Modelling, Optimization, and Simulation of Several First Aids in

an Area with Plant Simulation

Jolana Sebestyénová

a

and Peter Kurdel

b

Institute of Informatics, Slovak Academy of Sciences, Bratislava, Slovakia

Keywords: Discrete-event Systems, Modelling, Optimization, Simulation, Genetic Algorithm, Distributed Computing,

Plant Simulation.

Abstract: Plant Simulation software comprises all the features needed to model the functional aspects of most real-

world systems. Specification of complex optimization problem (in sense of many optimization parameters)

and its solving in Plant Simulation by genetic algorithm is possible, but it leads to significantly ascending

simulation time. The paper presents division of the optimization to two parts: first part of the optimization via

GA using distributed computing, and the second part of optimization parameters that will be used in the

second stage of the optimization. Modelling, optimization, and simulation procedure proposed for Plant

Simulation is presented and tested on a simple use case. In the first stage, the placement of several first aid

posts in the area where distinct happenings can go on is optimized, the second stage of the optimization is

done using Experiment manager with the aim to select the best solution, i.e. optimal number of first aids in

the area depending on additional optimization parameters.

1 INTRODUCTION

Dynamic systems modelling and discrete event

simulation represents a very wide range of research

and development effort for many years. In 1998, the

authors of this paper presented their modelling and

simulation tool for discrete event dynamic systems

with statecharts formalism used for description of the

system’s behaviour in (Sebestyénová, 1998). Matlab

Stateflow was used in (Kurdel and Sebestyénová,

2010, 2011) for application-based heuristic

scheduling of a production process in flexible

manufacturing.

Plant Simulation software based on discrete-event

simulation contains all the necessary required to

model the operational facets of real-world systems

(Bangsow, 2015). As it abstracts to deal with just

important aspects, it is able to simulate months of

factory operation in just seconds. Its primary role is

to provide for integrated, graphic and object-oriented

modelling, simulation and animation. A lot of

complicated and sophisticated systems may be

modelled and displayed in great detail closely

corresponding to reality using 2D/3D simulation.

a

https://orcid.org/0000-0003-4677-9972

b

https://orcid.org/0000-0002-8080-2411

Plant Simulation is well equipped for animation

and visualisation of results, which are used in great

extent in commercial applications to provide for

communication with the user. Quite often, it is

adequate to concentrate on functional aspects, as the

model itself is not of the primary importance. This

enables to use animation only at the debugging phase,

so as to accelerate the model performance in other

circumstances.

Well-structured simulation models reflect the

natural hierarchy of systems to be simulated. The

basic object Frame can be put into the RootFrame or

in another Frame, and create thus a dynamical

hierarchy of models. Moreover, one can in this way

break down complex tasks into manageable parts. In

a case of several similar processes, setting up of the

Frame of this process and adding multiple instances

of this Frame on the RootFrame enables to structure

the models and make them easier to maintain, with

the help of modular design and object-oriented

programming.

Survey on the use of simulation for manufacturing

system design and operation are given in (Smith,

2013). Blaga et al. (2018) compares modelling with

Petri nets to Tecnomatix Plant Simulation in the field

Sebestyénová, J. and Kurdel, P.

Modelling, Optimization, and Simulation of Several First Aids in an Area with Plant Simulation.

DOI: 10.5220/0007927602850292

In Proceedings of the 9th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH 2019), pages 285-292

