Neural Network Contour Error Prediction of a Bi-axial Linear Motor

Positioning System

Krystian Erwinski

a

, Karol Kowalski and Marcin Paprocki

b

Departament of Automatics and Measurement Systems, Faculty of Physics Astronomy and Informatics,

Nicolaus Copernicus University in Torun, Grudziadzka 5, Torun, Poland

Keywords: Following Error, Contour Error, Prediction, Narx Neural Network, NURBS, Linear Motor, Feed Drive Model.

Abstract:

In the article a method of predicting contour error using artificial neural network for a bi-axial positioning

system is presented. The machine consists of two linear stages with permanent magnet linear motors controlled

by servo drives. The drives are controlled from a PC with real-time operating system via EtherCAT fieldbus. A

randomly generated Non-Uniform Rational B-Spline (NURBS) trajectory is used to train offline a NARX-type

artificial neural network for each axis. These networks allow prediction of following errors and contour errors

of the motion trajectory. Experimental results are presented that validate the viability of the neural network

based contour error prediction. The presented contour error predictor will be used in predictive control and

velocity optimization algorithms of linear motor based CNC machines.

1 INTRODUCTION

Multi axis machines are widely used in industrial

manufacturing in the form of numerically controlled

machine tools (CNC) and robots. Each mechanical

axis is driven by a linear or rotary feed drive. Com-

position of their movements constitutes the output

motion trajectory of the machine’s end effector (i.e.

milling tool, laser head, welding head, gripper) also

called a toolpath. Position commands for each feed

drive are generated by interpolating the given tool

path according to pre-planned or on-line generated

velocity profiles.

In order to enhance machine performance much

attention has been given to improving the motion

planning process by developing new feedrate profile

generation algorithms. Several authors propose us-

ing optimization algorithms to generate an optimal

feedrate profile (Xu et al., 2018; Ni et al., 2018;

Zhang et al., 2019). An optimal feedrate profile maxi-

mizes speed while simultaneously respecting the feed

drives’ and machine’s constraints in order to shorten

machining time. Most approaches neglect the influ-

ence of machining errors in the feedrate planning pro-

cess. Machining errors are often defined as contour

errors which are the minimum distances between the

a

https://orcid.org/0000-0001-6899-1785

b

https://orcid.org/0000-0003-2687-1181

reference toolpath and actual tool positions (Ramesh

et al., 2005; Tang and Landers, 2013) as shown in

figure 1. Some authors propose including error con-

straints in the feedrate planning process but usually

use simplified models that do not accurately predict

actual following errors (Jia et al., 2017).

ɸ

dž

ɸ

LJ

ɸ

Đ

Z

ŝ

W

ŝ

Figure 1: Contour error definition. ε

c

- contour error, ε

x,y

- axis following errors, R

i

- toolpath reference point, P

i

-

actual toolpath point.

Optimizing feedrate with respect to contour er-

ror constraints is especially important for machines

that utilize linear motor feed drives such as laser cut-

ters. These machines can achieve very high speeds

802

Erwinski, K., Kowalski, K. and Paprocki, M.

Neural Network Contour Error Prediction of a Bi-axial Linear Motor Positioning System.

DOI: 10.5220/0007957908020809

In Proceedings of the 16th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2019), pages 802-809

ISBN: 978-989-758-380-3

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

and accelerations which significantly reduces machin-

ing time. At the same time they simultaneously

need to ensure accurate toolpath following. Most

multi axis machines use permanent magnet rotary

synchronous motors which produce rotary motion and

torque. Some mechanism is usually required to con-

vert rotation into linear motion. These are usually

ballscrews, racks and pinions or toothed belts some-

times with an additional reduction gear. Permanent

magnet linear synchronous motors produce linear mo-

tion directly without the need for additional mecha-

nisms. This has the advantage of greatly simplifying

the machines construction and eliminating backlash

and compliance in the feed drive which leads to de-

creased following errors. On the other hand the linear

motor does not have the mechanical advantage pro-

vided by these mechanisms and has to drive the ma-

chines mass directly. Linear motors are controlled us-

ing the same field oriented control techniques used in

rotary motors therefore the same servo drives can usu-

ally be used.

The authors previously developed a feedrate opti-

mization method which accounts for contour error for

traditional ballscrew driven machines (Erwinski et al.,

2016; Szczepanski et al., 2017). A fundamental re-

quirement for such an algorithm is an accurate pre-

dictor which can predict the contour error generated

by the feed drive (both the servo drive and the me-

chanical part). It is important that the parameters of

the predictor used are easy to identify and can be eas-

ily ported to any machine with any servo drive. The

main contribution of the paper is the development of

a contour error predictor that can perform a multi-

step-ahead prediction of the contour error based on

a velocity demand input signal. The proposed pre-

dictor is a non-linear black-box input-output model

that accounts for the dynamics of both the servo drive

and mechanical components of the linear motor feed

drive. This predictor will be used in a multi-axis ma-

chine feedrate optimization algorithm to constrain the

maximum contour error by adjusting the feedrate pro-

file. The authors will implement this approach for lin-

ear motor based machines which will be an extension

of their previous works.

