Selection of Tubular Membrane Separation based on the Resistance

Performance

Lilis Sukeksi

1,2

, Che Rosmani Che Hassan

2

, Nik Meriam Sulaiman

2

and

Mohamed Kheireddine Aroua

2

1

Department of Chemical Engineering, Faculty of Engineering, Universitas Sumatera Utara, Jl. Almamater Kampus USU,

Medan 20155, Indonesia

2

Department of Chemical Engineering, Faculty of Engineering, Universiti Malaya, 50603, Kuala Lumpur, Malaysia

Keywords: Tubular Membrane, Polyphenols, Resistance, Mass Transfer and Permeate.

Abstract: Processing of fruits (such as pink guava) to produce fruit juices results in high amount of waste materials that

still contain valuable by-products (e.g. antioxidants or polyphenols). Analysis of hydrodynamic resistances

that considers gel layer formation as the main fouling mechanism and permeate flux decline was studied.

Using tubular membrane FP 100 and ES 404 performed the experiments, with a molecular weight cut-off of

100 kDa and 4 kDa respectively. Results showed that the permeate fluxes for both of the membranes increased

by increasing the Trans Membrane Pressure (TMP) and it would decrease with time. All of the resistances

increased with TMP meanwhile the mass transfer of polyphenols did not affect the TMP. All the TMP resulted

in similar fouling values for both membranes.

1 INTRODUCTION

The waste-to-wealth approach for management of the

residuals will result in the recovery of valuable by-

products as well as solving the waste disposal

problem. In the case of pink guava processing waste,

the recovery of bioactive compounds is a profitable

venture that can result in the recovery of polyphenols

and other antioxidants. Polyphenols have good

properties because they have anti-oxidant activity

properties that are beneficial for enhancing health

effects for humans (Friedman, 2002). Polyphenols

can counteract the attacks of free radicals, therefore

polyphenols can avoid the body from hereditary

diseases such as cancer and other diseases (Gökmen,

2003).

In general, polyphenol compounds can be isolated

or taken from fruit or vegetable processing wastes by

the extraction process (D’Alvise, 2000). The use of

filtration membranes for recovery, purification or

concentration of fruits and vegetables has been

extensively studied for the past 25 years. (Czekaj,

2000) identify restoration of polyphenols from pink

guava manufacture residual pulp, and these processes

can be done at low temperature; do not involve a high

energy usage and makes it possible to separate

bacterial and spore cells and to completely remove

suspended solids. However, the decrease in permeate

flux along with the increase in reaction time will

occur, this is because some material will clog the

membrane pores while others will thicken on the

membrane surface and will shape a gel. Membrane

contamination resulting in membrane fouling has

been explored by many membrane separation

researchers because it can make lower the

productivity and age of membranes. (Nilsson, 1990).

However, the decrease in flux caused by increasing

the concentration of the solution on the surface of the

membrane so that gel formation caused by complex

polyphenols substances needs to be studied further.

Furthermore, the basic mechanism so that the

occurrence of fouling which causes a decrease in flux

during the ultra filtration process of polyphenols is

still not known correctly.

Fouling membrane that occurs in membrane

filtration is influenced by three main factors, namely,

the nature of the material or membrane material used,

characteristics of the feed or sample and parameters

of the operation process. In most studies related to

ultrafiltration separation membranes (UF) a model is

made using the hydrodynamic theory based on the

formation of polarization concentrations and the

formation of solids or gels on the membrane surface,

Sukeksi, L., Hassan, C., Sulaiman, N. and Aroua, M.

Selection of Tubular Membrane Separation based on the Resistance Performance.

DOI: 10.5220/0008551501870192

In Proceedings of the International Conference on Natural Resources and Technology (ICONART 2019), pages 187-192

ISBN: 978-989-758-404-6

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

187

which produce hydrodynamic resistance to absorb

flow (Fane, 1987). This model can also be applied to

the process of separating polyphenols from pink

guava because this process also forms a layer of cake

and gel on the surface of the separating membrane.

