Data Analytics for Smart Manufacturing: A Case Study

Nadeem Iftikhar

1

, Thorkil Baattrup-Andersen

2

, Finn Ebertsen Nordbjerg

1

, Eugen Bobolea

1

and Paul-Bogdan Radu

1

1

University College of Northern Denmark, Aalborg 9200, Denmark

2

Dolle A/S, Frøstrup 7741, Denmark

Keywords:

Industry 4.0, Data Analytics, Smart Manufacturing, Logistic Regression.

Abstract:

Due to the emergence of the fourth industrial revolution, manufacturing business all over the world is chang-

ing dramatically; it needs enhanced efficiency, competency and productivity. More and more manufacturing

machines are equipped with sensors and the sensors produce huge volume of data. Most of the companies do

neither realize the value of data nor how to capitalize the data. The companies lack techniques and tools to

collect, store, process and analyze the data. The objective of this paper is to propose data analytic techniques

to analyze manufacturing data. The analytic techniques will provide both descriptive and predictive analysis.

In addition, data from the company’s ERP system is integrated in the analysis. The proposed techniques will

help the companies to improve operational efficiency and achieve competitive benefits.

1 INTRODUCTION

Industry 4.0 is a name given to the current trend of

automation and data exchange in manufacturing tech-

nologies (Wiki), where new technologies merge the

physical, digital and biological spheres. Industry 4.0

requires no human involvement in manufacturing and

depends on artificial intelligence, machine learning

and big data technologies. Dolle

1

is a market leader

in Europe for wooden loft ladders. In order to retain

the prospective and competitive position in the inter-

national market and to optimize productivity, Dolle

relies on business analytics. Business analytics can

be used to explore large volumes of data, expose un-

detected patterns, correlations and other new key pro-

duction parameters.

Industry proven Cross-industry Standard Process

for Data Mining (Chapman et al., 1999) is used in

Dolle’s business analytics. It consists of following

phases: business understanding, data understanding,

data preparation, modeling, evaluation and deploy-

ment. This paper presents data analytic techniques

capable of performing both descriptive and predic-

tive analysis. In order to demonstrate the techniques,

a real-world case study from manufacturing indus-

try is selected. The sensor, alarm and enterprise re-

source planning (ERP) system data provided by the

1

www.dolle.eu

case study is first consolidated at a central repository.

Then, an exploratory analysis is performed in order to

gain insight into the real business problems. Further,

a predictive analysis using machine learning is per-

formed. To summarize, the main contributions in this

paper are as follow: (1) Proposing a data pipeline to

handle ingestion, processing and analysis; (2) Provid-

ing an in-depth exploratory analysis of the data; (3)

Presenting a statistical-based model to predict costly

production line disruptions; and (4) Comprehensive

evaluation of the equipment effectiveness and the per-

formance of the proposed model.

The paper is structured as follows. Section 2 de-

scribes the objectives and requirements from a busi-

ness perspective. Section 3 provides initial data un-

derstanding. Section 4 provides data pipeline and

exploratory analysis. Section 5 presents the model.

Section 6 evaluates the equipment effectiveness and

model performance. Section 7 presents the related

work. Section 8 concludes the paper and points out

the future research directions.

2 BUSINESS UNDERSTANDING

The focus of this section is to understand the basic

concepts of smart manufacturing in consultation with

domain experts. Project objectives are derived from

the viewpoint of Dolle requirements and later con-

392

Iftikhar, N., Baattrup-Andersen, T., Nordbjerg, F., Bobolea, E. and Radu, P.

Data Analytics for Smart Manufacturing: A Case Study.

DOI: 10.5220/0008116203920399

In Proceedings of the 8th International Conference on Data Science, Technology and Applications (DATA 2019), pages 392-399

ISBN: 978-989-758-377-3

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

verted into data science problem definitions. Some

of Dolle’s primary objectives, from a business per-

spective are described as follow. When machines are

started, Dolle would like to know how long it takes

before the right output pace with regards to the prod-

uct manufactured is achieved. Output pace is the av-

erage time between the start of production of one unit

and the start of production of the next unit. How fast

are items moving through the machines? What is op-

timal rate? In addition, what are the causes of pro-

duction disruption? Dolle would also like to know

how much time is spent on changeovers. A business

goal states objectives in business terms, whereas, a

data mining goal states objectives in technical terms.

A non-exhaustive list of data mining goals is as fol-

low. What is the frequency of machine stops and total

down time due to faulty strings/screw errors? How

fast are items moving through the machine? What is

the maximum pace and are there any delays in the

pace? Based on historical patterns, predict machine

stops and how to prevent them? What is the overall

downtime of a machine and what are the costs?

In general, production with 80-85 % efficiency is

considered very efficient. It is of interest to look into

every predicted and unpredicted issue/challenge dur-

ing production. Why did it happen? Can it be pre-

dicted and if so can it be prevented or prepared for?

How can production be optimised? Some challenges

during production are known, such as, breakdowns,

changeovers, minor stoppage, reduced speed, defects

and setup scrap. As a result, the success of the manu-

facturing process can be measured by calculating the

Overall Equipment Effectiveness (OEE)

2

. OEE is one

of the most widely used standards for measuring man-

ufacturing productivity.

