

sub-tasks, each performed by one of the robot hands.

If the robot hands are programmed so that each of the

hands executes their own skills, these skill functions

must be coordinated with each other. The most

important criteria are: 1) Ensure that the main phase

of the desired task succeeds; 2) Achieve the shortest

cycle time. Since the duration of individual tasks

differ, it is usually not possible to schedule bimanual

manipulation without waiting times. When the

success of a two-handed manipulation task requires

one hand to wait on the other, optimal scheduling can

avoid excessive waiting times.

In the following, we consider the general modes

of synchronization between parallel processes and the

execution of skill functions as well as the

corresponding (sub-) tasks of an application, and then

discuss how the different types of two-handed

operations can be synchronized.

3.1 Synchronization Modes

Theoretically, five modes of task synchronization can

apply (Table 1). However, not all of them are

essential for two-handed assembly. The most

common mode is of type a) End-start

synchronization. Special applications require

synchronous motion (type e). Other modes can be

beneficial in some cases but are not necessarily

required.

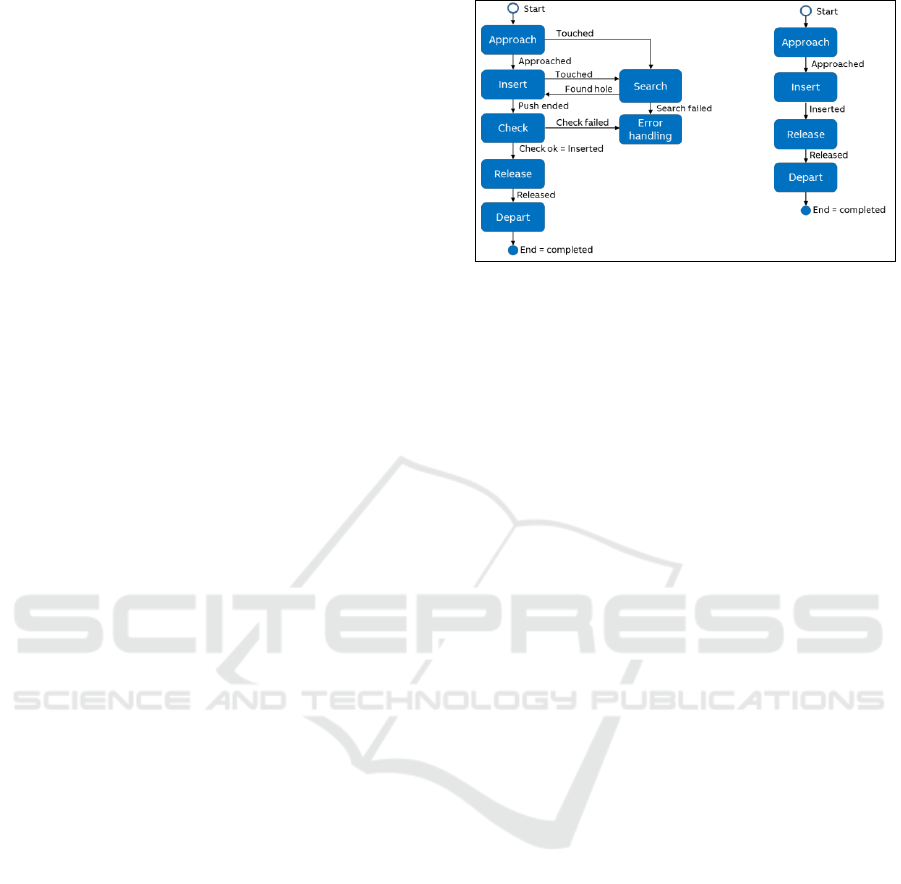

Table 1: Task synchronization modes.

a) End-start: Start of task A

(e.g. left arm) waits until

end of task B (e.g. right

arm)

b) Start-start & end-end:

Starting and ending at the

same time.

c) Start-start: synchronous

start, free ends

d) End-end: free starts,

synchronous ending

e) Synchronous motion: The

complete motions of both

hands are synchronized

To know which mode is required in which

situation, we analyse in more detail below the phases

of assembly skills as they are executed by one hand,

and how they can be used in the two-handed

Towards Skills-based Easy Programming of Dual-arm Robot Applications

365

application examples.