ISBN: 978-989-758-381-0

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

285

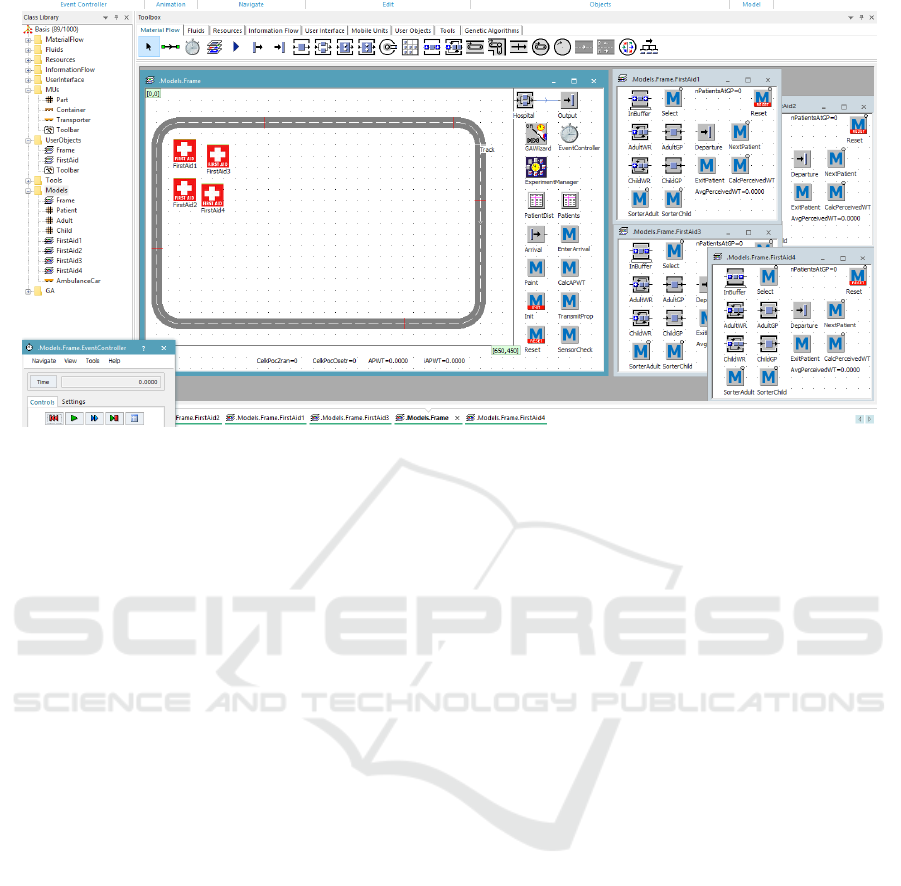

Figure 1: A frame of the model with an area, and sub-frames of four first aids (represented as icons in the area).

of manufacturing process management. In order to

organize the smart manufacturing, and flexible and

efficient production processes, Kokareva, Malyhin &

Smelov (2015) used Plant Simulation for optimizing

and validating process performance. Possibilities and

examples of using Tecnomatix Plant Simulation to

simulate the production and logistics processes was

presented in (Siderska, 2016). Vavrík, Gregor &

Grznár (2017) described Computer simulation as a

tool for the optimization of logistics. This paper

comes up with modelling, optimization and

simulation schema proposed for Plant Simulation and

testing it on the use case taken from the Plant

Simulation manual (Mes, 2017, pp. 88-91); the use

case was extended to comply to the purpose.

As a problem description, one can suppose there

is a festivity terrain for which it is necessary to setup

first aid posts. One needs to distribute first aid posts

with efficiency in order to get a good coverage over

the whole area. In certain cases the modelled process

involves the transportation of entities (e.g., patients)

and the transportation might necessitate a vehicle.

The use of the Track object and the Transporter object

seems to be in this case a reasonable choice.

Specification of complex optimization problem

(in sense of many optimization parameters) and its

solving in Plant Simulation by genetic algorithm is

possible, but it leads to significantly ascending

simulation time. The paper presents division of the

optimization parameters to its first part used in the

first stage of the optimization using GA, whereas the

second part of parameters will be used in second stage

of the optimization using Experiment Manager.

The programming language SimTalk extends the

ways of modelling and control of the simulation. The

Interpreter executes the source code entered into the

Method. SimTalk 2.0 is used in presented model.

In the second section, a generic model of a first

aid post is created. Instances of the model will then

be used in three area frames representing placement

of two, three, and four first aid posts in the areas,

where many people are moving and passing their

time. Some of them sometimes suffer an accident, and

require a medical treatment. The third section

presents the first step of two stages of optimization of

the number and placement of the first aids in the area.

In the section 4, some simulation results are given,

and the second stage of optimization is presented.

2 FRAMES OF A MODEL

At first, a model of a first aid post is created in Class

library under User objects, followed by a model of an

area where some events may go on with different

number of incoming people. EnterArrival method of

the frame of the model, in which the area is presented,

generates random appearance of some accidents in

the area.

The Fig. 1 presents the frame containing the area

with four derived first aids (FAs) from the user object

FirstAid (see in Class Library at the left). In the frame

with the area, the FAs are represented by icons, and

in the right part of the picture, they are open. Some of

the methods in this sub-frames are inherited, which is

visualized by a little grey circle at the upper right

SIMULTECH 2019 - 9th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

286

corner of the method (to be seen in the sub-frames at

the right).

The arrival rate of adults and children is given in

a PatientDist tablefile of the frame with the area. A

visitor having an accident selects to go to the nearest

FA. Here, he/she will wait in a waiting room or move

to a general practitioner (in a case that he/she is free)

according to patient's urgency or time of arrival. The

patients are sorted to a general practitioner (GP) for

adults and GP for children. The treatment times of

patients are random, some 20 minutes for adults and

30 minutes for children.