3 DATA UNDERSTANDING

This section starts with initial data collection and pro-

ceeds with activities that targets understanding the

data. These activities include first insight into the

data, identifying data for analytic purposes, discov-

ering data quality issues and/or detecting interesting

subsets to form hypothesis regarding previously un-

detected patterns. Machine data (sensors and alarms)

and ERP system data (product, job execution and

work calendar) are provided by Dolle. The machine

data is provided in the form of binary values of 0’s

and 1’s. The number of attributes depends on the ma-

chine in question. The product dataset consists of 85

attributes, the job execution dataset consists of 69 at-

2

www.oee.com

tributes and the work calendar dataset contains 10 at-

tributes. Each job represents a specific business task

that is carried out for a certain time interval to produce

particular type of ladders. The structure of the data

does not conform to any standard and additionally no

assumptions can be made that two identical machines

display identical structures. Dolle’s case study clearly

illustrate the challenges faced in data analysis in the

smart manufacturing industry.

In this case study machine data (from the pro-

duction facility) has to be logged in order to regis-

ter the states of the machines. The logged data is

initially kept in detailed format in different database

tables (a separate table for each machine). As men-

tioned above, each machine has a different set of sen-

sors/attributes, for that reason only one of the ma-

chine is considered for demonstration purposes. The

selected machine consists of the following attributes:

(DateTime, MachineOn, PaceIn, PaceOut, FaultyS-

tring, ScrewError, Alarm). The DateTime is a record-

ing of a date and time event at one second granular-

ity. The MachineOn sensor indicates the machine is

running for a given job. The PaceIn of a string/beam

sensor represents an incoming string. The PaceOut

of a ladder sensor represents an outgoing ladder. The

FaultyString sensor signifies the quality of the string,

the bended or twisted strings are regarded as faulty

strings. The ScrewError sensor corresponds to the

screw machine that screw strings into place. Finally,

the Alarm stands in for abnormality in the machine.

To provide a snapshot of data, a real machine

dataset provided by Dolle is used. The snapshot con-

tains 7 attributes for job no. 307810 to produce Click-

Fix type ladder. In Table 1, the granularity of the de-

tailed data is at second by job by machine. For in-

stance, row number 1 reads as follows: DateTime=19-

02-2019 09:53:07 (represents: second granularity. It

is important to note that if the next row has same

values as the previous row in that case the next row

will not be logged to the database, for that reason the

holes at the second granularity are visible), Machi-

neOn=1 (represents: machine is running), PaceIn=0

(represents: no string is entering), PaceOut=1 (repre-

sents: exiting of the ladder), FaultyString=0 (repre-

sents: the quality is OK), ScrewError=0 (represents:

no error) and Alarm=0 (represents: no abnormality).

Whereas, Id is used only for row identification pur-

poses. Further, initial look into the data in Table 1

reveals some interesting facts, such as, the ladder is

produced (row 5) in 09:54:04-09:53:07=57 seconds,

where as, the next ladder is produced (row 10) in

09:56:29- 09:54:04=145 seconds. The delay in the

production of the next ladder is due to the fact that a

screw machine error has caused the delay (row 8).

Data Analytics for Smart Manufacturing: A Case Study

393

Table 1: Snapshot of sensor and alarm data.

Id DateTime MachineOn PaceIn PaceOut FaultyString ScrewError Alarm

1 19-02-2019 09:53:07 1 0 1 0 0 0

2 19-02-2019 09:53:09 1 1 1 0 0 0

. . . . . . . .

3 19-02-2019 09:53:56 1 1 0 0 0 0

4 19-02-2019 09:53:58 1 0 0 0 0 0

5 19-02-2019 09:54:04 1 0 1 0 0 0

6 19-02-2019 09:54:09 1 0 0 0 0 0

7 19-02-2019 09:54:14 1 1 0 0 0 0

. . . . . . . .

8 19-02-2019 09:56:14 1 0 0 0 1 0

9 19-02-2019 09:56:16 1 0 0 0 0 0

10 19-02-2019 09:56:29 1 0 1 0 0 0

11 19-02-2019 09:56:31 1 1 1 0 0 0

12 19-02-2019 09:56:33 1 0 0 0 0 0

After having a first insight into the data, it is ob-

served that data requires thorough cleansing. Data

show a number of issues such as, duplicates, incor-

rect, incomplete and missing values, however, the

most critical issue is the presence of partial dupli-

cates. Partial duplicates means that more than one

row is connected with the same observation, however,

the values in the rows are not exactly the same. Fur-

ther, several interesting subsets are also identified to

form hypothesis regarding initial data patterns. For

example, whether screw machine errors causes more

machine stops than faulty strings.

4 DATA PREPARATION

This section provides insight into the business prob-

lems before performing data modeling. The data

preparation phase include activities, such as data se-

lection, data transformation, data cleaning and data

validation. Data preparation tasks may be performed

several times and not in any given order. During this

phase important issues are addressed like selecting the

relevant data, cleaning of data, discarding unaccept-

able data and how the ERP system data can be inte-

grated into the final data sets. Some of the cleaning

techniques discussed in (Iftikhar et al., 2015) may be

applicable here as well.

