Modelling of CNC Machine Tools for Augmented Reality Assistance

Applications using Microsoft Hololens

Meysam Minoufekr

1a

, Pascal Schug

2

, Pascal Zenker

2

and Peter Plapper

1b

1

University of Luxembourg, Rue Richard Coudenhove-Kalergi 6, Luxembourg, Luxembourg

2

Dropslab Technologies, Papiermühlenweg 12, Aachen, Germany

Keywords: Industry 4.0, Augmented Reality, Industrial Augmented Reality, Internet of Things, Cyber-physical Systems,

Industrial Operator Support, Smart Factory, Task Execution, Edge Computing.

Abstract: With the ongoing development of both, augmented and virtual reality new important paths open for the use

of computer aided manufacturing. Microsoft’s new mixed reality device, the HoloLens bridges the gap

between reality and digital content by injecting holograms into the user’s field of view. This new way of

showcasing digital data enable whole new fields to for development. In this paper, the verification of CNC

machining with the Microsoft Hololens will be illustrated and examined. This paper will introduce a

framework which enables users to perform machine simulation using Augmented Reality. Machine models

can be picked on a remote computer and be loaded into the Hololens as holograms. Through the framework

they can be simulated, and the machining processes observed before the actual process starts.

1 INTRODUCTION

The flexibility in production processes demanded by

customers implicates major challenges, especially for

small and medium-sized enterprises (SMEs). As a

result, companies must meet increasing demands for

both, complexity and quality and have to deliver in

increasingly shorter cycle times. Hence, innovative

approaches are needed, particularly for machining

and manufacturing.

Unarguably Augmented Reality (AR) is

promising great potential in industrial applications,

especially manufacturing and assembly lines. AR also

has great potential for the computer numeric control

(CNC) machining sector: production workers could

gain more process relevant content without the need

to access a computer. This allows humans to have a

better understanding of the designed process, which

makes rapid prototyping for visual feedback

unnecessary.

This paper introdces a communication framework

to simulate CNC machine productions through

augmented reality using the Microsoft Hololens. The

second section outlines the motivation and objective

of the paper. In section 3 the state of the art of process

a

https://orcid.org/0000-0002-5877-0820

b

https://plapper.com

simulations and AR is examined. Section 4 analyzes,

how CNC machines can be mathematically describes.

Section 5

illustrates a trial process in our laboratory.

Finally, section 6 summarizes the paper and gives an

outlook onto future work.

2 PROBLEM DEFINITION

The modern production heavily relies on CNC

machines (Altintas, 2012). These need to be

controlled with different data sets and mostly

simulations are run beforehand to ensure machining

processes will lead to the expected results. While

CNC machines are a huge assistance for modern

production chains, for the production worker, they are

mostly black boxes.

The workpiece that should be created is designed

as 3D model in a CAD software. Afterwards the

designed 3D model is used in a Computer Aided

Manufacturing (CAM) software. The CAM software

translates the model data into different working steps

and toolpaths. It compiles all these steps into so called

G code, which is the major implementation to control

Minoufekr, M., Schug, P., Zenker, P. and Plapper, P.

Modelling of CNC Machine Tools for Augmented Reality Assistance Applications using Microsoft Hololens.

DOI: 10.5220/0007920806270636

In Proceedings of the 16th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2019), pages 627-636

ISBN: 978-989-758-380-3

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

627

CNC machines. The G code contains all necessary

commands for the production and tells the NC

machine "what" must be done to manufacture the

product, see Figure 1.

Figure 1: Sequential CAx process chain for machining.

To enable automated production of components

on an NC machine, process conditions are analyzed

using Finite Element Methods (FEM), then the G

code is first checked and optimized by the machine

operator line by line on the machine. This phase of

the production is called the process “start-up” which

includes the so called “verification phase”, in which

the toolpaths are checked manually by the operator.

The current method for verifying the CNC process is

as follows: The operator loads the G-code, all

required tools and the workpiece manually into the

CNC machine and initiates the process. The resulting

machined part is then verified in a Computer Aided

Quality assurance step (CAQ). However, the current

procedure for verifying and optimizing the

production of components using CNC machines has

several drawbacks.

The verification phase currently takes about 60%

of the start-up phase (Arntz, 2013). Even under

optimal conditions, the verification phase has a large

impact on the overall process time and production

costs and is one of the highest cost factors for

production due to its susceptibility to errors. During

the start-up phase, no added value is created, while

the machine and the operator are completely

occupied.