In each of the FA frames, an inherited method

NextPatient moves a patient (modelled as a mobile

unit Adult/Child) to the appropriate GP if free, and

then moves treated patients to an exit. In a case the

patient needs any further treatment in a hospital, an

ambulance car appears on a track and transports the

patient from one of the FA posts to the hospital. The

car stops near the calling FA at the place specified by

a sensor and boards the patient.

During the testing or presentation of the model, it

is advantageous to animate movements of the mobile

units, but as expected, eventual animation slows

down optimization run.

The procedure proposed to face up to complex

optimization problem (with many optimization

parameters) describes all steps from starting with

creation of some useful objects ... up to creation and

simulation of the root frame containing the whole

model. Some simulations can run simultaneously,

which saves simulation time. Trying to use all

optimization parameters in GA wizard (which could

be done only for the version with 2 FAs, because of

our educational licence with limits, specification of

all optimization parameters for 3 / 4 FAs was not

possible), the simulation time rose significantly.

Modelling, optimization and simulation of the

use-case follows the procedure:

Create model of an FA (mobile units MUs created

here: Patient -adult, -child, General practitioner

GP -for adults, -for children).

Create the frame with an area where sub-frames

of the FAs will be placed (MUs created here: an

ambulance car AC on a track).

Make separate/simultaneous optimization of

placements of FAs in the area, first with 4 FAs,

then with 3 FAs, and finally with 2 FAs placed in

the area. (Though in simple cases one could

relatively easily guess the best placements, in case

of more complicated models such as e.g.

workshops or logistics in a factory such an

optimization can appear to be indispensable.)

Create a root frame (main frame of the model)

containing in our test 3 area frames (mobile units

created here: GP that in last step after the

optimizations will move to the AC of the area with

optimal number and placement of the FAs, so

called winner area).

Make simulations using best placements of FAs in

three different areas (modelled as sub-frames of a

root frame) - this can be done simultaneously.

The second stage of optimization runs (also

simultaneously) some experiments based on

additional optimization parameters, in order to get

the best solutions from usage of 4, 3, or 2 FAs.

This approach can bring useful results in various

situations, such as in a case of planned

reconstruction of a workshop, where one can

acquire knowledge about how many stations of

different types is optimal to use, or how many

workers of different qualifications is optimal to

use after the reconstruction.

Make simulation of the whole model comprising

the winner area with its FAs. In the presented

case, the GP starts from the input of the root frame

to move to the AC of the winner area (as it can be

seen in the last figure in section 4). But in a more

complicated situation, input from the root frame

may be changed for interfaces connecting outputs

from a number of different previous frames to this

frame. Modelling, optimization and simulation

schema of that kind could be helpful for a

designer.

In the following, an event starting at noon with

duration time 6 hours, attendance about 1000 people

(40% of them being children) are supposed.

Approximately 70 accidents are expected to occur

during the event.

3 OPTIMIZATION USING GA

The popularity of genetic algorithms (GA) stems

from the fact that they return good results while being

task-independent. The GAs are therefore perfectly

convenient in miscellaneous simulation-based

optimization tasks. For example, routing optimization

for ATM cash replenishment with many optimization

parameters using GA is described in (Kurdel and

Sebestyénová, 2013a, 2013b), with optimization pa-

rameters divided to pattern and route chromosomes.

The Plant Simulation wizard for GA (GAWizard)

integrates GA into an existing simulation model.

At first, the definition of the optimization problem

was done using fitness function specified in Optim

method, which returns the fitness value. An

Modelling, Optimization, and Simulation of Several First Aids in an Area with Plant Simulation

287

individual representation consists of two

chromosomes. The user defined optimization

parameters (a number of FAs and their positions)

create a placements chromosome. The fitness

function used in this test:

f = max (w

1

Treated) + min (w

2

APWT)

(1)

where Treated is number of the patients treated to the

end of the event in the area with given number of the

FAs posts (4 / 3 / 2); APWT is average waiting time

calculated from waiting times of the patients at the

FAs in the given area.

Further, the individual representation was

enlarged by creating a second chromosome consisting

of three more optimization parameters: fee of one FA

service, and penalty cost for the number of patients

not cared to the end of the event (NoWP), and penalty

cost for average waiting time of the patients (APWT).

The fitness function was modified to:

f = min (α cost

1

+ β cost

2

+ ϒ cost

3

)

(2)

where α, β, ϒ are weights,

cost

1

... cost of still waiting patients at end of the event

calculated: NoWP * penalty

1

cost

2

... cost of average waiting time of the patients

calculated: APWT * penalty

2

cost

3

... cost of the FA posts calculated: number of

FAs * penalty

3

(fee of one FA service).

As more than 20 user defined optimization

parameters were set, the specification of appropriate

lower and upper bounds of the parameters has been

complicated, and the work was slow. So the decision

was made to use the above proposed modelling,

optimization and simulation schema.