3.2 Phases, States, and Events

If we look at manipulation tasks with one robot arm,

typically, they consist of the following major

execution phases:

Approach – go to the starting position for the

main phase

Main phase – execute the intended action, such

as grasping, pushing, insertion, snapping,

screwing, etc.

(Optional) Release – release the work piece e.g.

by opening the gripper, if is holds the part

Depart – move away from the current work area

The details of the main phase depend on the type of

actions. Taking snap insertion as example, we can

have the following sub-phases:

Push towards the goal position with compliance

until measures of completion are met

Check for success, if necessary, by trying to pull

the part back, or move around, or by any other

means of sensing

Error handling, e.g. retry, dispatch, or report

error.

While moving towards the goal position (approach or

push), it can happen that the part misses the correct

starting position for insertion and touches the base

object. In this case, an additional phase is necessary:

Search for the correct starting position.

The above described phases and their conclusions are

actually the significant states of the snap insert

execution. Each phase change (state transition) can be

exposed to another task for synchronization. While

the phases are natural states, the phase end states

would automatically be the start states for the next

phase, if no waiting for external events is introduced.

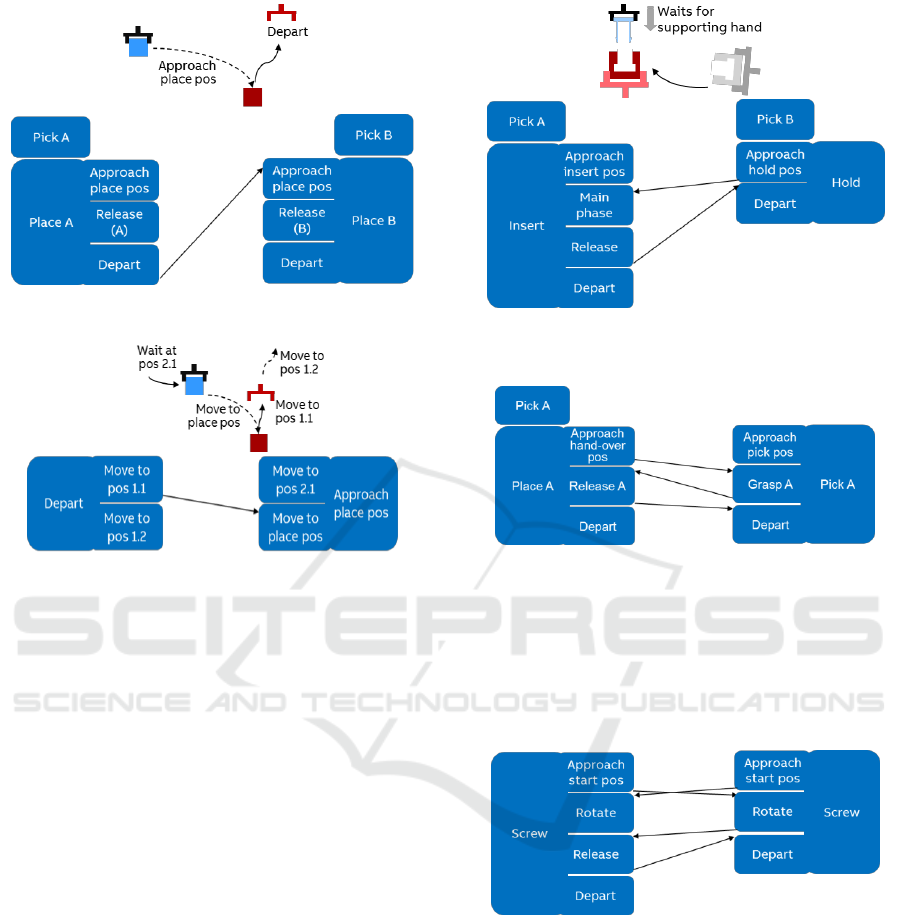

Figure 6 shows a flow chart with these phases and

phase changes. The Search phase can be entered from

the Approach phase, when the part contacts the base

object while moving towards an incorrectly defined

start position, or from the Insert phase, when the

Insert phase starts from an incorrect position. In both

cases, the part would touch the surface of the base

object in an unintended way.