2 BI-AXIAL LINEAR MOTOR

POSITIONING SYSTEM

The linear motor positioning system used in this re-

search consists of two linear motor positioning units

representing X and Y axes of a multi-axis machine.

The positioning units use Tecnotion TM6 iron core

flat linear motors mounted on an aluminium chas-

sis with linear roller guideways. The motors are

controlled by Kollmorgen AKD-P00307 servo drives

with feedback provided by Renishaw optical linear

scales. The high resolution feedback provides po-

sitioning accuracy of around 0.01 micrometre. The

positioning units’ servo drives receive position, ve-

locity or torque commands from a PC-based numeri-

cal controller via EtherCAT fieldbus (Jansen and But-

tner, 2004; Paprocki et al., 2018). The PC controller

runs TwinCAT 3 real-time control software on a stan-

dard Windows 10 operating system. Special real-time

mechanism implemented in TwinCAT such as pro-

cessor core isolation ensure hard real-time operation

of the CNC controller. This allows for implementa-

tion of typical PLC or CNC controllers in software

without any dedicated hardware extensions. Twin-

CAT also implements a real-time EtherCAT commu-

nication stack and driver which enables determinis-

tic communication with many commercial automa-

tion equipment such as servo drives or input output

devices.

TwinCAT also enables the user to implement cus-

tom real-time control programs in C++. This ap-

proach was used in this research to develop a trajec-

tory interpolator for both linear axes. The intepolator

generates position commands in 250 microsecond in-

tervals and sends them over EtherCAT to the drives

to realize the reference motion trajectory. The de-

veloped software can also send direct commands to

the drive over Ethercat to initiate the device, perform

homing, clear errors and change between position, ve-

locity and torque modes according to the Can in Au-

tomation CIA402 device profile. The picture of the

linear motor positioning system test stand is shown of

figure 2 and its schematic is shown of figure 3.

Figure 2: Linear motor positioning system test stand.

The linear motor motion path is defined as a third

order Non-Uniform Rational B-Spline (NURBS)

(Piegl and Tiller, 2012). Such path description is often

used in CNC machining because of guaranteed conti-

nuity, ability of local shape modification and ability

to easily describe complex shapes (Heng and Erkork-

maz, 2010; Liu et al., 2015). Interpolation of NURBS

Neural Network Contour Error Prediction of a Bi-axial Linear Motor Positioning System

803

ƚŚĞƌd /ϰϬϮ

ƌĞĂůͲƚŝŵĞ ĚƌŝǀĞƌ

WͲďĂƐĞĚ ĐŽŶƚƌŽůůĞƌ

Figure 3: Linear motor positioning system test stand

schematic.

toolpaths is performed according to a predefined, op-

timized polynomial feedrate profile. This allows to

maximize drive capabilities without violating their

speed and acceleration limits.

3 LINEAR MOTOR FEED DRIVE

MODEL

Main factors that contribute to the dynamics of the

linear motor positioning system are the mass of the

motor and carriage attached it and guideway friction.

Due to lack of a drive train effects such as backlash

or compliance do not influence the positioning accu-

racy. An additional effect typical of flat iron core lin-

ear motors is the cogging force. This force is due to

the attraction between the motor’s iron core and the

permanent magnets and is dependent on their relative

position. This causes a periodic force ripple the fre-

quency of which is proportional to the motor speed

and magnet pitch (distance between adjacent magnet

poles).

The cogging force has significant effect on po-

sitioning accuracy mainly at low speeds. Because

this effect depends only on motor position it can be

mapped and eliminated by using static feedforward

compensation. This functionality is implemented in

the Kollmorgen AKD servodrives and was used in this

research to significantly eliminate its effect on posi-

tioning accuracy.

Friction force is influenced by several friction

components. When the drive tries to move the mo-

tor from standstill it has to overcome static friction.

Then as the speed increases the friction force drops

and after reaching a certain speed rises again. This

is called the Stribeck effect and the velocity at which

the friction minimum is reached is the Stribeck ve-

locity. Friction then increases as a linear function of

speed and this component is called the viscous fric-

tion. There is also a constant velocity independent

component called the Coulomb friction which de-

pends only on mass. Friction is usually assumed to be

symmetric for positive and negative velocities. This

is not always the case if the motion unit is inclined or

the guideways are not exactly parallel to each other.

A block schematic of the linear motor feed drive is

presented in figure 4.

1/M

v

a

x

F

F

cog

F

fri

ŶŽŶͲůŝŶĞĂƌ

ĨƌŝĐƚŝŽŶ

ĐŽŐŐŝŶŐ

ĨŽƌĐĞ

+

+

-

+

Figure 4: Linear motor model, M - motor and carriage mass,

a - motor acceleration, v - motor speed, x - motor position,

F

f ri

- friction force, F

cog

- cogging force.

In order to identify the Linear Motor Feed Drive

Model a series of experiments were performed on the

system. In order to identify carriage mass a current

step command of 2A was issued and actual veloc-

ity was measured. Total carriage and motor forcer

mass was identified using MATLAB System Identifi-

cation Toolbox to be 3.61kg. In order to identify fric-

tion a series of constant positive and negative veloc-

ity movements were performed in velocity mode from

0.1 mm/s to 2000 mm/s. Motor current was measured

for each run in order to determine the friction force.