In the first stage, the placement of 4 / 3 / 2 FAs in

the area of the event is optimized using as

optimization parameters the total number of treated

patients in 6 hours duration of the event, and

minimization of the waiting time of the patients. This

optimization is done using fitness function (1). (The

optimization according to the second chromosome

will be described later using Experiment manager.)

For the optimization problem, fitness calculation

is specified by table in GA wizard, which can be seen

at the bottom part of Fig. 2. Weights w

1

, w

2

of this

fitness calculation are set to 0.8 for number of treated

patients and to 0.2 for inversion of the waiting time.

GA wizard enables to maximize/minimize all parts of

the fitness, but needing to maximize the first of them,

and minimize the second, inversion was used.

Optimization parameters are x, y positions of the FAs

- their ranges are defined by lower and upper bounds

and an increment as given in the top part of Fig. 2.

The number of required simulation runs for an

optimization can become quite large. The number of

individuals to be evaluated depends on the number of

generations and size of a generation. In the first

generation, Plant Simulation evaluates the specified

size of generation, and in each of the following

generations it has to evaluate twice as many

individuals. Length of an individual is given by the

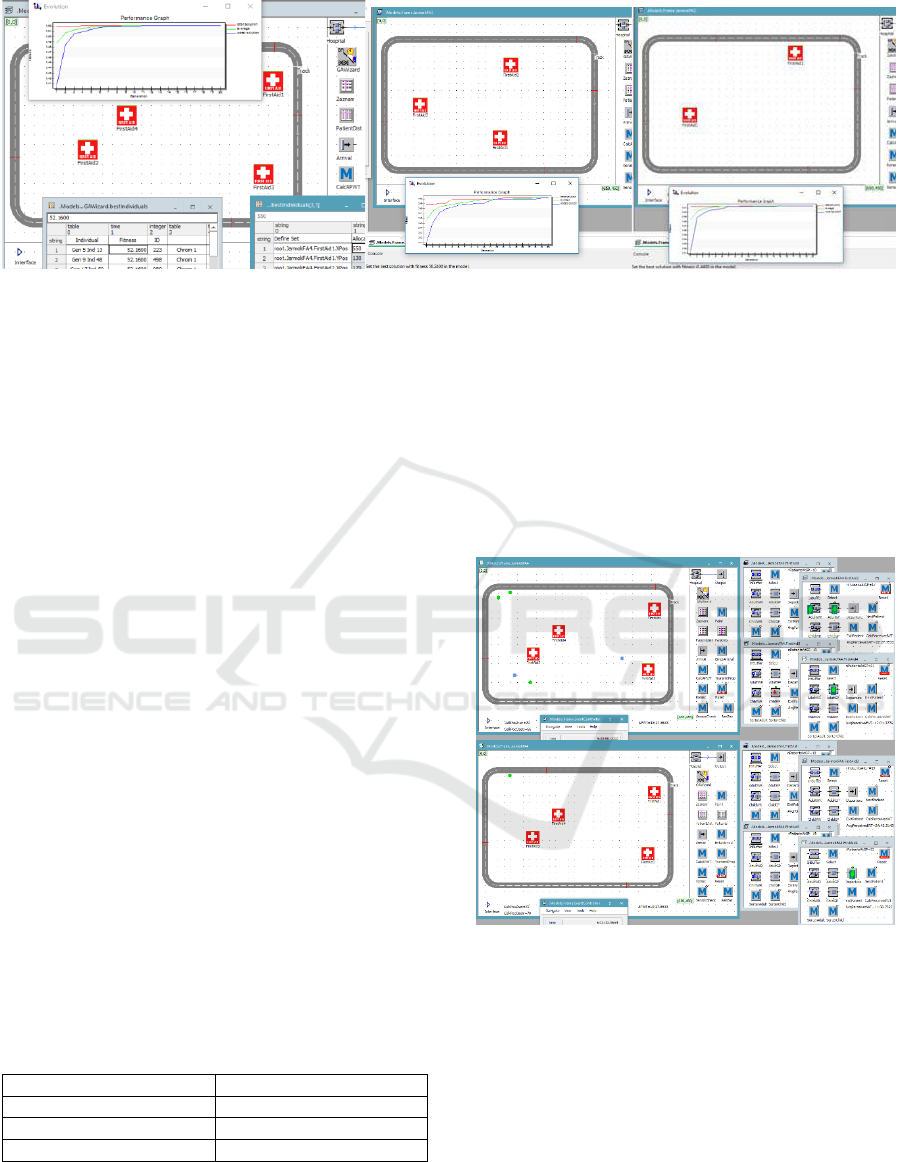

Figure 2: Problem definition in GA wizard.

length of the above mentioned chromosomes.