Polarization of the concentration and layer of cake

can facilitate irreversible membrane contamination

by revising interactions between solvents, solutes and

membranes. Therefore, to understand the

phenomenon of the fouling process which results in

membrane process failure is by analyzing the surface

chemistry of the membrane, the interaction of solutes

to the membrane and the interaction between the

solute. So, the interaction between separation

membrane and solution can determine the occurrence

of fouling caused by adsorption of dissolved

polyphenols on the membrane surface.

The paper is part of the research that has been

done on the recovery of polyphenols from the

processing of pink guava waste (Sukeksi & Sarah,

2016), (Sukeksi et al., 2016). This paper will discuss

the effects of differences in operating pressure or

TMP on membrane fouling and permeate flux in two

types of membrane separation during the polyphenol

recovery process.

Permeate flux decline over time is the main

limiting factor that influence the membrane process.

The permeate flux decline because of feed

components increases inside the pores. This process

results in membrane fouling. The feed component

also increases on the membrane surface that result

forming concentration polarization or gel layer. Some

researchers have learned about fouling that occurs in

membranes, this is done because fouling can reduce

the productivity and lifetime of the membrane

(Nilsson, 1990). However, a decrease in flux due to

polarization and concentration of the solution

resulting in fouling, and the complex effects of

polyphenol substances need to be investigated

further.

2 MATERIAL AND METHODS

2.1 Materials

Two commercial tubular membranes with FPDF FP

200 type with nominal MWCO 200,000 and ES 404

membranes with a nominal 4,000 MWCO with a pH

operating range ranging from 1.5 - 12, and a

maximum operating pressure of 10 bar, and a

maximum operating temperature of 80 ̊ C.

Membranes are supplied and manufactured by PCI,

UK. The membrane housing used was supplied by

local supplier, with 14 mm of inner diameter and 325

mm of length, with the module configuration

contained two tubular membranes. Prior to use is

soaking overnight in 0.3% HNO

3

to eliminate

impurities left from the mechanized process or

additives used for stabilization washes the

membranes. Membrane equipment modules used for

polyphenol recovery from pink guava processing

waste consist of one diaphragm pump, 10 liter

capacity feed reservoir, permeate collection reservoir,

two inlet and outlet pressure gauges, valves for

control and balance pressure and equipped with

monitors for data processing. The all material of

equipment such as, pump, feed reservoir and all

connection tubing are used material base of stainless

steel. Folin-Ciucalteu and Gallic acid were from

Sigma-Aldrich (Germany) and Sodium Carbonate

powder, Nitric Acid is supplied by Fluka (Germany).

Processing of pink guava waste is collected from

Sitiawan Perak, which is produced from a Decanter

separator and Refiner separator with a composition of

50%. If this pink guava waste is stored in an improper

manner it will result in a rapid loss of polyphenols, so

the extraction process cannot be carried out.

Therefore, the waste must be stored properly in the

refrigerator to prevent fungal growth and oxidation.

2.2 Methods

2.2.1 Extract Preparation

Extraction methods using solvents are the most

common way to isolate a compound from various

fruits, as well as vegetables, such as polyphenol

compounds. To isolate the substance in the extract is

very dependent on the type of solvent used, because

each type of polyphenols compound has a different

polarity. Waste pink guava processing extract for

total polyphenols content analyses are prepared by

following method of Swain and Hillis (1959), with

some modifications. Base in our study before, the best

solvent for extraction to recovery polyphenol from

pink guava wastes processing are Methanol/Water at

60% and the second is water. The best composition

ratio between the sample wastes and solvent is 1:40.

In this project the polyphenols within the pink guava

wastes processing is extracted using water as a

solvent. The choice of water as a solvent is based on

the information that water more saves for human than

organic solvent. Solid pink guava waste and water are

then stirred using a blender constantly for 10 minutes

until a homogeneous slurry or solution is produced.