This current was averaged to eliminate any force rip-

ples and multiplied by the motor force factor Kf equal

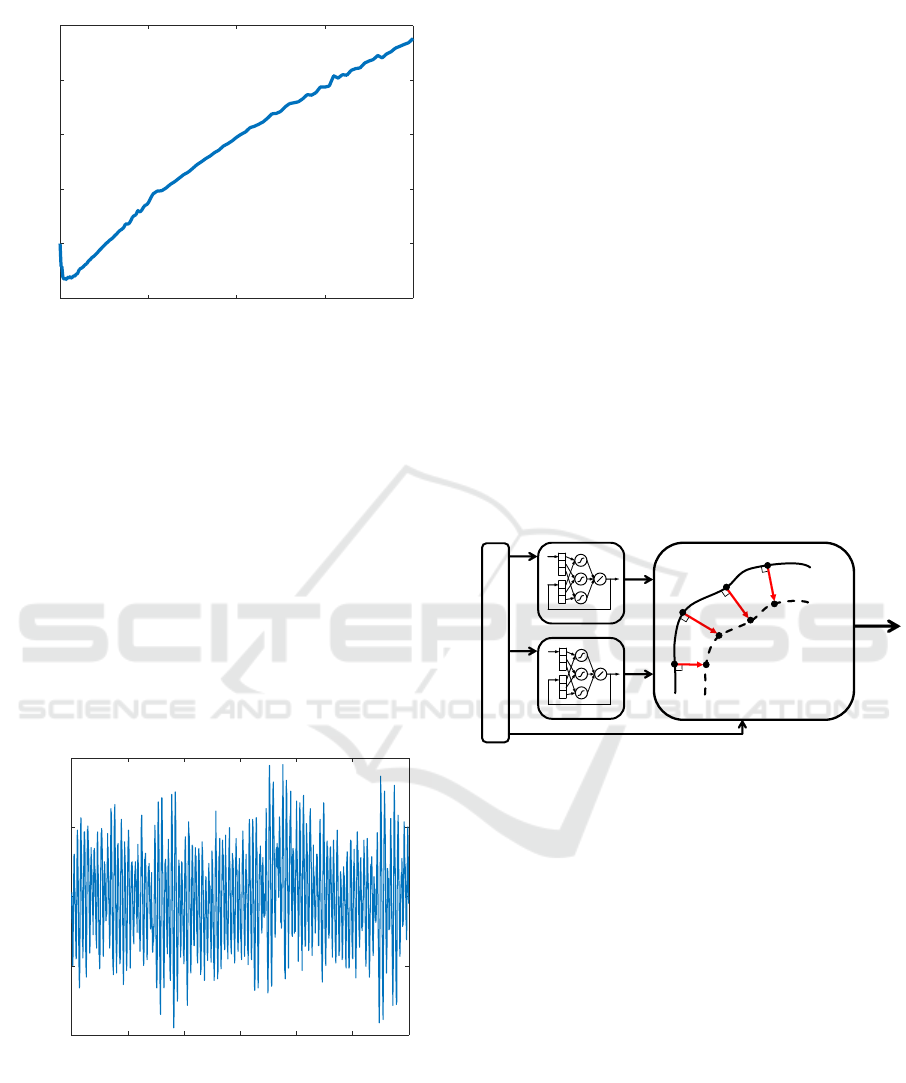

to 39. The resulting friction map is shown in figure 5.

It can be clearly seen that for large velocities from

about 500mm/s the viscous does not increase linearly

with the increase in speed as is usually assumed. The

discrepancy between a linear friction characteristics

and actual friction curve is significant at large speeds.

For 2 m/s the actual friction current is 20% smaller

than a linear friction model would predict. The linear

motor also has a large static friction requiring about

ICINCO 2019 - 16th International Conference on Informatics in Control, Automation and Robotics

804

0 500 1000 1500 2000

Velocity [mm/s]

400

500

600

700

800

900

Friction Current [mA]

Figure 5: Current due to friction as a function of velocity.

500mA current to start motion. This was identified by

generating a ramp current command and recording the

amount of current at which the motor starts to move.

This is caused by large magnet attraction forces and

lack of mechanical advantage offered by traditional

drive train mechanisms.

Cogging force was also identified during constant

velocity movement of 5 mm/s. Because this effect

is depends motstly on motor position a current ver-

sus position table can be recorded and used for feed-

forward compensation. Figure 6 presents the drive

current as a function of position. The period corren-

sponds to distance of 12mm which is the distance be-

tween north and south poles of the permanent magnet

track.

0 200 400 600 800 1000 1200

Position [mm]

-0.5

-0.25

0

0.25

0.5

Current [A]

Figure 6: Linear motor (Tecnotion TM6) current due to cog-

ging force at constant speed of 5 mm/s in velocity mode.