Metadata originating from discussions between

data scientists and domain experts has shown great

importance in the process of data validation. Some

meta issues can not be inferred from the sensor data

but require domain expertise like: is the machine out-

put reliable, especially when the alarm is ON, can this

be verified? Logically the answer is YES, as during

production of certain types of ladders the alarm is dis-

regarded. Another anomaly is that the output showed

double the numbers of ladders produced that actually

produced. The reason is that the pace out sensor was

triggered twice in the process of folding the ladder,

this was subsequently corrected in the logging pro-

cess. The other aspect of data validity is adequacy,

is there sufficient amount of data to make valid pre-

dictions? By examining data from one of the ladder

machines where no output was generated the ques-

tion “why”, arises. In this case, the machine in ques-

tion was jammed and the ladder machine could not

deliver it’s output and hence stood still. An addi-

tional sensor would have enabled the predictive abil-

ity to identify why no output was produced. Deci-

sions about the format of the final data sets and gran-

ularity are also made at this phase. When address-

ing the data granularity, the maximum data sample

rate is “1 second”, however, the data set shows that

more than one sensor status changed within the lim-

ited time (see row 11 and 12 in Table 1). It can seen

in row 11 that the PaceIn and PaceOut sensors both

have values “1” at 09:56:31, as there is no change in

the status of the sensors at 09:56:32 for that reason

no row has been recorded. Similarly, row 12 shows

that PaceIn and PaceOut sensors both have values “0”

at 09:56:33, which means that multiple sensors status

changes within 1 second. Based on this observation,

when trying to establish a relation it is important to

know if A follows B or B follows A, hence the used

method of recording sensors status at a granularity of

1 second may not be a good option, it should be at a

finer granularity, such as 500 milliseconds or better.

Another aspect of data preparation phase is to con-

struct data pipelines and perform EDA. The focus of

this paper is on data pipeline and EDA rather than data

cleansing/validation for that reason only data pipeline

and exploratory analysis are further discussed.

DATA 2019 - 8th International Conference on Data Science, Technology and Applications

394

4.1 Data Pipeline

The proposed data pipeline consists of digesting or

processing raw data, extracting meaningful features

and applying machine learning model.

Figure 1: Proposed data pipeline.

Fig. 1 presents the data pipeline along with the

proposed technologies. This pipeline is not specific to

Dolle and may easily be adapted to other situations.

At data acquisition step, raw data is collected from

multiple data sources and stored at a central reposi-

tory. Data acquisition can be performed with Python,

R or Scala. Next, a data wrangling step transforms

the data into a canonical data format. Data clean-

ing, reduction and integration also takes place at this

stage. Further, data exploration step performs initial

descriptive analysis and visualization. For data wran-

gling and exploration, Python’s pandas, Scala’s slick

and R’s dplyr are recommended technologies, where

as, for visualization Python’s matplotlib and seaborn,

Scala’s vegas and R’s ggplot2 are powerful technolo-

gies. Furthermore, data modeling step is the general

concept of building a model that is capable of mak-

ing predictions. For predictive modeling, Python’s

tensorflow and scikit-learn, Scala’s spark mllib & ml

and R’s h2o are well known technologies. In addition,

the dashboard may displays the intput/output pace and

OEE in near real-time. For dashboard, Python’s dash

and bokeh, Scala’s flink and R’s shiny are typical tech-

nologies.

4.2 Exploratory Analysis

Exploratory data analysis (EDA) is primarily a

graphic approach that provides a first insight into the

data. There are no formal set of rules that can be used

in EDA, however, common approaches are: summary

statistics, correlation, visualization and aggregation.

Summary statistics or univariate analysis is the first

step that helps us to understand data. Univariate anal-

ysis is the simplest form of data analysis where the

data being analyzed contains only one variable. Fur-

ther, data correlation or multivariate analysis helps us

to find relationships between two or more variables.

Finding connections between variables also has a cru-

cial impact on choosing and building the predictive

model(s). Data visualization helps us to gain perspec-

tive into the data, such as to find anomalies and to

detect outliers. Finally, data aggregation helps us to

group data from coarser to finer granularities in order

to improve understanding.

The most interesting findings in the univariate

EDA are skewness and kurtosis. Skewness is a mea-

sure of symmetry and kurtosis is a measure of tailed-

ness. The MachineOn (-6.59) variable is extremely

skewed towards right side (98% of the rows shows

that machine is on). FaultyString (6.18) and Screw-

Error (3.08) variables are also extremely skewed to-

wards left. Similarly, MachineOn (41.50) and Fault-

yString (36.24) variables have very high positive Kur-

tosis values that means that MachineOn is substan-

tially peaked towards 1 and FaultyString is peaked to-

wards 0. As, for perfectly symmetrical data the skew-

ness is 0 and kurtosis is 3 for that reason it can be

concluded that at least half of the variables of the ma-

chine data are highly skewed towards either 1 or 0.