The combination of the latest advances in AR,

sensors and networking, together with paradigms like

IoT, enable the development of advanced applications

for industrial systems (Yan, 2017). Among the

enabling technologies, industrial Augmented Reality

has proven to be a suitable tool for the manufacturing

strategies proposed by different countries (Suárez-

Albela, 2016). In this context, the following

assumption can be formulated:

An assistance tool that enables machine

operators to verify CNC processes handsfree during

the start-up increases productivity and is more

intuitive, while allowing the operator being fully

aware of their surroundings considering the

industrial configuration of the production field.

While measuring the productivity as an added

value of using an AR assistance tool needs several

field studies, there is a main research issue, which can

be derived from assumption:

How can machining processes be mapped in AR

glasses worn by the operator on the factory floor?

Answering this question involves the modelling

of machining process for AR glasses and the

realization of a communication to the AR device,

which allows a sufficiently accurate transmission of

process data, in particular simulated toolpath and the

contact conditions between the cutting tool and the

workpiece for multi-axis machining. The core

element for the communicating between the AR

glasses and the CNC machine is a reliable

mathematical representation of machine tools, which

can be used as a basis for industrial Augmented

Reality applications.

3 STATE OF THE ART

It is difficult to understand what is happening inside

the machine, as well as it is very difficult to combine

simulation data with real machining steps during the

process (Schug, 2015). Due to this lack of knowledge,

it is hard to recognize errors or malfunctions of a CNC

machining process. To compensate the gaps in error

recognition, production workers and operators often

decide between working at the machine or relying on

the computer-optimized data, that tells the operator

what is happening inside the machine. The critical

question “What is more reliable?” cannot be

answered clearly, because both sets of data, the real

machine data as well as the computer-generated data

reveal only one part of the machining process

(Minoufekr, 2014). While these two sets of data were

strictly separated in the past, modern technologies

arise, which can help to bridge these gaps by

approaches like “Digital Twin” (Ding, 2019)

In order to use process simulation on the shop

floor, Augmented Reality (AR) techniques are needed

to dynamically display relevant information to the

operator. Azuma (Azuma, 1997) describes AR as the

integration of 3D virtual objects into our real 3D

environment, see Figure 2. Virtual data is processed

and can be used or interacted with in real-time. With

this definition in mind, we can compare Virtual

ICINCO 2019 - 16th International Conference on Informatics in Control, Automation and Robotics

628

Reality (VR) and AR easily. While VR completely

relies on a virtual representation of the world, AR is

the step between VR and real life, where digital and

real objects are merged in real time.

Figure 2: Mixed Reality continuum defined by (Milgram

1995).

In the Hololens, the digital copy of the real world

is created by using sensory techniques, which can

scan the real world and transfer it into a mesh

representation. Holograms that are projected into the

real world can use the data of the virtual pendant. This

allows the device to mimic interaction from

holograms with real world objects (Microsoft, 2017).

This work will focus on the Hololens and therefore

act in the range of this specific MR or generally AR.

4 SOLUTION METHOD

The main goal of this paper is to discuss, CNC

machining processes can be modelled for AR devices,

see Figure 3. By using appropriate, knowledge-based

techniques, it is possible to enhance the process

quality to a higher accuracy level (Schug, 2012).

Figure 3: Expanding workers vision with AR.

Exploiting this idea, the solution path consists of

the availability of process design knowledge

providing process parameters, simulation data and

technology information during process setup in real-

time corresponding to the current process using the

Augmented Reality technology. Hence, this paper’s

focus is on how CNC simulations can be carried out

by using AR and more specifically, what is a

kinematic chain and how to mimic the kinematic

chain that every CNC machine inhabits to be

represented visually

.

4.1 Modelling of CNC Machine Tools

CNC machines are machine tools which have the

capability of producing high precision workpieces

using modern control techniques. In a CNC machine,

a toolpath for the workpiece is defined. The machine

rapidly checks the relative movement between

workpiece and working tool, which travels along the

toolpath. The machine continuously controls the

relative movement to correct position errors between

actual values and nominal values. There are different

types of CNC machines with different kinematics or

axis configurations, for example with head rotation or

with a rotating table (Altintas, 2012).

The kinematics of CNC machine tools can be

expressed by the coordinate systems of each machine

element of the machine, see Figure 4. The machine

coordinate system [MCS] is the root of the linked

coordinate systems. Every milling tool of the machine

has its own coordinate system and can have children.

The children are always moving relative to their

position in their parents coordinate system, which is

referred as a kinematic chain. If axis X is moved, the

table, which consists of axis A and B, moves as well.

Figure 5 shows the according 5-axis CNC machine.