It is clear that the linear motor positioning system

although mechanically very simple has non-linear

characteristics. Identification of a model presented in

fig. 4 is time consuming and requires switching the

drive to velocity and torque modes. This is not always

possible on commercial multi-axis machines. Also

when using off-the-shelf servo drives the actual con-

troller structure is not always precisely known. Due

to these problems a black box modelling approach is

used instead in order to obtain following and contour

error predictions.

4 NARX NEURAL NETWORK

CONTOUR ERROR

PREDICTION

In order to obtain contour error predictions of a linear

motor positioning system with NURBS motion path

definition following error prediction of each axis have

to be determined first. Predicted following errors are

combined with information about local toolpath ge-

ometry to obtain and estimated contour error. The

structure of a neural network contour error predictor

is shown in figure 7.

EhZ^/EdZWK>dKZ

s

dž

ɸ

dž

ɸ

LJ

EhZ>EdtKZ<

&K>>Kt/E'ZZKZWZ/dKZ^

KEdKhZZZKZ

KDWhdd/KE

ɸ

Đ

EhZ^dKK>Wd,'KDdZz

s

LJ

Z

ŝ

Z

ŝнϭ

Z

ŝнϮ

Z

ŝнϯ

W

ŝнϭ

W

ŝнϮ

W

ŝнϯ

W

ŝ

Figure 7: Structure of neural network prediction block.

Prediction of axis following errors is performed

by using a Non-Linear Auto Regressive Exogenous

Input Neural Network (NARX). Such networks dif-

fer from traditional multi-layered perceptrons (MLP)

by adding a feedback between output and input lay-

ers and delays in the input layer. This allows to

model non-linear dynamical systems. An example of

a NARX neural network used for following error pre-

diction is presented in figure 8. Reference velocity

obtained from differentiating polynomial toolpath and

feedrate profile is used as input.

Training the network is a process of minimizing

the mean squared errors based on error backpropa-

gation. Training of the NARX following error pre-

dictor is performed first in series-parallel form where

the network feedback is disconnected and target series

(following error) is fed into the network along the in-

put signal (reference velocity). In this form standard

static network training algorithms are used (Xie et al.,

2009). Training is finished when the prediction error

Neural Network Contour Error Prediction of a Bi-axial Linear Motor Positioning System

805

nj

Ͳϭ

nj

Ͳϭ

nj

Ͳϭ

ǀ;ƚͲϮͿ

ǀ;ƚͿ

ǀ;ƚͲϯͿ

Ğ;ƚͲϯͿ

Ğ;ƚͲϮͿ

Ğ;ƚͲϭͿ

ǀ;ƚͲϭͿ

nj

Ͳϭ

nj

Ͳϭ

nj

Ͳϭ

Ğ;ƚͿ

н

н

н

н

Figure 8: Example structure of a NARX neural network

used for following error prediction.

stops decreasing. The feedback is then reconnected

and training is continued in parallel form. In this

form dynamic training algorithms such as backpropa-

gation through time have to be used. These are more

computationally demanding and are sensitive to ini-

tial weight values (Horne and Giles, 1995). Weights

obtained from the series-parallel training phase are

used as initial guess for parallel training which gives

good initial values and decreases total training time.

Training is finished when the prediction error does not

change significantly for some period of time. MAT-

LAB Neural Network Toolbox function TRAINBR is

used to train the network.

If motion paths are defined as Non-Uniform

Rational B-Splines (NURBS) or other polynomial

curves the contour error cannot be computed exactly

and has to be estimated (Uchiyama et al., 2011). Sev-

eral contour error estimation techniques for free-form

toolpaths have been proposed (Yeh and Hsu, 2002;

Huo et al., 2012; Sencer et al., 2009; Chen et al.,

2008). All of these are either simple estimates which

have large errors for curves with high curvatures or

are computationally demanding. In one interesting

algorithm proposed in (Zhu et al., 2013) the contour

error vector is approximated by a Taylor series which

yields accurate estimates without high computational

demand. This method was chosen for developing the

contour error predictor. The contour error is estimated

using the following closed form formula:

~

ε

c

=

−~c −

1

2

κ ( ˆc · ˆn)(

ˆ

t ·

~

ε

t

)

ˆ

t

1 −κ (ˆc · ˆn)

·

~

ε

t

(1)

ˆc = −

~

ε

t

·

ˆ

t

p

||

~

ε

t

||

2

−

~

ε

t

·

ˆ

t

ˆ

t +

1

p

||

~

ε

t

||

2

−

~

ε

t

·

ˆ

t

~

ε

t

(2)

where: κ - toolpath curvature at the reference

point,

ˆ

t, ˆn - tangent and normal unit vectors at the ref-

erence point,

~

ε

t

- following error vector. Curvature,

tangent and normal vectors can be computed using the

following formulas:

κ =

||C

0

(u) ×C

00

(u)||

||C

0

(u)||

3

(3)

ˆ

t =

C

0

(u)

||C

0

(u)||

ˆ

b =

C

0

(u) ×C

00

(u)

||C

0

(u) ×C

00

(u)||

ˆn =

ˆ

b(u) ×C

0

(u)

||

ˆ

b(u) ×C

0

(u)||

(4)

where: C

0

(u),C

00

(u) - are first and second derivatives

of the NURBS toolpath position vector with respect

to the toolpath parameter u obtained from the NURBS

interpolator.