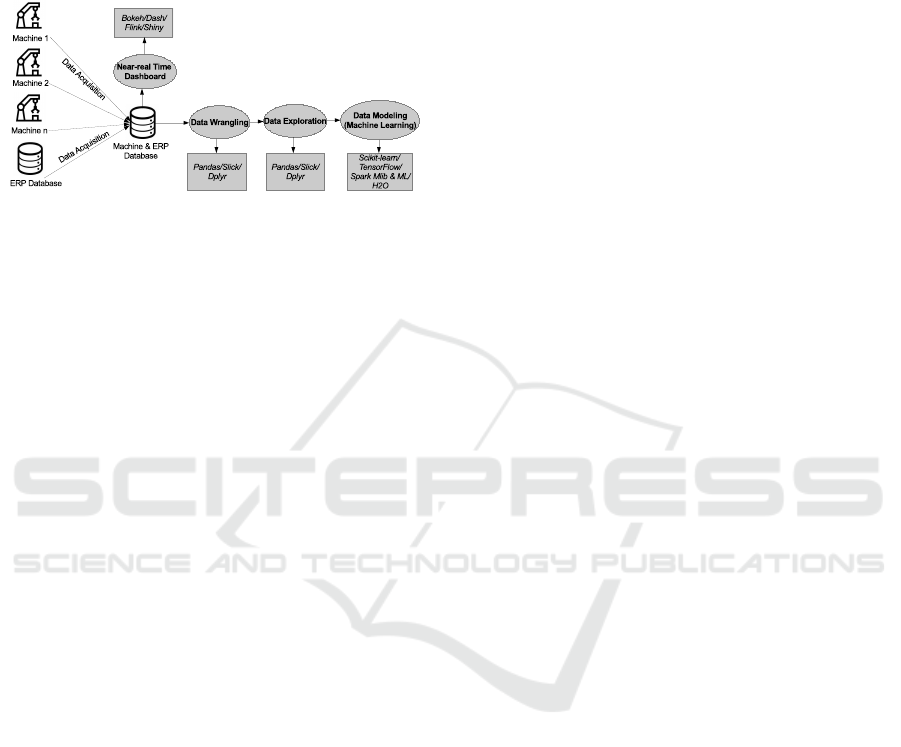

In addition, correlation matrices are constructed to

carry out multivariate EDA. The correlation matrix of

the sensor and the alarm variables at second granular-

ity shows no interdependence. For that reason, data is

being aggregated at daily granularity by job. Fig. 2,

shows some interesting positive and negative correla-

tions. The correlations with respect to pace in, pace

out, screw error, faulty string, machine off, number

of unplanned stops and downtime are of particular in-

terest. Due to the fact that one of the main aims of

this analysis is to figure out which factors slow down

the production and eventually triggers the machine to

stop. The coefficient values (-0.35 and +0.37) be-

tween pace in/out duration and faulty string/machine

stops indicate both weak negative and positive cor-

relations. Further, the coefficient values (+0.37 and

+0.38) between screw error/faulty string duration and

machine stops indicate weak positive correlations.

Moreover, the coefficient values (+0.54 and +0.96)

between downtime and job duration/machine off du-

ration indicate moderate to strong positive correla-

tions. Hence, it can be concluded that screw error and

faulty string both have weak to moderate effect on the

number of unplanned machine stops, however, the du-

ration of these stops have a strong positive correlation

with down time.

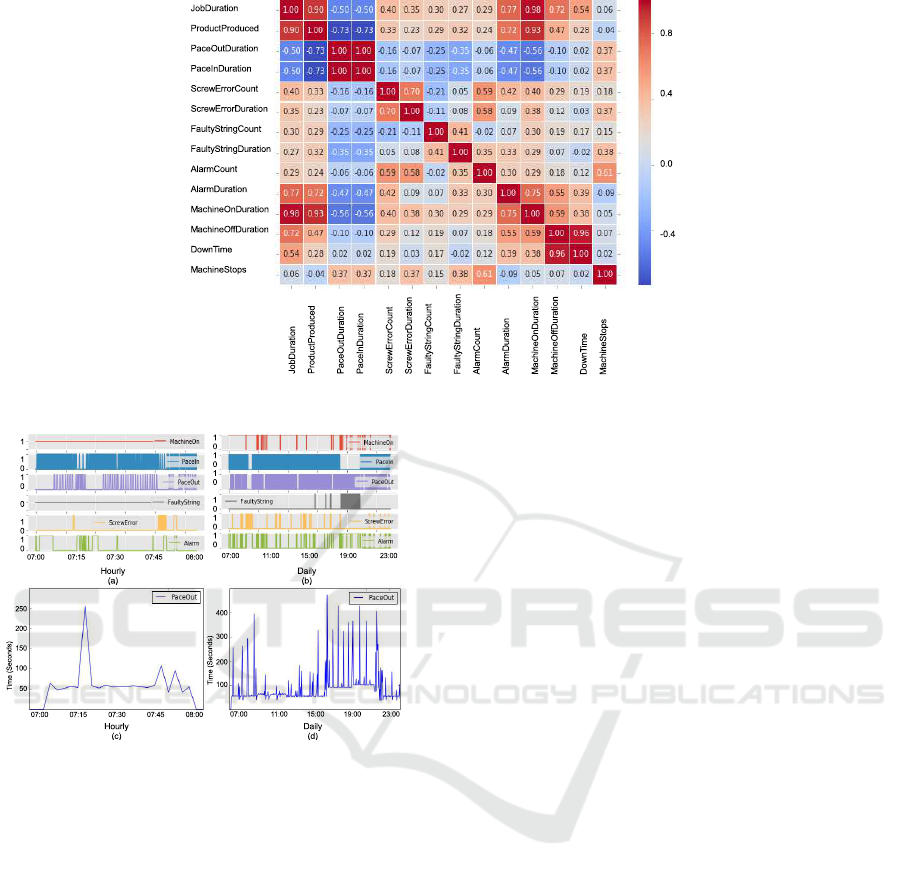

Furthermore, Fig. 3 (a-d) provide an overview of

the sensor and alarm data at hourly and daily granu-

larities, respectively. It is seen in Fig. 3 (a) that the

machine is on almost all the time. The pace of the in-

coming strings is also fine with very few stops, how-

ever, the pace of outgoing ladders has some stops.