The different coloured elements, can move along

their axis into the according axis direction, namely X,

Y and Z. The rotating axis are A and B and allow the

machine to rotate according to the table of the

machine.

Figure 4: Coordinate system of a CNC machine.

In general, machine kinematics or a kinematic

chain can be described as a series of rigid bodies that

are connected with joints. Each machine parts

movement is restricted through the parent part’s

movements. Parts can be transformed.

Modelling of CNC Machine Tools for Augmented Reality Assistance Applications using Microsoft Hololens

629

Transformation are in machine kinematics either

translations, a movement, or rotations. When a parent

part is transformed, its children will take an according

transformation, so that the relative position to its

parent part is still the same.

Figure 5: Model of a CNC machine with its axis.

The position of every individual object can be

changed with rigid transformations. Rigid

transformations are transformations, rotations and

shearing, which can be formulated as matrices. Most

of the machines use the Cartesian Coordinate System.

In computer graphics, we use for the same

transformation the more user-friendly extended

coordinates. Extended coordinates have 4 entries and

the resulting matrices are 4x4 matrices. This allows to

define rotations together with translation in one single

matrix. Translating a point pos, where

,

(1)

about the amount of another vector tra, where

,

(2)

can be expressed as

100

010

001

0001

∙

1

1

(3)

The following matrix expresses the rotation of an

object around the z-axis. The angle α

determines the

amount of degree, the object is rotated:

cos sin 0

sin cos 0

001

(4)

To rotate an object around a normalized vector

rot, where

,

(5)

it is possible to calculate a matrix that transforms the

coordinate system, so that rot is the new rotation axis.

This can be done by calculating the orthonormal base

and writing its vectors into a new matrix T. After

applying the transformation, the transformation can

be inverted by multiplying it with its inverse T

-1

. For

rotation matrices, it is set that

, where T

T

is

the transposed matrix of T. This leads to the following

matrix for a rotation around an arbitrary axis x:

∙

∙

.

(6)

After introducing the basic mechanics, the

advantages of extended coordinates are evident. The

inner 3x3 matrix of a homogenous matrix allows to

rotate the object, while applying a simultaneously a

translation within the same matrix. The following

matrix rotates an object around axis R

z

, translates it

about tra and additionally scales it with factor s:

∙cos sin 0

sin ∙cos 0

00

0001

.

(7)

Using transformation matrices containing

homogeneous coordinates, translations become

linearly independent, and thus can be seamlessly

composed with all other types of transformations.

Although a translation is a non-linear transformation

in a 3D Euclidean space and cannot be combined with

other transformations while preserving

commutativity and other properties, it becomes, in a

4D projective space described by homogeneous

coordinates, a simple linear transformation. Thus all

affine transformations can be obtained by

composition of two or more affine transformations.

We can now stack different transformations, which

results in a complete transformation M, where

∙

∙

∙….

(8)

Z

Y

A

B

X

ICINCO 2019 - 16th International Conference on Informatics in Control, Automation and Robotics

630

However, Equation 8 is only true, if every element

in the kinematic chain of the machine tool is

expressed using the same coordinate system. While in

computer graphics applications this requirement may

be true, most machine tool kinematics are not

expressed using the same coordinate system. Usually

every part of the machine has its own coordinate

system, which is based on its origin, because the

movements of the single machine element are always

expressed relatively to their parent. For example, the

rotation table around B in Figure 5 always rotates

around its own y-axis, while its position and

orientation can change, when B is rotating. The

problem is explained in Figure 6.

Figure 6: Two machine elements and their individual

coordinate systems.

For finding the homogeneous matrix describing

different coordinate systems, it is enough to translate

every coordinate system, so that the coordinate

system of each element is based on the global

machine coordinate system. Hence, Equation 8 can

now be formulated as

∙cos sin 0

∙

sin ∙cos 0

∙

00

∙

0001

(9)

With this transformation all parts of the kinematic

chain can be converted to a transformation series of

rigid bodies, which are multiplied to one complete

transformation of the entire machine. The final matrix

M describes the complete transformation of the CNC

machine, for its individual part (Uicker, 2011).

4.2 Implementation of Machine Tool

Kinematics using Game Engines

Due to our focus on implementing an AR solution on

the Microsoft Hololens, it is important to note that

developing a basic kinematic chain on the Hololens

AR device can be realized most efficiently through

the Unity game engine (Huang, 2019). The

comparison between the Unity engine and other

frameworks like Unreal shall be neglected here and

might be a topic for further investigations. Due to the

native support for Hololens applications, the Unity

framework allows to access features like spatial

mapping or gesture control. Hence, the Hololens

paired with the Unity engine seems to be the current

state of the art for AR Hololens development and a

suitable basis to implement CNC machine

kinematics.