From a task-oriented point of view, Search, Check

and Error-handling are internal phases that do not

reflect the intended states of task accomplishment. A

synchronization of such phases with external actions

is not required in general, except for certain error

states, if strategies for error handling involving both

hands are introduced. But error handling is a very

a) State model with internal phases b) Simplified model

Figure 6: Phase of snap insertion.

complex and special topic, which we do not further

discuss in this article.

For simplicity, we use in the following the

simplified state model shown in Figure 6 b), in which

insertion can be replaced by other skills such as

screw-driving, etc.

3.3 Two-handed Operations with

Synchronization

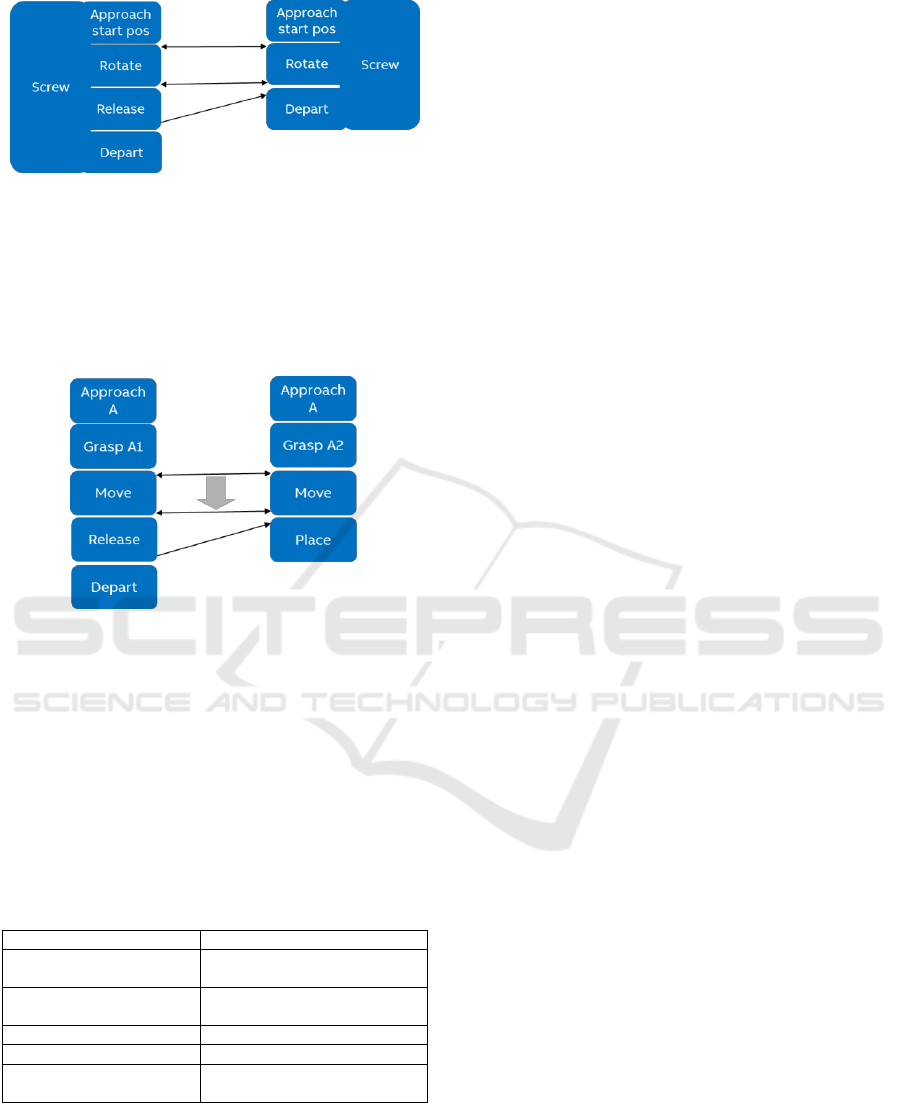

When looking into the application examples, we can

group them into: 1) Sharing work space; 2) One hand

as part holder; 3) Hand-over; 4) Two-handed

symmetric assembly; 5) Two-handed synchronous

motion. In the following, we discuss how these

groups of applications can be implemented with

corresponding phase synchronizations.