Data Analytics for Smart Manufacturing: A Case Study

395

Figure 2: Sensor and alarm (aggregated at daily granularity) correlation heat map.

Figure 3: Sensor and alarm data overview.

The outgoing pace slows down (Fig. 3 (c)) between

07:15 and 07:20 as well as between 07:45 and 07:55.

These slow downs are partly caused by errors in the

screw machine, also both these slow downs trigger

the alarm. Fig. 3 (b) demonstrates that the machine is

on most of the time, incoming pace slows down be-

tween 16:00 and 21:00 mainly due to faulty strings

that also slow down the outgoing pace (Fig. 3 (d)).

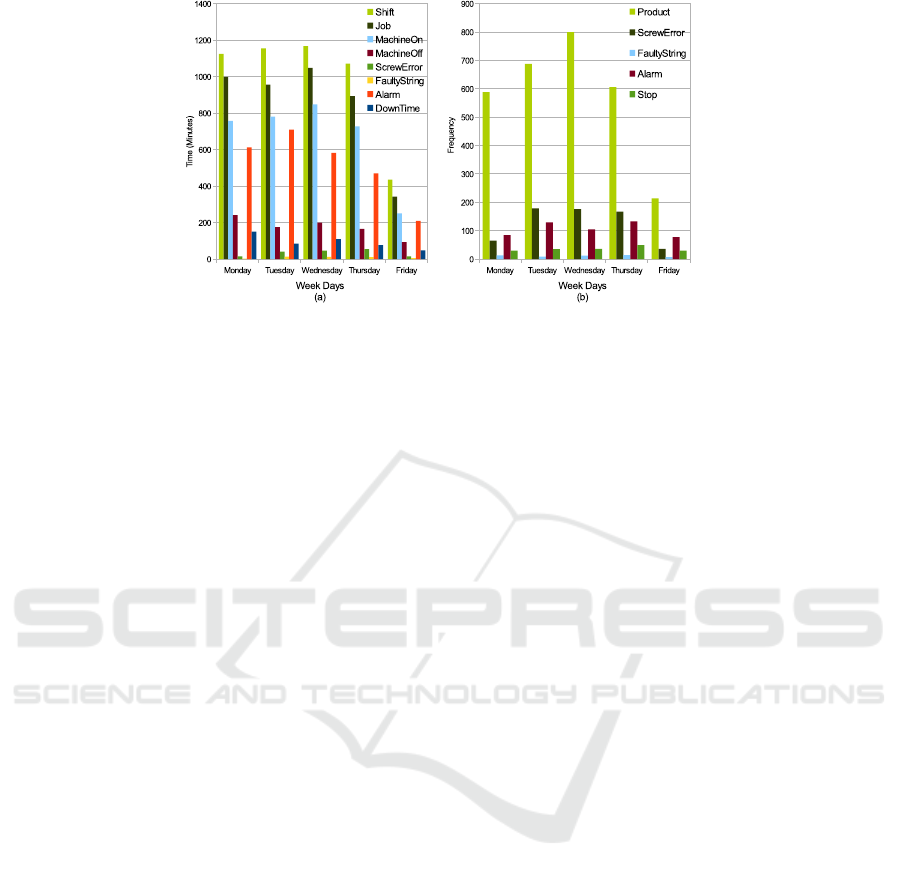

Moreover, the results of the detailed analysis at daily

granularity are illustrated in Fig. 4 (a-b). Fig. 4 (a),

shows that there are opportunities both for undertak-

ing more jobs as well as for increasing the “machine

on” duration. Likewise, “machine off” duration and

downtime are also quite significant. Screw machine

errors are little more frequent than faulty strings and

definitely alarm duration is also quite high. Fig. 4 (b)

presents the frequency of products produced, screw

machines errors, faulty strings, alarms and stops. The

frequency of the screw machine errors, the alarms and

the machine stops are noticeable. The average pace

of incoming strings and outgoing ladders is also cal-

culated. The optimal incoming pace is 9.5 seconds

and outgoing pace is 60 seconds, however, the actual

incoming pace is 15.5 seconds and outgoing pace is

93.5 seconds.

To summarize, the EDA discloses that data is not

uniformly distributed and almost half of the variables

are highly skewed and/or peaked. Further, due to

the binary nature of data, correlation matrices only

reveal weak interdependence between the variables.

In addition, visualisation and aggregations confirm

that screw machines errors are causing more machine

stops than faulty strings and machine downtime needs

to be reduced. In addition, to give these findings a

commercial value a learning loop must be introduced

where the finding are followed by actions and new

data is compared to “old” data to check if actions have

the anticipated effect.

