Research on Ultra-precision Technology for Fault Law and

Operation Trend Prediction of Machinery and Equipment

Jinghua Yu

1, a

1

Wuhan Institute of Shipbuilding Technology, Wuhan 430050 China

Keywords: Mechanical fault prediction, Vector regression method, Full vector technology, Operation trend prediction

model, Spectrum structure.

Abstract: Mechanical equipment is the key to ensure industrial production, which determines whether industrial

production links can operate efficiently and continuously, but the occurrence of mechanical failure is an

important factor hindering its stable operation. Therefore, accurate diagnosis and prediction of mechanical

faults has become a hot research topic in the field of industrial production. In this paper, a fault diagnosis

and operation trend prediction model of mechanical equipment will be established by combining vector

regression and full vector technology. Compared with the traditional time domain model, the model built in

this paper mainly uses spectrum structure to predict the model. Finally, this paper establishes the prediction

model of fault operation trend based on gear trend development. The results show that the prediction model

proposed in this paper can realize the prediction of gear fault trend development.

1 INTRODUCTION

Industrial production determines the industrial and

economic level of a country, and mechanical

equipment, as an extremely important factor in

industrial production, determines whether industrial

production can operate efficiently, safely and

steadily (

Wang Y, Wei Z, Yang J, 2018; Shi M, Lu J, Fu Y,

2018

). The occurrence of mechanical failure to a

certain extent restricts the service life of mechanical

equipment, but also affects the production efficiency

of industrial production. Therefore, efficient and

reasonable technology of mechanical equipment

fault detection and operation trend prediction is the

key to effectively solve the above problems, and it

has also become a hot and difficult point in

industrial research (

Zhou Z Q, Zhu Q X, Xu Y, 2017; Yang

H L, Yang Y L, Yu C, et al, 2018; Rathore S S, Kumar S, 2017;

Wei J, Wang L, 2017; Rajagopalan R, Litvan I, Jung T P, 2017

).

At present, fault detection and operation trend

prediction technology of mechanical equipment

mainly concentrates on rolling bearings and gears.

Based on a large number of scholars and research

institutes in the above-mentioned fields, this paper

carries out research and Analysis on it. American

scholar (

Pyo S, Lee J, Cha M, et al, 2017; Kumar M, Parmar K

S, Kumar D B, et al, 2018

) has proposed fault diagnosis

technology based on spectrum analysis method,

which mainly carries out uninterrupted spectrum

analysis for bearings and gears, and takes timely

measures once spectrum abnormalities occur.

Relevant scholars (

Hake A, Pfeifer N, 2017; Michiels B,

Nguyen V K, Coenen S, et al, 2017

) have proposed the

prediction and analysis of mechanical fault based on

vibration signal, which mainly uses the cut-off

frequency of the peak value of vibration to judge the

fault, but there are a lot of noise hazards in the

collected signal, so it needs to increase the signal

pretreatment link in the actual analysis. Relevant

scholars (

Chaudhuri D, 2017; Bahrami M, Bazrkar, Samira,

Zarei, Abdol Rassoul, 2018; Lin Y, Zhang J W, Liu H, 2018

)

proposed fault prediction based on precise diagnosis.

Although this method can achieve certain results to a

certain extent, it actually requires a lot of manpower

and financial resources.

In order to solve the above problems and put

forward an efficient and reasonable mechanical fault

prediction model, this paper proposes a fault

diagnosis and operation trend prediction model of

mechanical equipment based on vector regression

and full vector technology. Compared with the

traditional time domain model, the model built in

this paper mainly uses spectrum structure to predict

the model. Finally, this paper establishes the

prediction model of fault operation trend based on

gear trend development. The results show that the

Yu, J.

Research on Ultra-precision Technology for Fault Law and Operation Trend Prediction of Machinery and Equipment.

DOI: 10.5220/0008386301390143

In Proceedings of 5th International Conference on Vehicle, Mechanical and Electrical Engineering (ICVMEE 2019), pages 139-143

ISBN: 978-989-758-412-1

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

139

prediction model proposed in this paper can realize

the prediction of gear fault trend development.

The structure of this paper is as follows: In the

second section of this paper, the combination

algorithm of vector regression method and full

vector technology proposed in this paper will be

analyzed concretely, and the prediction model of

mechanical equipment fault and operation trend

based on this algorithm will be constructed; in the

third section, the gear fault prediction model based

on this algorithm will be analyzed concretely, and

the experimental conclusion will be given; in the last

section, this paper will do a summary.