3.3.1 Sharing Work Space

In case both hands must accomplish actions within

the same work space, they cannot execute these

simultaneously. Sometimes, the order of the actions

is defined by the application itself; sometimes

serialization is needed for collision avoidance.

For example, the piling-up example could be done

by two-hands with one waiting for the other to finish

its placing action (Figure 7).

But this may cause unnecessary waiting time. In

this example, the most feasible way is in fact, that one

hand waits at an intermediate approaching position

until the other hand has left the departing position.

Thus, introducing intermediate synchronization

points can reduce the overall cycle time. Here, depart

(of one hand) and approach phase (of the other hand)

each can be split into two sub phases for better

synchronization (Figure 8), but the synchronization

mode is still “end-start” sequencing of these two

phases.

ICINCO 2019 - 16th International Conference on Informatics in Control, Automation and Robotics

366

Figure 7: Piling up with two hands.

Figure 8: Use sub phases to reduce cycle time.

This intermediate approach position is normally

different from the approach position of single hand

operations, because it must ensure that no collision

with the other hand can occur.

3.3.2 One Hand as Part Holder

When one hand acts as part holder like in the two-

handed snap-insertion example, it requires that the

supporting hand is in position before the inserting

hand starts the main phase of insertion, but the latter

can already move to the approaching position. This

can be simply implemented using “end-start”

synchronization as depicted in Figure 9.

Certainly, it could also run with synchronized

ends of the approaching phases. However, this does

not lead to any benefits.

3.3.3 Hand-over

For hand-over operations, the one hand releases the

part after the other hand has picked it. It is again a

simple “end-start” relationship between the

corresponding phases as depicted in Figure 10.

Figure 9: Using “end-start” for synchronization of two-

handed insertion.

Figure 10: Synchronizations for hand-over.

3.3.4 Two-handed Symmetric Assembly

As shown in Figure 11, two-handed symmetric

assembly (taking the example of screwing) always

can be implemented using “end-start”

synchronization as well.

Figure 11: Using “end-start” synchronization in two-

handed symmetric screwing.

This is equivalent to “start-start” synchronization

of the rotate phases, if no additional waiting time

before the starts of these phases is introduced by other

events that are in principle possible, but not relevant

here. Of course, symmetric assembly could also be

implemented with synchronized start and end (“start-

start & end-end”) of corresponding phases of both

hands (e.g. Figure 12.), though this is not really

required. In the practice, “end-start” synchronization

is easier to implement.

Towards Skills-based Easy Programming of Dual-arm Robot Applications

367

Figure 12: Using “start-start & end-end” for two-handed

symmetric screwing.

3.3.5 Two-handed Moving

Different from the above use cases, synchronous

motion is required in such special cases as lifting or

moving a large or heavy part with two hands.

Figure 13: Synchronous motion (may also require

simultaneous release).

3.4 Usage Summary of

Synchronization Modes

Based on the above observations, we can conclude

that “end-start” is the most commonly used mode,

where “synchronous motion” is required for special

cases. Other modes are not necessary for

implementing two-handed assembly applications.

Table 2: Usage of synchronization modes.

Synchronization mode

Usage

End-Start

Most applications can be

implemented this way

Start-start

Can be achieved with “End-

start” mode (see e.g. Figure 12)

Start-start & end-end

Not required

End-end

Not required

Synchronous motion:

Required in special cases e.g.

two-handed lifting

4 ROBOT SKILLS AND VISUAL

PROGRAMMING

From a programming point of view, robot skill

functions are nothing else than higher-level

parameterizable functions. These can be used by

application programmers in any programming

environment with any programming tools including

simple text editors. We also proposed to use visual

programming for guiding and assisting the

application programmer to use skill functions in an

intuitive way (Dai et al., 2016).

In a concept demo implementation, the skill

description is stored in XML format including:

function name, parameters, locations of other related

data, e.g. source code of the skill function, support

functions used by the skill function or for applying it,

UI elements that can be optionally used, description

and help text, including multimedia presentations.

For the UI and multimedia presentations, XAML was

chosen, which can be dynamically loaded to the App

to provide individually customized user interface

pages.

According to our phase-based synchronization

concept, parameters of the skill functions also include

skill phases and the skill execution state.