5 MODELING

This section introduces the basic concepts of ma-

chine learning based models and explains some of

the key issues such as model sampling. One of the

main goals of this case study is to predict the ma-

chine’s unplanned stops based on historical conse-

quences/patterns. Based on the kind of data available

and the research question/goal, supervised machine

learning can be used to predict when the machine is

going to stop. Supervised learning algorithms train

from historical data, such as Machine is on “1” or off

“0”. The algorithm determines which label should

be given to new data based on historical patterns.

Most commonly used classification algorithms in ma-

DATA 2019 - 8th International Conference on Data Science, Technology and Applications

396

Figure 4: Detailed data analysis at daily granularity.

chine learning are logistic regression, naive bayes,

support vector machines, decision trees, neural net-

works, ARIMA and so on (Gooijer and Hyndman,

2006). In this paper, logistic regression is used for

the reason that it is one of the frequently used ma-

chine learning approaches for two-class binary clas-

sification. It is called regression, however, it per-

forms classification based on regression by classify-

ing the binary dependent variable into either zero or

one. Out of 1.2 million instances only in 25000 in-

stances the machine is off. Even though the duration

of these stops (downtime) is considerable (Fig. 4 (a)),

still their frequency is only 2%. Meanwhile, major-

ity of the machine learning algorithms presume that

the data set is balanced for that reason the predictions

for minority target class can be poor. As, the minor-

ity target class “MachineOn = 0” (means machine is

off) is the main focus of prediction, thus the data set

has to be re-sampled. Two common approaches are

over-sampling that is to add instances of “MachineOn

= 0” and under-sampling that is to delete instances of

“MachineOn = 1” (Gonzalez et al., 2019). In this pa-

per, under-sampling is used by dividing the machine

on/off frequency into a 50/50 ratio. This means that

randomly selecting 25000 instances where machine

is on and 25000 instances where the machine is off.

The sample size has dramatically reduced, however,

the prediction will not be biased. The following set of

equations present the logistic model for binary data:

y = β

0

+ β

1

X

1

+ β

2

X

2

+ ..... + β

n

X

n

(1)

Equation 1, is a linear regression equation, where

y is dependent variable and X

1

, X

2

... and X

n

are ex-

planatory variables. β

0

is the intercept and β

1

, β

2

...

and β

n

represent the slope of the regression line.

p = 1/(1 + e

−y

) (2)

The logistic function presented in Equation 2 is

the sigmoid function. The sigmoid function is a math-

ematical function having an “S” shaped curve (sig-

moid curve). The logistic function applies a sigmoid

function in order to restrict the y value between zero

and one.

p = 1/(1 +e

−(β

0

+β

1

X

1

+β

2

X

2

+.....+β

n

X

n

)

) (3)

Finally, Equation 3 is applying Sigmoid function

on the linear regression.

6 EVALUATION

6.1 Equipment Effectiveness

This section evaluates OEE of Dolle’s manufactur-

ing process. OEE calculates the percentage of man-

ufacturing time that is actually productive. It can be

used as a benchmark as well as a baseline. In gen-

eral, OEE consists of three factors, which are avail-

ability, performance and quality. Availability consid-

ers all the incidents that stop the planned production.

Performance considers those events that causes the

manufacturing process to run at less optimal speed.

Where as, quality takes into consideration the man-

ufactured products that do not meet the quality stan-

dards. An OEE score of 100% means that the man-

ufacturing is going along at an optimal pace, without

any unplanned stops and producing only good qual-

ity products. In order to provide a clear picture of the

productivity and the areas for further improvements

the OEE calculation of Dolle’s manufacturing process

is performed based on the following items and data:

Morning Shift Length = 510 min, Breaks = 60 min,

Stop/Down Time = 80 min, Ideal Production Time =

60 sec, Total Count = 260 ladders and Reject Count

= 2 ladders. In order to calculate OEE, these steps

are followed. First, Planned Production Time (PPT)

and Run Time (RT) are calculated. The Planned Pro-

duction Time is the standard shift time excluding the

Data Analytics for Smart Manufacturing: A Case Study

397

planned breaks, such as lunch/coffee breaks as well

as shift change over time. The Run Time is the ac-

tual time of production excluding both the planned

and unplanned stops, such as job/product switch over

stops, stops caused by faulty string or by screw ma-

chine error and so on. Afterwards, Good Count (GC)

is calculated by rejecting the defected ladders.

PPT = Shift Length - Breaks =

510 minutes - 60 minutes = 450 minutes

RT = PPT - Stop Time =

450 minutes - 80 minutes = 370 minutes

GC = Total Count - Reject Count =

260 ladders - 2 ladder = 258 ladders

Next, Availability (A), Performance (P) and Qual-

ity (Q) are calculated. Availability, calculates the time

when the manufacturing process is not running or ma-

chine is “OFF” for some reasons. It takes into account

machine failure (unplanned stops) and setup for next

job and/or adjustments (planned stops). Performance,

estimates that whether the process is running at its op-

timal pace and quality concerns with quality standards

of the products being produced.