After 12 hours, the aqueous extract is separated from

the solid by removed the upper of solution to reduce

ICONART 2019 - International Conference on Natural Resources and Technology

188

the suspended solid content. The clear solution

produced will be used for the recovery process of

polyphenols using FP 200 and ES 404 membrane UF.

2.2.2 Recovery Polyphenols

Membrane separation is an alternative method for the

solvent separation process from polyphenol extract.

The system consists of PVDF 200 FP and ES 404

membrane connected to a feed reservoir and a

diaphragm pump. The steps involve in experiment

are:

To determine the flux of water by entering tap

water into the membrane by turning on the pump at a

certain TMP and calculating the volume of permeate

(Vp) generated at a certain time (t) passing through

the surface area of the separation membrane (A) using

the equation below:

J =

First Cleaning.

The cleaning involved by initial water flushing for ten

minutes and nitric acid 0.3% 30 minutes followed by

water flushing again for ten minutes, to remove

impurities left from the mechanized process or

additives used for stabilization. The end of water

flushing flux was measured by using data storing

from the data lodging.

Ultra Filtration.

In operation, the feed stream extract of pink guava

processing wastes is pumped using a diaphragm

pump through the both of tubular PVDF membrane.

The process of ultra filtration tubular membranes

begins with the permeate port being closed, this is to

allow cross speed before permeating out, with both

inlet valves for feed solution and retentate solution in

wide open conditions. After the pump is run, the valve

for the inlet channel is opened and the valve for the

solution on the retentate is slowly closed to produce

the preferred Trans Membrane Pressure (TMP). With

the increase in volume of solution at the permeate, the

concentration of polyphenols will also increase. Ultra

filtration experiment is carried out with continuous

retentate recycling. The result permeate is

continuously removed, until the desired volume

concentration ratio (VCR) is achieved.

VCR =

Where:

VCR or (Volume of Concentration Ratio),

V

f

(m

3

) is initial volume of the feed

V

R

(m

3

) is retentate volume

All data is collected and record by computer via a

data logger. The samples that are resulted from

permeate and retentate are provided to analyze total

polyphenols content.

Second Cleaning.

The cleaning procedure is the same with the first

cleaning procedure before ultra filtration processing,

and the water flushing flux was also measured by

using data storing from the data lodging.

All the processing procedures were repeated for

three times, by using the same membrane which are,

each step operation until VCR = 4 were reached and

at TMP = 1, 2 and 3 bar, respectively.

Determination of Total Polyphenols Content.

The total polyphenol content produced was

determined in all samples using the Folin-Ciocalteau

method, which was modified by the theory of

(Singleton, 1965) with some modifications. Gallic

acid calibration standard solution is prepared for

0.01-0.1 mg/ml by accurately weighing and

dissolving with of distilled water as a solvent. The

solution mixture consisted of 200 l extract of pink

guava waste sample mixed with 1.5 ml of Folin-

Ciocalteau reagent and left at room temperature for 5

minutes then 1.5 ml of sodium bicarbonate solution

was added to the mixture. After standing 90 minute at

room temperature, absorbance is measured at 760 nm.