In the realized test case, number of generations

was set to 20, size of generation was set to 30, and a

number of observations per individual was set to 10.

More people arriving to the event or happening,

more accidents can occur, and more FAs will be

needed. The second stage can optimize the selection

of the number of the FAs placed on the area according

to the number of people arriving to the given event

and FA service fee, which will be described later after

some simulations in section 4.

3.1 Results from GA

In the test case, running times of optimizations ranged

approximately from 3 to 5 minutes. As Plant

Simulation provides possibility of distributed

computing, it has been used to run GA wizard.

Usage of distributed computing on PC with 4

cores reduced the optimization running times

approximately to half of the values without the usage

of distributed computing. In presented simple use

case this speedup makes only a small difference, but

the gain in complex models can be important.

Placement of 4 FAs in the area: Left part of Fig. 3

presents the best individual for 4 FAs in the area and

a performance graph, where no further improvement

can be observed after about the 10th generation. For

illustration, a screenshot of evaluated best individuals

is given at the bottom part of the picture. Best

achieved fitness value is 52.1600. One can see that

the best individual did not place the FAs

SIMULTECH 2019 - 9th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

288

Figure 3: Best individuals for 4 / 3 / 2 FAs with performance graphs of GA.

symmetrically around the centre of the area, which

seems to be apparently their best placement. This

result can be partly due to random appearance of the

accidents as well as to the fact that working with

Educational license does not allow to improve GA

settings via GA Optimization wizard.

Placement of 3 FAs in the area: In the middle part,

Fig. 3 presents the best individual for 3 FAs in the

area and a performance graph, where improvement

can be observed in about 18th generation. Best

achieved fitness value is 50.2400, which is less than

in previous case, because more patients still wait for

treatment in the FAs in this case. The bottom part of

the picture contains a console with information about

setting of the best solution in the model after the end

of GA optimization, via configuration method

TransmitProperties.

Placement of 2 FAs in the area: Right part of

Fig. 3 presents the best individual for 2 FAs in the

area and a performance graph. Best achieved fitness

value is 41.4400, which is less than in previous two

cases, because more patients still wait for treatment in

the FAs in this case.

3.2 Best Fitness

For smooth comparison, a summary of the best fitness

values of the three GA optimizations are given in

table 1.

Table 1: Summary of best fitness of the 3 optimizations.

No of FAs in the area

Best fitness

4

52.1600

3

50.2400

2

41.4400

4 SIMULATION RESULTS

Simulations were run for all versions, i.e. for the

event in the area with 4 / 3 / 2 FA posts, using their

previously optimized positions. From the following

simulations, one receives values of the variables:

average waiting time of the patients, number of the

patients still waiting for care at the closing time of the

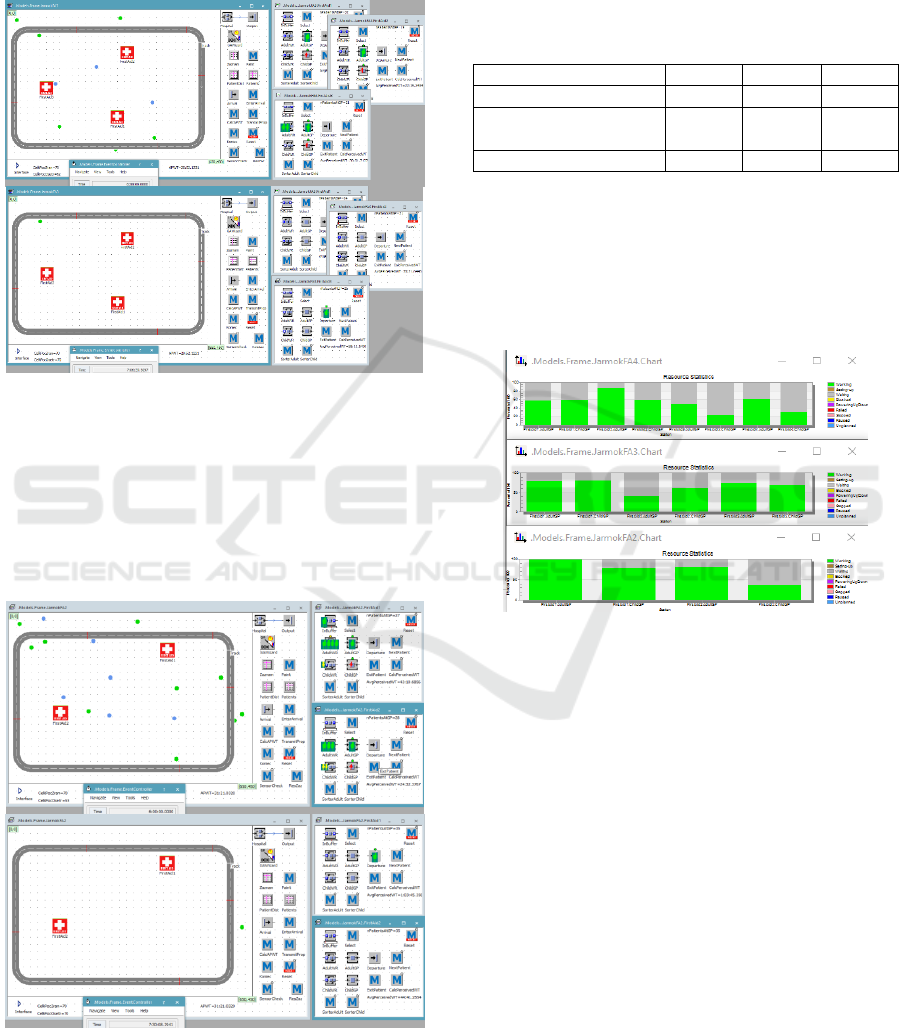

Figure 4: Top part of the picture presents situation at the

closing time of the event with 4 FAs, bottom part of the

picture presents situation when last patient goes away.

event, time when the last patient leaves the area.

Fig. 4 presents simulation results in the case of 4

FAs in the area. Top part of the picture presents

situation at the closing time of the event (6:00:00

[h:m:s]). The blue and green circles in the area

represent locations where these last patients suffered

accidents. These circles representing the accident

placements are removed after any patient leaves any

FA. At the end of the event, 4 patients remain to be

cared for. In the opened frames of the FAs, the

Modelling, Optimization, and Simulation of Several First Aids in an Area with Plant Simulation

289

patients are animated at the closing time of the event.

The last patient goes away at 6:11:13, and one can see

this last patient animated on the departure in the open

frame of the FA. Average waiting time of all the

patients is 13:27 in this case.

Figure 5: Top part presents situation at the closing time of

the event with 3 FAs, bottom part presents time when last

patient goes away.

Fig. 5 presents simulation results in the case of 3

FAs in the area. At the end of the event 8 patients

remain to be cared for. The last patient goes away at

7:06:39. Average waiting time of all the patients is

20:52.

Figure 6: Top part presents situation at the closing time of

the event with 2 FAs, bottom part presents time when last

patient goes away.

Fig. 6 presents simulation results in the case of 2

FAs in the area. At the end of the event 15 patients

remain to be cared for. The last patient goes away at

7:30:08. Average waiting time of all patients is 31:21.

To make some comparison, part of the simulation

results are summarized in table 2.

Table 2: Simulation results.

Area with:

4 FAs

3 FAs

2 FAs

Average waiting time

13:27

20:52

31:21

No of waiting patients

at closing time

4

8

15

Time of last departure

6:11:13

7:06:39

7:30:08

4.1 Resource Statistics

Resource statistics charts in Fig. 7 present GPs

working (green) and waiting (grey) times for all three

cases (top for 4 FAs, middle for 3 FAs, bottom for 2

FAs).

Figure 7: Statistics of the working time of the adult/child

GPs.