A = RT / PPT = 370 minutes / 450 minutes =

0.8222 = 82.22%

P = (Ideal Production Time * Total Count) / RT

= (60 seconds * 260 ladders) /

(370 * 60 seconds) = 0.7027 = 70.27%

Q = Good Count / Total count = 258 ladders /

260 ladders = 0.9923 = 99.23%

Finally, OEE score is computed.

OEE = A * P * Q = 0.8222 * 0.7027 * 0.9923 =

0.5733 = 57.33%

OEE score of 57.33% is fairly typical for automate

manufacturing industry, however, it indicates there

is significant opportunity for improvement in perfor-

mance. The performance score can be improved by

reducing the switch over time between the jobs, by

identifying the reasons for machine stops and finally

by tackling the major cause(s) of downtime and so on.

6.2 Model Performance

This section measures the performance of the chosen

classification technique (logistic regression).

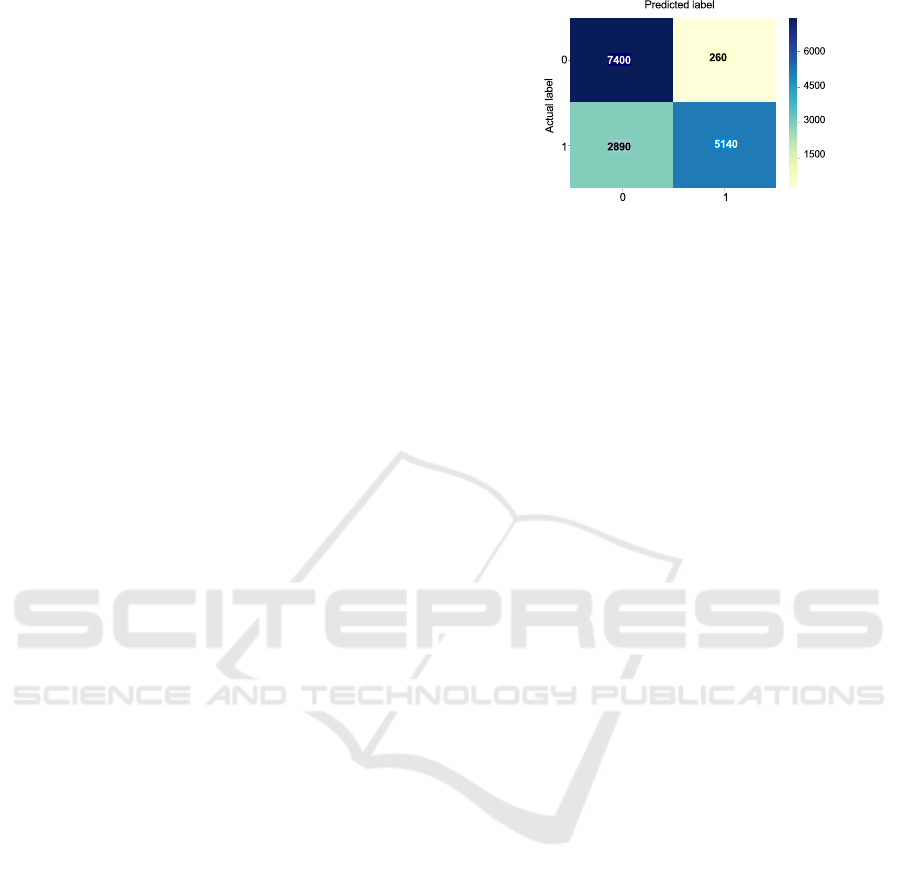

Fig. 5, presents a confusion matrix using heat

map. The matrix shows that out of 7660 actual in-

stances (first row) of “MachineOn = 0” (true nega-

tive), the classifier predicted correctly 7400 (96%) of

them. Similarly, out of 8030 instances (second row)

of “MachineOn = 1” (true positive), the classifier pre-

dicted correctly 5140 (64%) of them. The area under

the curve (AUC) score of the proposed classifier is

0.87, which means that the classifier is quite reason-

able. If the AUC score is close to 0.5, the classifier

Figure 5: Confusion matrix.

is just doing the random predictions, however, it pre-

dicts better as the score approaches close to 1.

7 RELATED WORK

This section mainly concentrates on the previous

work done in relation to data analytics for smart man-

ufacturing. According to (Lee et al., 2014), smart

manufacturing still lacks smart analytical techniques

and tools. In order to improve productivity, per-

formance of the manufacturing machinery should be

measured and optimized with the help of data ana-

lytics technologies. A state-of-the-art review of deep

learning techniques for machinery fault diagnosis,

predictive analytics and defect prognosis is presented

by (Wang et al., 2018). Similarly, big data analytics

in semiconductor manufacturing industry was stud-

ied by (Moyne and Iskandar, 2017). Further, (Muller

et al., 2018) described that big data analytical assets

are associated with an average of 3-7 % improvement

in firm productivity. (Tao et al., 2018) mentioned that

data analytics provides an opportunity in the manu-

facturing industry to adopt data-driven strategies in

order to become more competitive. Further, a survey

by (Kamble et al., 2018) highlighted that the manu-

facturing industry has realized that the data analytics

capabilities are must for future growth. These pre-

vious works focus on various aspects and recent ad-

vancements of data analytics in smart manufacturing.