The basic structure of the kinematic chain is

established, as illustrated in Figure 7. Every child’s

transform is bound to the parents transform, while the

whole machine has one root object. For the kinematic

chain, the task is to find an implementation using

Unity. The Unity engine already has a structure,

which the kinematic chain can be easily based on. In

Unity, every scene is populated with so-called

“GameObjects”. These are hierarchically structured

and can be compared to a scene graph (Burns, 2004).

In a scene graph every object can have children or

parents. Every object holds its own transformation

matrix. If you manipulate an object, all the child

objects of the object are transformed with the same

matrix as well.

Figure 7: Transfer of the kinematic chain.

Unity also provides functions to translate and

rotate GameObjects. Translations can be performed,

regarding the local coordinate system of each

GameObject or to the global coordinate system.

Rotations can be done in regard to the local or the

world system, while they either rotate around the

centre of the model or a predefined point. We exploit

the scene graph structure to implement the

representation of machine kinematics. Using

GameObjects, it is not necessary to calculate a

specific matrix or translate objects into its parents

coordinate system. To implement the structure of the

machine tool, the realized framework parses the

machine kinematic recursively:

Modelling of CNC Machine Tools for Augmented Reality Assistance Applications using Microsoft Hololens

631

GameObject load_model ()

{

//Create a gameobject for machine

GameObject m = new GameObject(“r”);

//Load all axis

foreach (machine_axis a in m.axis)

{

load_axis (a, machine);

}

//Load all single models to unity

foreach (machine_def g in m.geometry)

{

loadgeo (g, machine);

}

//Return complete kinematic chain

return machine;

}

void load_ax(Axis a, GameObject p)

{

//Create an own gameobject for axis

GameObject ax = new GameObject(a.id);

//Attach it to the parents transform

axis.transform.parent = p.transform;

//Attach axis script to it

[ … ]

// load all children recursively

foreach(var c in a.Items)

{

if (c is Axis) load_ax (c, a);

elseif(c is Geometry) loadGeo(c,ax);

}

}

While this works perfectly with translation

commands, an unexpected behaviour regarding

rotation of machine parts can be observed, when the

CAD data of the machine elements are designed in

different coordinate systems. Usually, when creating

a 3D CAD model, it is cantered in the origin

O(0, 0, 0). However, most machine tool

manufacturers provide the CAD data in a different

spatial location. The 3D model of each machine part

is positioned at the unique location it would have,

relative to the entire machine tool setup, refer to

Figure 8. This makes one more information necessary

to be stored in the machine definition: the rotation

axis. Normally in Unity, if you rotate an object, you

either rotate it around the world origin or translate it

into the origin to rotate it around its centre.

Figure 8: Errors in machine representation due to incorrect

CAD modelling coordinate system.

However, in most cases machine parts

do not rotate around the origin, but a

specific rotation axis. This can be seen in Figure

9.

Unity solves this problem by providing

RotateAround(Vec3 po,Vec3 ax, float a)

,

which allows to rotate around a certain point and a

specified axis. Hence, it is enough to use this

function with

po

being the rotation point provided

in the machine definition and

ax

the according

rotation axis.

Figure 9: Illustration of model positioning.

4.3 Connectivity & Inclusion

Several implementation ideas for a connection and

transfer system to the Hololens are discussed. Some

of these played major roles:

Server system that runs directly on the Hololens

(asp.net or Appache)

Messaging middle-ware like DDS

Rest interface

Direct socket communication with own protocol

ICINCO 2019 - 16th International Conference on Informatics in Control, Automation and Robotics

632

During development, it appeared that most ideas

needed to be scrapped. While the Hololens runs

Windows 10, nevertheless, applications that are

developed for the Hololens are restricted to using the

Universal Windows Platform (UWP). UWP is a

sandboxed run-time environment that only runs

applications written in C# (Garofalo, 2013). UWP has

access to most functions of the .net software

framework by Microsoft but is partially restricted.

Due to the sandbox restrictions of the UWP, there are

currently no server systems or messaging systems

available that run on the UWP. Therefore, these ideas

could not be realized.

However, there exist some REST interfaces for

UWP, which allows to post and get data from a

remote device, with an URL based access system.

They only support post data in form of strings and no

direct binary upload. Because of this binary would

need to be transformed into some format which can

be put into a string. This can be done with a

serialization as for example the Base64 encoding.

This would make a lot of conversions necessary and

make the framework slow and hard to be included

into other systems. Therefore, the final decision was

to use a direct socket communication.