Taking a snap insertion skill programmed in the

robot programming language RAPID as an example,

the robot skill functions have the following constructs

allowing the synchronization concept described in the

sections above:

PROC SnapIn(pose StartPose,

\pers state myState,

\pers state waitToStart,

\state waitToStartValue,

\pers state waitToInsert,

\state waitToInsertValue,

\pers state waitToRelease,

\state waitToReleaseValue,

\pers state waitToDepart,

\state waitToDepartValue)

myState := stateWaiting;

IF (Present(waitToStart) AND

Present(waitToStartValue))

THEN

WaitUntil

(waitToStart>=waitToStartValue)

\pollrate:=0.004;

ENDIF

myState := stateApproaching;

!start approaching

…

!end approaching

ICINCO 2019 - 16th International Conference on Informatics in Control, Automation and Robotics

368

myState := stateApproached;

IF (Present(waitToInsert) AND

Present(waitToInsertValue))

THEN

WaitUntil

(waitToInsert>=waitToInsertValue)

\pollrate:=0.004;

ENDIF

myState := stateInserting;

! start inserting

…

!do something

myState := stateEnd;

ENDPROC

The user can compose the action sequences for each

robot hand (i.e. the corresponding robot control task)

by selecting and concatenating these skill functions

and program elements.

To compose two-handed applications, one usually

also must specify the synchronization points for the

two hands. This can be done based on the concept as

discussed in the previous chapter. The UI page is

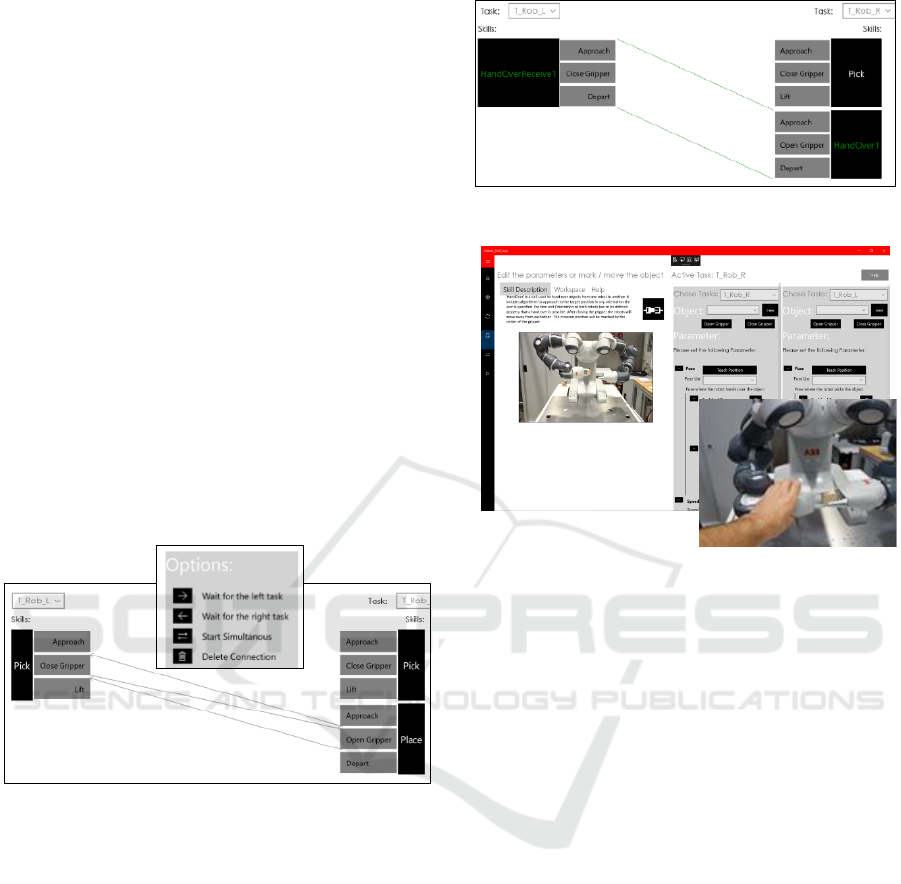

shown below in Figure 14.

Figure 14: Skill phase synchronization page (arrow

indicates the order).

For a pre-defined two-handed skill, there is no

need for manual editing of the synchronization points.

Therefore, we have chosen a different type of

visualization (two lines without arrows) as shown

below in Figure 15. It indicates that both skills are

considered as a unit, so that user doesn’t need to see

the internal synchronization.