The results obtained are expressed as mg / ml Gallic

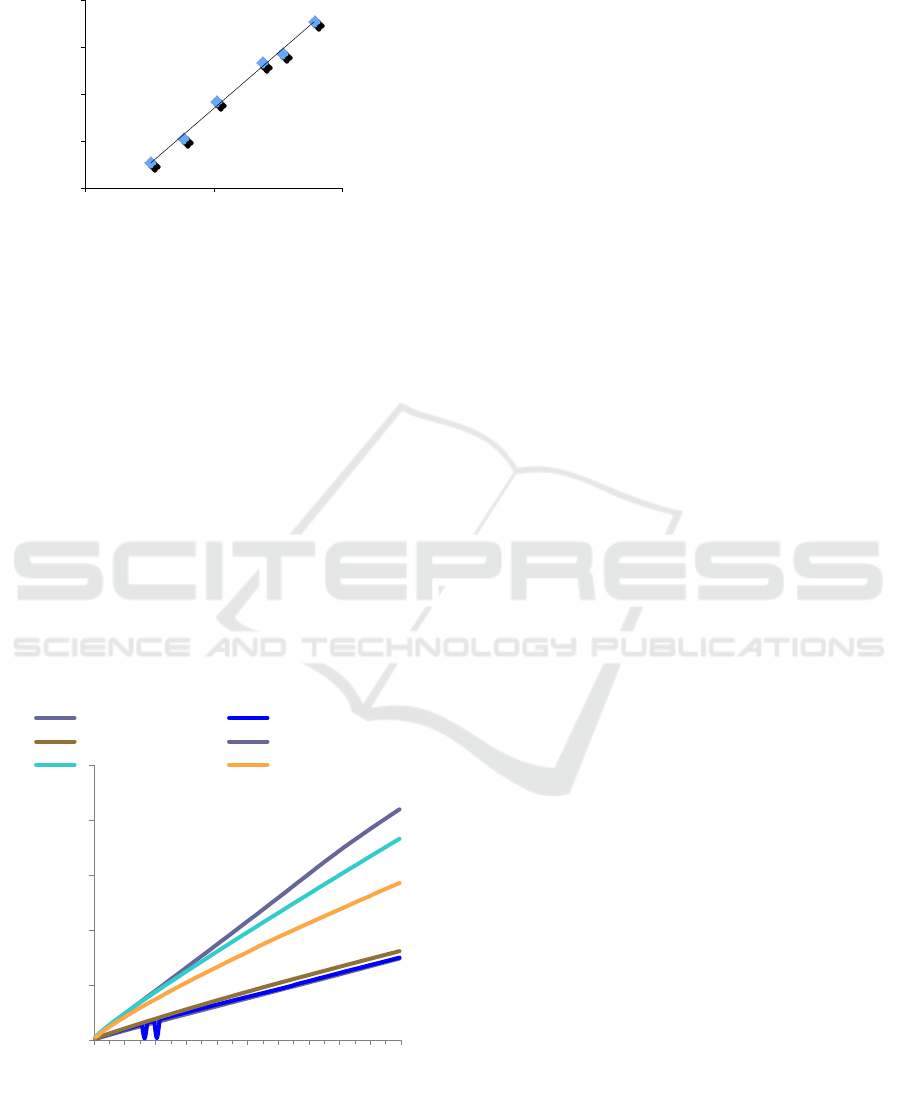

equivalent (GAE). The gallic acid standard curve can

be seen in Figure 1 which is in the range of Gallic acid

concentration from 0.025 to 0.1 mg / ml, and this will

be used to make a calibration curve.

Calculation of Membrane Performance.

The membrane performance was measured by

concentration factor (C

R,P

) and recovery (C

R,P

) of

polyphenols content. Concentration factor is the

concentrations of polyphenols in either permeate or

retentate solution divided by its concentration in the

feed solution.

R

(R,P)

(%) =

Selection of Tubular Membrane Separation based on the Resistance Performance

189

Figure 1: Gallic acid standard curve based on the data

collected at absorbance 760 nm.

3 RESULTS AND DISCUSSIONS

3.1 Influence of TMP on the Permeate

Volume

The increasing permeates volume as a function of

time for tubular membrane at different pressures is

shown in Figure 2. The permeate volume collected

during recovery of pink guava processing wastes

increased with time but at a decreasing rate. For

membrane ES 404, the increasing of permeate

volume for all transmembrane pressure are similar

trend, there is no significant different between them.

Figure 2: Permeate volume vs time for recovery

polyphenols using PVDF membrane FP 200 and ES 404 at

different TMP.

But for the membrane FP 100 the permeate volume

collected at any time decrease with TMP increase.

The lower permeation rates for pink guava processing

wastes in comparison with those of water were due to

membrane fouling.