As base for the protocol the “Transmission

Control Protocol” (TCP) was chosen. The protocol

should consist of different parts in the header. Instead

of relying on a slow string base message approach,

integers will be used to encode the commands. Due to

the use of TCP sockets, a stream is used to write data

in. From the other side of the stream, data can be read

out. Because two-sided connection could be useful

later, when data from the Hololens should be sent to

the remote computer, two different modes should be

implemented. One mode is for sending files and

messages, the other one for receiving files and

messages on the server side. The other one sends a

starting signal to the Hololens to send its data to the

server. The server part decides whether the Hololens

can send its data or should queue up its message and

send them later.

The first and only mandatory part of the protocol

header is the command part. The sender decodes the

command for the device with help of a shared header

file. Currently, the framework only needs three

commands, one for sending a message, which is

stored in the memory. Another one for sending files

which are stored on the HDD directly. The last one is

for switching the mode from only receiving Hololens

to sending and therefore allows the Hololens to

transfer its queued data. While this implementation

uses only two commands, the header file can be

extended just by writing new commands into it. When

the protocol header is parsed, a call-back with the

according command is called, where you can simply

switch case over your own implemented commands.

To make a fast switch between sending and not-

sending mode of the Hololens possible, the header is

finished if the command is “SND” or “RCV”. There

is no need to write additional information in the

header (Figure 10).

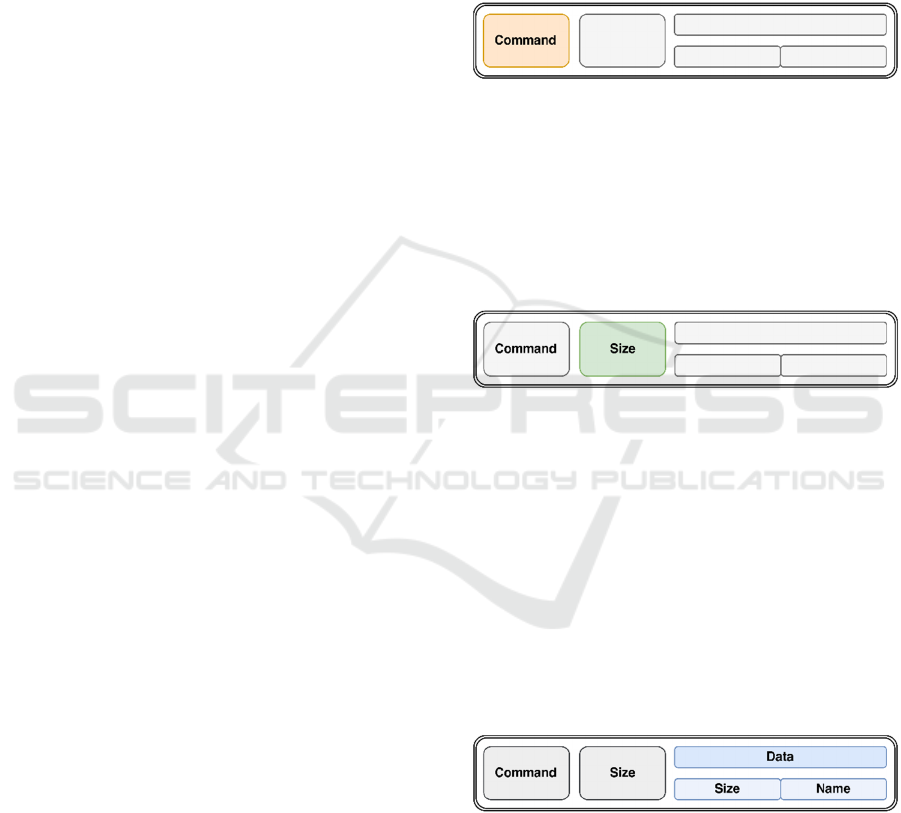

Figure 10: The first part of the header, manages the

commands.

Because every message and every file have

different sizes, the next part of the header defines the

size of the attached data (Figure 11). This part of the

header is only used, if the command is a command

that indicates a data transfer. Otherwise the header

ends here.

Figure 11: The second part of the header, defines the packet

size.

The third part of the header contains data

(Figure 12). If the data consists only of a message, it

can be read straight away and stored into memory. No

further information is necessary. In the other case,

when the command, which stores data on the HDD, is

transmitted, the header needs to be extended. It will

be extended with two new parts, the first one being

the file name size of the file which is transferred and

the second one the file name. Through this the file can

be stored under correct name on the Hololens hard

drive.