4.2 Second Stage of Optimization

In case of too expensive service fee of the FA post, it

may sometimes be better to provide fewer FAs. One

will select the best solution (number of FAs in the

area) depending on the following parameters: service

fee of one FA, average waiting time of the patients,

number of patients still waiting for treatment at the

closing time of the event. The second stage of the

optimization is done using Experiment manager of

Plant Simulation. Optimization using Experiment

manager is a good option in cases similar to tested

one, as one can add on a step by step basis new

experiment specifications based on formerly found

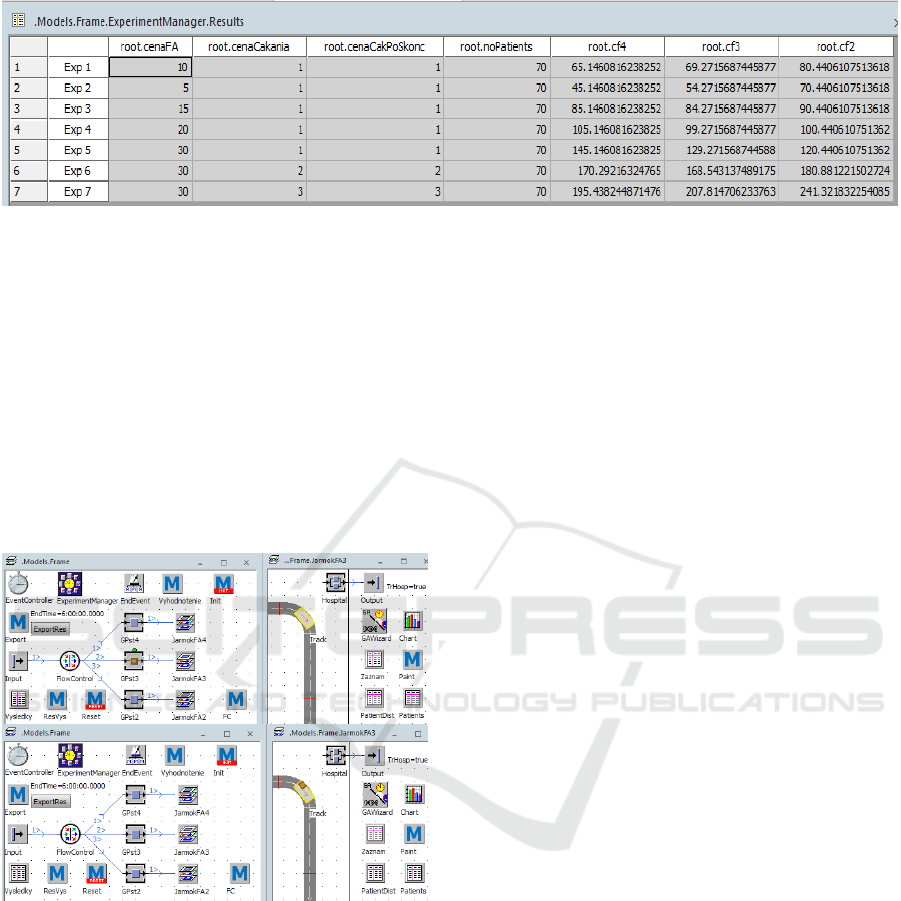

best solutions. Results from Experiment manager are

given in Fig. 8 in a form of a screenshot, but it is also

possible to export results from the Plant Simulation

model to Excel file and continue analysis of achieved

big data using another approaches.

SIMULTECH 2019 - 9th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

290

Figure 8: Results from Experiment manager.

In the first three columns, the fee of one FA

service, the fee of the waiting time of the patients, and

the fee of number of the patients still waiting for

treatment after the end of the event are set. (In the 4th

column, a total number of the patients was in all

experiments equal.) Last three columns give the best

fitness in cases of 4 / 3 / 2 FAs. Thus, the experiment

6 e.g. reveals that the best solution is to place 3 FAs

in the area, because in this second stage of

optimization a minimum total cost is the best one.

Finally, the presentation of the complete model

follows, where the GP working in the AC moves to

Figure 9: Start of the complete model simulation.

the AC created in the frame with the best result, which

is for example (according to above mentioned

experiment 6) the area frame with 3 FAs. Top part of

Fig. 9 presents movement of the GP serving in the AC

from Input in direction to the frame with 3 FAs

(represented by a small brown square icon). The

bottom part presents him/her sitting in the AC on the

Track (the small brown square icon moved from the

root frame to AC parking close to the hospital on the

Track in the winner area frame), in the next step of

the simulation.

Program code of FC method applied as exit

strategy in Flow control object (move of the GP to the

AC is based on it):

-> integer

-- @ is the movable unit

var r:integer

if bestNoOfFA = 4

if .Models.Frame.JarmokFA4.TrHosp =

true

r := 1

end

elseif bestNoOfFA = 3

if .Models.Frame.JarmokFA3.TrHosp =

true

r := 2

end

elseif bestNoOfFA = 2

if .Models.Frame.JarmokFA2.TrHosp =

true

r := 3

end

end

return r

In presented test case, the necessity of the

transport is represented by a boolean variable

TrHosp. Its value is set by the FA that provided the

treatment of the patient needing the further care in the

hospital. For simple test purpose, the patients with

highest urgency are all supposed to need the transport.

5 CONCLUSIONS

Dynamic systems modelling and discrete event

simulation represents a very wide range of the

research and development effort for many years.

Plant Simulation software comprises all the features

needed to model the functional aspects of most real-

world systems. The procedure proposed to face up to

complex optimization problem (with many

optimization parameters) describes all steps from

starting with creation of some useful objects ... up to

creation and simulation of the root frame containing

Modelling, Optimization, and Simulation of Several First Aids in an Area with Plant Simulation

291

the whole model. Some simulations can run

simultaneously, which saves simulation time. The

proposed modelling, optimization and simulation

schema for Plant Simulation was tested on a simple

use case taken from the Plant Simulation manual.