For the pure water, the permeate volume collected

during ultra filtration increase linearly with time for

both of the membrane. In these cases, total resistance

(R

t

)

and membrane resistance (R

m

)

constant

throughout the whole operation and J or flux also

constant at TMP constant.

3.2 Influence of TMP on The Permeate

Flux

Investigational data related to the permeate flux

decline for both of the membrane are presented in

Figure 3.

The initial flux decline was 20-37% and 17-29%

of the total flux decline for membrane FP 100 and ES

404, respectively at TMP 1-3 Bar.

The steady state was established after 20 minute

of operation and the steady state permeate fluxes were

60-80% and 70-80% of their initial values for

membrane FP 100 and ES 404, respectively.

Note that the initial flux of the permeate does not

depend on the speed of the feed flow in the tubular

membrane. This can be explained by the fact that at

the start of the separation process, permeate flux is

caused more by fouling that occurs on the internal

membrane, which is clearly not significantly affected

by the feed flow rate. Generally, the permeate flux

increases initially with the transmembrane or TMP

pressure applied, and then the flux will decrease with

increasing pressure from the transmembrane.

Contrary to this, the permeate flux for FP 100

membrane decreased with increased the TMP and for

ES 404 all the permeate flux for different TMP has

similar value.

The flux will reach steady state condition when

the cake layer has grown to the equilibrium thickness.

From the Figure 4.19 the steady state of flux

decreased with the increase of TMP. (Song, 1998),

already assumed the equilibrium thickness of cake

layer increase with the applied pressure. It is because

a thicker cake layer is needed to absorb a higher

pressure.

Cassano et al. (2008) found the effect of TMP on

the steady state of permeate flux which show a linear

increase with TMP at lower pressures. Meanwhile at

higher pressures the permeate fluxes approach a

limiting value independent of further increases in

TMP. Their point was considering the pressure

independence as the peak of TMP (100 kPa). The first

y = 4,7354x - 0,0676

R² = 0,9953

0,00

0,10

0,20

0,30

0,40

0,00 0,05 0,10

Absorbance (nm)

Concentration gallic acid (mg/ml)

0

500

1000

1500

2000

2500

1 31 61 91

Permeate volume (ml)

Time (minutes)

TMP = 1 Bar ES 404 TMP = 2 Bar ES 404

TMP = 3 Bar ES 404 TMP = 1 Bar FP 200

TMP = 2 Bar FP 200 TMP = 3 Bar FP 200

ICONART 2019 - International Conference on Natural Resources and Technology

190

fluxes decline at their first domain and was 75.8-

89.1% of the total flux decline. The steady state value

of flux shown after 34-84 minutes of processing and

steady state of permeate fluxes were 22-43% from

their first value.