5 EXPERIMENTAL RESULTS

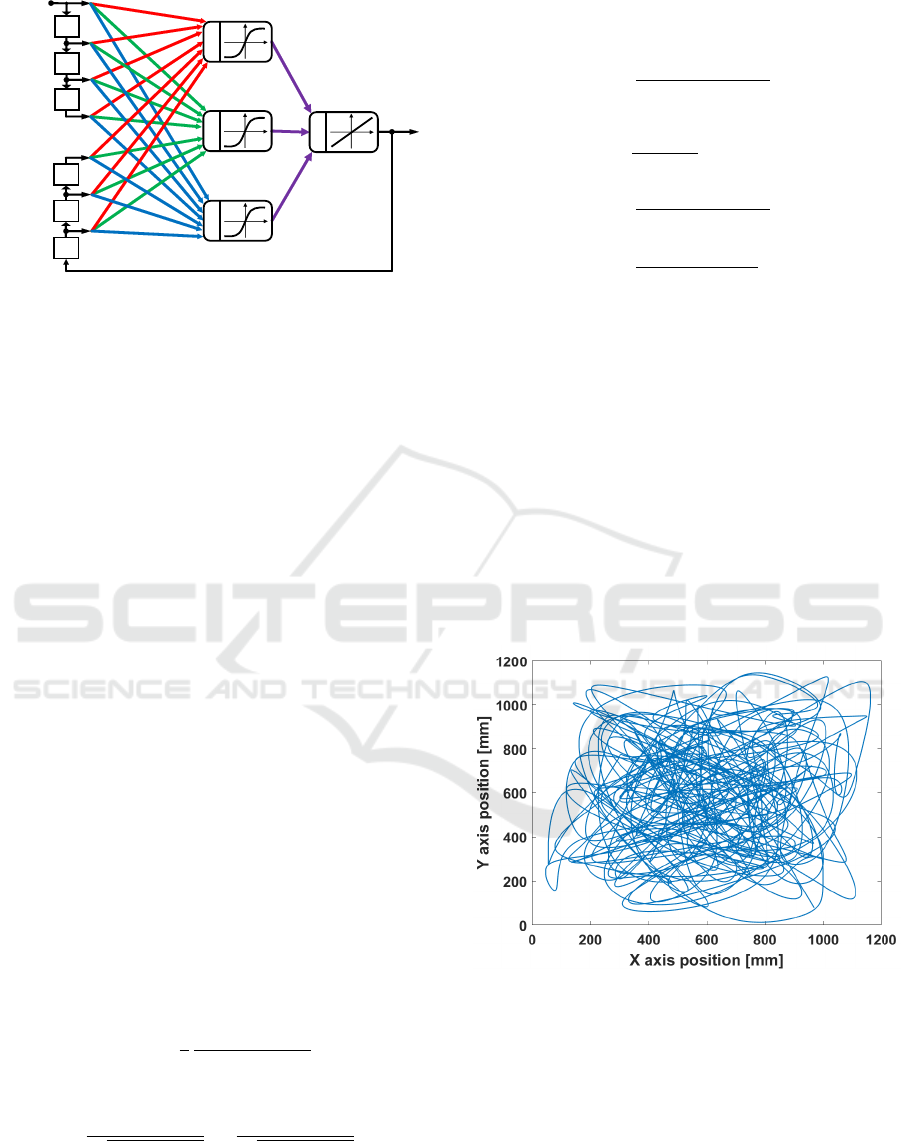

In order to generate training data for training the con-

tour error predictor a NURBS trajectory was con-

structed by randomly generating curve control points

in the whole positioning system travel range between

0 and 1200mm in both axes. The toolpath used is pre-

sented in figure 9.

Figure 9: Randomly generated NURBS curve motion path

used for neural network training.

A feedrate profile was generated which forced

high variations and values of velocity,acceleration

and jerk in each axis while simultaneously keeping

them within safe limits. The maximum values of ve-

locity, acceleration and jerk were set to 2500mm/s,

25000mm/s

2

and 500000mm/s

3

respectively. This

was done to sufficiently capture following error dy-

namics and avoid drive saturation and positioning sys-

tem damage. The motion path was executed using the

ICINCO 2019 - 16th International Conference on Informatics in Control, Automation and Robotics

806

feedrate profile using the PC-based controller control-

ling the linear motor positioning system. Axis veloc-

ity demand and actual following error for each axis

were recorded and transfered to MATLAB. Datasets

of velocity demand (input) and following error (tar-

get) were generated with 455559 samples (at 0.25 ms

sampling rate) for both X and Y axes. The velocity

demand signal and following errors are shown on fig-

ures 10 and 11. Only the first half of each dataset was

used as a training set. The second half was used for

validation.

0 1 2 3 4

10

5

-3000

-1500

0

1500

3000

X axis velocity [mm/s]

0 1 2 3 4

sample number

10

5

-3000

-1500

0

1500

3000

Y axis velocity [mm/s]

Figure 10: Velocity demand for x and y axes (input values)

used in training and testing.