Typical for two-handed skills, some motion

positions can be taught for both hands together, e.g.

via lead-through as shown in Figure 16.

Finally, the app will create the main modules for

the robot control tasks, which call the corresponding

skill functions with these parameters (including

synchronization points). The finished application is

then ready to be started.

Figure 15: Hand-over as two-handed skill function.

Figure 16: Teaching motion positions for both hands.

5 CONCLUSIONS AND FUTURE

WORK

The robot skills concept can be applied to support

more intuitive and easy programming of two-handed

robot applications by synchronization of skill

execution phases. Our analysis has shown that the two

basic synchronization modes: end-start

synchronization and synchronous motion are

sufficient for all these applications. With pre-

implemented synchronization points and optional

parameters, the skill functions can be flexibly used by

application programmers for different situations.

Visual programming can also contribute to ease of

use. The skill execution phases can be shown beside

the skill function. Known graphical interaction

methods can be applied to define the synchronization

between skill functions of the two robot hands, e.g.

by connecting anchor points of the graphical

elements.

Still, programming two-handed applications

requires good knowledge of the skill functions, the

synchronization modes, and logical reasoning. To

further increase ease of use of robot systems like

YuMi, two-handed skills or skill templates may be

provided. Such skills may consist of pairs of skill

functions for both hands with well-defined

Towards Skills-based Easy Programming of Dual-arm Robot Applications

369

synchronizations, considering the following two-

handed operations:

Sharing work space

One hand as part holder

Hand-over

Two-handed symmetric assembly

Two-handed moving of parts

In this context, we did experimental implementations

of “hand-over” and “sync move” (two-handed

moving of parts) with corresponding user interface

elements.

Certainly, the mechanism of synchronization

enables two-handed applications, but the efficiency of

such applications depends also on other factors that

influence the behaviour of the robot hands, e.g. the

“intelligence” of the underlying skill functions, the

execution parameters of the primary functions used

by the skills. These are also coupled with the skill

phase design and synchronization type. Therefore, we

will further work on studying the correlations

between both, and how machine learning methods

can help to increase efficiency of two-handed skills

and two-handed applications.

ACKNOWLEDGEMENTS

Research partially supported by European Union as

part of the Productive 4.0 project

(https://productive40.eu).

REFERENCES

Smith, Ch., Karayiannidis, Y., Nalpantidis, L., et al. (2012)

“Dual arm manipulation—A survey”. Robotics and

Autonomous Systems 60(10), October 2012. pp. 1340–

1353.

Zöllner, R., Asfour,T., Dillmann, R. (2004) “Programming

by demonstration: dual-arm manipulation tasks for

humanoid robots”. IEEE/RSJ International Conference

on Intelligent Robots and Systems (IROS), Sept. 2004.

Kröger, T., Finkemeyer, B., and Wahl, F. M. (2010)

“Manipulation primitives—A universal interface

between sensor-based motion control and robot

programming,” in Robot Systems for Handling and

Assembly, 1st ed., ser. Springer Tracts in Advanced

Robotics, D. Schütz and F. M. Wahl, Eds. Berlin,

Heidelberg, Germany: Springer, 2010, vol. 67.

Thomas, U., Hirzinger, G-, Rumpe, B., Schulze, Ch. and

Wortmann, A. (2013) A New Skill Based Robot

Programming Language Using UML/P Statecharts,

2013 IEEE International Conference on Robotics and

Automation (ICRA), Karlsruhe, Germany, May 6-10,

2013

Dai, F., Wahrburg, A., Matthias, B., Ding, H. (2016)

“Robot Assembly Skills Based on Compliant Motion”,

47th International Symposium on Robotics (ISR 2016),

June 2016

Szynkiewicz, W. (2012) “Skill-Based Bimanual

Manipulation Planning”, Journal of

Telecommunications and Information Technology,

2012(4): December 2012, pp. 54-62

Stenmark, M., Topp, B.A., Haage, M., Malec, J. (2017)

“Knowledge for Synchronized Dual-Arm Robot

Programming”, AAAI Fall Symposium Series 2017.

ICINCO 2019 - 16th International Conference on Informatics in Control, Automation and Robotics

370