Figure 12: The data part of the header can contain additional

information.

While the whole header is very small, it could be

optimized further. Figure 13 shows the complete

header file.

Modelling of CNC Machine Tools for Augmented Reality Assistance Applications using Microsoft Hololens

633

Figure 13: The whole protocol header.

The theoretical approach for the protocol header

above is implemented on the Hololens as well as a

server for testing the functionality. On the server side,

the connection is not very complicated. The server

opens a socket through the .net class TcpClient,

which handles the TCP specific connection setup.

The following code fragments are part of the class

TcpServer.cs, which is part of the Hololens

framework.

public void StartServer(port, size){

HostName h = new HostName (GetIP() );

StreamSocketListener s = new

StreamSocketListener();

IAsyncAction outstandingAction =

server.BindEndpointAsync (h , port );

}

Because any connection from any endpoint to the

Hololens is accepted, a socket listener needed to be

implemented. This listener waits for connection at-

tempts on a predefined port. As already stated earlier,

the Hololens only supports UWP applications. For

UWP applications, there is a provided class

“StreamSocketListener”, which can handle incoming

connections. After the listener registers a connection

attempt, it fires a call-back and gives this call-back to

the socket which can be used to read data from the

regarding stream. Once the call-back is received, a

reader for the created socket can be used to wait for

incoming data. For the implementation refer to the

next two code segments.

public async void ReadFromStream( ) {

awaitreader.LoadAsync (size_16);

int command = reader.ReadUInt16();

awaitreader. LoadAsync (size_32 );

UInt32 size = reader.ReadUInt32 ( );

switch (command){

case POST:

string path=awaitReceiveFile( size);

callback_post ( size, path );

break;

case INFO:

byte[]data2=awaitReceiveData( size);

callback_info ( size, data2) ;

break ;

case RCV:

callback_rcv();

break ;}

ReadFromStream ( ) ;}

The function ReadFromStream waits for available

data and parses the data accordingly to the protocol.

This happens asynchronously which means the call of

the function is not blocking but happens in a separate

thread in the background. Inside this function, three

different call-backs can be called. Any class can

extend TcpServer and overwrite the call-backs, to

manage the received data or to decide how data

should be sent.