The work presented in this paper is build on top of

the ideas presented in those previous works. Most of

them focus on theoretical issues in relation to storage,

management and data processing. Hence, the focus

of this paper is to provide practical application of data

analytics technologies.

There are also works that focus on predictive an-

alytics for smart manufacturing. (Auschitzky et al.,

2014) proposed the use of advanced analytics such

as, data visualization, correlation analysis and artifi-

cial neural networks to take a deep dive into historical

data, in order to identify initial patterns. Further, pre-

dicting the bottlenecks in a production system based

DATA 2019 - 8th International Conference on Data Science, Technology and Applications

398

on the active periods of the machines using ARIMA

method was proposed by (Subramaniyan et al., 2018).

Similarly, a big data analytical architecture for prod-

uct life cycle management was presented by (Zhang

et al., 2017). Furthermore, (Shin et al., 2017) pre-

sented an analytic model for predicting energy con-

sumption of manufacturing machinery.

In the best of our knowledge, this paper is the first

to deal with in-depth analysis of sensor binary data

in order to enhance operational efficiency for smart

manufacturing based on the real world case study.

8 CONCLUSIONS AND FUTURE

WORK

This paper presents the fundamental concepts of data

analytics based on a real world case study. These

concepts include data understanding, data prepara-

tion, data pipeline and data analytics technologies. To

enhance the operational efficiency in-depth descrip-

tive and predictive analysis were performed. Super-

vised machine learning technique was used to create

the classification model to predicts machine stops. In

addition, Overall Equipment Effectiveness (OEE) and

the performance of the prediction method were com-

prehensively evaluated. The results have drawn atten-

tion towards improving the production performance

by reducing the machine downtime. Whereas, the

predictions made by the model are quite acceptable in

terms of predicting the unplanned stops, as unplanned

stops are one of the main reasons of reduced produc-

tion performance.

For the future work, several prediction based ma-

chine learning models will be used and compared. In

addition, a near real-time dashboard will be developed

to display the input/output pace along with the OEE

information. Finally, it will be investigated that how

descriptive analysis, predictive analysis and near real-

time dashboard help the smart manufacturing compa-

nies in general, to enhance their operational efficiency

and productivity.

REFERENCES

Auschitzky, E., Markus, H., and Agesan, R. (2014).

How big data can improve manufacturing.

Available online at: https://www.mckinsey.

com/business-functions/operations/our-insights/

how-big-data-can-improve-manufacturing.

Chapman, P., Clinton, J., Kerber, R., Khabaza, T., Reinartz,

T., Shearer, C., and Wirth, R. (1999). Crisp-dm 1.0

step-by-step data mining guide. In 4th CRISP-DM

SIG Workshop in Brussels in March (Vol. 1999). SPSS

Inc.

Gonzalez, S., Garcia, S., Li, S. T., and Herrera, F. (2019).

Chain based sampling for monotonic imbalanced clas-

sification. Information Sciences, 474:187–204.

Gooijer, J. G. D. and Hyndman, R. J. (2006). 25 years of

time series forecasting. International Journal of Fore-

casting, 22(3):443–473.

Iftikhar, N., Liu, X., and Nordbjerg, F. E. (2015).

Relational-based sensor data cleansing. In ADBIS’15,

East European Conference on Advances in Databases

and Information Systems, pages 108–118. Springer,

Cham.

Kamble, S. S., Gunasekaran, A., and Gawankar, S. A.

(2018). Sustainable industry 4.0 framework: A sys-

tematic literature review identifying the current trends

and future perspectives. Process Safety and Environ-

mental Protection, 117:408–425.

Lee, J., Kao, H. A., and Yang, S. (2014). Service innova-

tion and smart analytics for industry 4.0 and big data

environment. Procedia CIR, 16:3–8.

Moyne, J. and Iskandar, J. (2017). Big data analytics for

smart manufacturing: Case studies in semiconductor

manufacturing. Processes, 5(3):39–58.

Muller, O., Fay, M., and vom Brocke, J. (2018). The ef-

fect of big data and analytics on firm performance: An

econometric analysis considering industry character-

istics. Journal of Management Information Systems,

35(2):488–509.

Shin, S. J., Woo, J., and Rachuri, S. (2017). Predictive ana-

lytics model for power consumption in manufacturing.

Procedia CIRP, 15:153–158.

Subramaniyan, M., Skoogh, A., Salomonsson, H., Banga-

lore, P., and Bokrantz, J. (2018). A data-driven algo-

rithm to predict throughput bottlenecks in a produc-

tion system based on active periods of the machines.

Computers & Industrial Engineering, 125:533–544.

Tao, F., Qi, Q., Liu, A., and Kusiak, A. (2018). Data-driven

smart manufacturing. Journal of Manufacturing Sys-

tems, 48:157–169.

Wang, J., Ma, Y., Zhang, L., Gao, R. X., and Wu, D. (2018).

Deep learning for smart manufacturing. Journal of

Manufacturing Systems, 48:144–156.

Zhang, Y., Ren, S., Liu, Y., and Si, S. (2017). A big data

analytics architecture for cleaner manufacturing and

maintenance processes of complex products. Comput-

ers & Industrial Engineering, 142:626–641.

Data Analytics for Smart Manufacturing: A Case Study

399