2 COMPREHENSIVE ANALYSIS

OF VECTOR REGRESSION

AND FULL VECTOR

TECHNIQUES

This section will mainly analyze the comprehensive

analysis and research based on vector regression and

full vector technique proposed in this paper, and

discuss and analyze the vector regression method

and full vector technology in detail.

2.1 Vector Regression Method and Full

Vector Synthesis Technology

Analysis

This section will abandon the shortcomings of the

original mechanical equipment fault prediction

algorithm, and propose a mechanical equipment

fault prediction algorithm based on vector regression

algorithm and full vector synthesis technology. First,

the regression function used in the vector regression

algorithm is shown in Equation 1, where the

corresponding x and w are the algorithm samples,

and the corresponding b is a constant.

bxwxf ).()(

(1)

In this paper, taking the gear as an example,

according to the mechanical characteristics of the

gear, the corresponding linear regression function of

the mechanical equipment fault can be obtained, as

shown in Equation 2, where the corresponding C is

the penalty factor of the regression function, which

mainly depends on the complexity of the gear. The

corresponding function Q represents the optimal

constraint solution of the linear regression problem.

)().(

2

1

)( fCRwwwQ

emp

(2)

The corresponding Remp in the formula of the

above optimal constraint solution depends on the

loss function L (f, y), and the corresponding loss

function selected in the algorithm is an insensitive

loss function, and its corresponding function

expression is as shown in Equation 3.

others

yfyf

yfL

,0

),(

(3)

An image of the insensitive loss function is

shown in Figure 1:

Figure 1. Insensitive loss function image.

In the practical application of the algorithm in

this paper, it is mainly considered that the empirical

risk of mechanical equipment needs to be minimized,

so it is assumed that its ideal state is f-y=0. At this

point, the corresponding loss of the mechanical

device is considered to be lossless, and the

corresponding linear regression image is shown in

Figure 2:

Figure 2. Linear regression function image of insensitive

loss function.

ICVMEE 2019 - 5th International Conference on Vehicle, Mechanical and Electrical Engineering

140

Based on Fig. 2, the empirical function of

mechanical equipment loss corresponding to the

gear studied in this paper can be further obtained, as

shown in Equation 4:

l

i

ii

xfy

l

CwwwQ

1

)(

1

).(

2

1

)(

(4)

The corresponding constraint condition is as

shown in Equation 5, wherein the corresponding

related parameters A and B are corresponding slack

variables, and the corresponding C is a strip region

of the regression function.

ii

iii

iii

BA

niBCbyxw

ACbxwy

.

...5,4,3,2,1.

.

(5)

Based on the above formulas 2, 3, 4, 5, the

corresponding gear prediction function based on the

regression algorithm can be obtained as shown in

Equation 6. The acquisition technique used in this

equation is a time interval sample acquisition

technique, and its core principle lies in the interval.

Data acquisition takes a certain amount of time and

is used as a basis for prediction of the next collection

point. The corresponding m in Equation 6 is the

predicted target acquisition quantity value.

),....,(

111

miiii

xxxfx

(6)

Based on the prediction formula of the above

formula 6, the corresponding prediction result

evaluation formula can be further obtained as shown

in Equation 7, which mainly reflects the prediction

accuracy of mechanical equipment failure. The

corresponding x1 is the predicted value, and the

corresponding x2 is the true value.

n

i

x

xx

n

MAPE

1

2

12

%100*

1

(7)