5 RESULTS AND DISCUSSION

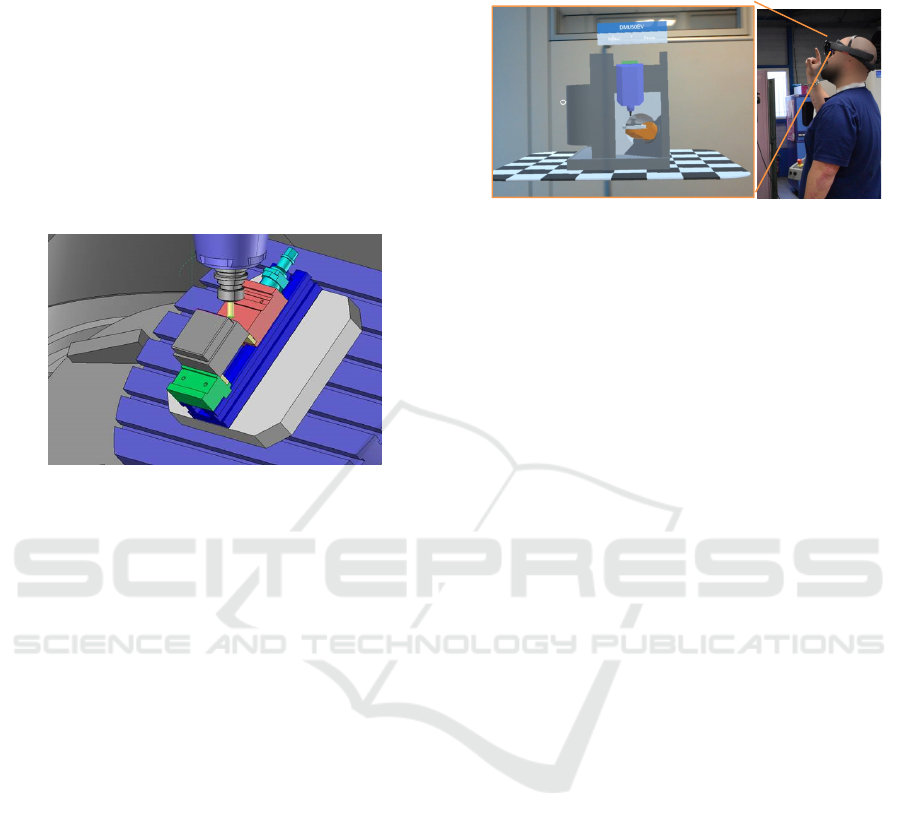

Through Unity and a scene graph structure, a

straightforward approach is chosen to model

kinematic chains of CNC machine tools. We use an

DMU 50 eVolution by the manufacturer DMG Mori

is used to carry out the experiments in our current

setup, which is controlled and interfaced through a

Siemens 840D control computer, as shown in

Figure 14. The production engineers typically design

the machining process using a CAD/CAM (computer

aided design and manufacturing) software on a

designated computer. When the required process

design is completed, a CNC program is exported,

which specifies a toolpath for the machine tool and

thus directly controls the operation of the CNC

machine.

Figure 14: The CNC machines used for trials and

experiments.

To demonstrate the concept of linking simulation

data with AR glasses, a test geometry is defined. The

test part consists of simple geometric features. A

cuboid is machined on a rectangular base, Figure 15.

The used tool is a standard 10 mm diameter shaft mill

with four cutting edges.

While the program is running, the control

computer provides real-time access to relevant

measurements from the process, such as tool position

and orientation. Additional sensors for measuring

power, torque, forces and vibrations, can often be

installed in the industrial machines (Minoufekr,

ICINCO 2019 - 16th International Conference on Informatics in Control, Automation and Robotics

634

2013). In our setup, we did not consider

dynamometers or other sensor technologies.

The DMU 50 employs a control system, which

has limited capabilities for external connectivity. It

does however support Dynamic Data Exchange

(DDE), a legacy protocol for inter-application

communication. We use the DDE communication

over the network to access the current position of the

milling tool. An interface program handles the

communication with the machining centre’s control

computer, while streaming coordinate data over TCP

to subscribing PCs on the network.

Figure 15: The process design using the Siemens NX

CAD/CAM software.

One of the main requirements for AR-based

machining assistant is the ability to blend the user’s

view of the real environment with overlaid virtual

imagery of the process. In our use case holographic

optical machine elements of the DMU 50 are overlaid

onto the Hololens headset, while the machine’s safety

glass is covered with coolant fluid, which allows the

machine operator to simultaneously see the real

environment, as well as superimposed 3D graphics,

see Figure 16.

We currently use the Hololens Version 1 model

with a native viewing angle (FoV) of 30°. A higher

FoV of at least 60° is desirable in our trials, since it

allows the operator to view the entire machine setup

in AR. The current FoV of Hololens Version 1 has the

ability to create extremely bright graphics, however

the AR content visible to the operator is too small at

the moment. Furthermore, the visualization of

sections with rather high details can be optimized in

order to increase visual geometry quality.

The ability to provide real-time visual feedback to

the operator is specifically useful when the operator

designs a new program or modifies existing ones.

Experimentations and research with different tools

and materials can also benefit from a better

understanding of the current state of the operation.

The visualization of process data directly in the

workspace reduces mental load for the operator and

provides intuitive access to the information.

Figure 16: The operator views the machine operation

through the Hololens, which is projecting stereoscopic

images, augmenting the operator’s view of the process with

relevant information.

One particularly interesting property of Hololens

is the ability of reducing the impact of occlusion and

enhancing the visibility of real-world objects. In the

case of machining processes, it might be difficult to

see the tool as the cutting tool is covered by the

workpiece. Particles, such as swarf or cutting fluids,

can also reduce the visibility or there is no visibility

at all. The ability to render bright 3D graphics at any

location in the workspace always makes it

straightforward to indicate the tool position.

6 CONCLUSION AND FUTURE

WORK

In our system, we visualized the production

machine’s dynamic behaviour during the

manufacturing process using AR glasses. We also

provide a 2D overlay of the CNC toolpath, projected

on the AR device.

This paper focussed mainly on the

implementation of the kinematic chain for CNC

machines. The representation of kinematic chains

was introduced as computer graphic GameObjects.

Using basic rigid body transformations, like

rotation or translation provide the basic

mathematical tools to describe the dynamic

behaviour of a machine tools and its sub-elements.

These mathematical concepts can directly be

implemented in scene graphs like Unity, which

allows projecting the machine tool behaviour in

AR. After illustrating the actual implementation of

the kinematic chain in Unity, an experiment was

carried out using a CNC machining centre.