Training was performed for each axis NARX neu-

ral network multiple times in order to determine the

best network architecture (trial and error approach)

by using an automated script in MATLAB. Each net-

work was trained first in series-parallel mode and then

further trained in parallel mode. A training period of

2000 epochs and 4000 epochs in the series-parallel

and parallel mode respectively was used. A NARX

neural network with 5 input, 4 feedback delays and 6

sigmoid hidden neurons was chosen as the following

error predictor for X and Y axes. This network struc-

ture achieved the lowest following error prediction

mean squared error. Prediction mean squared error of

6.59e-4 mm and 4.75e-4 mm was achieved for the X

and Y axis respectively. If only series-parallel train-

ing was to be used, the training would complete much

faster but at the cost of much worse mean squared pre-

0 1 2 3 4

10

5

-0.8

-0.4

0

0.4

0.8

X axis following error [mm]

0 1 2 3 4

Sample number

10

5

-0.8

-0.4

0

0.4

0.8

Y axis following error [mm]

Figure 11: Following error for x and y axes (target values)

used in training and testing.

diction error (5e-1 mm average).

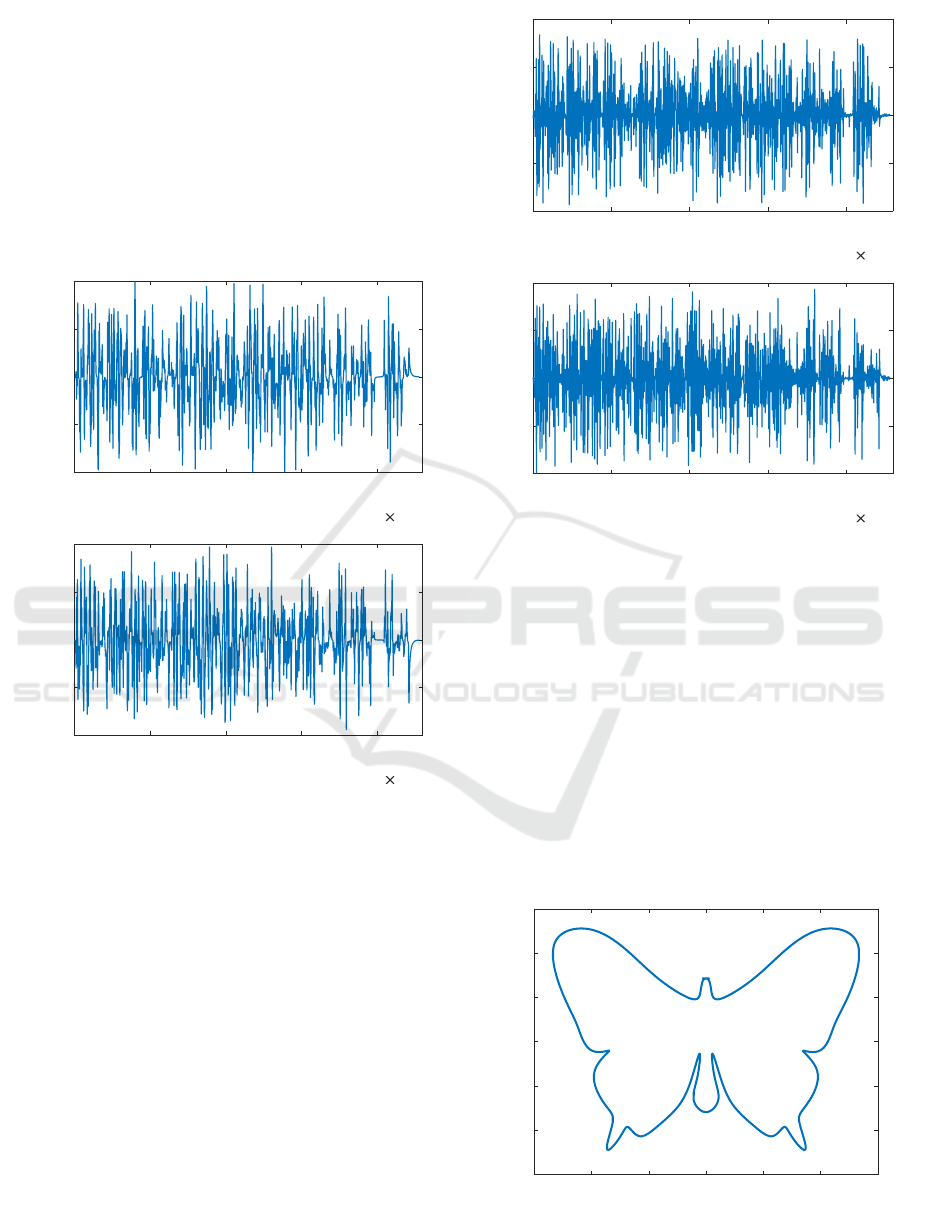

In order to test the contour error prediction error

for a typical trajectory another toolpath was used. The

obtained neural network contour error predictor was

used to verify contour error prediction accuracy of a

butterfly curve (figure 12). An appropriate feedrate

profie with the same limits as stated above was gen-

erated. The curve was run on the linear motor po-

sitioning system and actual contour error was com-

puted and compared with values predicted from the

proposed predictor.