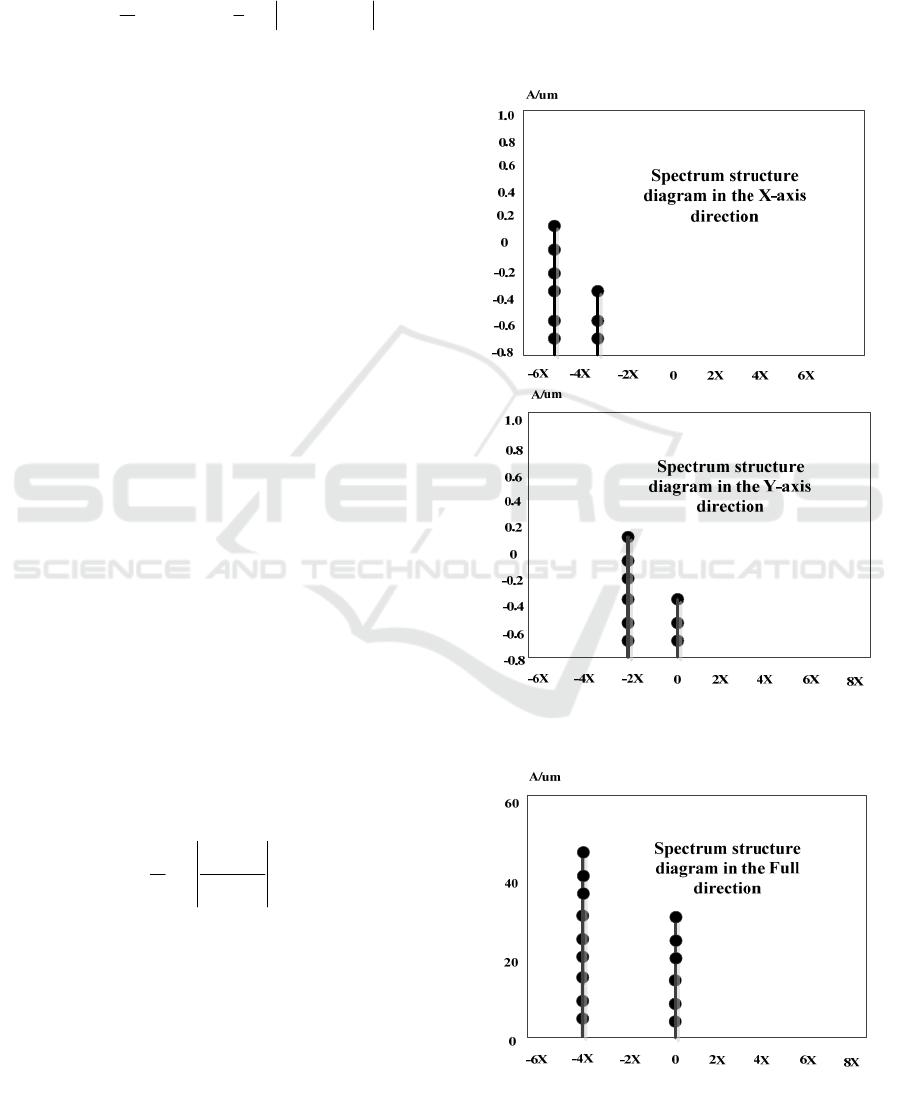

In order to make the proposed algorithm

accurately predict the type of mechanical equipment,

this paper creatively adds full vector prediction

technology to the regression algorithm, which is

mainly to calculate, select and analyze the spectrum

in the frequency domain. In the practical application

of this paper, this paper introduces the full vector

technique to analyze the spectrum of the X and Y

directions of the mechanical equipment, and based

on the spectrum in these two directions, the

corresponding full vector diagram is synthesized to

further accurately predict the mechanical equipment.

failure. Take the steam turbine unit as an example,

as shown in Fig. 3, the corresponding spectrum

structure diagram in the X and Y directions, as

shown in Fig. 4 is the corresponding synthetic full

spectrum diagram.

Figure 3. Spectrum structure diagram of the steam turbine

group in the X and Y directions.

Figure 4. Turbine unit full vector spectrum structure

diagram.

Research on Ultra-precision Technology for Fault Law and Operation Trend Prediction of Machinery and Equipment

141

2.2 Predictive Model Establishment

Based on the analysis in Section 2.1 above, it can be

concluded that the corresponding gear failure

prediction model is constructed as shown in FIG. 5,

wherein in the corresponding step 3, it is necessary

to note that the extraction time interval is consistent

when performing feature quantity extraction. At the

same time, in the X and Y direction data acquisition,

it is necessary to pay attention to the collected data

to form a corresponding discrete sequence.

Figure 5. Flow chart of gear mechanical failure prediction

model based on the algorithm of this paper.

3 EXPERIMENTAL ANALYSIS

In order to further verify the accuracy of the

proposed algorithm in mechanical equipment failure

prediction, this paper uses a certain type of gear as

the prediction object. At the same time, when using

the algorithm proposed in this paper, the insensitive

loss function is used as the function of the prediction

model. Gaussian radial is chosen as the base

function of the algorithm, and its corresponding

width coefficient w=3 is set. The corresponding

single-step prediction results are shown in Fig. 6,

and the selected training samples are 40. FIG. 7 is a

corresponding single-step prediction graph obtained

based on a conventional mechanical equipment

failure prediction algorithm.

Figure 6. Single-step prediction result diagram of gear

mechanical fault based on the algorithm of this paper.