The interactive visual feedback using our AR

platform is valuable technology in training and

education. In the current system, we merely highlight

Modelling of CNC Machine Tools for Augmented Reality Assistance Applications using Microsoft Hololens

635

the current CNC operation, but in the future, an CNC

interpreter could analyse the motion sequence of the

tool and allow the system to support the operator and

process designer. The operator would for example be

able to simulate the process with a virtual tool and real

workpiece, real tool and virtual workpiece, or with

both a virtual tool and virtual workpiece. This could

be powerful in online programming, providing a safe

and direct mechanism for iterative program

development with real-time visual feedback. The

simulator would also save time since the operator

could jump to any part of the program, having the

ability to fast forward or reverse the process.

The interpreter would be useful for real-time

operation, making it possible to visually indicate the

past and future trajectory of the real tool using motion

vectors. The operator could thus easily see the tool’s

expected position for a few seconds ahead of time. By

visualizing the complete tool trajectory of the

program, we could increase safety, by visually

making sure that the tool does not exceed any

geometrical bounds.

ACKNOWLEDGEMENTS

The authors would like to thank the INTERREG V A

de la Grande Région for the support of the depicted

research within the PRODPILOT project. The authors

also thank Dropslab Technologies for providing the

HoloConnector platform and the invaluable

discussions, suggestions and technical assistance with

the industrial implementation.

REFERENCES

Altintas, Y., 2012, Manufacturing automation: Metal

cutting mechanics, machine tool vibrations, and CNC

design, 2nd edn., Cambridge University Press,

Cambridge, New York.

Arntz, K., 2013, Technologie des Mehrachsfräsens von

vergütetem Schnellarbeitsstahl, Aachen

Azuma, R., 1997, A survey of augmented reality. Presence:

Teleoperators and virtual environments, 6(4):355–385.

Burns, D., Osfield, R., 2004, Tutorial: open scene graph A:

introduction tutorial: open scene graph B: examples

and applications. In Virtual Reality, 2004. Proceedings.

IEEE, pp. 265–265. IEEE.

Schug, P. et al, 2012, Durchgängige CAx-Prozessketten,

Forschung an der Werkzeugbau Akademie, Apprimus,

Aachen

Ding, K., Chan, F., Zhang, X., Zhou, G. & Zhang, F., 2019

Defining a Digital Twin-based Cyber-Physical

Production System for autonomous manufacturing in

smart shop floors, International Journal of Production

Research

Milgram, P., Takemura, H., Utsumi, A. and Kishino, F.,

1995, Augmented reality: A class of displays on the

reality-virtuality continuum, Photonics for industrial

applications, pp. 282–292. International Society for

Optics and Photonics.

Ohta, Y. and Tamura, H., 2014, Mixed Reality: Merging

Real and Virtual Worlds. Springer Publishing

Company, Incorporated, 1 ed.

Yan, J., Industrial Big Data in an Industry 4.0

Environment: Challenges, Schemes, and Applications

for Predictive Maintenance, IEEE Access, vol. 5, pp.

23 484-23 491, 2017.

Suárez-Albela, M., Fraga-Lamas, P., Fernández-Caramés,

Dapena, T: M. and González-López, M., Home

Automation System Based on Intelligent Transducer

Enablers, Sensors, vol. 16, no. 10, p. 1595, Sep 2016.

Garofalo, Emanuele, A. Liccardi and M. Aponte. 2013.

Windows Runtime Environment, pp. 31, 72. Apress,

Berkeley, CA.

R. Drath and A. Horch, “Industrie 4.0: Hit or Hype?” IEEE

Industrial Electronics Magazine, vol. 8, no. 2, pp. 56–

58, June 2014.

Microsoft, 2017. Microsoft HoloLens. Website. Retrieved

January 23, 2017, from https://www.microsoft.com/

microsoft-hololens/en-us.

Minoufekr, M., Glasmacher,L., Adams, O., ‘Macroscopic

Simulation of Multi-axis Machining Processes’, 10th

International Conference on Informatics in Control,

Automation and Robotics (ICINCO 2013), 505–516.

Minoufekr, M., Schug, P., Joshi, M., Process

Characterization and Evaluation of NC Machining

Processes based on Macroscopic Engagement

Simulation, 11th International Conference on

Informatics in Control, Automation and Robotics

(ICINCO 2014).

Uicker, J., Pennock, R., Shigley, J., 2011. Theory of

machines and mechanisms, vol. 1. Oxford University

Press New York.

Huang, L., Collins, S., Kobayashi, L., and Sgouros, T.,

Shared visualizations and guided procedure simulation

in augmented reality with Microsoft HoloLens, Proc.

SPIE 10951, Medical Imaging 2019: Image-Guided

Procedures, Robotic Interventions, and Modeling,

1095112

ICINCO 2019 - 16th International Conference on Informatics in Control, Automation and Robotics

636