Two optimization steps are used according to

proposed schema. In the first stage, three

optimizations of several FAs placement in the area

are separately done using GA with distributed

computing. Subsequent simulations of the three

distinct happening areas with their movable objects

can be done simultaneously. Acquired results, such as

e.g. average waiting time of the patients, are used in

the second stage of the optimization besides some

additional optimization parameters, e.g. fee of FA

service. This second stage of optimization is done by

Experiment manager.

In final simulation, the Flow control directs the

GP serving in the ambulance car to the winner area

frame, and only this area frame with its FAs frames

works in this simulation besides the root frame.

Presented results can be seen as the first part of

the project research. In further work, the authors plan

to examine in more detail some logistics problems,

a.o. the movement of the ambulance car transporting

the patients to the hospital if they need further

treatment. The proposed modelling, optimization and

simulation procedure (tested on a simple use case)

can prove its usefulness when dealing with more

complex processes.

ACKNOWLEDGEMENTS

The authors are grateful to Scientific Grant Agency

of Slovak Republic and Slovak Academy of Sciences

for partial support of this work by projects VEGA

2/0167/16 and VEGA 2/0155/19.

REFERENCES

Bangsow, S, 2015, Manufacturing Simulation with Plant

Simulation and SimTalk- Usage and Programming

with Examples and Solutions, Springer-Verlag,

Berlin Heidelberg, viewed 10/12/2018

https://link.springer.com/content/pdf/10.1007%2F978-

3-319-19503-2.pdf

Blaga, F, Stanasel, I, Pop, A, Hule, V & Karczis, A, 2018,

´The use of modeling and simulation methods to

improve the performance of manufacture lines´ in

ModTech2018 IOP Conf. Series: Materials Science and

Engineering 400 (2018) 042006, viewed 20/2/2019

https://www.researchgate.net/publication/327731392_

The_use_of_modeling_and_simulation_methods_to_i

mprove_the_performance_of_manufacture_lines

Kokareva, V, Malyhin, A & Smelov, V, 2015, ´Production

Processes Management by Simulation in Tecnomatix

Plant Simulation´ in Applied Mechanics and Materials,

Vol 756 (2015), pp. 604-609, Trans Tech Publications,

Switzerland, viewed 20/2/2019

https://www.researchgate.net/publication/277662116_

Production_Processes_Management_by_Simulation_i

n_Tecnomatix_Plant_Simulation

Kurdel, P, Sebestyénová, J, 2010, ´Statecharts model for

application based scheduling of a manufacturing

process´ in Process Control 2010, pp. C059a-1-C059a-

8. ISBN 978-80-7399-951-3.

Kurdel, P, Sebestyénová, J, 2011, ´Statecharts model and

heuristic scheduling of a production process´ in IEEE

INES 2011 - Budapest, pp. 309-314. ISBN 978-1-4244-

8955-8.

Kurdel, P, Sebestyénová, J, 2013a, ´Routing optimization

for ATM cash replenishment´ in International Journal

of Computers, 2013, vol. 7, pp. 135-144. ISSN 1998-

4308.

Kurdel, P, Sebestyénová, J, 2013b, ´Parallel genetic

algorithm for periodic vehicle routing and scheduling

problem´ in IEEE ICSSE 2013 - Budapest, pp. 111-116.

ISBN 978-1-4799-0007-7.

Mes, M, RK, 2017, Simulation Modelling using Practical

Examples. A Plant Simulation Tutorial. University of

Twente, viewed 15/10/2018

https://www.utwente.nl/en/bms/iebis/staff/mes/plantsi

mulation/tutorialplantsimulation13v20170726.pdf

Sebestyénová, J, 1998, ´Stacha: a computerized modelling

tool for DEDS´ in Advances in Systems, Signals,

Control and Computers. Edited by V. J. Bajic.

IAAMSAD. Vol III, 1998 Durban, pp. 389-393. ISBN

0-620-23136-X.

Siderska, J, 2016, ´Application of Tecnomatix Plant

Simulation for Modeling Production and Logistics

Processes´ in Business, Management and Education,

ISSN 2029-7491/eISSN 2029-61692016, 14(1), pp.

64-73, viewed 20/2/2019

https://www.researchgate.net/publication/305269846_

Application_of_Tecnomatix_Plant_Simulation_for_M

odeling_Production_and_Logistics_Processes, DOI:

10.3846/bme.2016.31

Smith, JS, 2013, ´Survey on the use of simulation for

manufacturing system design and operation´ in Journal

of Manufacturing Systems 22(2), pp. 157-171, viewed

20/2/2019 http://dx.doi.org/10.1016/S0278-

6125(03)90013-6

Vavrík, V, Gregor, M & Grznár, P, 2017, ´Computer

simulation as a tool for the optimization of logistics

using automated guided vehicles´ in Procedia

Engineering 192, pp. 923-928.

SIMULTECH 2019 - 9th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

292