0 200 400 600 800 1000 1200

X axis position [mm]

0

200

400

600

800

1000

1200

Y axis position [mm]

Figure 12: Butterfly NURBS curve motion path.

Neural Network Contour Error Prediction of a Bi-axial Linear Motor Positioning System

807

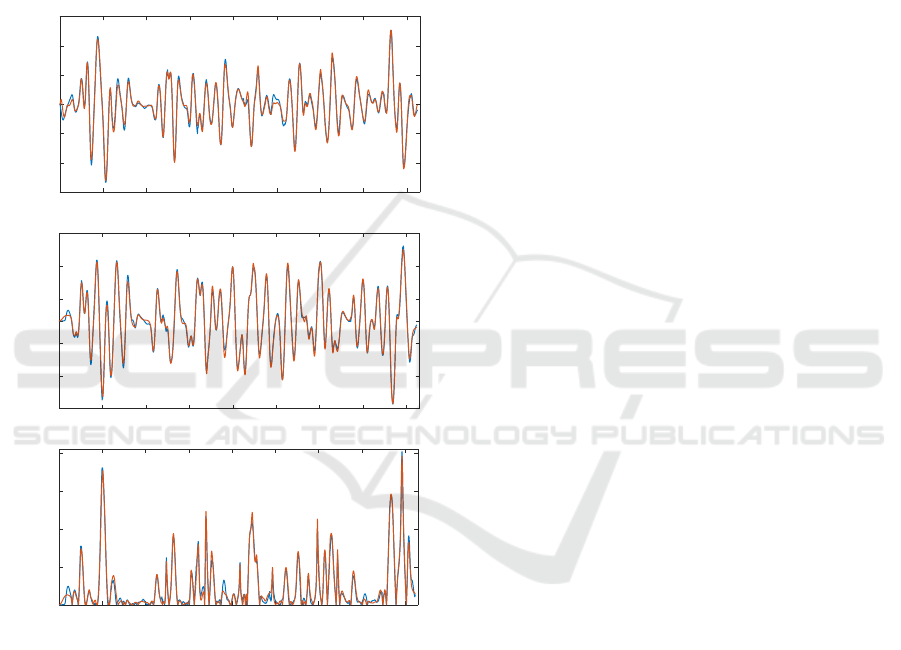

Figure 13 presents a comparison of following and

contour error resulting from realizing the actual mo-

tion path and predicted using the NARX contour error

predictor. The mean squared error (MSE) of contour

error prediction is 2.6921e-04 mm. It can be seen that

the predictor is able to accurately predict actual fol-

lowing errors and by extent the actual contour error.

It should be noted that the test toolpath was not used

in the neural network training process and the accu-

rate prediction is due to neural network generalization

abilities.

0 1 2 3 4 5 6 7 8

-0.6

-0.4

0.2

0

0.2

0.4

0.6

X following error [mm]

0 1 2 3 4 5 6 7 8

-0.6

-0.4

0.2

0

0.2

0.4

0.6

Y following error [mm]

0 1 2 3 4 5 6 7 8

time [s]

-0.6

-0.4

0.2

0

0.2

contour error [mm]

Figure 13: Predicted (orange) and actual (blue) follow-

ing error and contour error for validation dataset (butterfly

curve).

6 CONCLUSION

The article presents a contour error predictor for a bi-

axial linear motor positioning system based on neural

networks. Experimental results are presented which

show that linear motor exhibits non-linear dynamics

mainly due to non-linear friction at very low and very

high speeds. Due to complexity of identifying partic-

ular friction components and potentially incomplete

information about the commercial drive control struc-

ture a black box approach to predicting contour error

is proposed. This approach uses NARX neural net-

works to predict following errors of each axis. This in

turn is used to estimate contour error based on local

motion path geometry.

Experimental results show good accuracy in pre-

dicting contour error of a NURBS motion path. Ma-

jor advantage of this approach is the quick and easy

identification procedure. Actual toolpaths can be used

with following errors obtained during normal ma-

chine operation. Identification experiments in veloc-

ity and torque modes are not required. The neural

network can generalize and accurately predict actual

following and contour errors for toolpaths not used in

the training process.

The main contribution of this paper is developing

a fast and easy to use method to predict contouring

error in multi axis positioning systems such as CNC

machine tools. Compared to other modelling tech-

niques in literature this approach can use following

error data collected during normal machine opera-

tion. This allows considerable time savings because

dedicated identification experiments in velocity and

torque modes are avoided. The contour error predic-

tor will be used to develop an on-line feedrate op-

timization method for linear motor based multi axis

machines. Using The contour error predictor can also

be used for predictive control of such machines. Pre-

dictive techniques require a model to generate an op-

timal control signal. The proposed predictor in the

form of NARX neural networks is easy to implement

and computationally efficient.