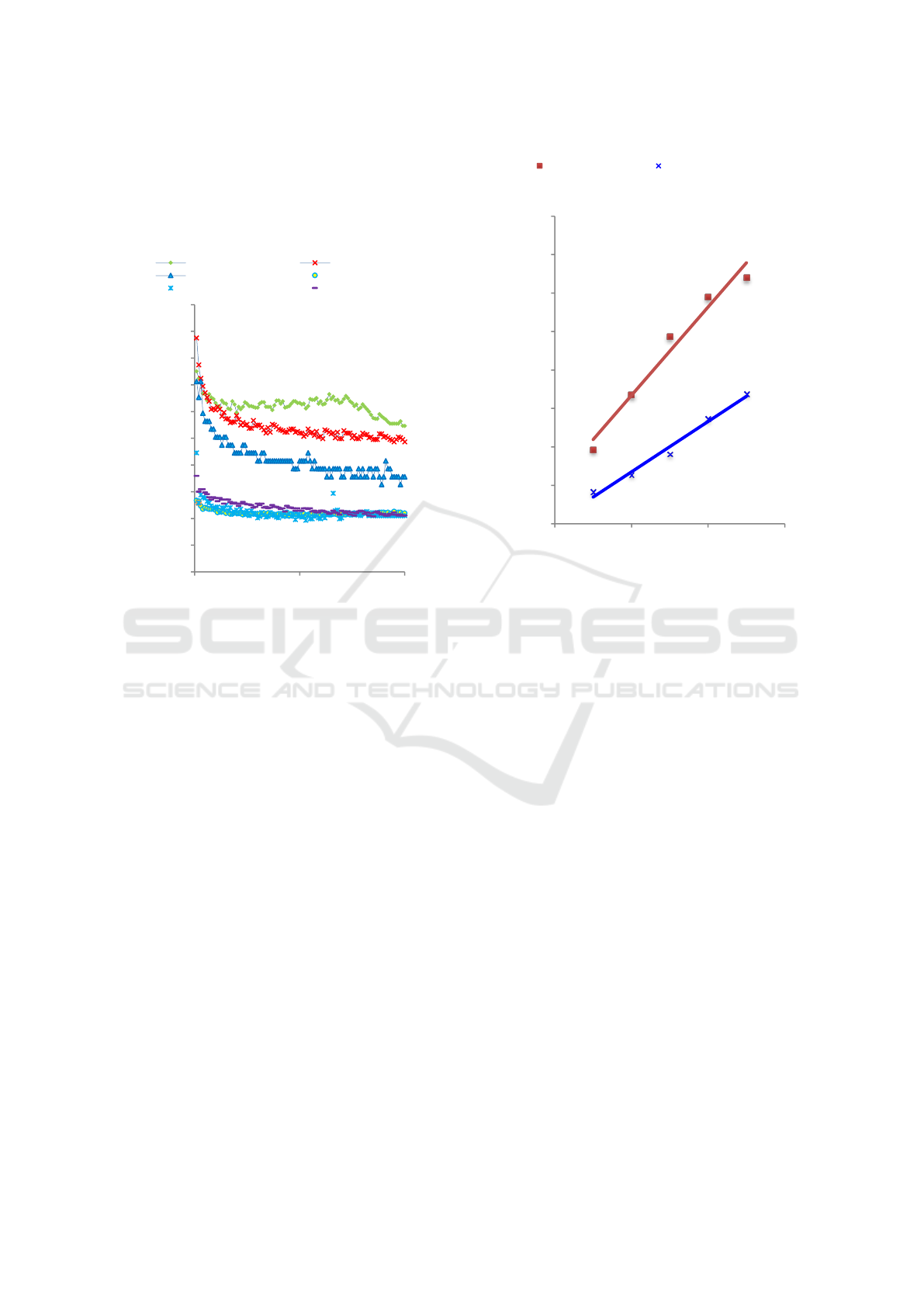

Figure 3: Permeate Flux Decline Vs Time.

3.3 Hydraulic Permeability and

Membrane Resistance

The hydraulic permeability of the new clean

membrane was 114.9 L/m2hBar for FP 100

membrane; meanwhile for ES 404 membrane was

70.8 L/m2hBar at 25ºC. New membrane resistance,

R

m

, was calculated from Eq. (3) to be 3.5 x 10

12

m

-1

forFP 100 membrane and 5.7 x 10

12

m

-1

for ES 404

membrane respectively. The membrane resistance

calculated after the cleaning procedure was reported

to its original value as observed from the hydraulic

permeability data.

3.4 Influence of Transmembrane

Pressure on the Total Resistance

As shown in Figure 4 the total resistance (R

t

)

increased with increased the TMP for both of the

membrane. This phenomenon can be explained by

assuming that an increase of pressure improved flux

and convective flow of the solute towards the

membrane. Therefore, the concentration polarization

was more evident determining an increase of fouling

resistance.

Figure 4: The influence of TMP on total resistance FP 100

membrane and ES 404 membrane.