Figure 7. Single-step prediction result diagram of gear

mechanical failure based on traditional algorithm.

Based on the above results, Fig. 6 and Fig. 7,

combined with the accuracy calculation formula

corresponding to Equation 7, it can be concluded

that the prediction accuracy corresponding to Fig. 6

is 3.23%, and the corresponding prediction accuracy

of Fig. 7 is 5.34%. It can be seen that the proposed

algorithm has obvious advantages in prediction

accuracy compared with the traditional regression

vector method, and it also has stronger

generalization ability.

4 CONCLUSIONS

In this paper, an in-depth analysis and research on

the fault prediction of mechanical equipment that is

urgently needed in industrial production is carried

out. By analyzing the domestic and international

research status and the related prediction schemes,

this paper combines vector regression and full vector

ICVMEE 2019 - 5th International Conference on Vehicle, Mechanical and Electrical Engineering

142

technology to establish a mechanical equipment

fault diagnosis and operation trend prediction model.

Compared with the traditional time domain model,

the model established in this paper mainly uses the

spectrum structure to predict the model. Finally,

based on the trend development of gears, the

prediction model of fault operation trend is

established. The results show that the proposed

prediction model can predict the development trend

of gear faults.

REFERENCES

Bahrami M, Bazrkar, Samira, Zarei, Abdol Rassoul.

Modeling, prediction and trend assessment of drought

in Iran using standardized precipitation index [J].

Journal of Water and Climate Change,

2018:jwc2018174.

Chaudhuri D. Empirical approaches in prediction of

reservoir sediment distribution - an experience of 57

reservoirs in the USA and India [J]. International

Journal of Sediment Research, 2017, 32(2):260-276.

Hake A, Pfeifer N. Prediction of HIV-1 sensitivity to

broadly neutralizing antibodies shows a trend towards

resistance over time. [J]. Plos Computational Biology,

2017, 13(10):e1005789.

Kumar M, Parmar K S, Kumar D B, et al. Long-term

aerosol climatology over Indo-Gangetic Plain: Trend,

prediction and potential source fields [J]. Atmospheric

Environment, 2018, 180.

Lin Y, Zhang J W, Liu H. An algorithm for trajectory

prediction of flight plan based on relative motion

between positions [J]. Frontiers of Information

Technology & Electronic Engineering, 2018,

19(07):95-106.

Michiels B, Nguyen V K, Coenen S, et al. Influenza

epidemic surveillance and prediction based on

electronic health record data from an out-of-hours

general practitioner cooperative: model development

and validation on 2003 - 2015 data [J]. Bmc Infectious

Diseases, 2017, 17(1):84.

Pyo S, Lee J, Cha M, et al. Predictability of machine

learning techniques to forecast the trends of market

index prices: Hypothesis testing for the Korean stock

markets. [J]. Plos One, 2017, 12(11):e0188107.

.Rajagopalan R, Litvan I, Jung T P. Fall Prediction and

Prevention Systems: Recent Trends, Challenges, and

Future Research Directions: [J]. Sensors, 2017,

17(11):2509.

Rathore S S, Kumar S. An empirical study of some

software fault prediction techniques for the number of

faults prediction [J]. Soft Computing, 2017,

21(24):7417-7434.

Shi M, Lu J, Fu Y. Study on Prediction Methods for the

Fault State of Rotating Machinery Based on Dynamic

Grey Model and Metabolism Grey Model [J]. Wireless

Personal Communications, 2018(2):1-13.

Wang Y, Wei Z, Yang J. Feature Trend Extraction and

Adaptive Density Peaks Search for Intelligent Fault

Diagnosis of Machines [J]. IEEE Transactions on

Industrial Informatics, 2018, PP (99):1-1.

Wei J, Wang L. Big data analytics based fault prediction

for shop floor scheduling [J]. Journal of

Manufacturing Systems, 2017, 43:187-194.

Yang H L, Yang Y L, Yu C, et al. Meta-Prediction of

MTHFR Gene Polymorphism and Air Pollution on the

Risks of Congenital Heart Defects Worldwide: A

Transgenerational Analysis[J]. International Journal of

Environmental Research and Public Health, 2018,

15(8):1660-.

Zhou Z Q, Zhu Q X, Xu Y. Time Series Extended Finite -

State Machine - Based Relevance Vector Machine Multi

- Fault Prediction [J]. Chemical Engineering &

Technology, 2017, 40.

Research on Ultra-precision Technology for Fault Law and Operation Trend Prediction of Machinery and Equipment

143