ACKNOWLEDGEMENTS

This research has been financed from the funds of the

Polish Ministry of Science and Higher Education for

statutory R&D activities supporting the development

of young scientists and PhD students (internal grant

no. 1035-F/2018)

REFERENCES

Chen, X., Yong, J., Wang, G., Paul, J., and Xu, G.

(2008). Computing the minimum distance between

a point and a nurbs curve. Computer-Aided Design,

40(10):1051–1054.

Erwinski, K., Paprocki, M., Wawrzak, A., and Grzesiak,

L. M. (2016). Pso based feedrate optimization with

contour error constraints for nurbs toolpaths. In 2016

21st International Conference on Methods and Mod-

ICINCO 2019 - 16th International Conference on Informatics in Control, Automation and Robotics

808

els in Automation and Robotics (MMAR), pages 1200–

1205. IEEE.

Heng, M. and Erkorkmaz, K. (2010). Design of a nurbs in-

terpolator with minimal feed fluctuation and continu-

ous feed modulation capability. International Journal

of Machine Tools and Manufacture, 50(3):281–293.

Horne, B. G. and Giles, C. L. (1995). An experimental

comparison of recurrent neural networks. In Advances

in neural information processing systems, pages 697–

704.

Huo, F., Xi, X.-C., and Poo, A.-N. (2012). Generalized

taylor series expansion for free-form two-dimensional

contour error compensation. International Journal of

Machine Tools and Manufacture, 53(1):91–99.

Jansen, D. and Buttner, H. (2004). Real-time ethernet: the

ethercat solution. Computing and Control Engineer-

ing, 15(1):16–21.

Jia, Z.-y., Song, D.-n., Ma, J.-w., Hu, G.-q., and Su, W.-

w. (2017). A nurbs interpolator with constant speed

at feedrate-sensitive regions under drive and contour-

error constraints. International Journal of Machine

Tools and Manufacture, 116:1–17.

Liu, H., Liu, Q., Zhou, S., Li, C., and Yuan, S. (2015).

A nurbs interpolation method with minimal feedrate

fluctuation for cnc machine tools. The Interna-

tional Journal of Advanced Manufacturing Technol-

ogy, 78(5-8):1241–1250.

Ni, H., Hu, T., Zhang, C., Ji, S., and Chen, Q. (2018).

An optimized feedrate scheduling method for cnc ma-

chining with round-off error compensation. The In-

ternational Journal of Advanced Manufacturing Tech-

nology, 97(5-8):2369–2381.

Paprocki, M., Wawrzak, A., Erwinski, K., and Klosowiak,

M. (2018). Flexible pc-based cnc machine control sys-

tem. Mechanik, 91(4):299–303.

Piegl, L. and Tiller, W. (2012). The NURBS book. Springer

Science & Business Media.

Ramesh, R., Mannan, M., and Poo, A. (2005). Tracking

and contour error control in cnc servo systems. Inter-

national Journal of Machine Tools and Manufacture,

45(3):301–326.

Sencer, B., Altintas, Y., and Croft, E. (2009). Modeling

and control of contouring errors for five-axis machine

tools. part i: Modeling. Journal of manufacturing sci-

ence and engineering, 131(3).

Szczepanski, R., Erwinski, K., and Paprocki, M. (2017).

Accelerating pso based feedrate optimization for

nurbs toolpaths using parallel computation with

openmp. In 2017 22nd International Conference

on Methods and Models in Automation and Robotics

(MMAR), pages 431–436. IEEE.

Tang, L. and Landers, R. G. (2013). Multiaxis contour con-

trol—the state of the art. IEEE Transactions on Con-

trol Systems Technology, 21(6):1997–2010.

Uchiyama, N. et al. (2011). Contouring controller design

based on iterative contour error estimation for three-

dimensional machining. Robotics and Computer-

Integrated Manufacturing, 27(4):802–807.

Xie, H., Tang, H., and Liao, Y.-H. (2009). Time series

prediction based on narx neural networks: An ad-

vanced approach. In 2009 International conference

on machine learning and cybernetics, volume 3, pages

1275–1279. IEEE.

Xu, G., Chen, J., Zhou, H., Yang, J., Hu, P., and Dai, W.

(2018). Multi-objective feedrate optimization method

of end milling using the internal data of the cnc sys-

tem. The International Journal of Advanced Manu-

facturing Technology, pages 1–17.

Yeh, S. and Hsu, P. (2002). Estimation of the contour-

ing error vector for the cross-coupled control design.

IEEE/ASME Transactions on Mechatronics, 7(1):44–

51.

Zhang, Y., Ye, P., Zhao, M., and Zhang, H. (2019). Dy-

namic feedrate optimization for parametric toolpath

with data-based tracking error prediction. Mechani-

cal Systems and Signal Processing, 120:221–233.

Zhu, L., Zhao, H., and Ding, H. (2013). Real-time con-

touring error estimation for multi-axis motion systems

using the second-order approximation. International

Journal of Machine Tools and Manufacture, 68(5):75–

80.

Neural Network Contour Error Prediction of a Bi-axial Linear Motor Positioning System

809