4 CONCLUSIONS

Permeate volume increase with time for both of

membrane ES 404 and membrane FP 200. For

membrane ES 404, the increasing permeate volume

for all TMP had a similar trend but for membrane FP

200 increasing of TMP resulted in increases of

permeate volume. Initial flux decline was achieved

20% for membrane FP 200 and 37% for membrane

ES 404 from the total initial flux at TMP 1-3 bar and

steady state settled after 20 minutes of processing for

both of membranes. The hydraulic permeability of the

new clean membrane was 114.9 L/m2hbar for FP 200

membrane. Meanwhile for ES 404 membrane was

70.8 L/m2hbar at 25ºC. New membrane resistance,

R

m

, was 3.5 x 10

12

m

-1

for membrane FP 200 and 5.7

x 10

12

m

-1

for ES 404. Total resistance (R

t

) increased

with increased of TMP for both of the membrane.

Meanwhile the R

2

for membrane FP 200 is 0.9719

and for membrane ES 404 is 0.9949.

REFERENCES

Cassano, A., Mcchia, A. and Drioli, E. (2008). Analyses of

hydrodynamic resistances and operating parameters in

0

10

20

30

40

50

60

70

80

90

100

0 50 100

Permeate Flux (l/m2hr)

Time (minutes)

FP 200, TMP = 1 bar FP 200, TMP = 2 bar

FP 200, TMP = 3 bar ES 404, TMP = 1 bar

ES 404, TMP = 2 bar ES 404, TMP = 1 bar

y = 114,9x + 104,3

R² = 0,9683

y = 65,5x + 4,1

R² = 0,9839

0

100

200

300

400

500

600

700

800

0 2 4 6

Flux (L/m2h)

TMP (bar)

Membrane FP 200 Membrane ES 404

Selection of Tubular Membrane Separation based on the Resistance Performance

191

the ultrafiltration of grape must. Journal of Foof

Engineering, 171-177.

Czekaj, P., F., Lopez, and Guell, C. (2000). Membrane

fouling during microfiltration of fermented beverage.

Journal of Membrane Science, 199-212.

D'Alvise, N., Lesuerur-Lambert. C., Fertin, B., Dhulster, P.

& Gillochon, D. (2000). Removal of polyphenols and

recovery of proteins from alfalfa white protein

concentrate by ultrafiltration and adsorbent resin

separation. Separation Science and Technology, 35,

2453-2472.

Fane, A. G., Fell, C., J., D. (1987). A review of fouling and

fouling control in ultrafiltration. Desalination, 117-136.

Friedman, M., Jurgens, H., S. (2002). Effect of pH on the

stability of plants phenolic compounds. Journal of

Agricultural and Food Chemistry, 48, 2101-2110.

Gokmen, V. A. (2003). Influence of conventional

clarification and ultrafiltration on the phenolic

composition of golden delicious apple juice. Journal of

Food Quality, 26, 257-266.

Nilsson, S., I. (1990). Protein fouling of UF membrane:

causes and consequences. Journal of Membrane

Science, 56, 121-142.

Singleton, V. L. (1965). Colorimetry of Total Phenolics

with Phosphomolybdic-Phosphotungstic Acid

Reagents. Amer. J. Enol. Viticult, 16, 144-158.

Song, L. (1998). Flux Decline in Crossflow Microfiltration

and Ultrafiltration: Mechanisms and Modelling of

Membrane Fouling. Journal of Membrane Science,

139, 183-200.

Sukeksi, L., Che Rosmani, C., H., Nik Meriam, N., S.,

Rashidi, H., Emami, S., D. (2016). Polyphenols

Recovery from Tropical Fruits (Pink Guava) Waste via

Ultrafiltration Membrane Technology Application by

Optimum Solvent Selection. Iranian Journal of

Chemistry and Chemical Engineering (IJCCE), 35 (3),

53-63.

Sukeksi, L., Sarah, M. (2016). Characterizations and

Extraction of Polyphenols from Residual Pulp of Pink

Guava as Source of Antioxidants. Journal of

Engineering Applied Science, 11, 5209-5216.

ICONART 2019 - International Conference on Natural Resources and Technology

192